Laminated aluminum plate for a notebook computer case

A notebook computer, aluminum plate technology, applied in the direction of coating, chemical instruments and methods, layered products, etc., can solve the problems of thermal conductivity and insulation performance that are difficult to meet at the same time, cannot meet customer needs, limit the application of high-end products, etc., to achieve good Physical barrier effect, both insulation and heat dissipation performance, good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

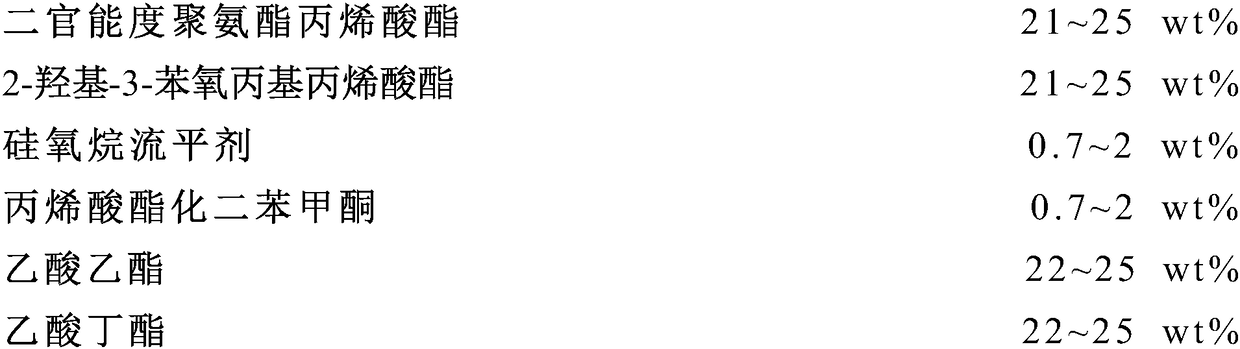

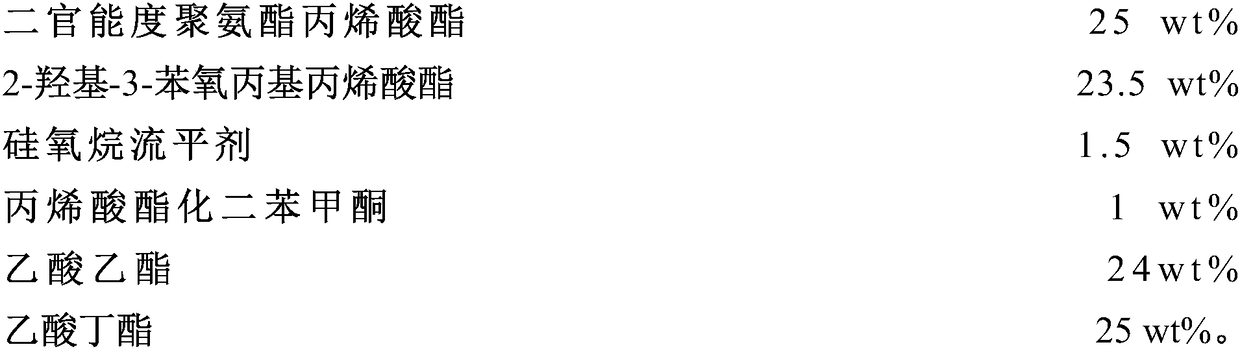

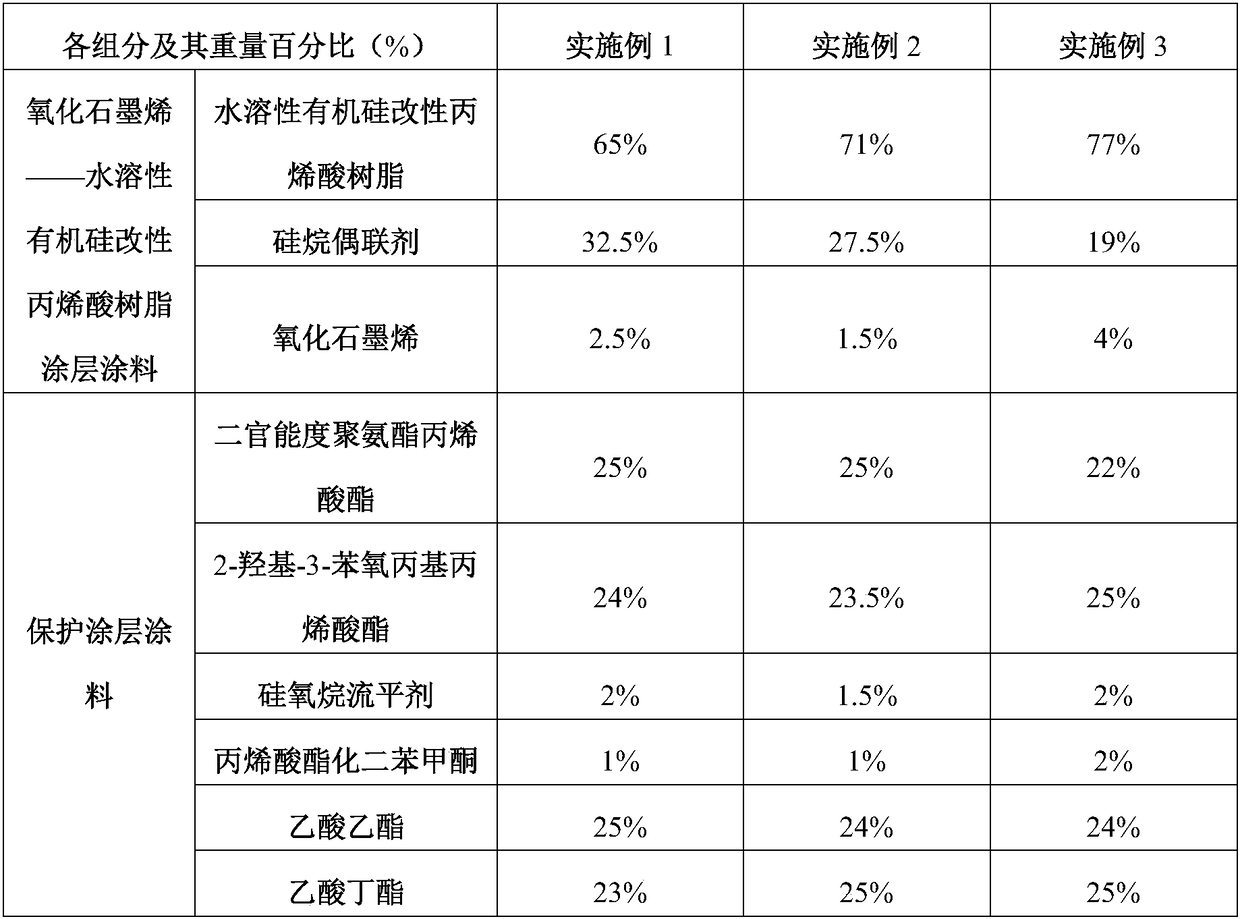

Embodiment 1~ Embodiment 3

[0041] The preparation method of embodiment 1~embodiment 3 coated aluminum plate is as follows:

[0042] Step 1: passivating the aluminum plate to form the base material;

[0043] Step 2: apply a chromate chemical pretreatment solution with a mass concentration of 40% on both sides of the above-mentioned passivated aluminum plate base material by a roller coating method to obtain a chemical coating;

[0044] Step 3: Apply graphene oxide-water-soluble silicone-modified acrylic resin coating on the chemical coating, dry and cure at 200°C to obtain graphene oxide-water-soluble silicone-modified acrylic resin coating layer;

[0045] Step 4: Apply polyurethane glue on the graphene oxide-water-soluble silicone-modified acrylic resin coating on the front, and cure at 220°C to obtain an adhesive layer;

[0046] Step 5: Paste PVC and PET composite color film on the adhesive layer at 230°C;

[0047] Step 6: Mix the protective coating paint and paint thinner in a mass ratio of 3:2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com