Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Not easy to open glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

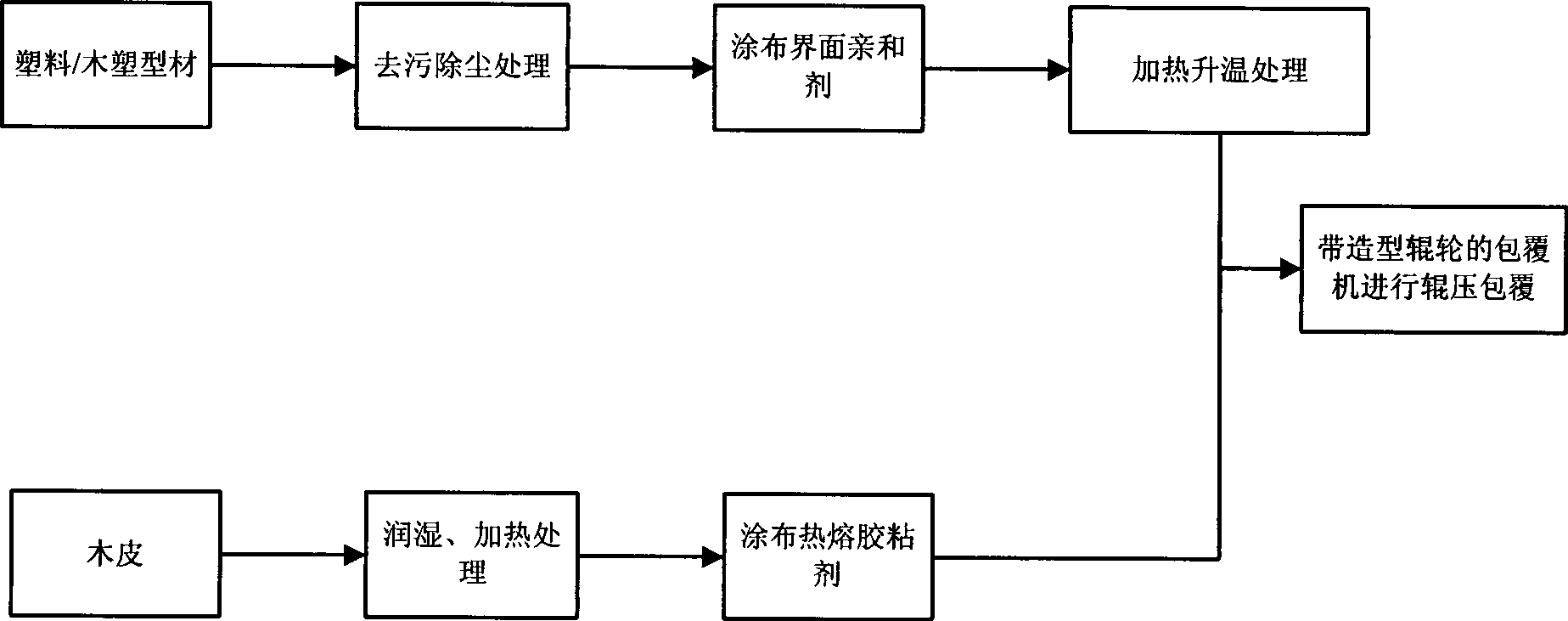

Composite section material for coating wood surface on surface of plastic/wood-plastic sectional material and manufacturing method therefor

InactiveCN101367220AFast curingIncrease productivityWood veneer joiningWood dampingEngineeringMechanical engineering

The invention provides a composite sectional material covering bark on the surface of a plastic / wood plastic sectional material and a manufacture method thereof, in order to overcome the defects of slow solidification speed, easy defect generation of glue films and unstable bonding caused by the mode of applying single cold glue to single side for bonding a plastic surface and a wood layer in the prior art. The method comprises the following steps: A. carrying out stain and dust removal treatment to the surface to be covered of the plastic / wood plastic sectional material; B. applying hot melt adhesive to the inner surface of the bark, and applying interface affine agent to the surface to be covered of the plastic / wood plastic sectional material which is subjected to the step A; and C. rolling and covering the bark on the surface of the plastic / wood plastic sectional material through a forming roll of a covering machine, so that the inner surface of the bark and the surface to be covered of the plastic / wood plastic sectional material can be bonded together. With the manufacture method, the bonding power between the surface of the bark and the surface of the plastic / wood plastic sectional material can be greatly improved, and the glue film has excellent quality, so that the plastic / wood plastic sectional material and the bark can be firmly bonded.

Owner:北京市森诺家具材料有限公司

Process of making PVC mosaic floor

InactiveCN101020363ARich variety of color changesGood decorative effectDomestic articlesMetal working apparatusEngineeringPost treatment

The technological process of making PVC mosaic floor includes the following steps: preparing PVC curled filament layer, punching to cut, exchanging mosaics, configuring bottom layer, ultrasonic pressure welding, hot molting to adhere, and post-treatment. The present invention makes it possible to obtain beautiful and firm PVC mosaic floor with rich and colorful pattern.

Owner:苏州元艺家庭用品有限公司

Decorative line covered by metallic film and producing method thereof

InactiveCN101352992AHigh bonding strengthImprove anti-aging propertiesPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentWeather resistancePliability

The invention provides a decorative line which coats metal films and a manufacturing method thereof and includes the following steps: a modeling substrate is preheated after being decontaminated and dusted and being coated with a surface affinity agent; a flexible metal film is coated with a hot-melt adhesive after being dusted and preheated; the metal film coated with the adhesive is rolled and coated with a modeling roll wheel on the surface of the modeling substrate on one surface of the surface affinity agent and the health is preserved. The decorative line made with the method is characterized by metal texture, high bonding strength, hydrolysis resistance, non-reversibility, weather resistance, and the like, and improves the texture grades of the decorative line.

Owner:北京市森诺家具材料有限公司

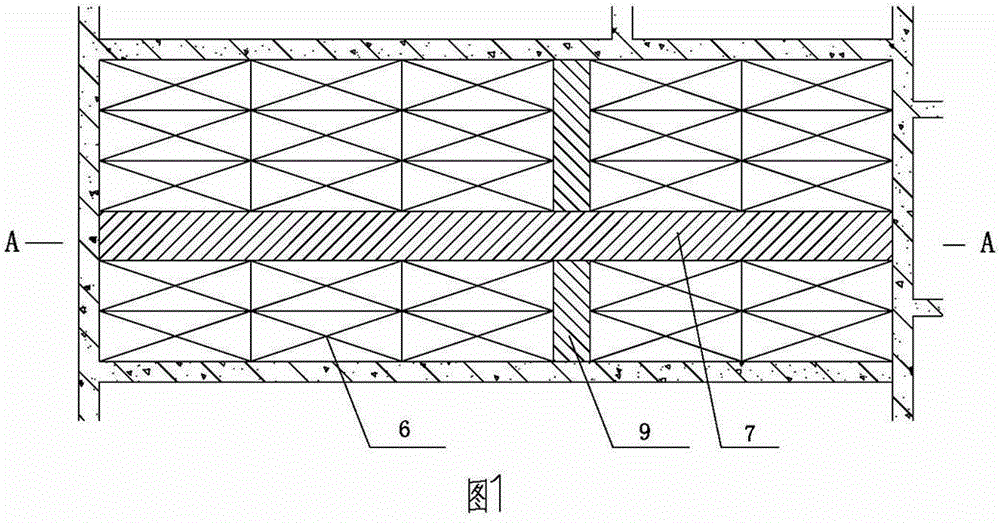

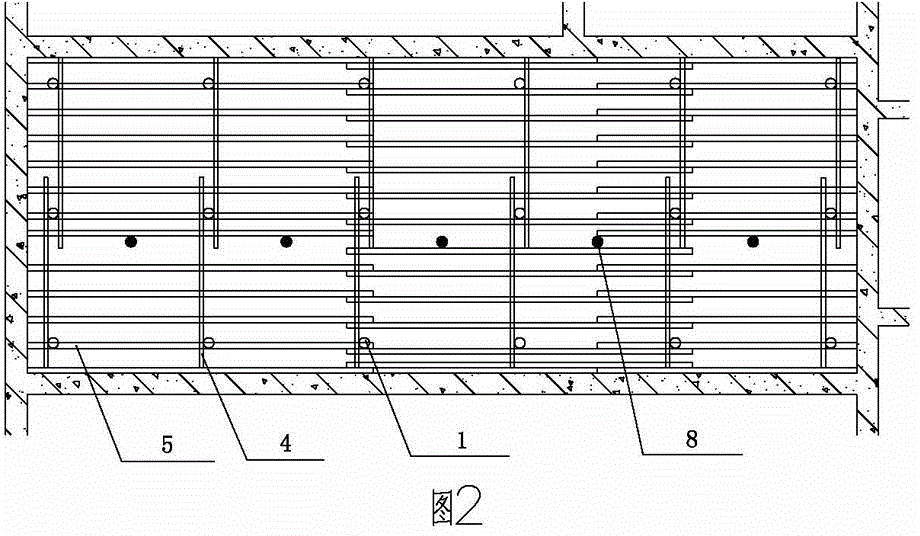

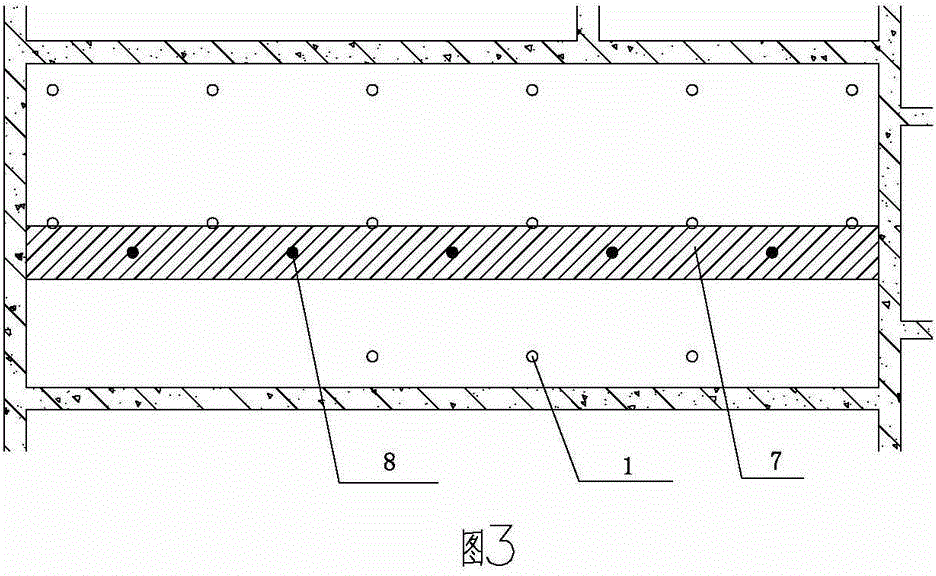

Steel beam grid floor formwork system

InactiveCN102720356AEasy to useImprove structural strengthForms/shuttering/falseworksShoresFloor slabHardness

The invention provides a steel beam grid floor formwork system, wherein a plurality of early removed steel supports and a plurality of late removed steel supports are evenly arranged on a bottom floor; the top end of an internal sleeve of each early removed steel support is provided with a jack; a plurality of rows of square steel beams are paved on the jacks in the transverse direction; and a plurality of rows of n-shaped steel beams are evenly arranged on the square steel beams in the longitudinal direction; faceplates are paved on the n-shaped steel beams; all the faceplates are arranged between collected strip clearances; late removed strips are paved in the longitudinal direction; and clearance plates are paved in the transverse direction; the bottom faces of the late removed strips are directly supported by the late removed steel supports; and longitudinal and transverse horizontal steel pull rods are buckled with the internal sleeves of all the steel supports through fasteners. Having the serialized structure sizes, the n-shaped steel beams, the square steel beams and the faceplates are convenient to use, and have great structural strength and high safety coefficient; and additionally, the n-shaped steel beams, the square steel beams and the faceplates are difficultly damaged so as to be reused for multiple times. The new type faceplates are low in toxicity and great in surface hardness, and are reused for multiple times which are three times that of the traditional faceplates. When the steel beam grid floor formwork system is used, the construction speed is high, the materials and the woods are saved, the environmental pollution level is low, less support steel is used, and the project cost is low.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

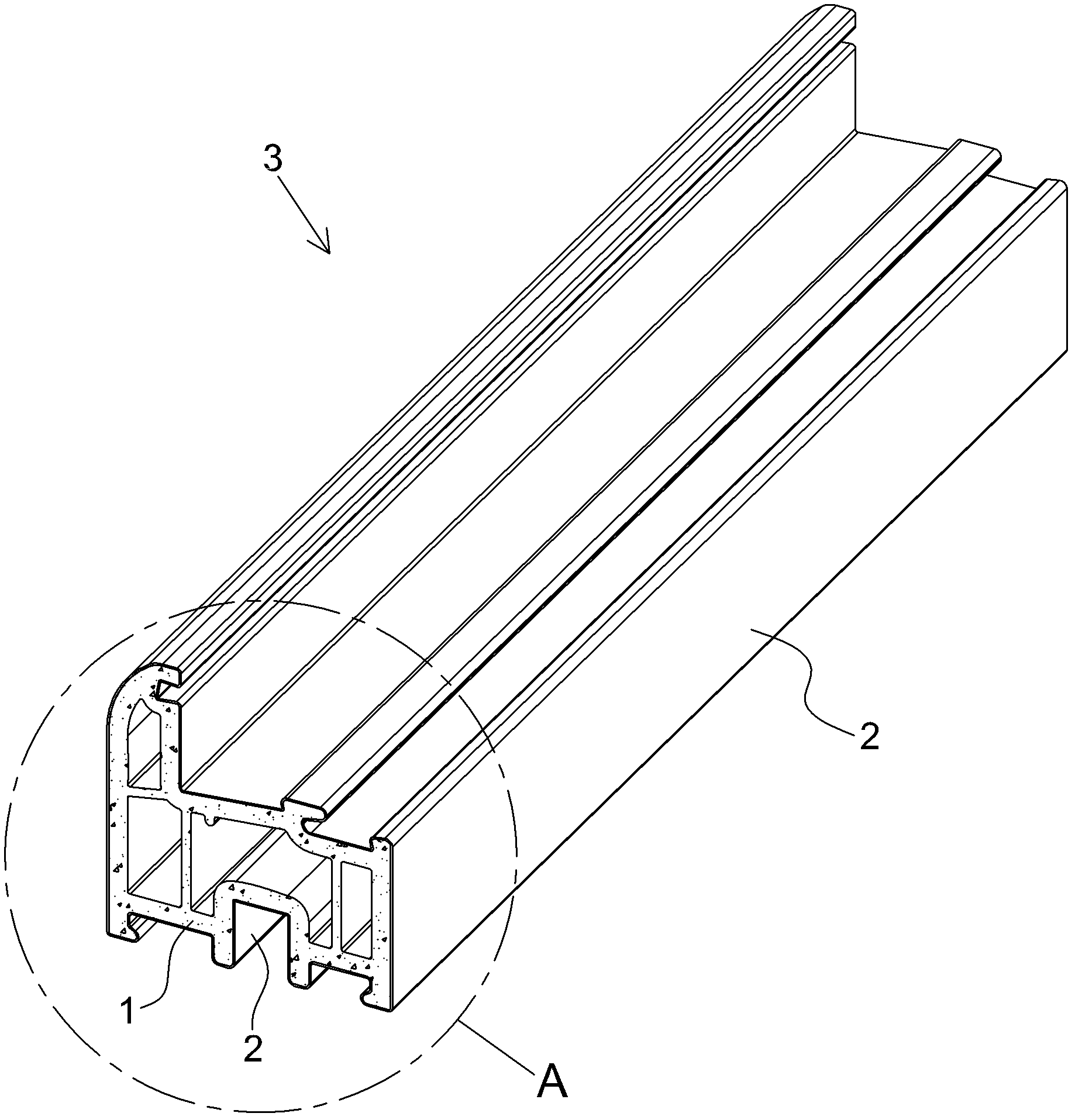

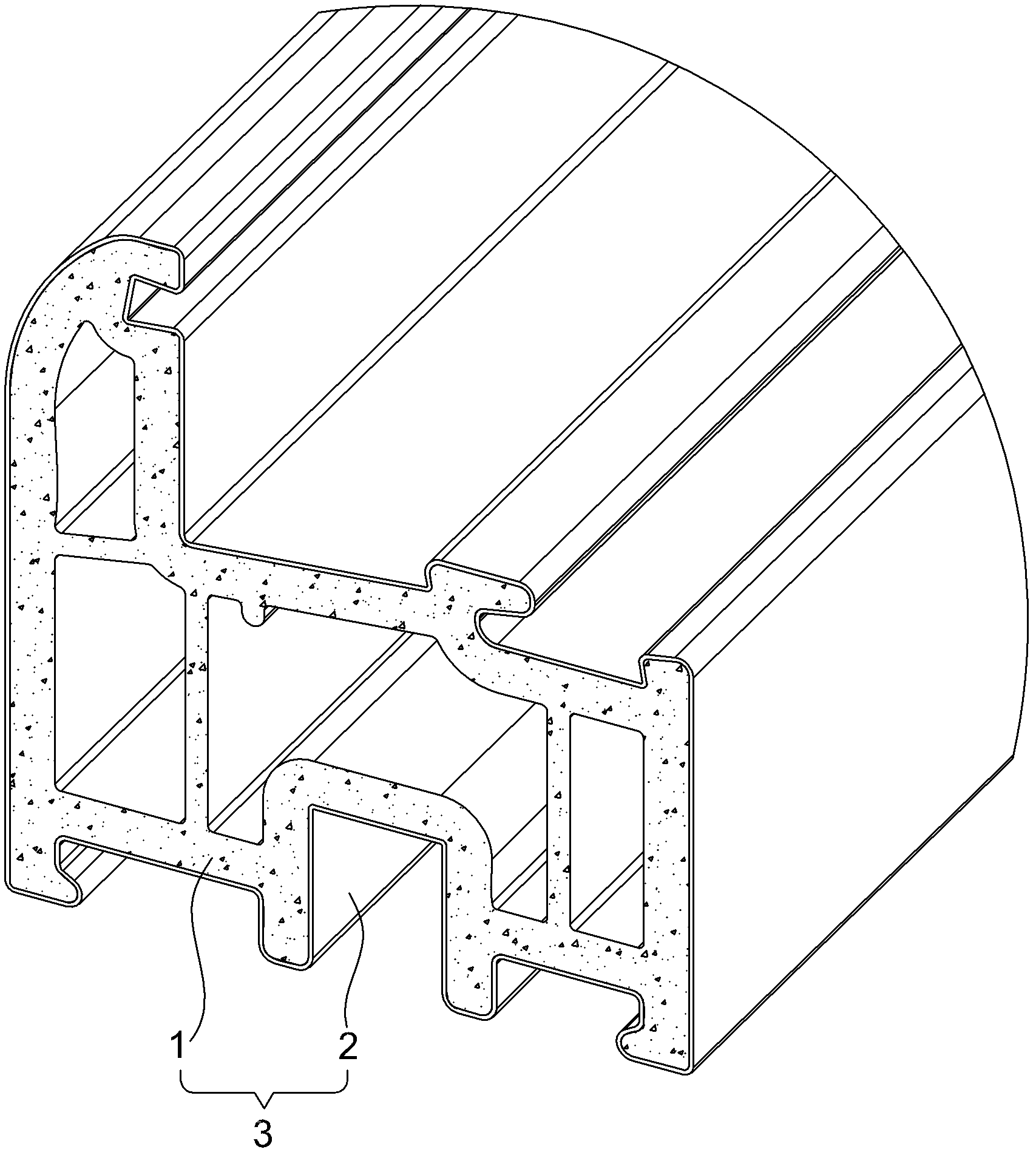

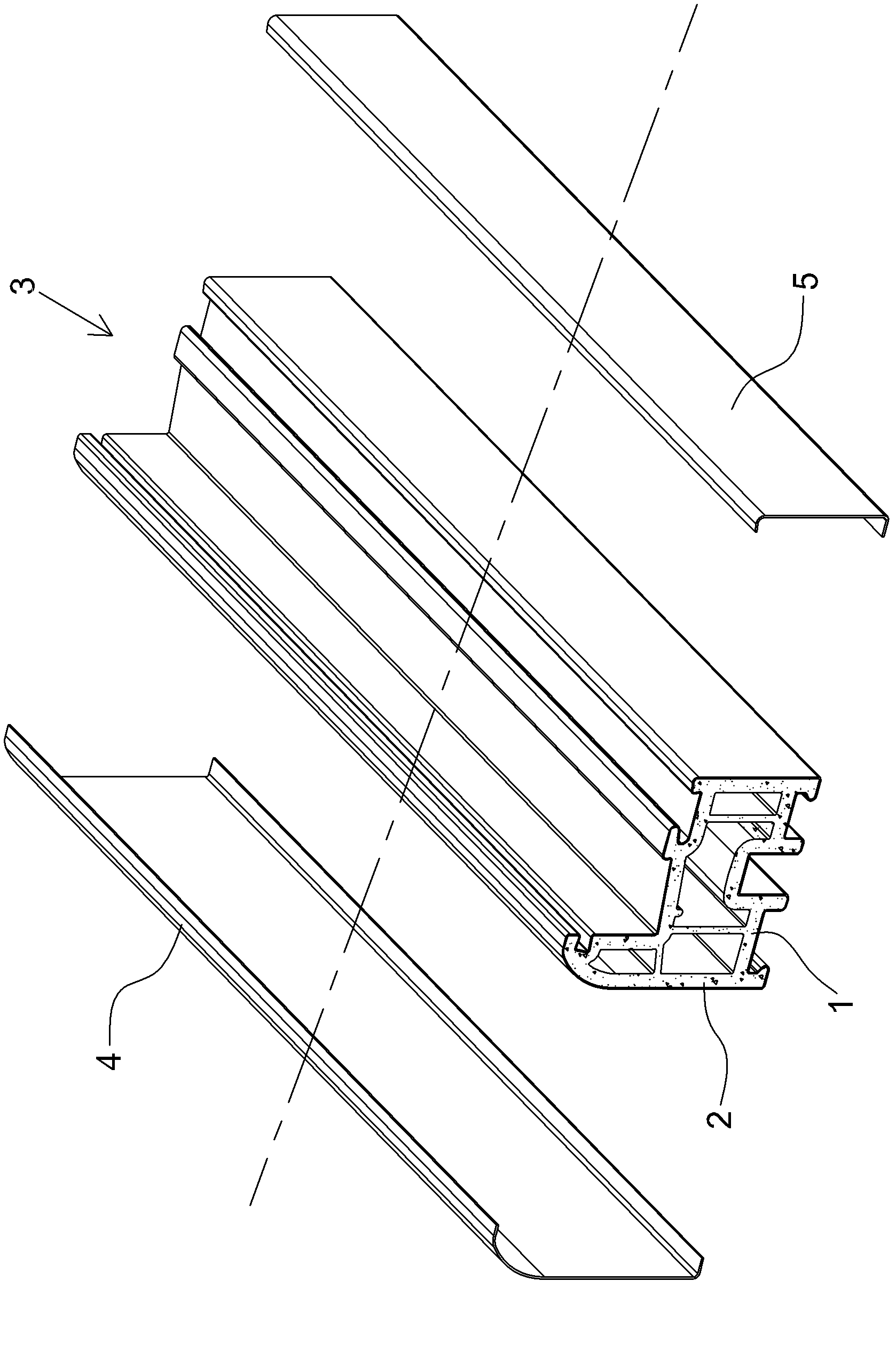

Production method of aluminum-plastic wood fiber composite profile

InactiveCN102441974AImprove flexibilityThe selection of materials and ingredients is scientific, reasonable and preciseCo extrusionChemical agents

The invention relates to a production method of an aluminum-plastic wood fiber composite profile. The method comprises three steps. The first step is a material preparing step, wherein: (1) waste plastic or novel plastic is adopted as a main material; (2) plant fiber is adopted as an auxiliary material; (3) purchased mineral powder is adopted as a filling material; and (4) a chemical agent with a coupling effect is adopted as an additive. The second step is a mixing step, wherein 30-55% of the main material by weight, 38-55% of the auxiliary material by weight, 5-30% of the filling material by weight, and 2-6% of the additive by weight are placed in a mixer, and are processed into particles; and the particles are adopted as a raw material of an inner core, and are preserved for later use. The third step comprises a process that: a body of the profile is produced by using a co-extrusion equipment production line, wherein the prepared material used for producing the inner core of the profile body and a material of a protective film are placed in a hopper of an extruding machine, and the extrusion processing of the inner core and the protective layer is simultaneously achieved with a co-extrusion manner, such that the profile body is formed. The construction profile provided by the invention is advantaged in high quality, long service life, good durability, and wide application range.

Owner:高红

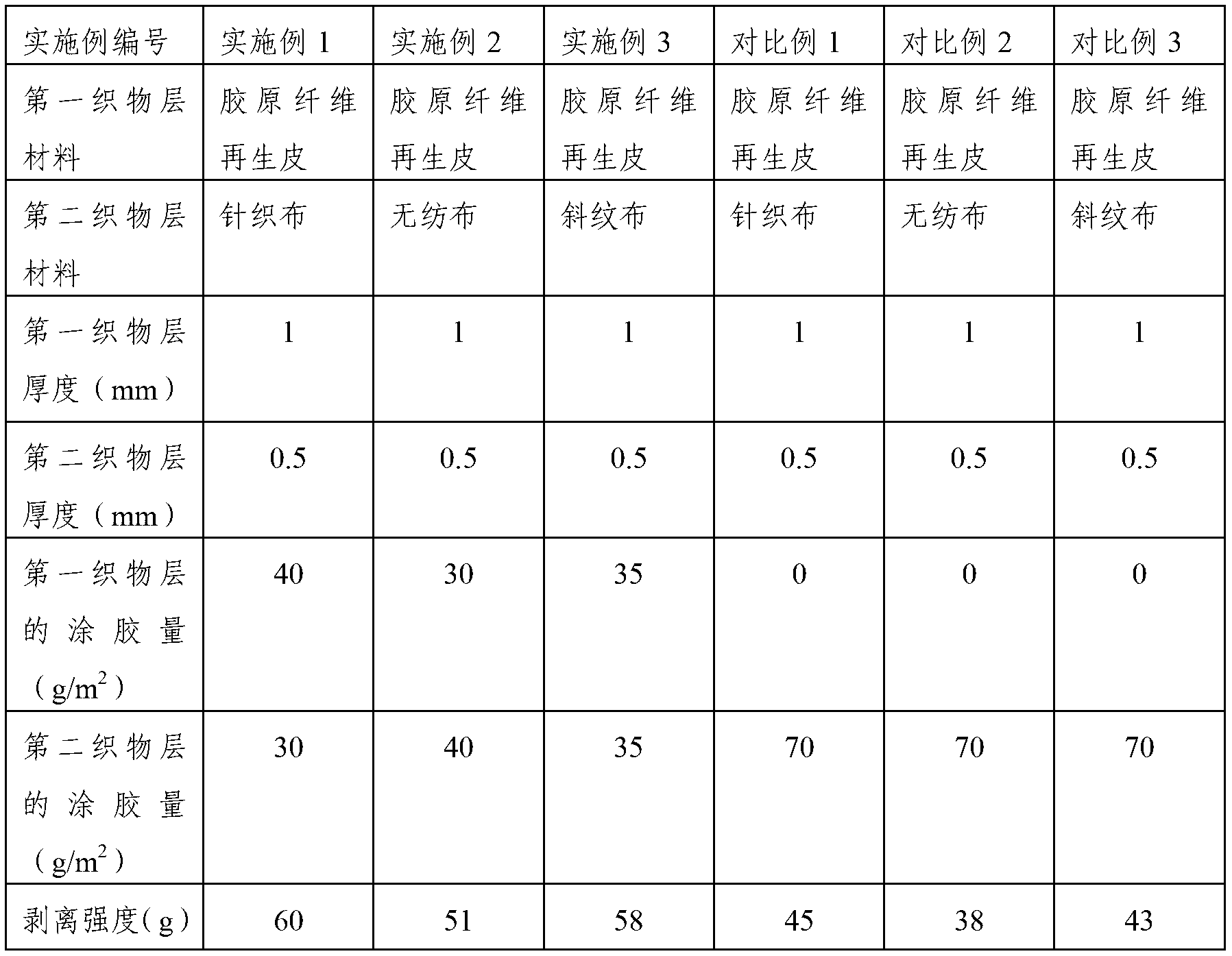

Double-side gluing composition process

InactiveCN103231577AHigh bond strengthReduce dosageLaminationLamination apparatusEngineeringBonding strength

The invention relates to a double-side gluing composition process sequentially comprising a cloth feeding step, a gluing step, a composition step, and a rolling step. A first fabric layer and a second fabric layer respectively pass between a gluing roller and a cloth guiding roller, such that gluing is carried out; a first glue surface is formed on the side of the first fabric layer facing the second fabric layer, and a second glue surface is formed on the side of the second fabric layer facing the first fabric layer; the first and second glue surfaces are both composed of glue dots distributed in a diamond or round scattered-dot mode; at least one layer of the first fabric layer and the second fabric layer is collagen fiber recycled leather. Compared with prior art, with the double-side gluing composition process provided by the invention, double-side scattered-dot gluing is adopted, such that bonding strength between the fabric layers is improved. Even if corners and edges of composed fabric are exposed, glue failure from the corners and edges is prevented. Also, glue material dose is saved, and production cost is reduced. The process is applied in composition of collagen fiber recycled leather and other fabric layer, such that composite leather application range can be widened.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Production technology for corrugated paperboard

ActiveCN107089037ANot easy to open glueNo fire hazardMechanical working/deformationEnvironmental resistanceFiber

The invention discloses a production technology for a corrugated paperboard. The corrugated paperboard is made of face paper, inner paper, core paper and corrugated paper machined into waveform corrugations through binding agents. The following raw materials including, by weight, 760 kg-790 kg of water, 183 kg-222 kg of starch, 5 kg-8 kg of caustic soda flakes, 3 kg-4 kg of borax, 8 kg-10 kg of a bridging agent, 1.2 kg-2.5 kg of a stabilizing agent, 0 kg-0.8 kg of a defoaming agent, 0.1 kg-0.5 kg of a waterproof additive and 0.2 kg-1.2 kg of an insecticide mixing agent are needed by producing 1000 kg of binding agents each time. The waterproof additive includes cellulose ether and wood fiber, and the insecticide mixing agent comprises plant insecticide powder and mild cypermethrin. By means of a corrugated carton made through the production technology, glue failure is not likely to happen even in a high-humidity and multi-insect environment, the product is free of toxins and explosion, the combustion risk is avoided, the production technology is simple, no three-waste emission exists during production, the environment-friendly requirement is met, and the production technology is worthy of application and popularization.

Owner:FUZHOU CITY HENGFENG IND CO LTD

Wear-resistant heat-vulcanized rubber shoes

The invention discloses a pair of wear-resistant heat-vulcanized rubber shoes. On the basis of the advantages of low price, firm combination of shoe uppers and shoe soles, prevention of glue failure and the like of the conventional heat-vulcanized rubber shoes, the pair of wear-resistant heat-vulcanized rubber shoes is consistent in style with foamed EVA (Ethylene Vinyl Acetate) / rubber sticky sports shoes, and has the advantages of attractiveness, lightness and wear resistance of shoe soles, high elasticity, comfort in wear and the like. The pair of rubber shoes is particularly suitable for units with high training strength, severe wearing environments, long finished product storing time and the like, such as the military training departments of armies, public security and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

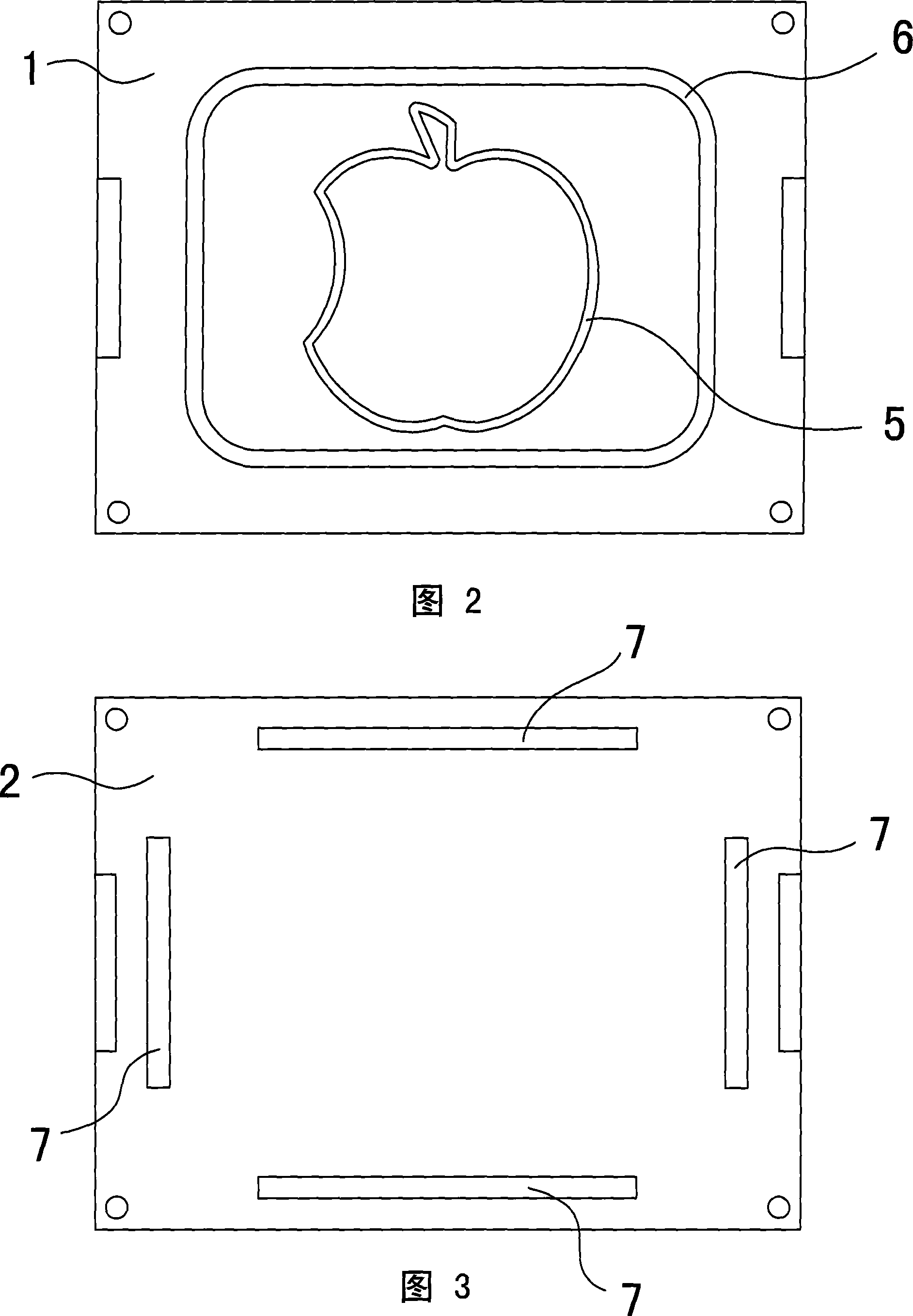

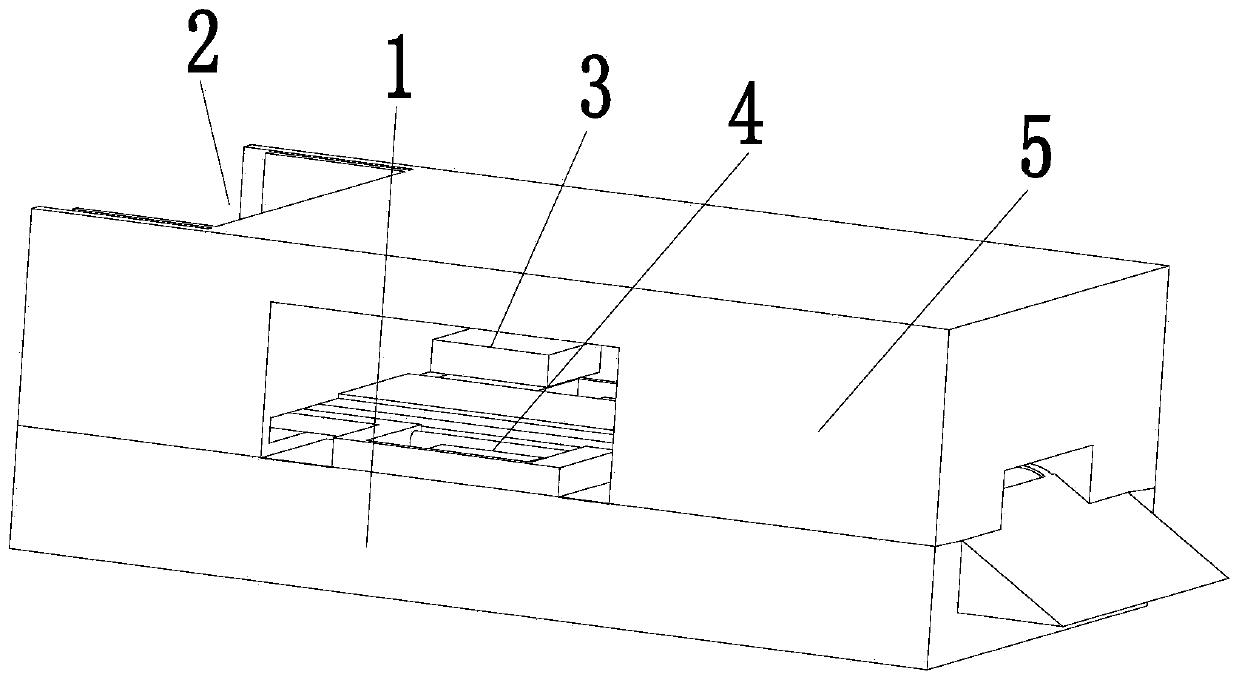

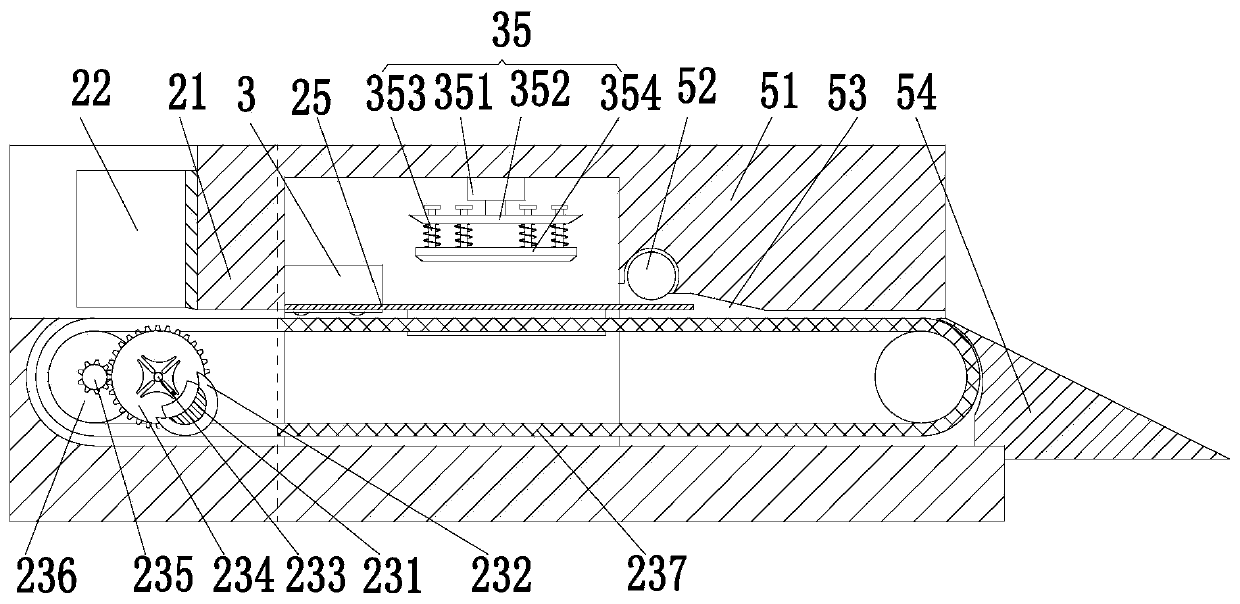

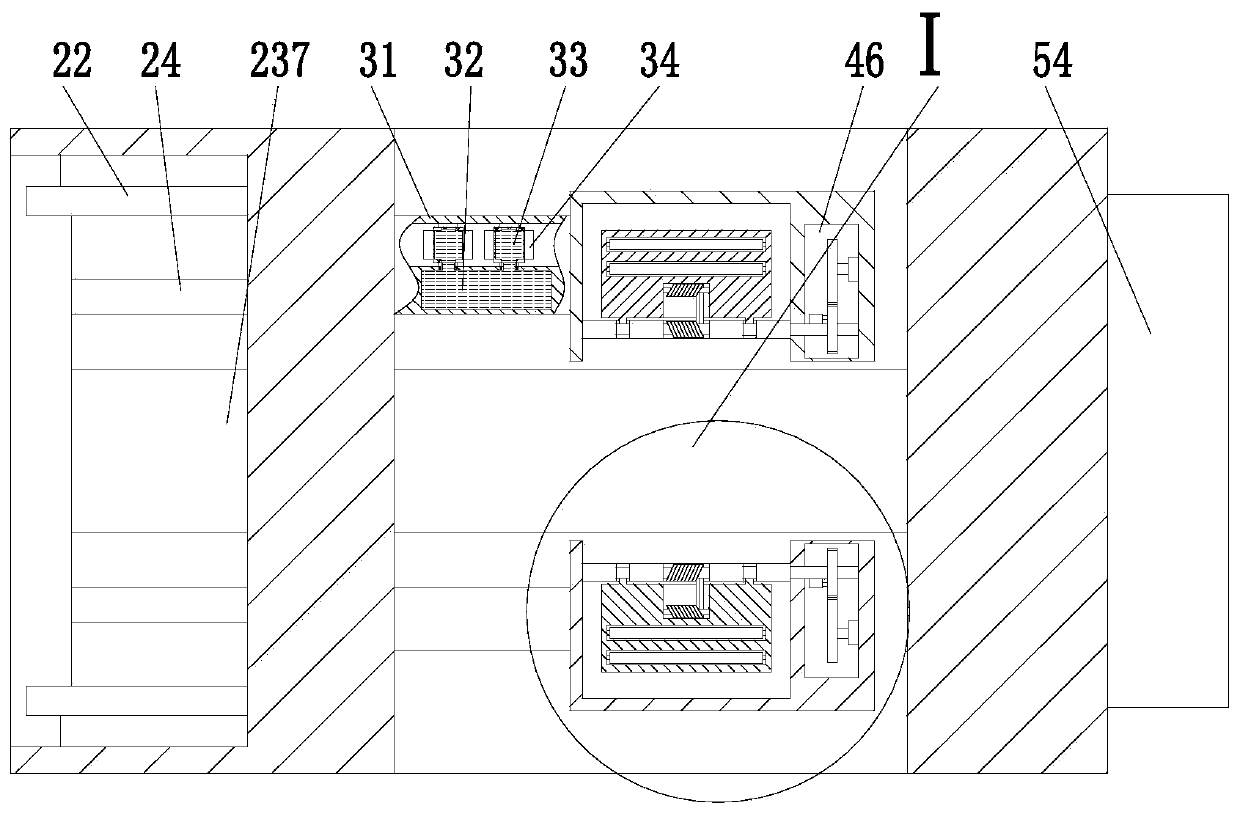

Box sticking and forming equipment for packaging carton manufacturing

ActiveCN110614798ASolve the problem of easy-open glueSmall footprintBox making operationsPaper-makingCardboardCarton

The invention relates to box sticking and forming equipment for packaging carton manufacturing. The box sticking and forming equipment comprises a base, a feeding device, a gluing device, an overturning device and a discharging device, a belt groove is formed in the upper end of the base, the base is sequentially provided with the feeding device, the overturning device and the discharging device from left to right, and the gluing device is mounted at the right end of the feeding device; and a carton board is fed through the feeding device, the gluing face is subjected to gluing treatment through the gluing device, the overturned face of the carton board is overturned upwards through the overturning device and is stuck, and the stuck carton board is guided out and discharged from the discharging device. According to the box sticking and forming equipment, through intermittent operation of feeding, the overall process is divided into the three steps of feeding, overturning and discharging, the carton board is stopped and placed at the overturning place to be overturned and compacted, thus overturning treatment of a whole assembly line is compressed in the pretty short space, the equipment cost of small-batch and self-production and self-using factories is lowered, through multiple times of compressing, a glue body is firm, and the problem that a carton is prone to coming ungluedis solved.

Owner:赣州市鸿方包装科技有限公司

Laminated aluminum plate and preparation method thereof

ActiveCN104626679ANot easy to deform and bulgeNot easy to decolorizeSynthetic resin layered productsVacuum evaporation coatingOrganic filmHigh resistance

The invention relates to a laminated aluminum plate which comprises a base material, wherein a laminated coating, a nanometer film layer, an adhesive layer, a laminating layer and a protective film layer are sequentially arranged on one side of the base material; a laminated coating and a paint layer are sequentially arranged on the other side of the base material; the base material is obtained by performing passivation or shot blasting treatment on an aluminum plate; the laminated coating is a meshed organic film formed by chromate; the nanometer film layer is formed by coating the base material with nanometer TiC or carbon-nitrogen co-doped nanometer TiO2 by virtue of physical vapor deposition; the laminating layer is made from a PET material; and the protective film is made from a PE material. Compared with the prior art, the laminated aluminum plate disclosed by the invention is unlikely to deform and bulge as well as discolor and unglue, has high resistance to acid and base, corrosion resistance and heat resistance and can be applied to various severe environments.

Owner:ZHUHAI SPEEDBIRD NEW MATERIAL CO LTD

Environment-friendly glue for corrugated board high-speed production line and preparation method thereof

InactiveCN104140772AFast bondingImprove adhesionNon-macromolecular adhesive additivesStarch adhesivesProduction lineAdhesive glue

The invention discloses an environment-friendly glue for a corrugated board high-speed production line. The glue is characterized by being prepared from the following raw materials by weight: 70% of water, 26.3% of corn starch, 1.8% of alkali lye, 0.5% of borax and 1.4% of a bridging agent. For the environment-friendly glue used for the corrugated board high-speed production line, the viscosity of a gluing machine is 18 s, the gelatinization temperature of the gluing machine is 56 DEG C, the viscosity of a single-side machine is 16 s, and the gelatinization temperature of the single-side machine is 58 DEG C. The invention also discloses a preparation method for the environment-friendly glue used for the corrugated board high-speed production line. The environment-friendly glue provided by the invention has the characteristics of low preparation and usage temperature, high adhesive strength, quick-drying performance, environment-friendliness and low usage cost; and the preparation method has the advantages of reasonable technology, easiness, low preparation temperature and capacity of improving adhesiveness of the adhesive glue.

Owner:LD PACKING PRINTING SHANGHAI

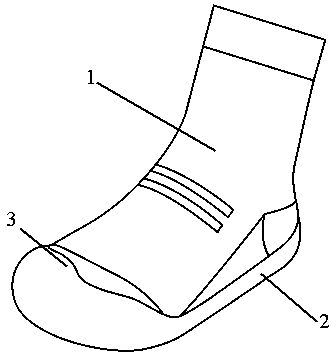

Infant shoe and technique for manufacturing infant shoe

The invention relates to the clothing field, and particularly discloses an infant shoe suitable for infants to wear and a technique for manufacturing the infant shoe. The infant shoe mainly relies on a sock main body which is accompanied by a soft rubber shoe sole, wherein the sock main body and the soft rubber shoe sole are fixed together through gluing. Accordingly, not only is the defect that feet of the infant easily catch cold when the infant walks on a floor for a long term solved, but also the soft rubber shoe sole can effectively protect the feet of the infant, and generation of flatfoot is avoided. Simultaneously, the infant shoe is low in weight, and therefore the infant can not fell uncomfortable when wears the infant shoe for a long term. The technique for manufacturing the infant shoe is characterized in that the sock main body and the soft rubber shoe sole are heated after glue is brushed on the sock main body and the soft rubber shoe sole, secondary glue brushing operation is performed during the heating process so as to enable the glue to immerge into the surfaces of the soft rubber shoe sole and the sock main body well, and good sole laying effects are obtained. According to the infant shoe and the technique for manufacturing the infant shoe, air pressure bonding is further performed after the sock main body and the soft rubber shoe sole are bonded so as to enable the bonding to be firm, and clod sizing technology performed after the bonding can effectively prevent the infant shoe from deforming, and glue failure difficultly appears between the sock main body and the soft rubber shoe sole.

Owner:新沂市棋盘工业集中区建设发展有限公司

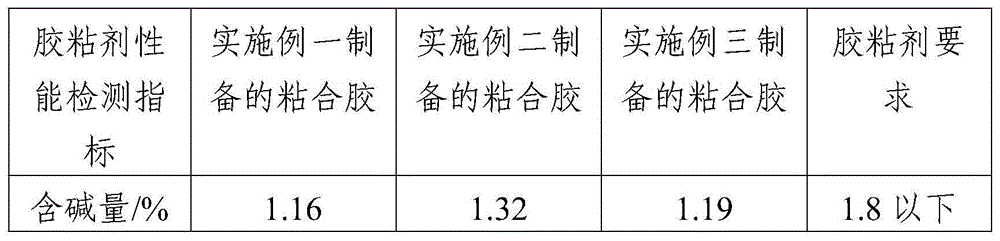

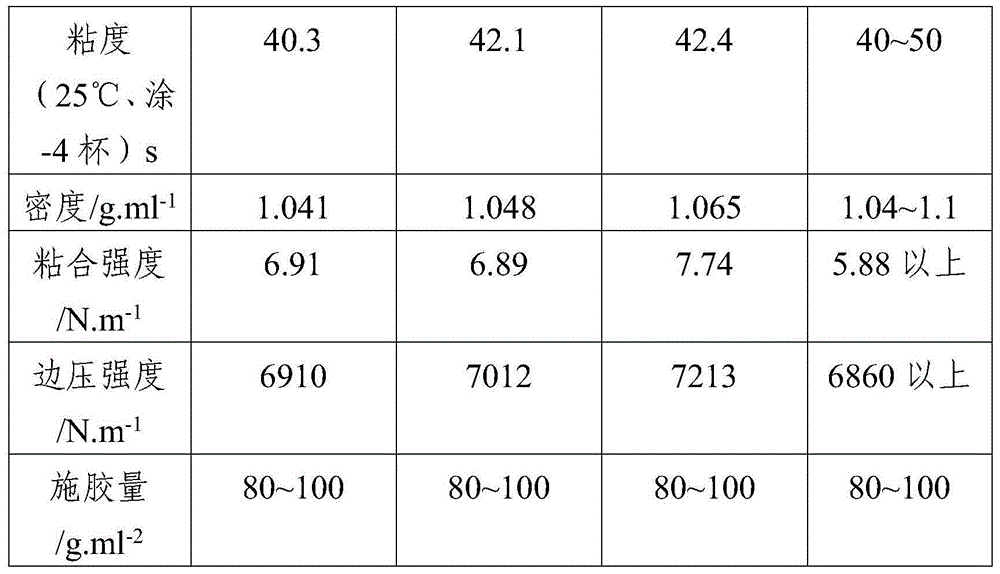

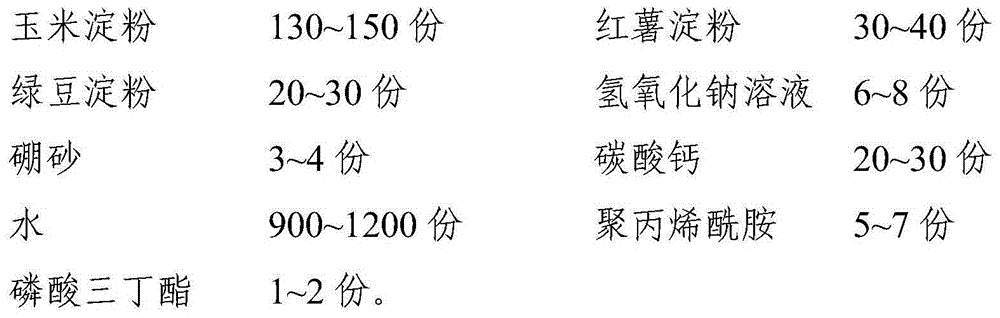

Corrugated paper adhesive and preparation method thereof

InactiveCN105315917AImprove stabilityEasy to useNon-macromolecular adhesive additivesStarch adhesivesAdhesivePotato starch

The invention discloses a corrugated paper adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The corrugated paper adhesive is prepared from, by weight, 130-150 parts of corn starch, 30-40 parts of sweet potato starch, 20-30 parts of mung bean starch, 6-8 parts of a sodium hydroxide solution, 3-4 parts of borax, 20-30 parts of calcium carbonate, 900-1200 parts of water, 5-7 parts of polyacrylamide and 1-2 parts of tributyl phosphate. The preparation method includes the steps that firstly, water is added into a stirring barrel and heated to 50-60 DEG C, then corn starch and the sodium hydroxide solution are added, and constant-temperature stirring is kept; secondly, mung bean starch and sweet potato starch are added, and stirring continues; thirdly, calcium carbonate, tributyl phosphate, borax and polyacrylamide are added, the mixture is heated to 70-80 DEG C, constant-temperature stirring is kept for a period of time, then heating is stopped, and the finished adhesive product is obtained. The corrugated paper adhesive is high in initial adhesiveness, small in usage amount, reliable in adhesion, not likely to fail and good in stability.

Owner:ZUNYI GOUJIANG TOWN XINXINYUAN PAPER CO LTD

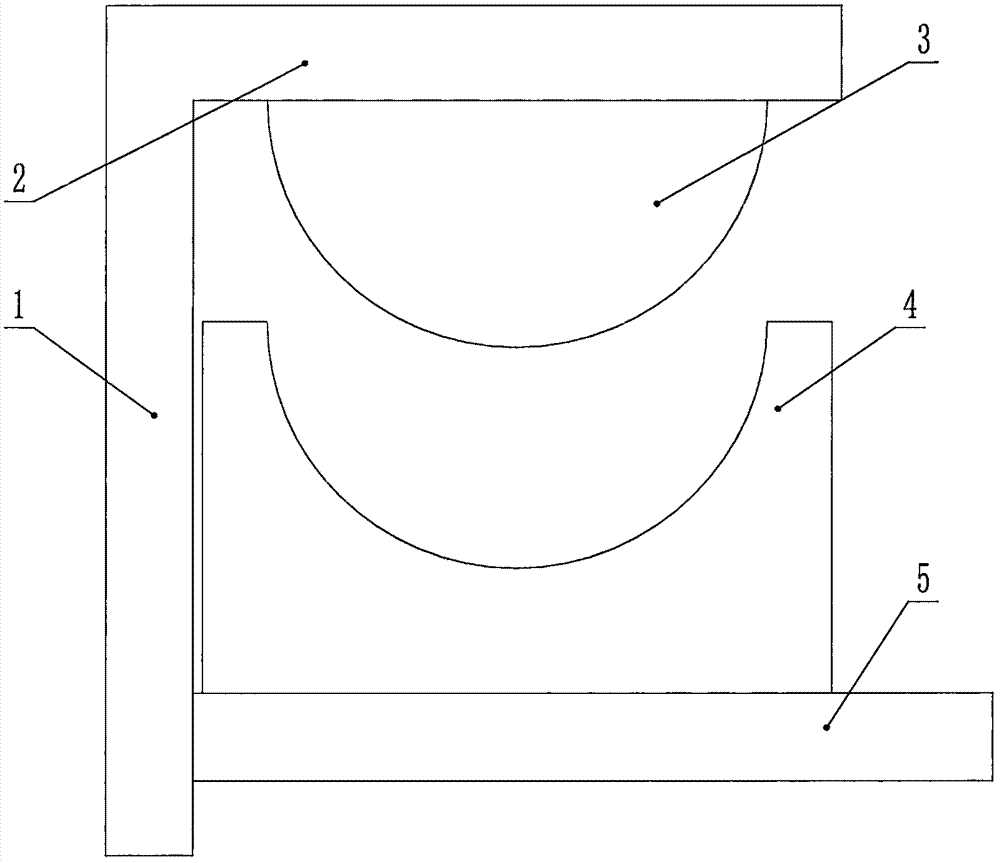

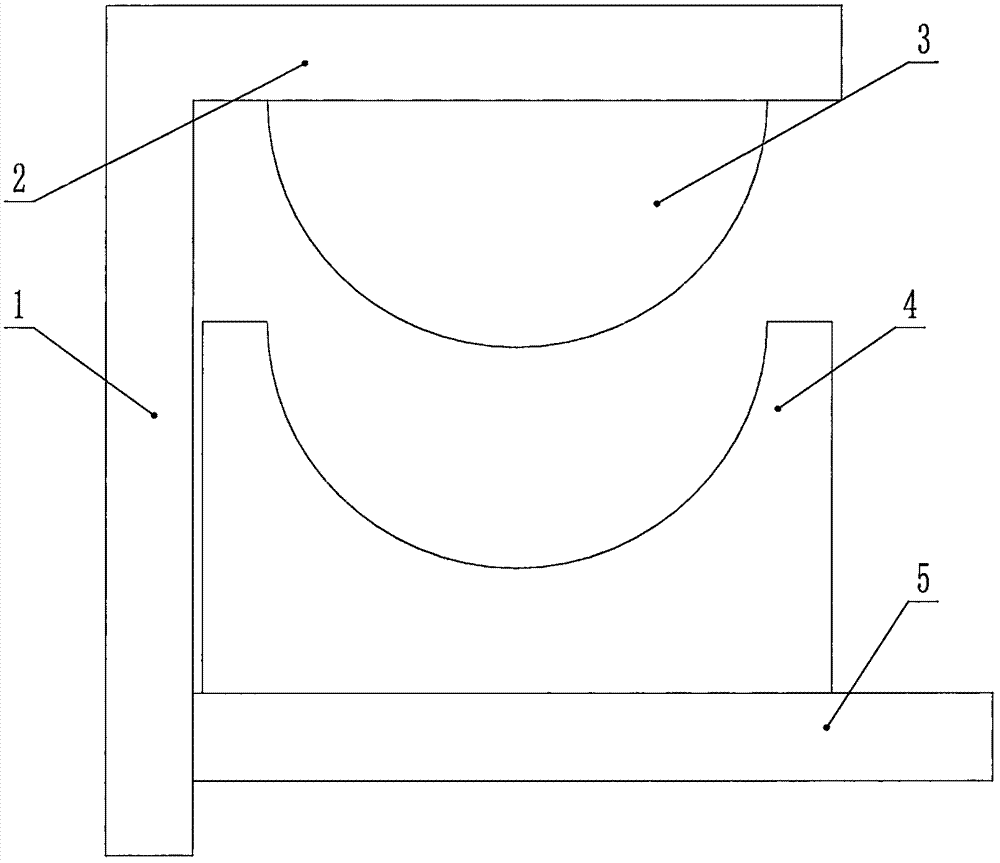

Cylindrical building template hot press

The invention relates to the technical field of hot presses, in particular to a cylindrical building template hot press. The cylindrical building template hot press comprises a main frame, an upper die, a lower die and a power device, the upper die is fixedly arranged on the main frame, the lower die is connected with the power device and can be driven by the power device to achieve die closing ofthe lower die and the upper die, and the upper die and / or the lower die are / is connected with a heating device which is used for heating the upper die and / or the lower die. By means of the cylindrical building template hot press, the problem of template rebound diameter expansion is solved; the arc face is used for heating, so that a template is evenly heated, and the production efficiency is improved; the die pressing time is long, stress is even, the molded template is high in press fit strength, and glue cracking is difficult; and the upper die and the lower die achieve joint press molding, and the template accuracy is guaranteed. The cylindrical building template hot press is simple in structure, convenient to use, low in cost and high in efficiency.

Owner:周瑞声

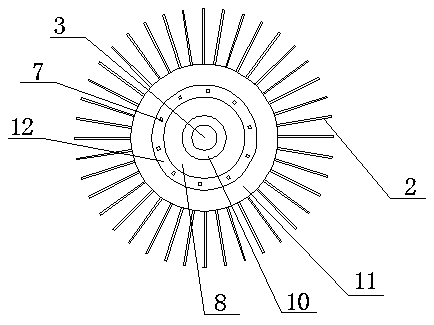

Flap disc with blades being not prone to falling off and bonder of flap disc

ActiveCN109159044AExtended service lifeNot easy to fall offNon-macromolecular adhesive additivesStarch adhesivesEngineeringScrew thread

The invention discloses a flap disc with blades being not prone to falling off. The flap disc comprises a tray and the abrasive cloth blades; the tray is provided with a bearing hole matched with a bearing; a two-stage stepped tray is used as the tray; the tray comprises a first-stage circular-truncated-cone tray and a second-stage circular-truncated-cone tray; the abrasive cloth blades are bondedon the first-stage circular-truncated-cone tray; the outer circumference of the first-stage circular-truncated-cone tray is provided with a mounting groove; the abrasive cloth blades are circumferentially and evenly distributed in the mounting groove of the outer circumference of the first-stage circular-truncated-cone tray; the space between the abrasive cloth blades and the mounting groove is filled with a bonder layer; a bonder injection hole is formed in the side face of the first-stage circular-truncated-cone tray; the second-stage circular-truncated-cone tray is provided with radiatingholes; and the inner wall of the bearing hole is provided with a thread matched with the flap disc bearing. The flap disc with the blades being not prone to falling off is long in service life, the blades are not prone to falling off, and meanwhile, the heat dissipation performance is good. The invention further discloses a bonder for effectively bonding the blades and a bonder preparation method.

Owner:盐城市锐克斯研磨科技有限公司

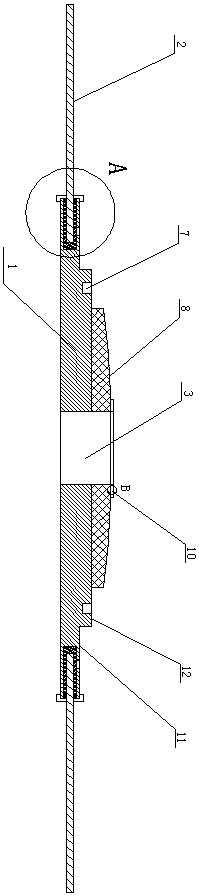

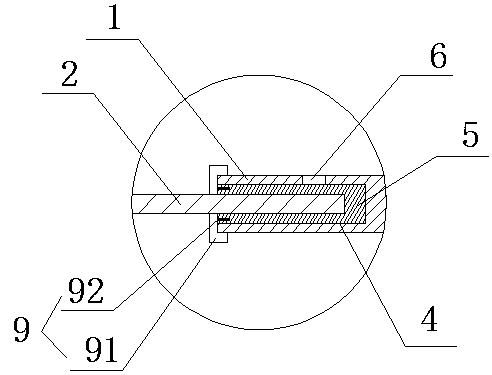

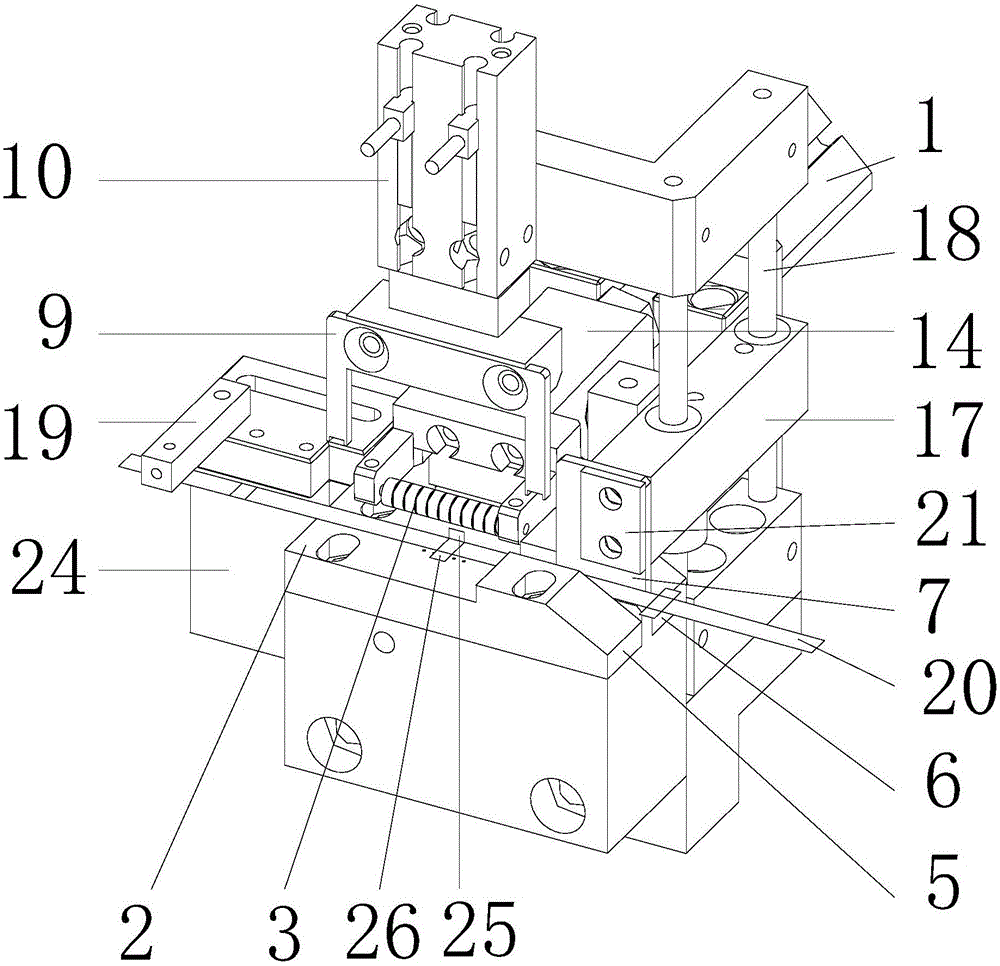

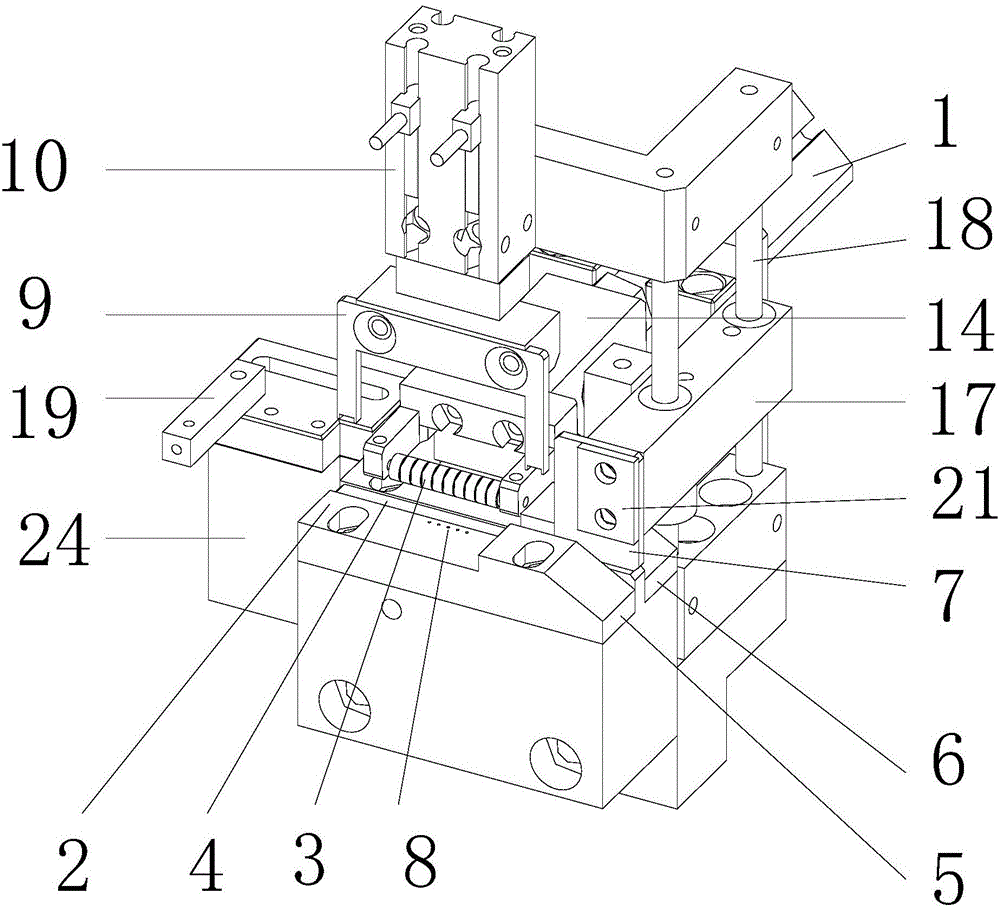

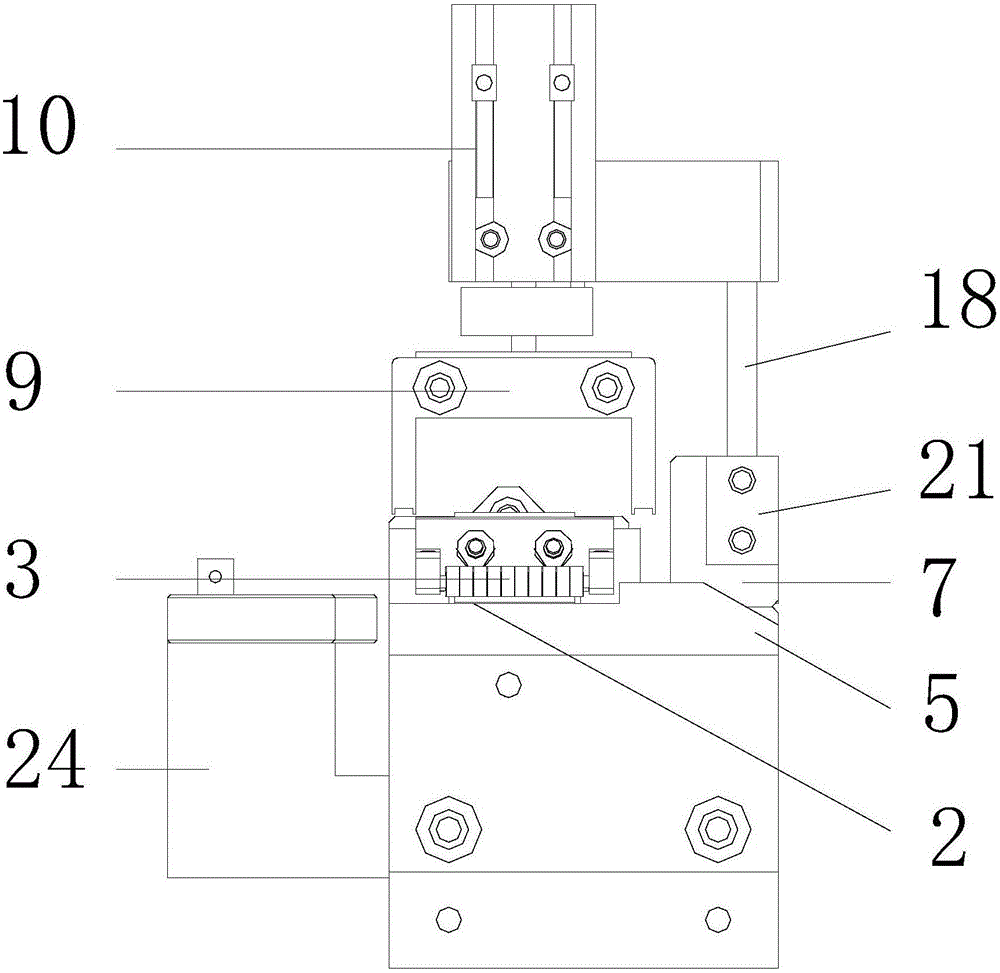

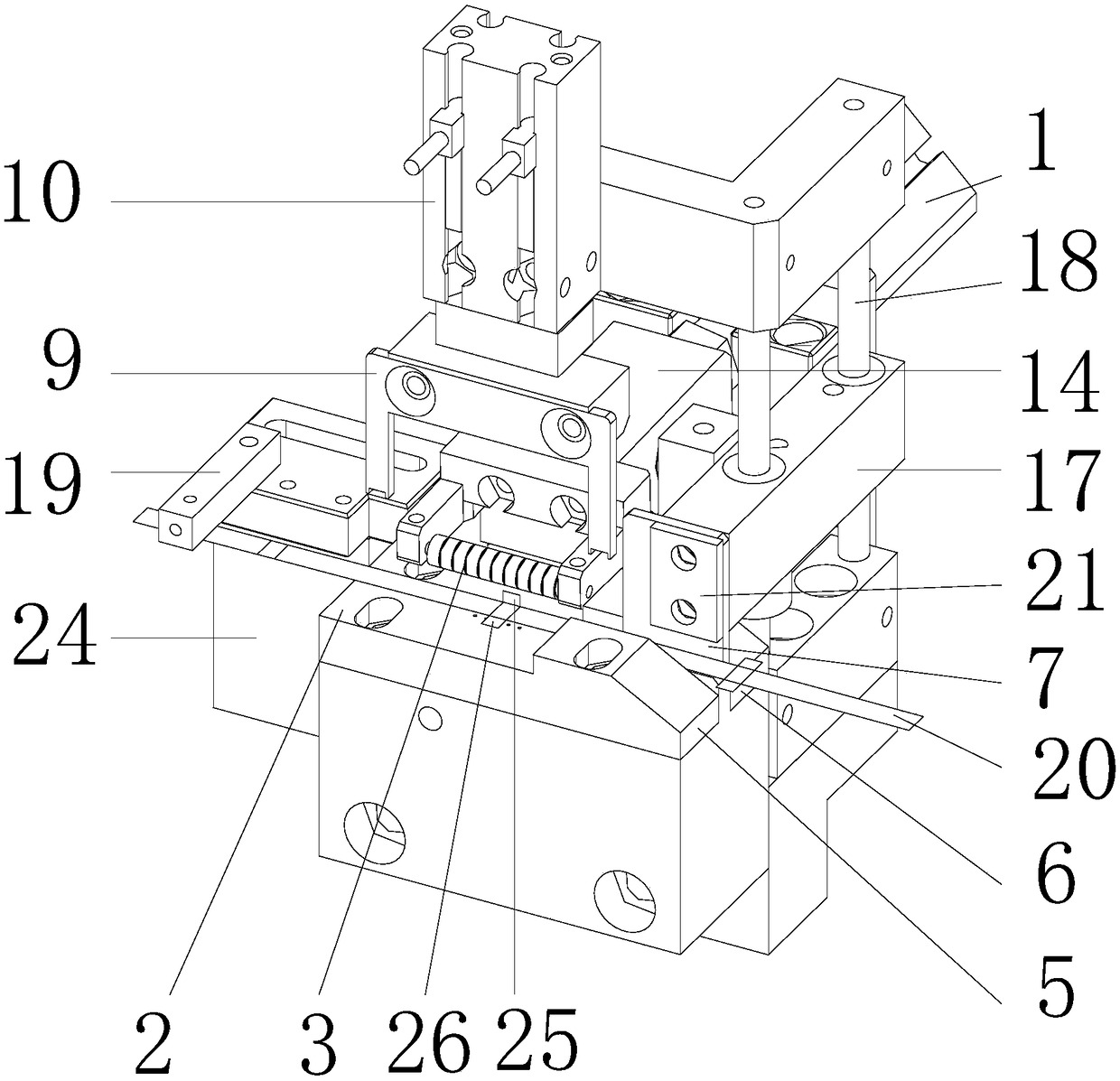

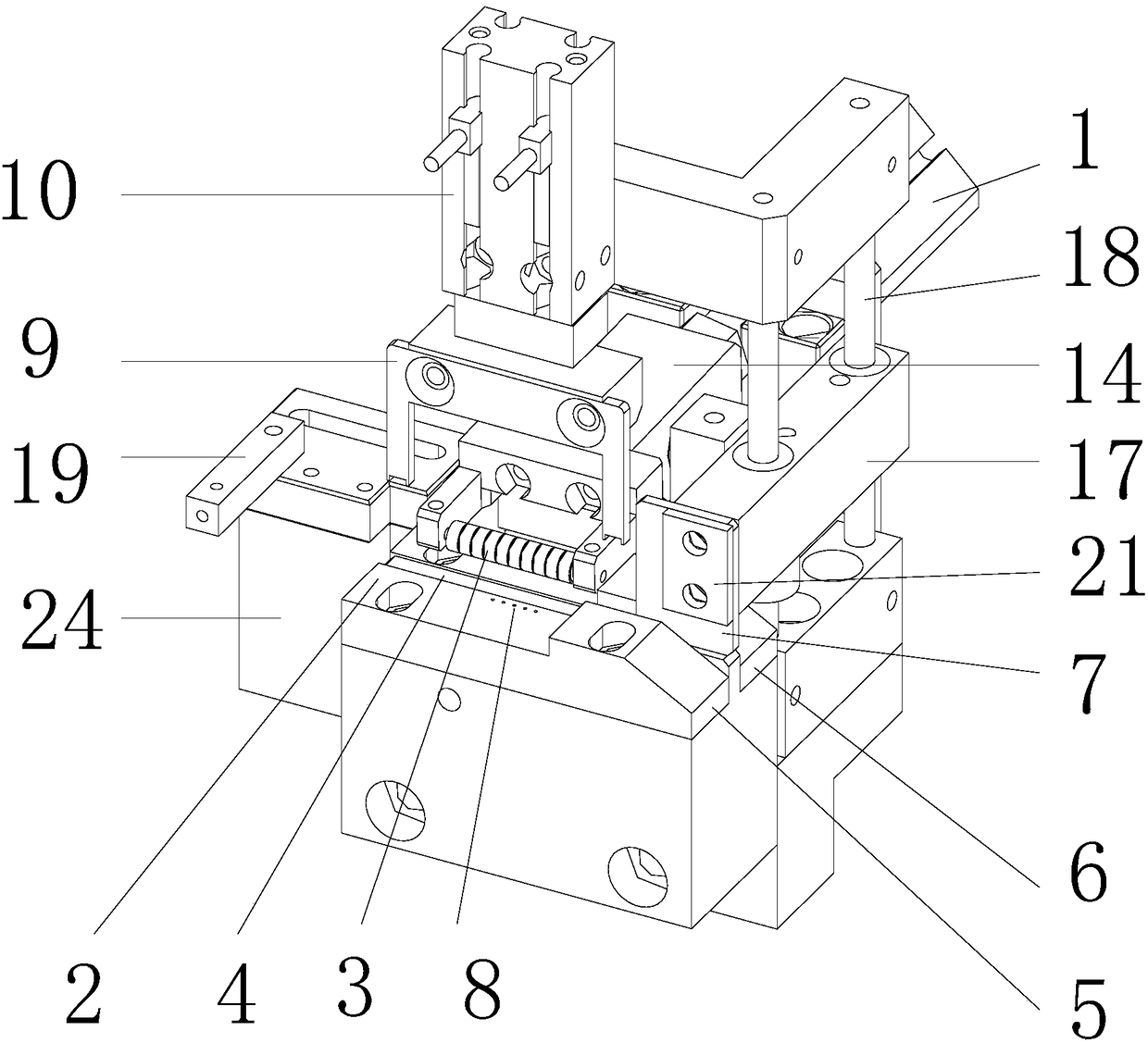

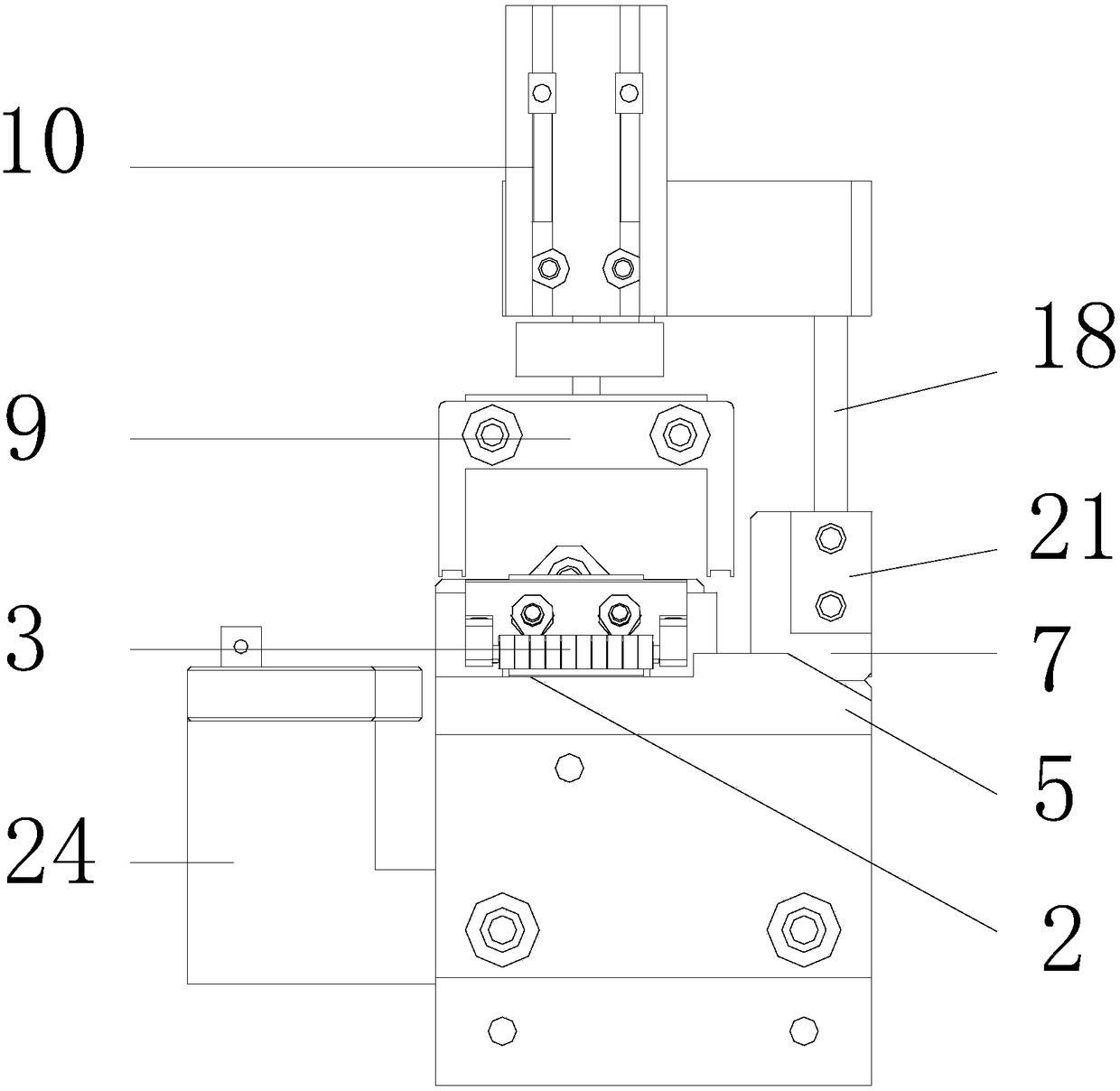

Power battery tab adhesive encapsulation device and adhesive encapsulation method thereof

ActiveCN106229458APaste effect is goodAvoid short circuitCell component detailsPower batteryReciprocating motion

The invention discloses a power battery tab adhesive encapsulation device and an adhesive encapsulation method thereof. The device comprises an adhesive encapsulation driver, a guide table and a pressing head for pressing adhesive tapes. The adhesive encapsulation driver drives the pressing head to carry out reciprocating motion on the guide table. The guide table is equipped with a channel for a tab to pass. The direction of the channel is vertical to the motion direction of the pressing head. A front side limiting block and a rear side limiting block are arranged at the inlet sides of the channel of the guide table. The front side limiting block and the rear side limiting block are located at two sides of the width of the channel. The front side limiting block and the rear side limiting block are slops at the inlet end of the channel. The bottom ends of the slopes are lower than the channel. A baffle plate is arranged above the channel. The baffle plate is located between the front side limiting block and the rear side limiting block and is adjacent to the rear side limiting block. An air blowing hole is arranged at the center of the guide table. The invention also discloses an adhesive encapsulation method employing the device. The device and the method have the advantages that laminated adhesive encapsulation is carried out on the tab, the adhesive tapes are firmer, an adhesive failure is not liable to generate when electrolyte is injected into a battery, the battery tab short circuit resulting from adhesive failure can be avoided, and the production loss is reduced.

Owner:江苏维利科自动化技术有限公司

Packaging box sticky folded surface processing method

InactiveCN101224644AExcellent adhesionHigh quality sticky effectContainer making machineryAdhesiveEngineering

The invention provides a bonding surface disposal method of a packing box. The surface of the bonding position of the packing box is disposed by a low-temperature plasma before the bonding is achieved by an adhesive. The method can effectively reinforce the bonding of the packing box, gains the bonding effect with high quality, and is safe and protects the environment.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

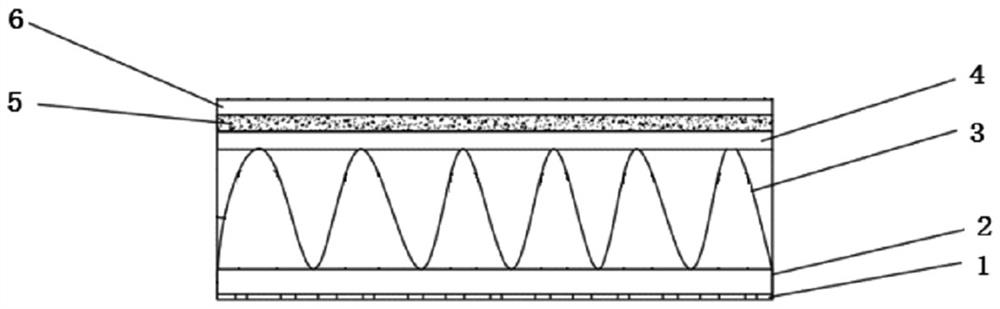

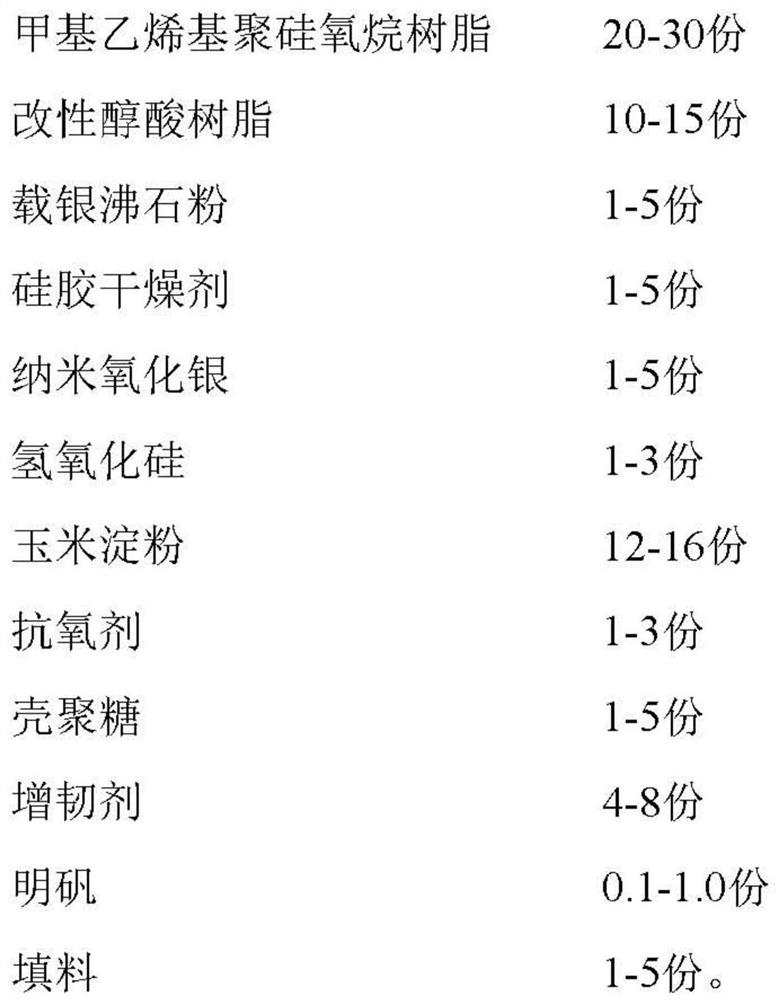

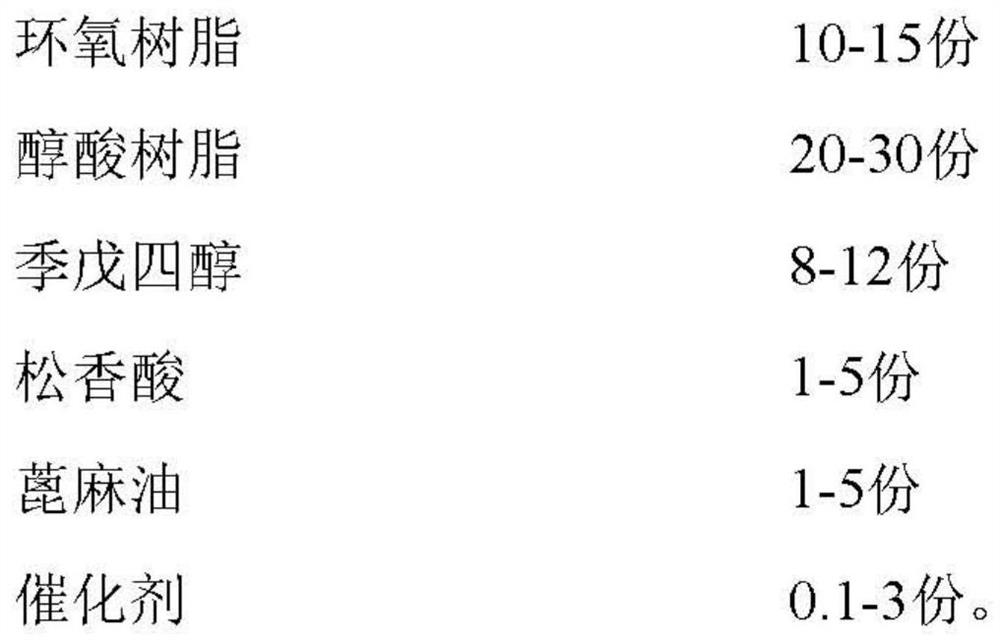

Damp-proof antibacterial corrugated paper and preparation method thereof

InactiveCN111926626AImprove wear resistanceGood film formingSpecial paperWater-repelling agents additionDesiccantSilica gel

The invention relates to the technical field of corrugated paper, in particular to damp-proof antibacterial corrugated paper and a preparation method thereof. The corrugated paper comprises corrugatedcore paper, first surface paper attached to the lower surface of the corrugated core paper, an antibacterial layer attached to the upper surface of the corrugated core paper, a damp-proof layer attached to the upper surface of the antibacterial layer and second surface paper attached to the upper surface of the damp-proof layer, and the corrugated paper and the first surface paper are bonded through a damp-proof antibacterial adhesive. The damp-proof antibacterial adhesive comprises the following raw material in parts by weight: 20-30 parts of methyl vinyl polysiloxane resin, 10-15 parts of modified alkyd resin, 1-5 parts of silver-loaded zeolite powder, 1-5 parts of a silica gel drying agent, 1-5 parts of nano silver oxide, 1-3 parts of silicon hydroxide, 12-16 parts of corn starch, 1-3parts of an antioxidant, 1-5 parts of chitosan, 4-8 parts of a flexibilizer, 0.1-1.0 part of alums and 1-5 parts of a filler. The corrugated paper disclosed by the invention has the characteristics ofgood mildew-proof and antibacterial effects and long service life.

Owner:东莞顺裕纸业有限公司

Glass cement

InactiveCN104263284AFast dryingHigh viscosityNon-macromolecular adhesive additivesOther rubber adhesivesPolyesterOLEAMIDOPROPYL BETAINE

The invention relates to a glass cement which is mainly prepared from 3-9% of rubber, 1.3-1.9% of pine oil ester, 4-12% of lauryl sodium sulfate, 6-12% of polyoxyethylene sorbitol monolaurate, 4-9% of cocamidopropyl betaine, 3-7% of sodium monofluorophosphate, 4-12% of clove oil, 3-11% of oxydol, 3-8% of mineral water 4-7% of triethylamine, 3-12% of ethylene glycol, 3-7% of polyester fiber, 3-8% of olive oil and 4-12% of theine. The glass cement has the advantages of high drying rate, high viscosity and low tendency to coming apart. The glass cement has wider application range, and is convenient for industrial production and living.

Owner:石麓瑶

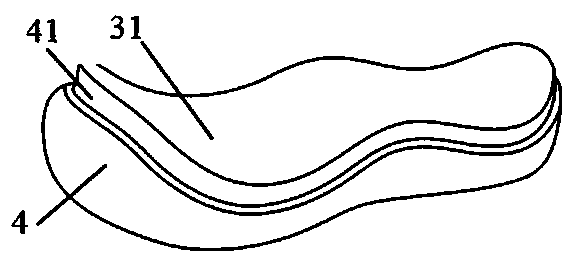

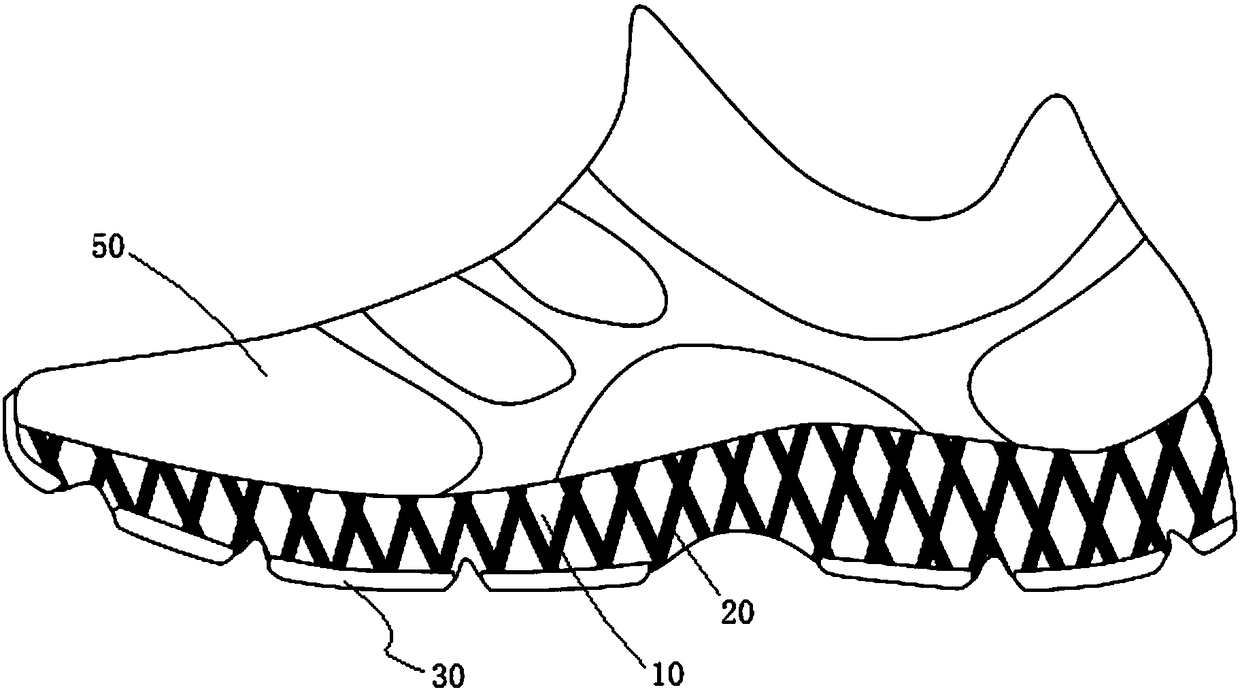

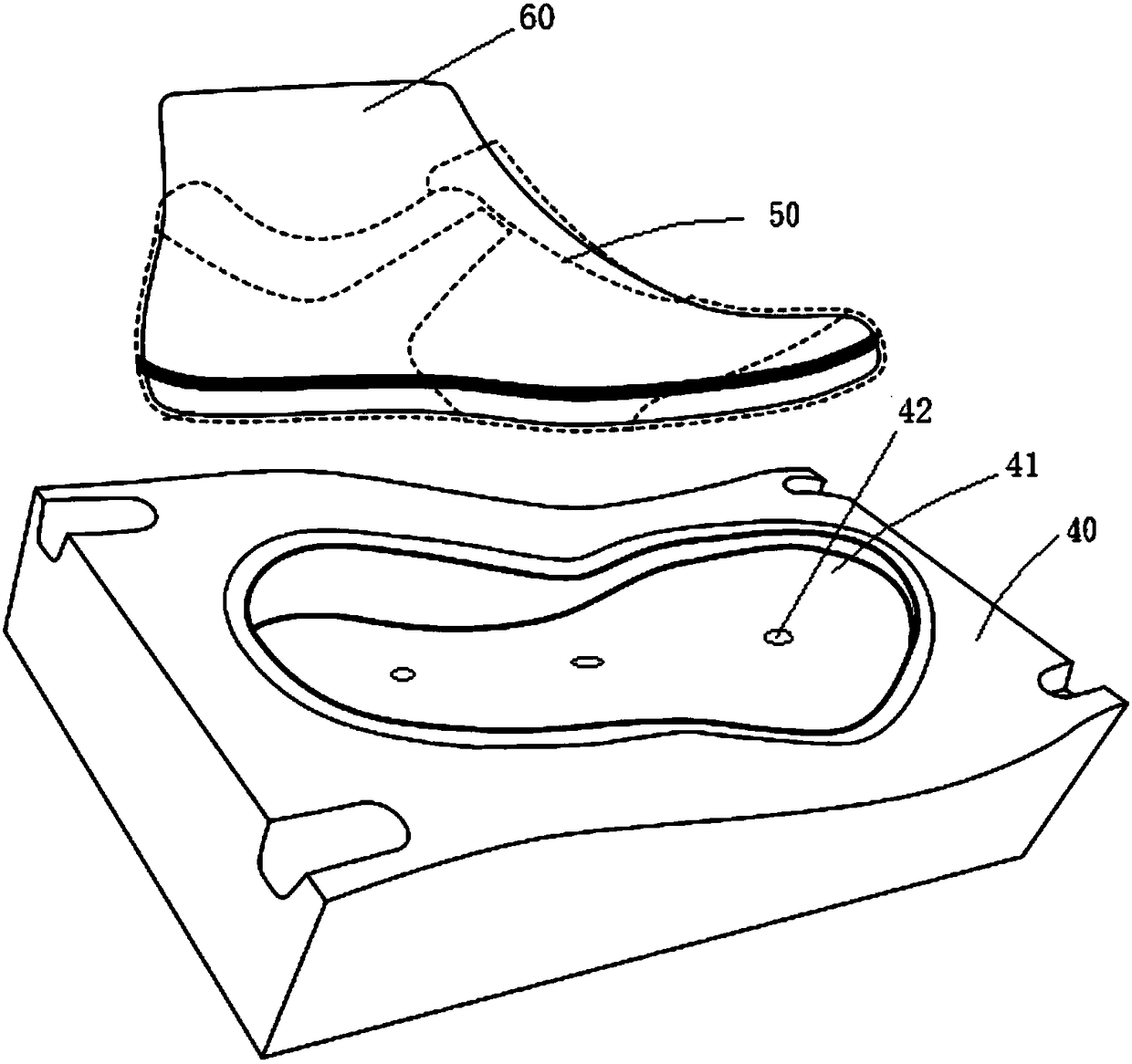

Reclaimed-material sole and production method of integrally-formed sole

InactiveCN108185573AImprove recycling ratesImprove product qualitySolesDomestic footwearRubber materialEngineering

The invention discloses a reclaimed-material sole and a production method of an integrally-formed sole. The reclaimed-material sole comprises an insole, a shoe film and an outsole and is characterizedin that the shoe film is arranged between the insole and the outsole, the peripheral edge of the shoe film extends and is adhered to the peripheral side of the insole, the shoe file is made of a TPUfilm, and the outsole is made of rubber. The reclaimed-material sole has the advantages that reclaimed EVA materials are sufficiently utilized to form the insole, the insole is tightly attached to shoe mold and a vamp, raw material recycling rate is increased effectively, and the produced sole is excellent in quality, less prone to glue failure, comfortable to wear, good in elasticity and simple in production process.

Owner:广东龙行天下科技有限公司

Heat-resistant polyurethane (PU) adhesive

InactiveCN106978124AImprove heat resistanceGuaranteed stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveSilicon dioxide

The invention relates to heat-resistant polyurethane (PU) adhesive. The PU adhesive is prepared from the following raw material components in parts by weight: 580-620 parts of polyol, 720-780 parts of toluene, 22-28 parts of isocyanate, 13-18 parts of monoethanolamine, 2-4 parts of a trimer, 140-160 parts of butanone, 17-22 parts of methyl ether, 770-790 parts of ethyl ester, 270-310 parts of acetone, 1180-1220 parts of dimethyl ester, 21-24 parts of fumed silica and 290-320 parts of fine methyl ester. The heat resistance of the PU adhesive prepared according to the formula provided by the invention is within a range of 120-145 DEG C, and is improved by about 70% compared with that of the conventional PU adhesive; the heat resistance of the PU adhesive is effectively improved, so that the PU adhesive can meet the use requirements of more industries; furthermore, the performance of the product is more stable; when being heated, the cured heat-resistant PU adhesive is not prone to have the phenomena of glue failure and glue overflow, so that the use stability of the PU adhesive product is better maintained.

Owner:陈建发

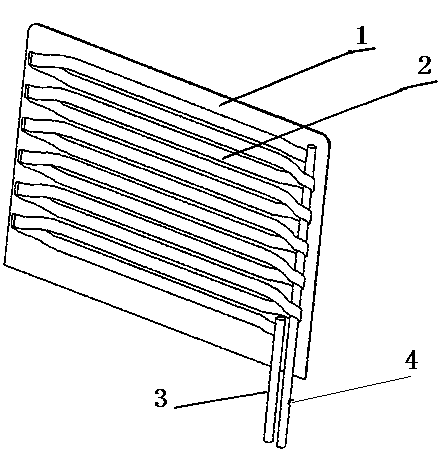

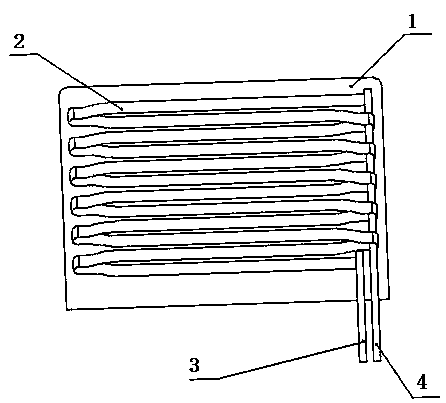

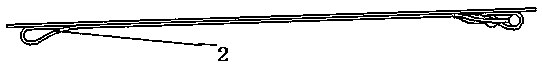

Microchannel plate type evaporator

The invention discloses a microchannel plate type evaporator. The microchannel plate type evaporator comprises an aluminum flat tube, the flat surface of an aluminum flat tube body is bonded with an aluminum plate, in the machining process, in order to prevent the situation that darts occur to the aluminum flat tube, then a refrigerant cannot flow, aluminum circular tubes are preset in an inner arc around which the flat tube overturns, the two preset aluminum circular tubes are pulled to be away from each other by a distance, one end of the aluminum flat tube is wound around one preset aluminum circular tube, and then the aluminum flat tube turned over by 360 degrees towards the lower portion of the other aluminum circular tube to be bent back and forth; after the aluminum flat tube body is formed, the preset aluminum circular tubes are drawn out from the two ends, an inlet tube is welded to the head end of the aluminum flat tube, the outlet tube is welded to the tail end of the aluminum flat tube, then the aluminum flat tube is bonded with the aluminum plate through a heat conduction adhesive film, and a microchannel plate type evaporator is formed; and the distance between the two preset aluminum circular tubes is based on the width of the aluminum plate. According to the scheme, the microchannel flat tube is adopted in a refrigerant channel, so that the thickness of a product is thin, and the space is saved; and the contact area between the microchannel flat tube and the aluminum plate is large, so that the flat tube and the aluminum plate are firmly bonded and are not prone to glue failure, and the heat exchange efficiency is high.

Owner:HENAN KELONG GRP

Antistatic water-based adhesive for vulcanized shoes and preparation method thereof

InactiveCN111253865AFast curing rateAccelerated curing moldingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseFiber

The invention discloses an antistatic water-based adhesive for vulcanized shoes and a preparation method of the antistatic water-based adhesive. The antistatic water-based adhesive for vulcanized shoes is prepared from a water-based polyurethane dispersion, dicyanoisobutyl acrylate, cassava starch, soybean fibers, polyethylene glycol, diaminodiphenyl methane, vinyltriamine, aluminum sulfate, an antistatic agent, sodium carboxymethyl cellulose and deionized water. The prepared antistatic water-based adhesive for vulcanized shoes is high in curing rate, can be quickly cured and formed in the vulcanized shoes, is smooth in surface and does not easily generate static electricity. The antistatic agent is added, so that the antistatic performance of the antistatic water-based adhesive is furtherenhanced, and the static electricity is not easily generated. The wearing comfort and safety can be obviously improved, and the application field is expanded.

Owner:泉州市泉石通智能科技有限公司

Production technology of waterproof plywood

InactiveCN106217575AImprove uniformityConvenient ArrangementNon-macromolecular adhesive additivesWood working apparatusAdhesiveConveyor belt

The invention provides a production technology of a waterproof plywood and relates to the technical field of plywood production. The production technology comprises the following steps: peeling barks from logs, annularly cutting the logs into wood sheets, and then air-drying; applying an adhesive, and coating the wood sheets with the adhesive which comprises the following components in parts by weight: 100-120 parts of UF resin, 10-20 parts of coking coal oil, 10-20 parts of metallic soap, 10-20 parts of alkanolamide, 6-10 parts of a curing agent, 30-50 parts of filler, 5-9 parts of a modifier and 90-110 parts of water; conveying the wood sheets onto a conveyor belt, softening the wood sheets by using a heating device to heat the wood sheets to 60-80DEG C, and then, planishing the wood sheets through compression rollers; replenishing the adhesive; assembling a blank; pre-pressing; trimming and hot-pressing; filling putty; and sawing edges and molding so as to obtain the polywood. The production technology is short in pre-pressing and hot-pressing time and high in production speed. The waterproof plywood is small in internal stress, cannot easily come apart or deform as the adhesive is good in thermosetting property, high in viscosity, high in strength, good in durability and is not prone to going bad, and is good in waterproof effect.

Owner:和县薛氏木制品制造有限公司

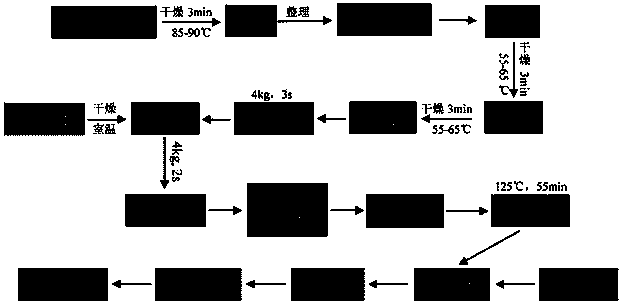

Shoe making process

The invention discloses a shoe making process. The shoe making process includes processing steps: step 1, performing rough shape cutting; step 2, cutting; step 3, making an upper; step 4, arranging ashoe tree; step 5, buckle-butting for shaping; step 6, removing the shoe tree; step 7, fixing a heel / pasting an insole; step 8, checking quality; step 9, finishing and packaging. By brushing glue forseveral times and baking, fusion of the glue can be accelerated, stickiness of the glue can be improved, and a produced shoe is less prone to glue failure; by adding protective steel pieces in mutualhinging to a sole to prevent nails penetrating the sole from causing harm to a foot, wearing life of the shoe is prolonged.

Owner:ANHUI SWAN TECH IND GRP

High-viscosity ultraviolet glue for sealing of LED (light emitting diode) lamp cups

InactiveCN106047257AImprove cooling effectLow failure rateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAcrylic resin

The invention discloses high-viscosity ultraviolet glue for sealing of LED (light emitting diode) lamp cups. The high-viscosity ultraviolet glue is characterized by comprising, by weight, 40-60 parts of prepolymer, 20-30 parts of a diluents, 2-5 parts of a photoinitiator, 10-20 parts of curing agent microcapsules, 1.5-2 parts of auxiliaries, 2-5 parts of heat conduction filler and 5-10 parts of heat conduction silicone grease, wherein the prepolymer comprises epoxy resin and polyurethane modified acrylic resin. The high-viscosity ultraviolet glue for sealing of the LED lamp cups has heat conductivity and makes LED lamps excellent in heat radiation effect and long in service life, and the high-viscosity ultraviolet glue is high in viscosity and less prone to failure at a low temperature. In addition, the high-viscosity ultraviolet glue is high in stability and available for long-term storage, and a curing agent is less prone to reacting with other components.

Owner:昆山初本电子科技有限公司

Laminated aluminum plate for a notebook computer case

ActiveCN107053788BImprove corrosion resistanceGood physical barrierPolyurea/polyurethane coatingsMetal layered productsPolyethylene terephthalate glycolPolyurethane adhesive

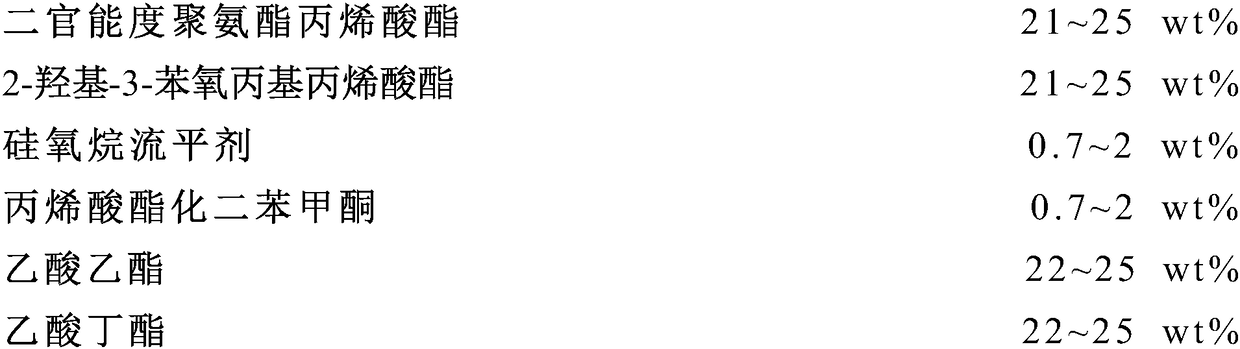

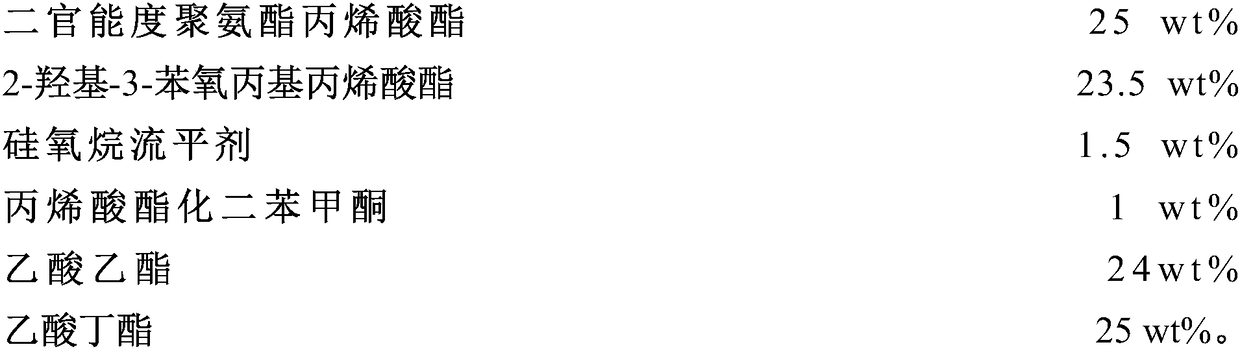

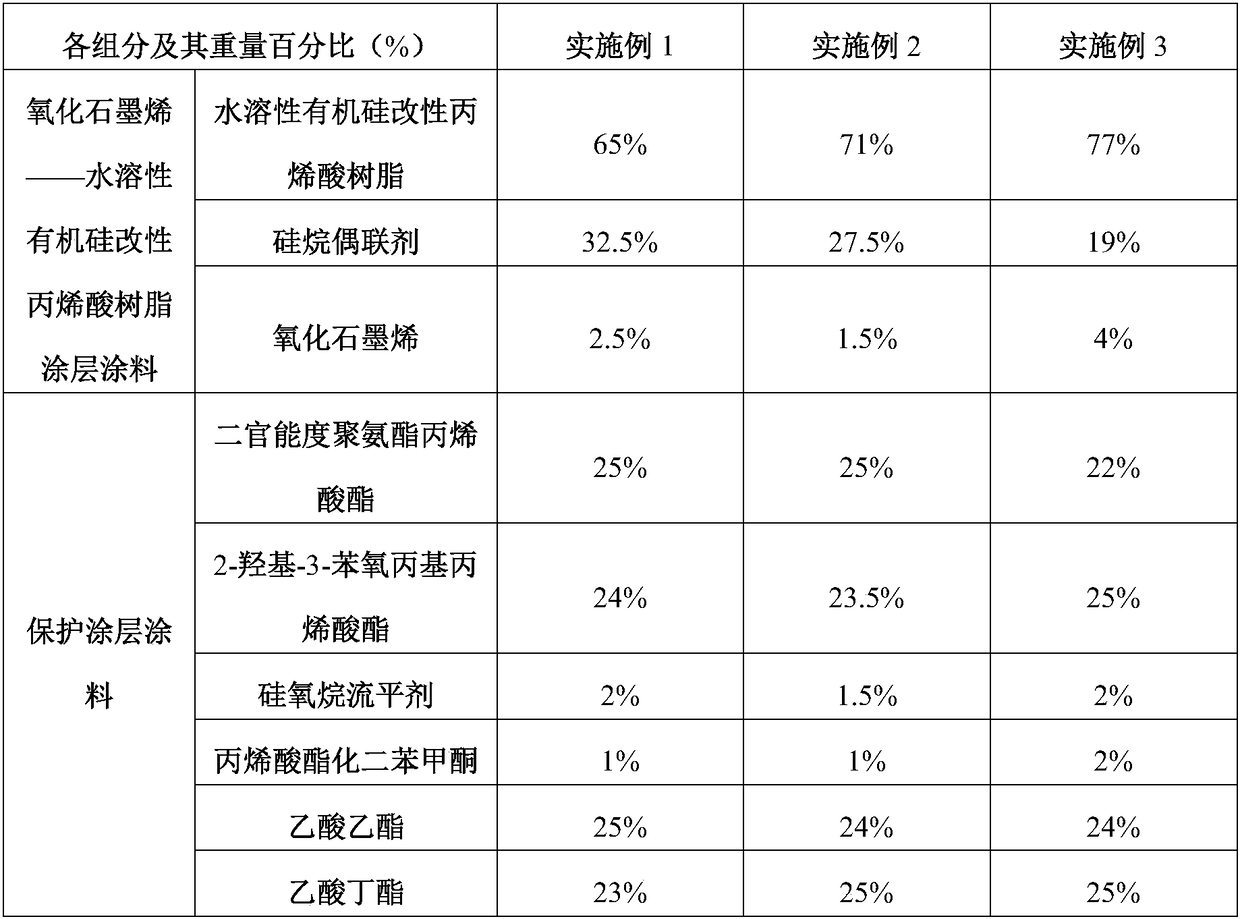

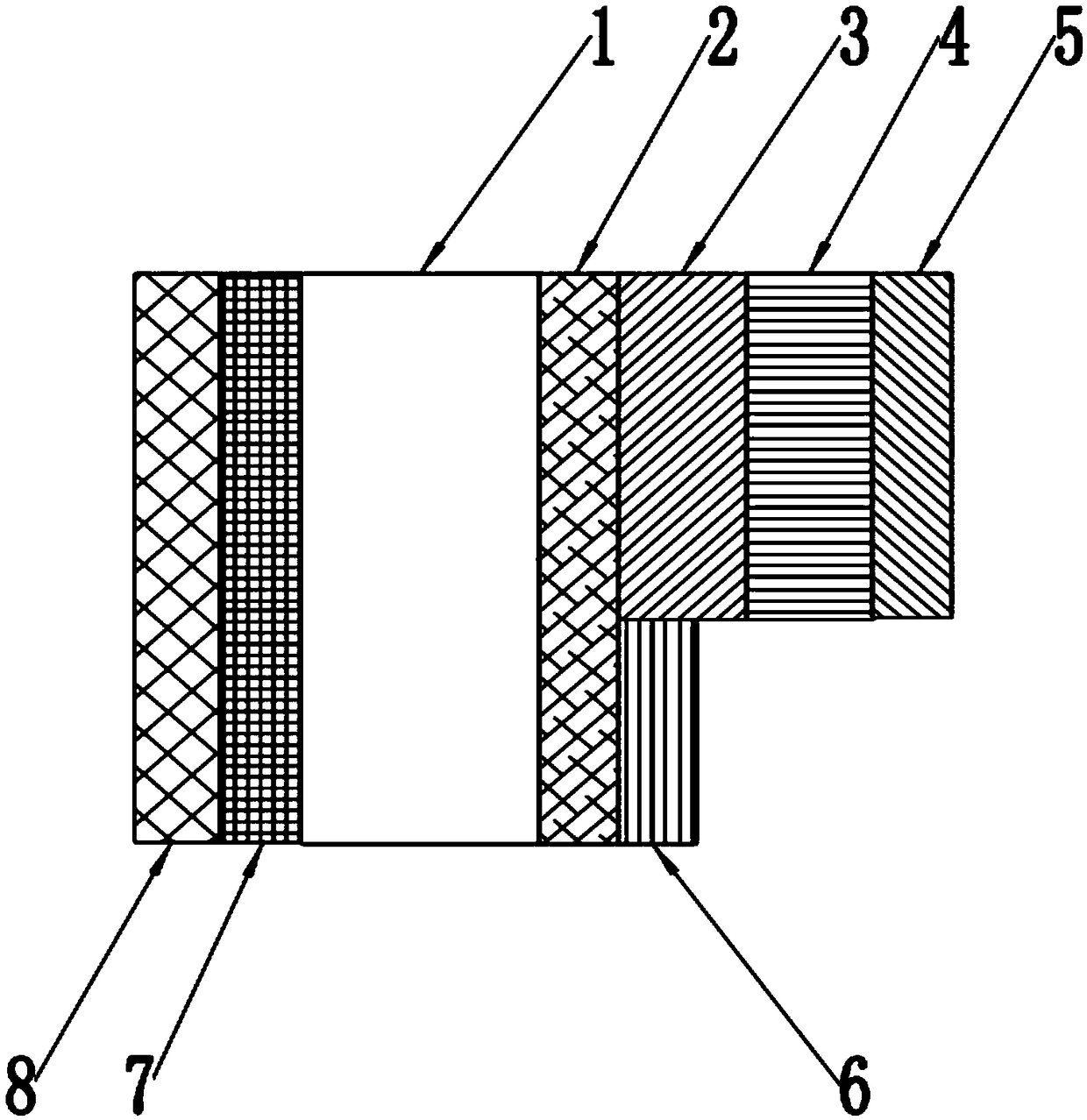

The invention discloses a film-coated aluminum plate for a laptop case. The film-coated aluminum plate comprises a passivated aluminum substrate, wherein a coating layer and a graphene oxide-water soluble organosilicon modified acrylic resin coating layer are sequentially laminated on the front surface and the back surface of the passivated aluminum substrate; then an adhesive layer, a film-coated layer and a protection coating layer are sequentially laminated on the graphene oxide-water soluble organosilicon modified acrylic resin coating layer which is laminated on the front surface; the coating layer is a film prepared from a chromic acid chemical pretreatment solution; the adhesive layer is prepared from a polyurethane adhesive; the film-coated layer is a PVC (Polyvinyl Chloride) and PET (Polyethylene Terephthalate) composite colorful film. A preparation technology comprises the following steps: coating; drying; coating the graphene oxide-water soluble organosilicon modified acrylic resin coating layer; coating a PET film; coating the protection coating layer. The film-coated aluminum plate disclosed by the invention is good in insulativity and thermal conductivity, higher in hardness, not easy to deform, decolor or degum, and good in protectiveness.

Owner:江阴海美金属新材料有限公司

Preparation method of liquid net glue adhesive

InactiveCN106010431ALow freezing pointNot easy to open glueNon-macromolecular adhesive additivesProtein adhesivesChemistryAdhesive

The invention discloses a preparation method of a liquid net glue adhesive, comprising the following steps: weighing methanol, net glue, distilled water, potassium thiocyanate, magnesium sulfate and sodium chloride, and then mixing the distilled water, potassium thiocyanate, Add magnesium sulfate and sodium chloride into a three-necked flask, heat up while stirring to fully dissolve potassium thiocyanate, magnesium sulfate and sodium chloride, then add net glue, stir at constant temperature, then add methanol, and then carry out stirring reaction to obtain A liquid mesh adhesive. The liquid mesh adhesive prepared by the method has the characteristics of low freezing point, stable bonding strength, and high temperature and is not easy to open the glue.

Owner:SHAANXI UNIV OF SCI & TECH

A thin half-covered TV metal backplane

ActiveCN107053779BReduce thicknessImprove shielding effectPolyurea/polyurethane coatingsMetal layered productsPolyurethane adhesiveMechanical property

The invention discloses a thin type half-covered TV (Television) metal backboard. The thin type half-covered TV metal backboard comprises a galvanized steel sheet substrate, wherein the galvanized steel sheet substrate is arranged at the rear side of a TV; a coating layer is laminated on the rear side surface of the galvanized steel sheet substrate; a polyurethane adhesive layer, a film covering layer and a hardened protective coating layer are sequentially laminated on the upper part of the rear side surface of the coating layer; an anti-corrosion anti-fouling coating layer is laminated on the lower part of the rear side surface of the coating layer; the coating layer and the anti-corrosion anti-fouling coating layer are sequentially laminated on the front side surface of the galvanized steel sheet substrate; the coating layer is a film prepared from chromic acid chemical pretreatment solution. According to the thin type half-covered TV metal backboard disclosed by the invention, the structure advantages and the function advantages are integrated, ultrathin appearance attractiveness and good physical and mechanical properties of electric and thermal conductivity, corrosion resistance, fouling resistance, impact resistance and the like are integrated, the hardness is high, the protectiveness is strong, manufacturing materials are saved, and the technology complexity is reduced.

Owner:江阴海美金属新材料有限公司

A power battery pole lug encapsulation device and encapsulation method thereof

ActiveCN106229458BPaste effect is goodAvoid short circuitCell component detailsPower batteryElectrolytic agent

The invention discloses a power battery lug wrapping device, which comprises a wrapping driver, a guide table, and an indenter for pushing the adhesive tape. The channel through which the tabs pass, the direction of the channel is perpendicular to the movement direction of the indenter, and the guide table is provided with a front limit block and a rear limit block on the entrance side of the channel, and the front limit block and the rear limit block are located at On both sides of the width of the channel, the front limit block and the rear limit block are slopes at the entrance of the channel, and the bottom of the slope is lower than the channel, and a baffle is arranged above the channel, and the baffle is located between the front limit block and the channel Between and adjacent to the rear limiting blocks, an air blowing hole is arranged in the center of the guide platform, and the invention also discloses a rubber encapsulation method using the device. The invention has the advantages of realizing the lamination of tabs with glue, the tape is firmer, and it is not easy to open the glue when the electrolyte is injected into the battery, avoiding the short circuit of the battery tabs caused by the opening of the glue, and reducing production loss.

Owner:江苏维利科自动化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com