Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Normal start" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

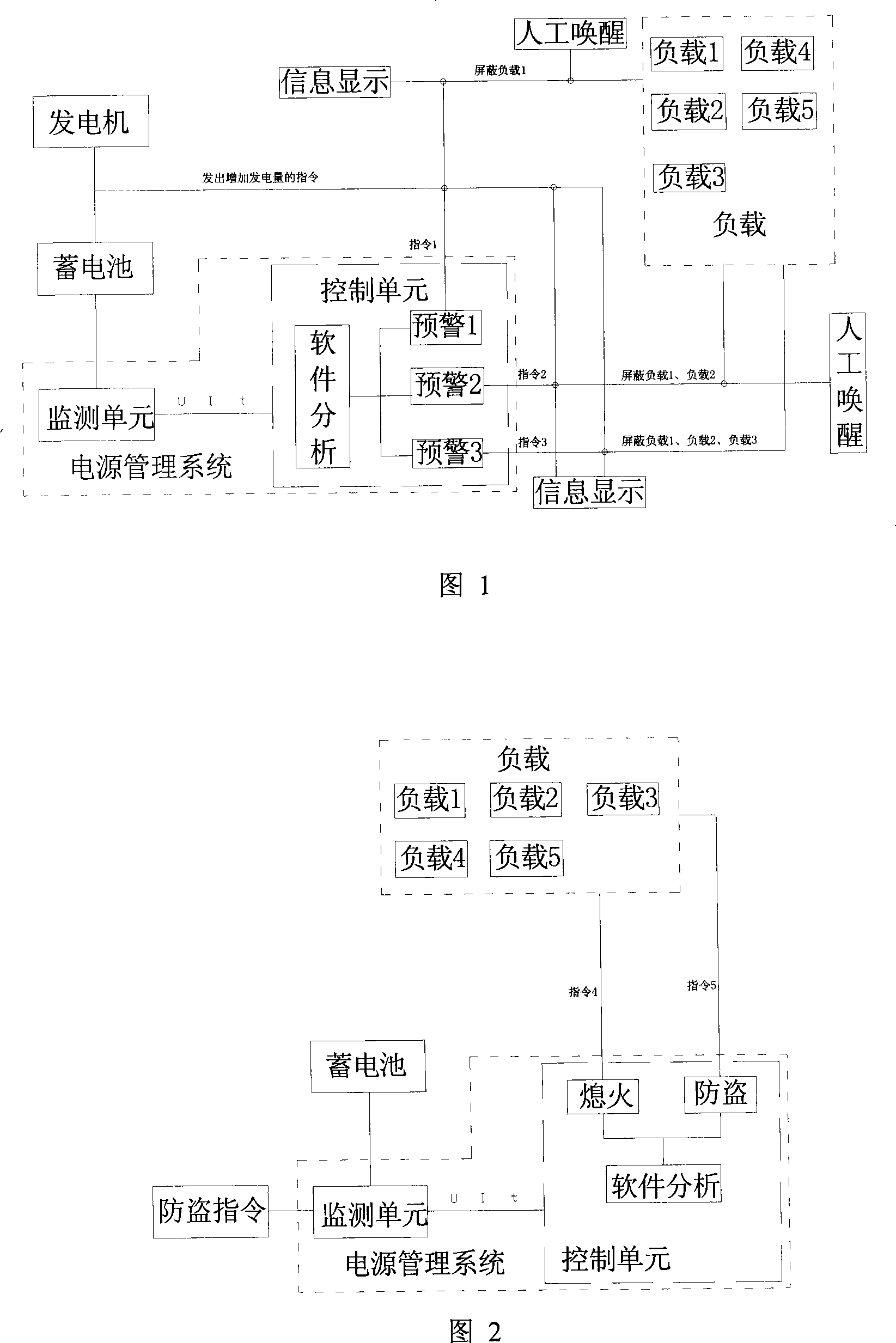

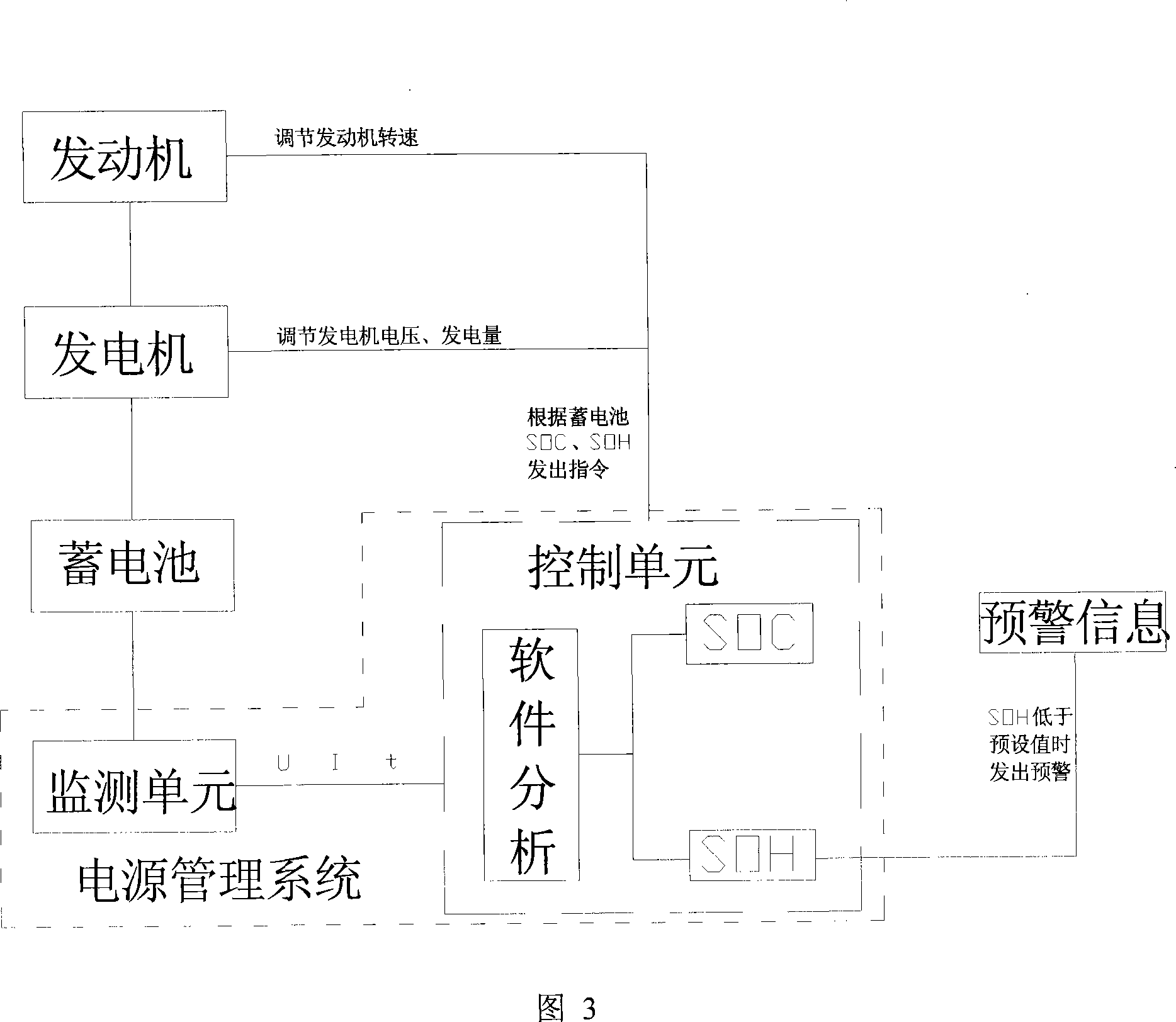

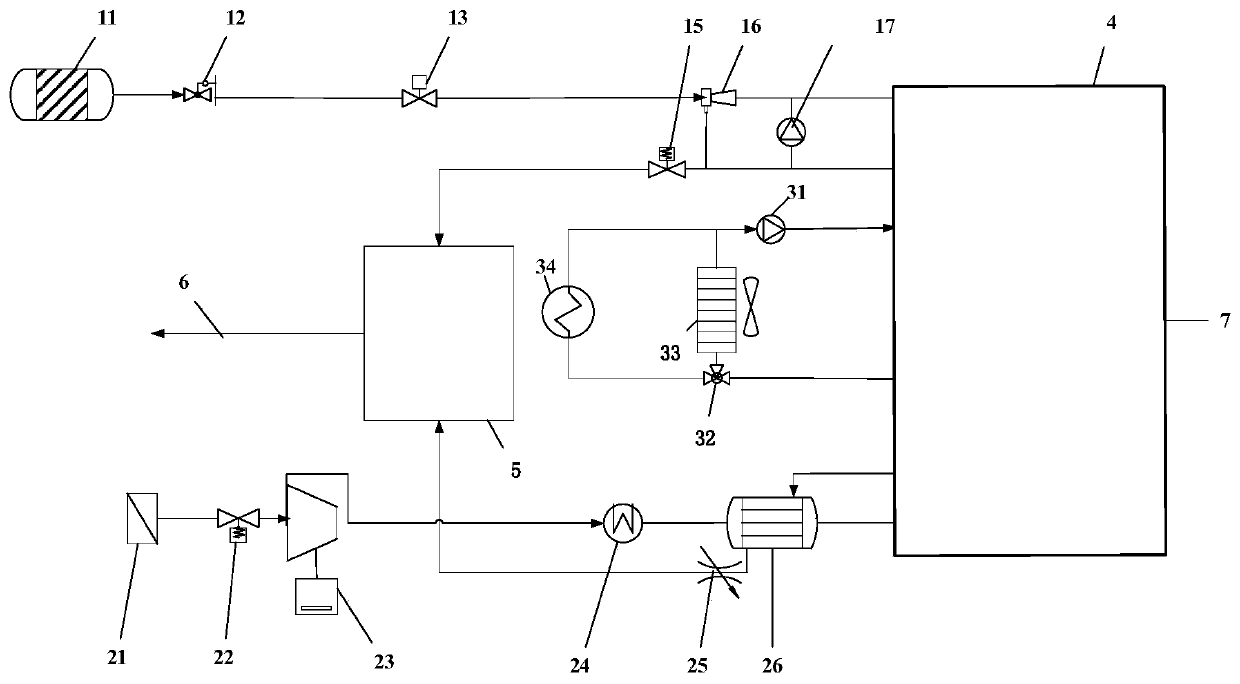

Vehicle power management system

ActiveCN101159340AReduce consumptionNormal startBatteries circuit arrangementsElectric powerDriver/operatorSupply management

The invention relates to an automobile power supply management system. Firstly, by monitoring the state of the storage battery, the application state of an electrical apparatus used in an entire automobile is controlled, simultaneously the generation power and the output power of a generator is controlled, and the state information of the storage battery is provided to a driver, thereofore maximally optimizing the electric balance of the entire automobile; besides, the static current of the entire automobile is controlled, and the consumption of the electric quantity of the storage battery caused by the static current is reduced, ensuring the time for normally starting after the automobile stops, as well as optimizing the charging and discharging state of the storage battery and prolonging the service life of the storage battery.

Owner:CHERY AUTOMOBILE CO LTD

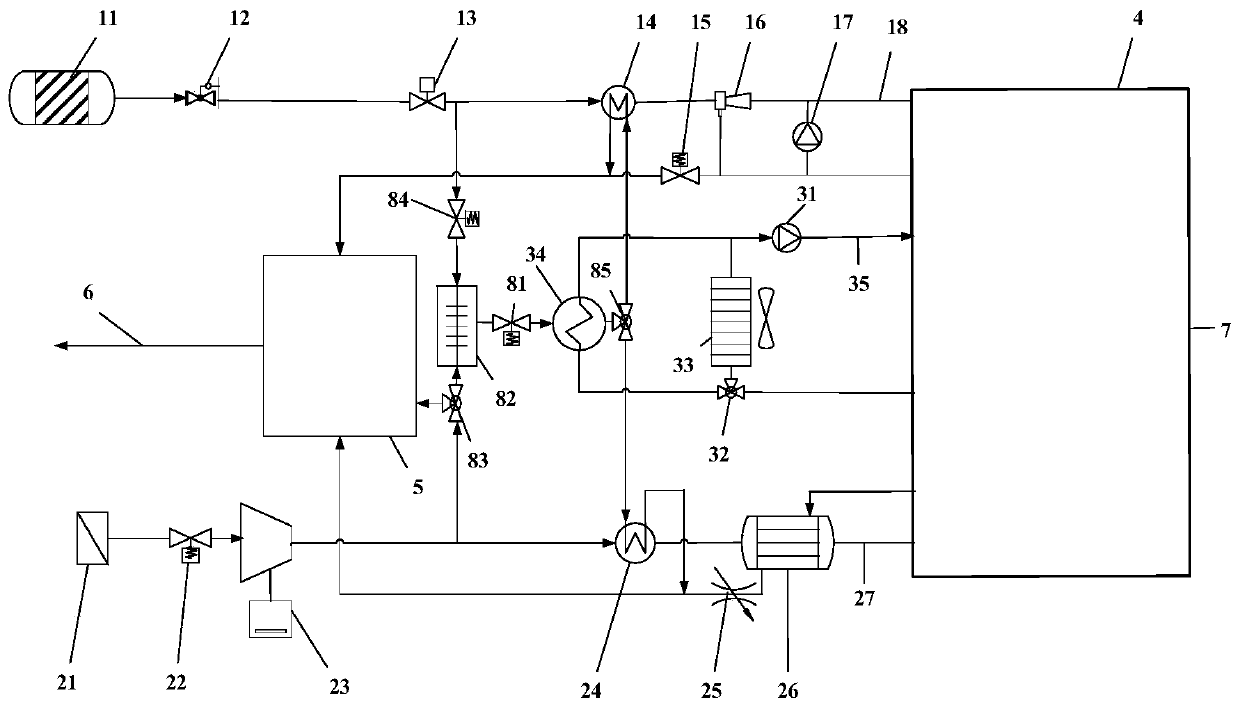

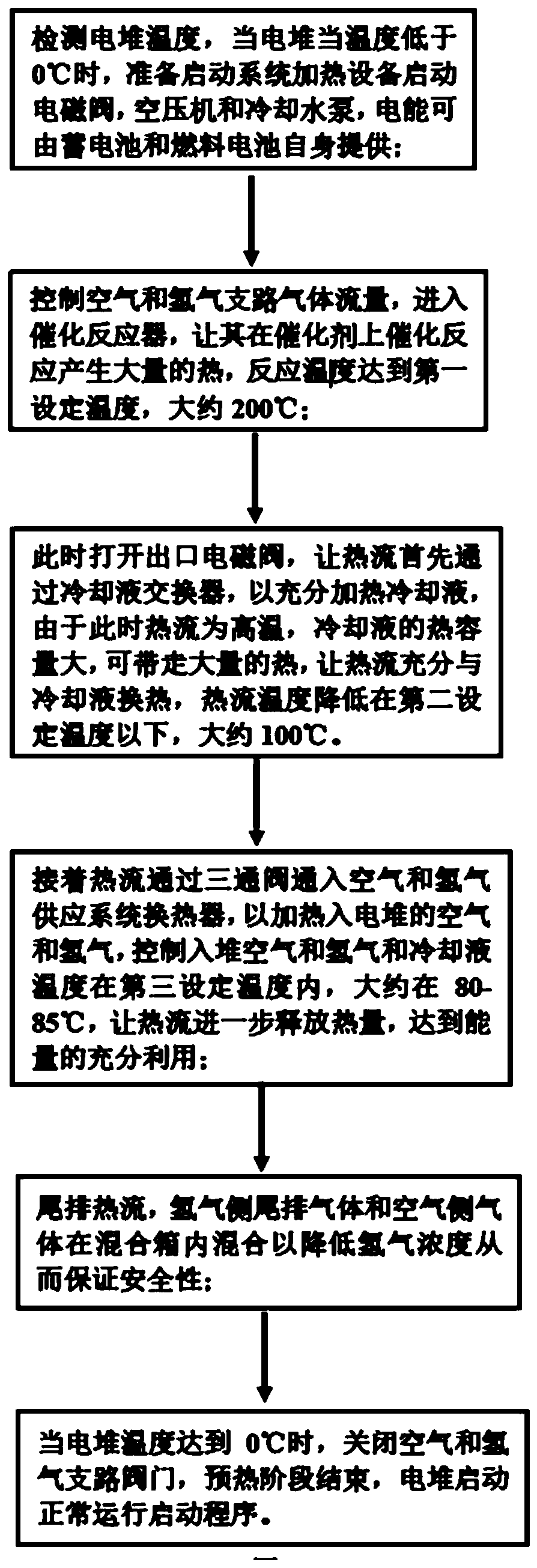

Combined heating fuel cell low-temperature starting system and working method

The invention relates to a combined heating fuel cell low-temperature starting system comprising a cooling liquid circulating pipeline, an electric pile, a waste gas mixing box, and an air supply pipeline and a hydrogen supply pipeline which are connected with the electric pile and the waste gas mixing box. The cooling liquid circulating pipeline is connected with the electric pile; the waste gasmixing box is communicated with the atmosphere to exhaust waste gas. The low-temperature starting system further comprises a heating assembly. The cooling liquid circulating pipeline comprises a cooling liquid heat exchanger; the air supply pipeline comprises an air heat exchanger, the hydrogen supply pipeline comprises a hydrogen heat exchanger, and the heating assembly is connected with the cooling liquid heat exchanger, the air heat exchanger and the hydrogen heat exchanger. Compared with the systems in the prior art, the system has the advantages that the fuel cell can be rapidly started in a low-temperature environment and the energy utilization rate is high.

Owner:TONGJI UNIV

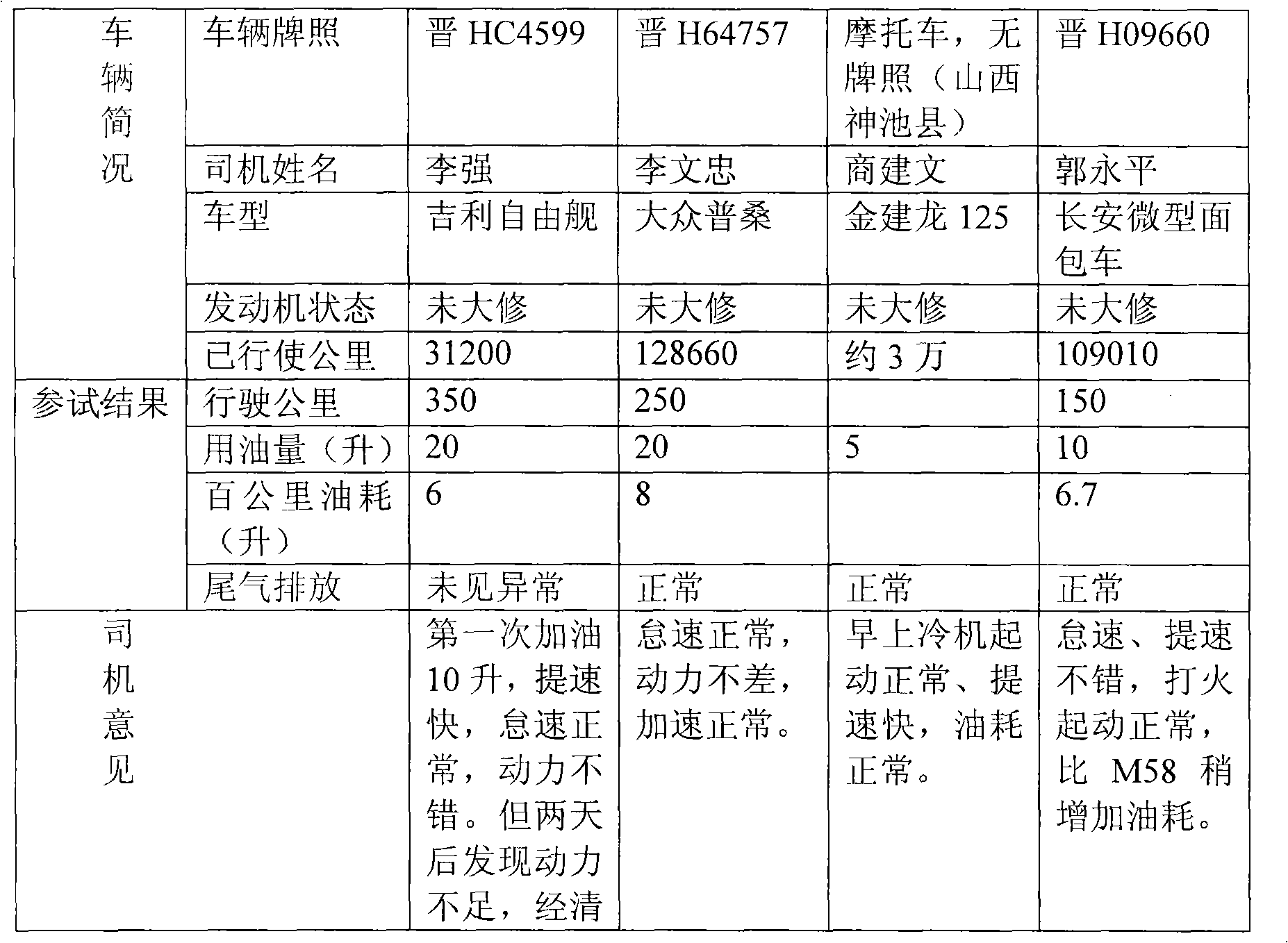

Methanol gasoline

InactiveCN102796574ANormal startImprove anti-corrosion performanceLiquid carbonaceous fuelsLiquid fuelFuel oil

Provided is methanol gasoline. The invention relates to the technical field of energy, and specifically relates to a methanol gasoline formula. The methanol gasoline formula includes adding a methanol gasoline compound additive to methanol by weight ratio of 0.05% for denaturation, and mixing 15-65 parts of methanol, 20-30 parts of 90 # gasoline, 10-30 parts of light aromatic hydrocarbons, and 10 parts of naphtha by weight after denaturation. The methanol gasoline is good in corrosion resistance, and generates chemical and physical adsorption to resist corrosion by inhibiting basic groups of molecules. The methanol gasoline is powerful in dynamic property, high in octane value, good in antiknock property, low in fuel consumption, and safe and reliable in use. The method makes alcohol and gasoline dissolve organically, and helps to enhance the stability without delamination and emulsification. The methanol gasoline can be used with ordinary gasoline by mixing or crossing. By using the methanol gasoline, motors are easy to start under the low temperature condition of -35 DEG C, and have no air resistance at high temperature, thereby being started normally. The methanol gasoline is suitable for gasoline and liquid fuels, and can help to save 10-25% of the fuel oil, to reduce the amount of smoke and exhaust gases, and to reduce pollution.

Owner:张伯义 +2

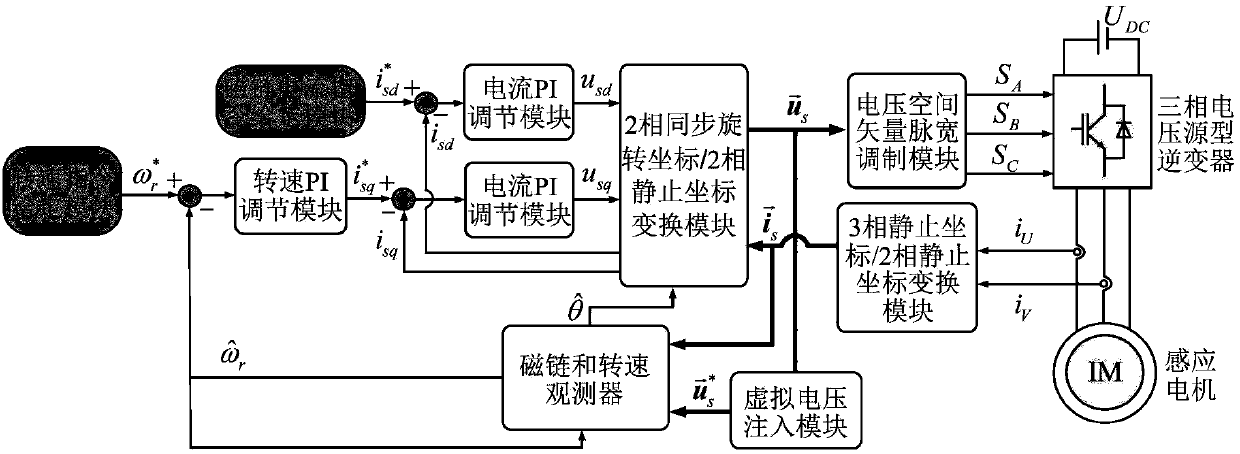

Induction motor speed sensorless drive control method based on virtual voltage injection

ActiveCN108599651AGuaranteed uptimeNormal startElectronic commutation motor controlElectric motor controlControl vectorElectric machine

The invention discloses an induction motor speed sensorless drive control method based on virtual voltage injection, firstly, a virtual voltage signal is injected into a motor magnetic chain and a rotation speed observer, thus, difference exists between input of the motor magnetic chain and the rotation speed observer and instruction input of the motor; secondly, any type of the motor magnetic chain and the rotation speed observer are taken as a basis, and consequently, a rotation angle of the motor magnetic chain and a rotation speed of a motor rotor are estimated, and the induction motor isdriven by certain control strategy (such as vector control) to run regularly; then, according to the the signal designed by the method and only injected into the motor magnetic chain and the rotationspeed observer, the induction motor driven by an induction motor speed sensorless drive control system is guaranteed to output 150% rated torque while running with low synchronous speed and running without synchronous speed, and can keep stability of the rated torque for long time.

Owner:HUAZHONG UNIV OF SCI & TECH +1

High-clean vast-scale methanol gasoline

The invention belongs to the fuel technical field, in particular relating to synthetic gasoline which takes methanol as main material. The compositions by weight percentage of the synthetic gasoline are: 58 to 85 percent of methanol, 14.2 to 40 percent of merchantable gasoline and 0.8 to 2 percent of comprehensive additives. The product of the synthetic gasoline can directly replace No. 90, No. 93, No. 97 and No. 98 national standard motor petrol, and a motor can be normally started and operated at an extreme temperature of 30 DEG C below zero. The synthetic gasoline not only can be used for gasoline cars with high compression ratio (the ratio of the cylinder total volume to the compressed cylinder volume is more than or equal to 9.5) but also can be used for gasoline cars with low compression ratio (the compression ratio is less than 9.5), including motorcycles which use carburetors.

Owner:周凯亮

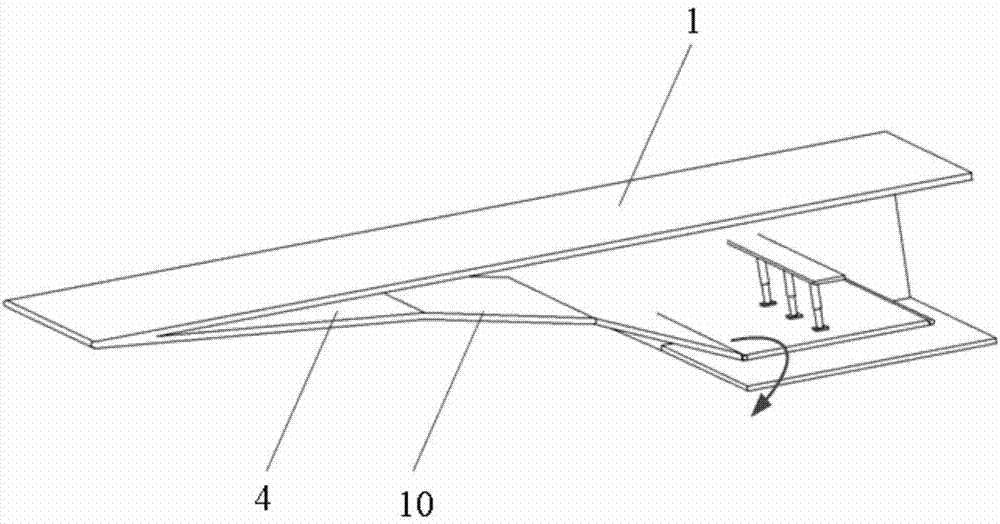

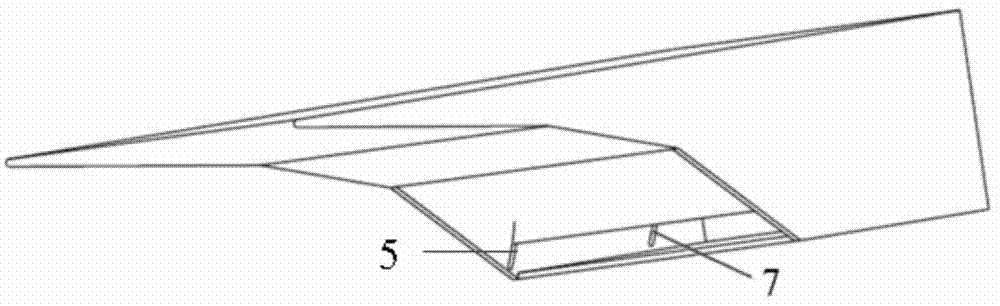

Two-dimensional supersonic air inlet passage with variable structure

InactiveCN104500228ASimple structureImprove work efficiencyGas turbine plantsJet propulsion plantsCombustion chamberEngineering

The invention discloses a two-dimensional supersonic air inlet passage with a variable structure. The air inlet passage and an aircraft body are of an integrated structure, a fixing plate is positioned in the air inlet passage and is arranged parallel to an upper supporting plate, a piston barrel and a piston rod are fixedly connected with an upper fixed support and a lower fixed support respectively, the piston barrel and the piston rod are synchronously matched and are positioned between the fixing plate and the upper supporting plate, a front compression plate is articulated with a movable compression plate by a first rotating rod, the movable compression plate is articulated with the upper supporting plate by a second rotating rod, the upper supporting plate and the air inlet passage are articulated by a third rotating rod, and two ends of each of the second rotating rod and the third rotating rod are positioned in a front sliding groove and a rear sliding groove on the two side walls inside the air inlet passage respectively for movement. The air inlet passage has simple structure and has strong realizability in engineering application, the compression angle of the air inlet passage is changed to directly adjust the quality of air flows entering into a combustion chamber, the aerodynamic performance and the working state of the air inlet passage operating in a wide range of mach number are ensured, and the working efficiency and the aerodynamic performance of the air inlet passage are greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

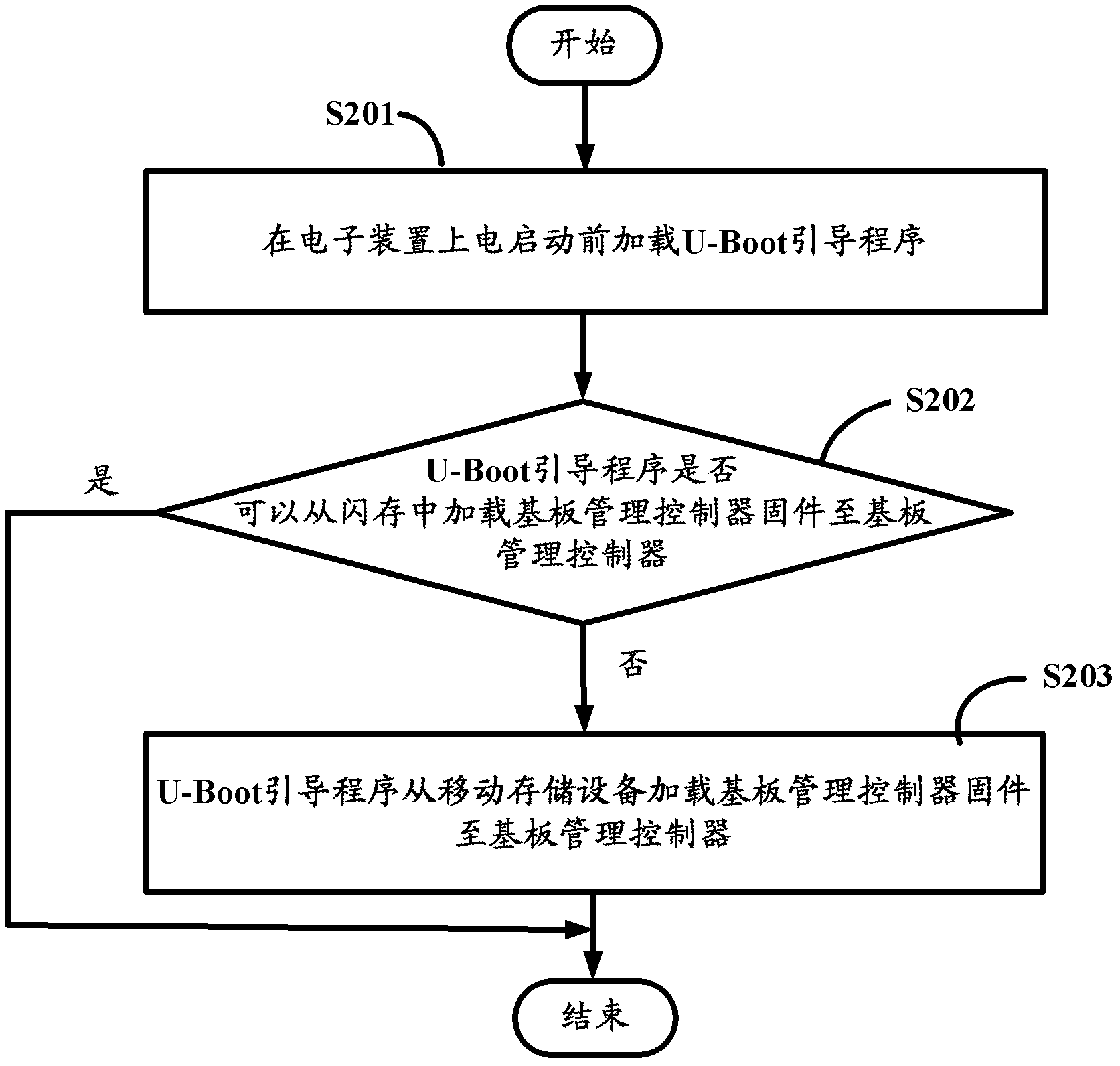

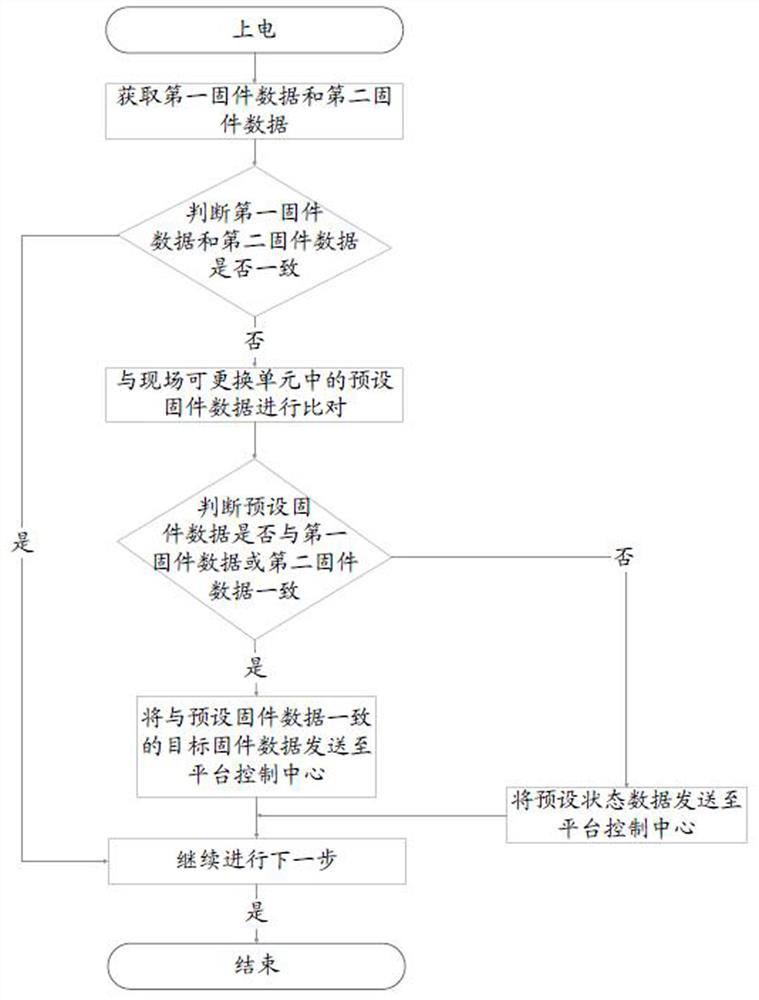

Electronic device with substrate management controller firmware and firmware loading method

An electronic device with substrate management controller firmware comprises a flash memory and a substrate management controller stored in the flash memory; the substrate management controller is equipped with a U-Boot loader; the U-Boot loader is used for loading the substrate management controller firmware stored in the flash memory to the substrate management controller after the U-Boot loader is loaded to the substrate management controller; and the U-Boot loader is loaded before the substrate management controller is electrically started on the electronic device. The U-Boot loader is also used for loading the firmware from one memory device electrically connected with the electronic device when the substrate management controller firmware cannot be loaded from the flash memory. The invention further provides a corresponding firmware loading method. Through the electronic device and the firmware loading method, the firmware which can not be loaded from the flash memory can be loaded from the memory device, so that the substrate management controller can be normally started.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

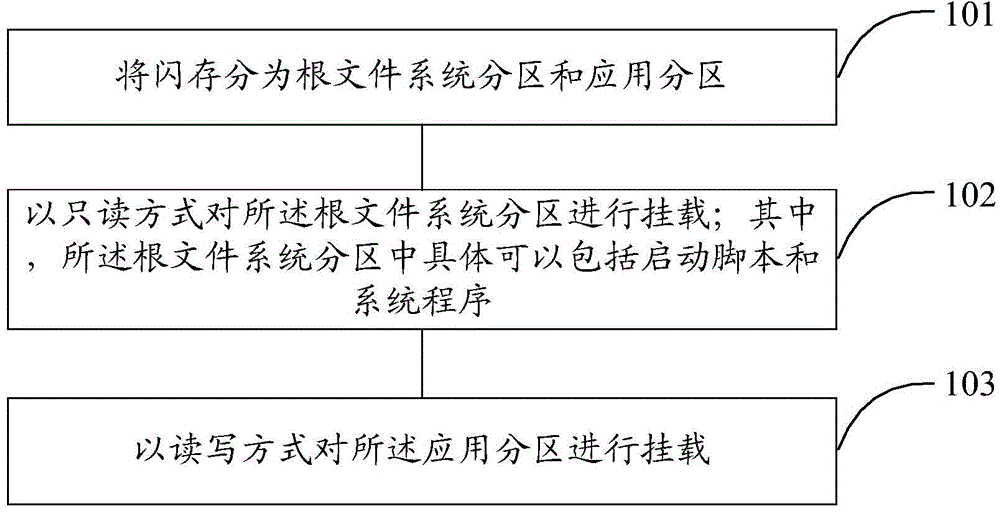

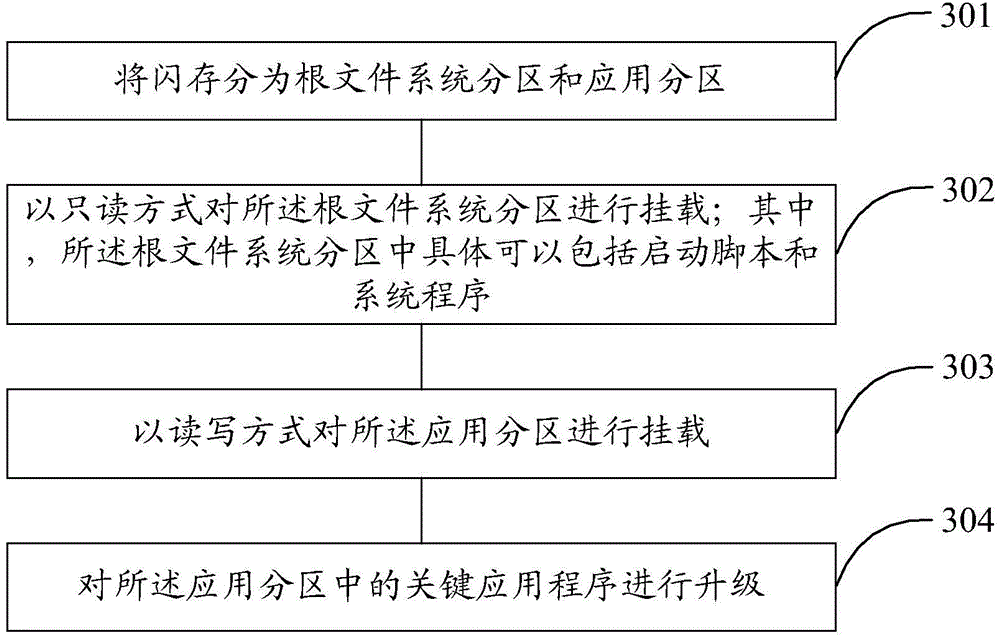

Method and device for processing flash memory partition

InactiveCN106033362AAvoid damageNormal startMemory loss protectionProgram loading/initiatingFlash file systemFile system

Embodiments of the present invention provide a method and device for processing flash memory partitions, wherein the method includes: dividing the flash memory into a root file system partition and an application partition; mounting the root file system partition in a read-only manner; wherein, The root file system partition includes startup scripts and system programs; the application partition is mounted in a read-write manner. The embodiment of the present invention can improve the stability of the flash memory file system.

Owner:VISIONVERA INFORMATION TECH CO LTD

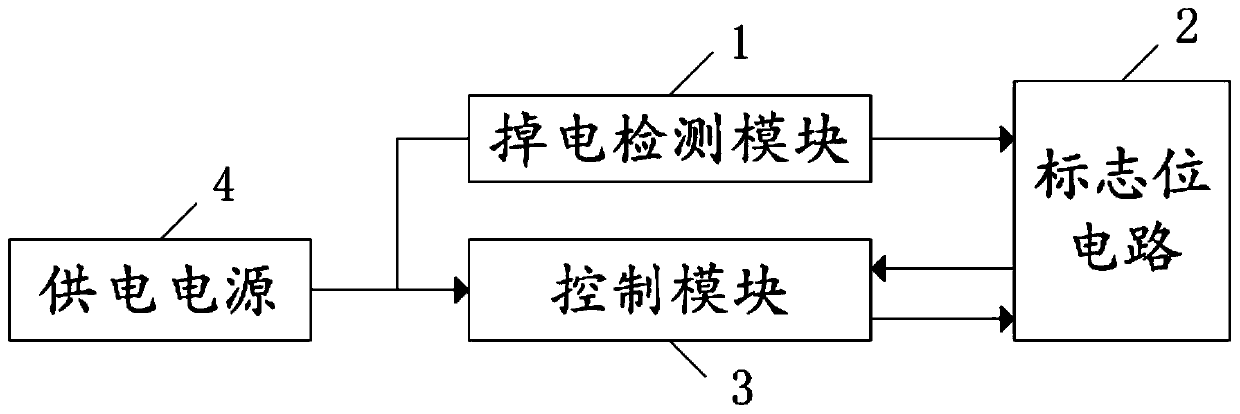

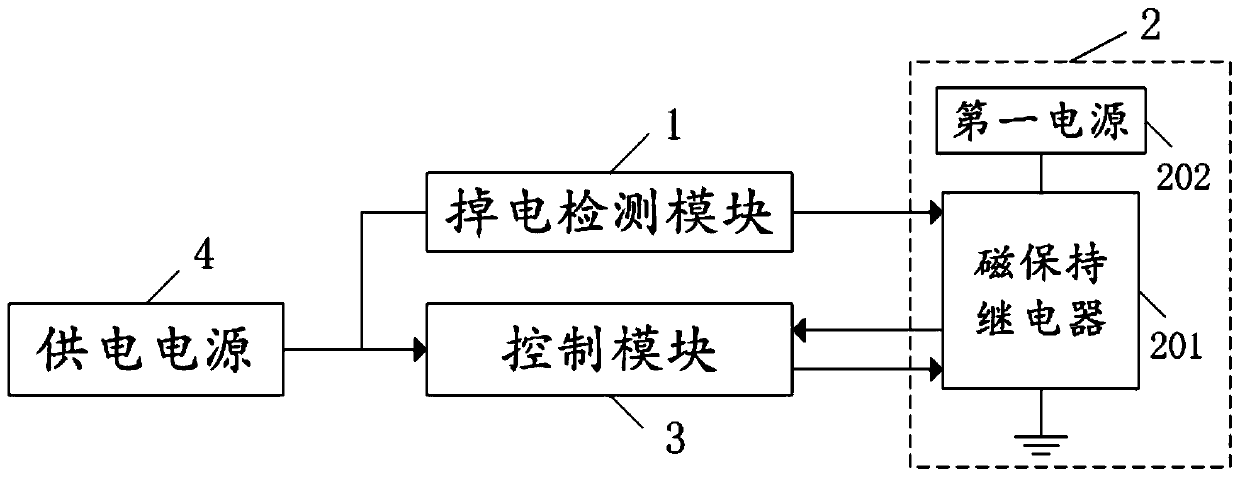

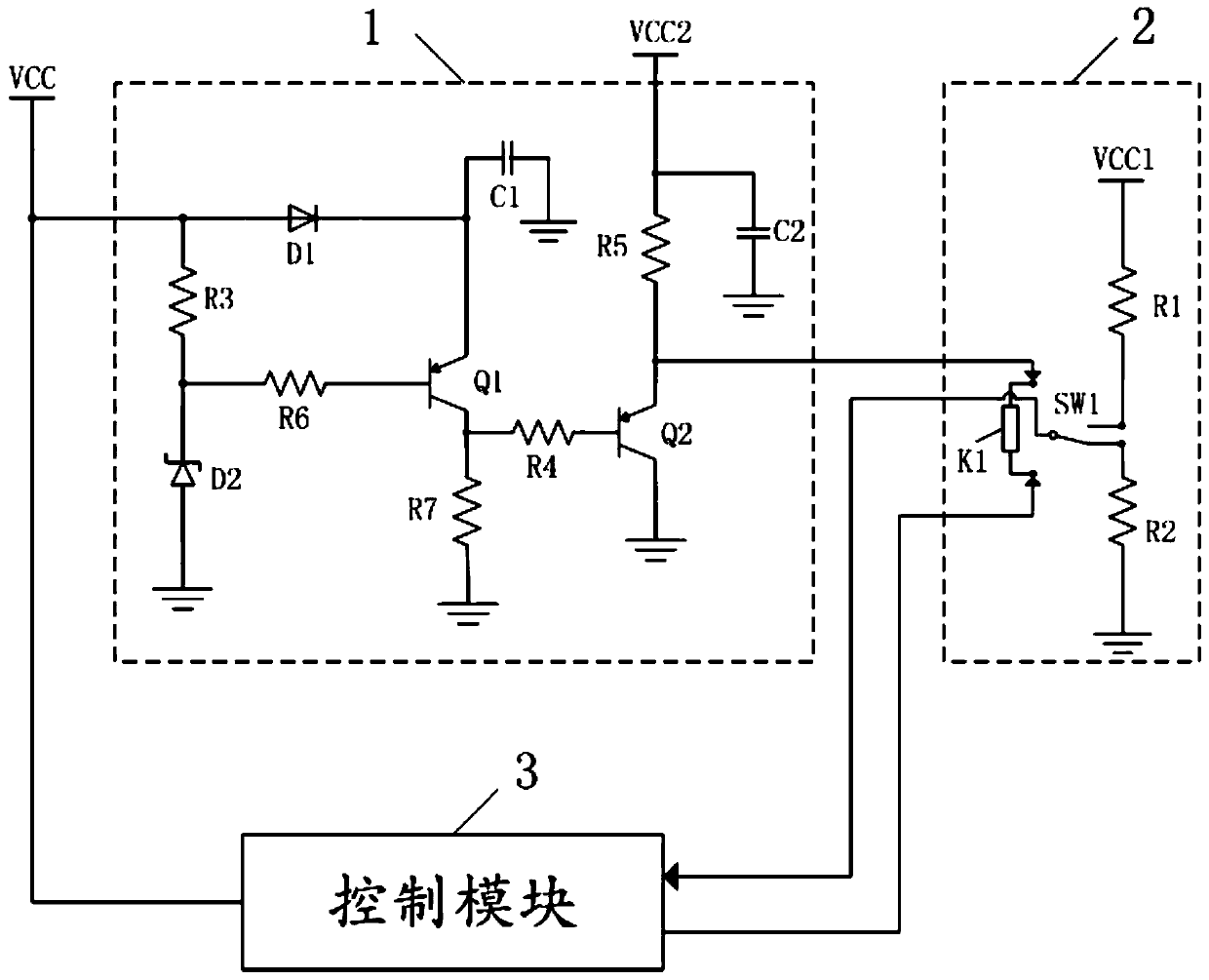

Power failure protection device

InactiveCN110597665ANormal startImprove reliabilityPower supply for data processingRedundant operation error correctionElectricityComputer module

The invention discloses a power failure protection device. The device comprises a power failure detection module, a flag bit circuit and a control module. The control module is used for upgrading andupdating the software data, software backup data corresponding to the software data being stored in the backup storage area; a power failure detection module used for detecting the power supply stateof the power supply, a first state signal being generated when abnormal power supply of the power supply is detected; a zone bit circuit used for setting the zone bit circuit to be in an action statewhen receiving the first state signal transmitted by the power failure detection module and generating an action zone bit signal. When the control module is normally powered on through the power supply and is in an initialization stage, the control module is further used for controlling the zone bit circuit to be in a reset state if receiving an action zone bit signal transmitted by the zone bit circuit, and software backup data is written into a storage area of the software data in a covering mode. The reliability of power-down protection can be improved, and it is ensured that the equipmentcan normally start software after power supply is recovered.

Owner:TP-LINK

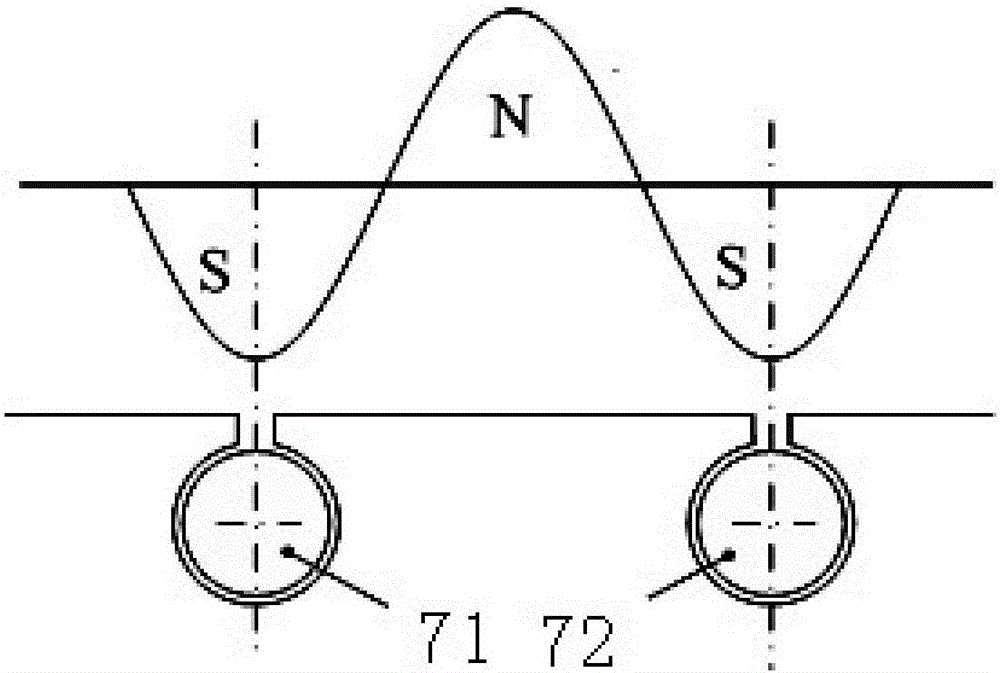

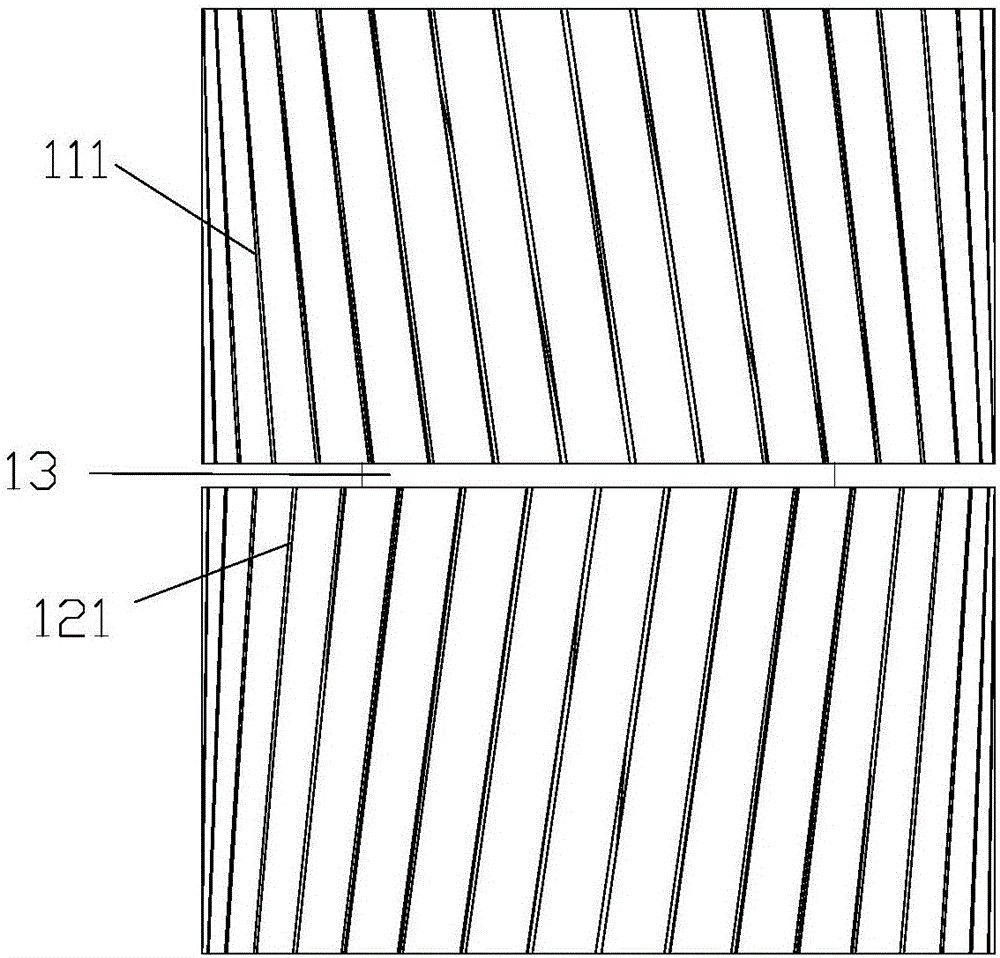

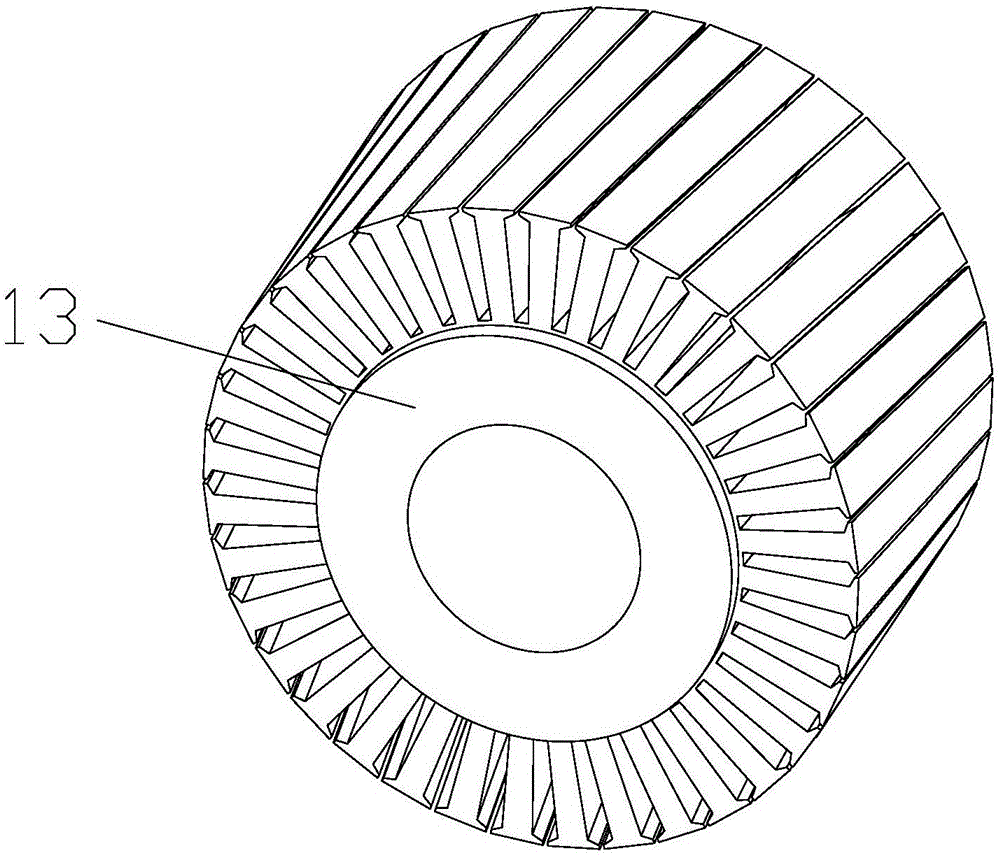

Double-skewed-slot rotor, and stator-rotor equal-slot matching structure based on rotor

PendingCN106849423ANormal startSynchronous additional torque reductionMagnetic circuit rotating partsStructure basedPhysics

The invention discloses a double-skewed-slot rotor, which relates to the technical field of motors. A slot number of the rotor is equal to that of a stator matched with the rotor. The double-skewed-slot rotor comprises a first rotor and a second rotor; a slot body of the first rotor and a corresponding slot body in the second rotor are twisted in opposite directions; skewed slot distances of the first rotor and the second rotor are both as follows: (shown in the description); skewed slot angles of the first rotor and the second rotor are both as follows: (shown in the description); Z1 is a slot number of the stator, p is a number of pole pairs of a motor, and Di1 is an inner diameter of the stator; and a staggered angle of the slot body of the first rotor and the corresponding slot body in the second rotor is as follows: (shown in the description), wherein Z2 is a slot number of the rotor. The invention also discloses a stator-rotor equal-slot matching structure based on the rotor. The double-skewed-slot rotor has the advantage that the limitation on the selection of the slot number of the stator and rotor of a traditional induction electric motor and the application of the equal-slot matching can be broken through.

Owner:HEFEI UNIV OF TECH

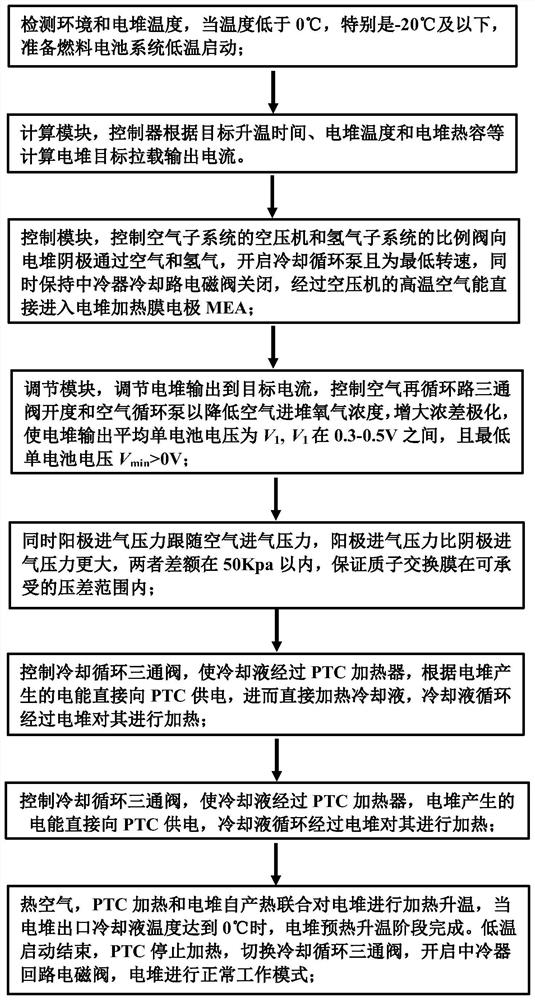

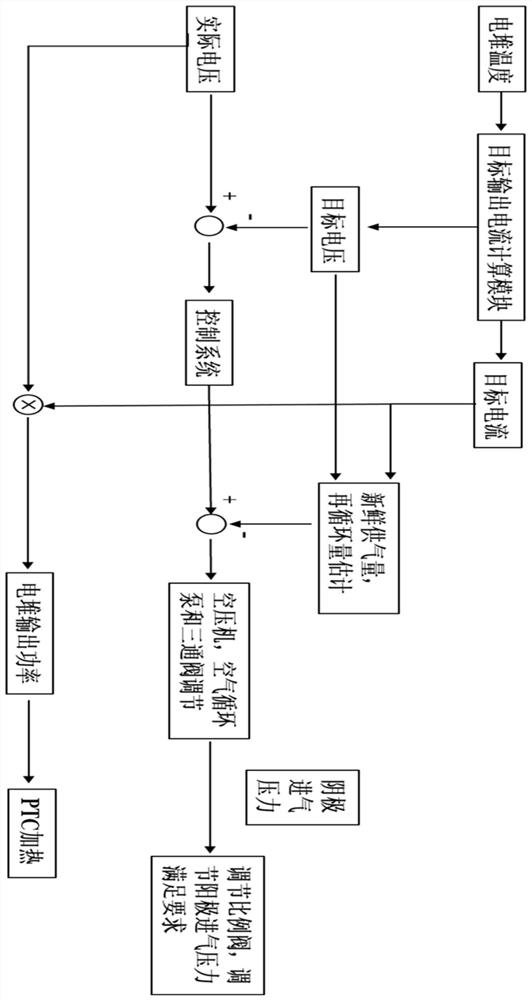

Fuel cell cathode recirculation low-temperature starting system and control method thereof

ActiveCN113629270AGuaranteed operating lifeNormal startFuel cell heat exchangeReactant parameters controlThermodynamicsProcess engineering

The invention relates to a fuel cell cathode recirculation low-temperature starting system and a control method thereof. The system comprises an air supply subsystem, a hydrogen supply subsystem and a cooling circulation subsystem. Through system control, hot air directly heats an MEA, electric energy output by a galvanic pile enables a PTC to heat cooling liquid, the operation conditions of the galvanic pile are controlled to increase self-produced heat, so that the galvanic pile is jointly heated, energy is utilized to the maximum extent to heat the galvanic pile, and the low-temperature starting capability is enhanced; when the temperature of the cooling liquid at the outlet of the galvanic pile reaches 0 DEG C, the galvanic pile preheating temperature rise stage is completed. Compared with the prior art, the method is beneficial to realizing quick start of the fuel cell in a low-temperature environment, the failure rate of low-temperature start of the fuel cell is reduced, and the service life of the fuel cell at a low temperature is prolonged.

Owner:TONGJI UNIV

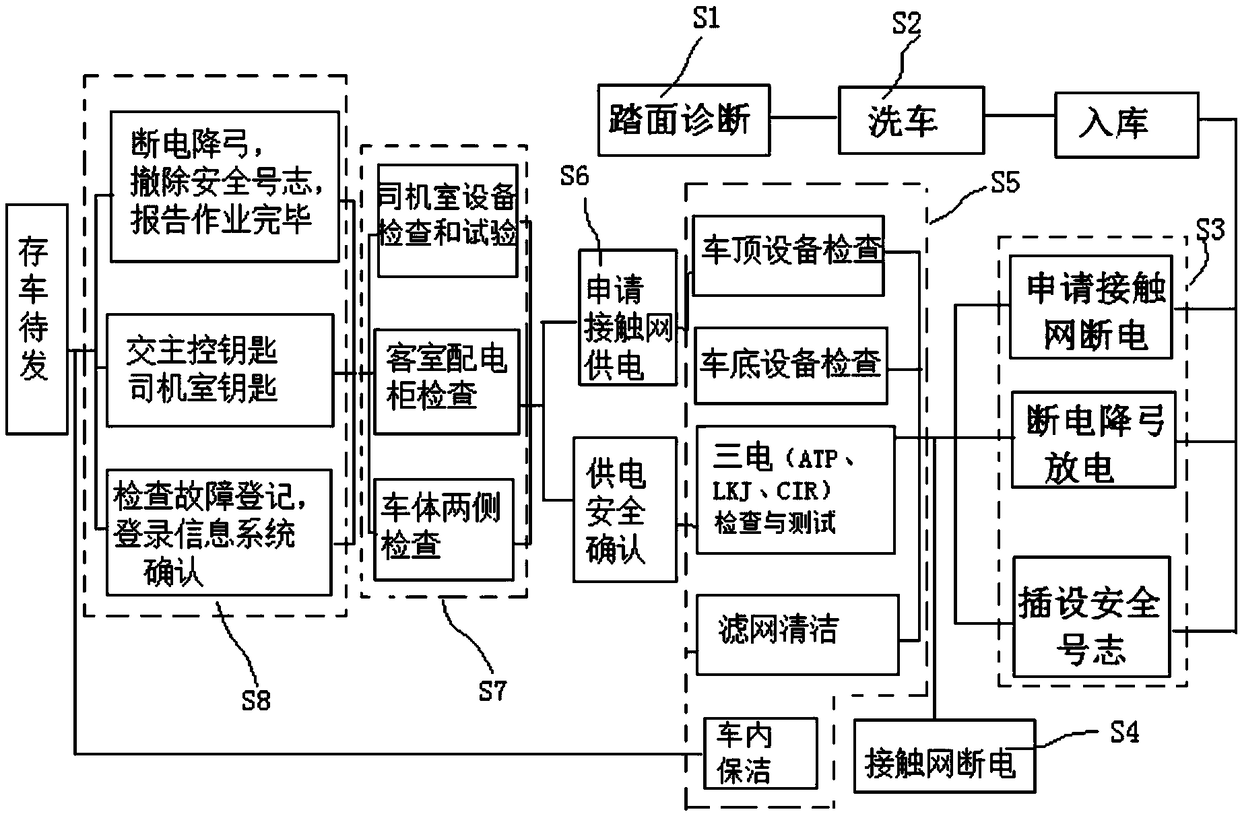

Primary repair technology for municipal railway vehicle

ActiveCN109436023AEnsure safetyImprove adaptabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesMachine bearings testingElectricityPrimary repair

The invention discloses a primary repair technology for a municipal railway vehicle. The primary repair technology includes the following steps that wheel-set tread diagnosis and pantograph detectionare performed; vehicles are cleaned, enters a garage for parking and are ready for power outage, after the municipal vehicle is parked well in the garage, preparation work is done before power outageof the vehicle, a ground rod is hung after it is determined that there is no power, and discharge operation is performed; no-power repair operation is carried out and includes vehicle roof equipment inspection, vehicle bottom equipment inspection, EIC system inspection and testing and filter net cleaning; power is supplied to the contact system, wherein a pantograph lands, and power is supplied tothe contact system after a ferry board withdraws and the ground rod is removed; power-on operation is performed and includes cab power-on inspection and test, passenger compartment power distributioncabinet inspection and vehicle-body two-sides inspection; equipment withdraws and the vehicle abnormal condition is inspected before the vehicle leaves from the garage, and the vehicle without the abnormal condition leaves from the garage. The primary repair technology for the municipal railway vehicle can adapt to the characteristics of rapid start and stop of the municipal railway vehicle for efficient and adaptive maintenance.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

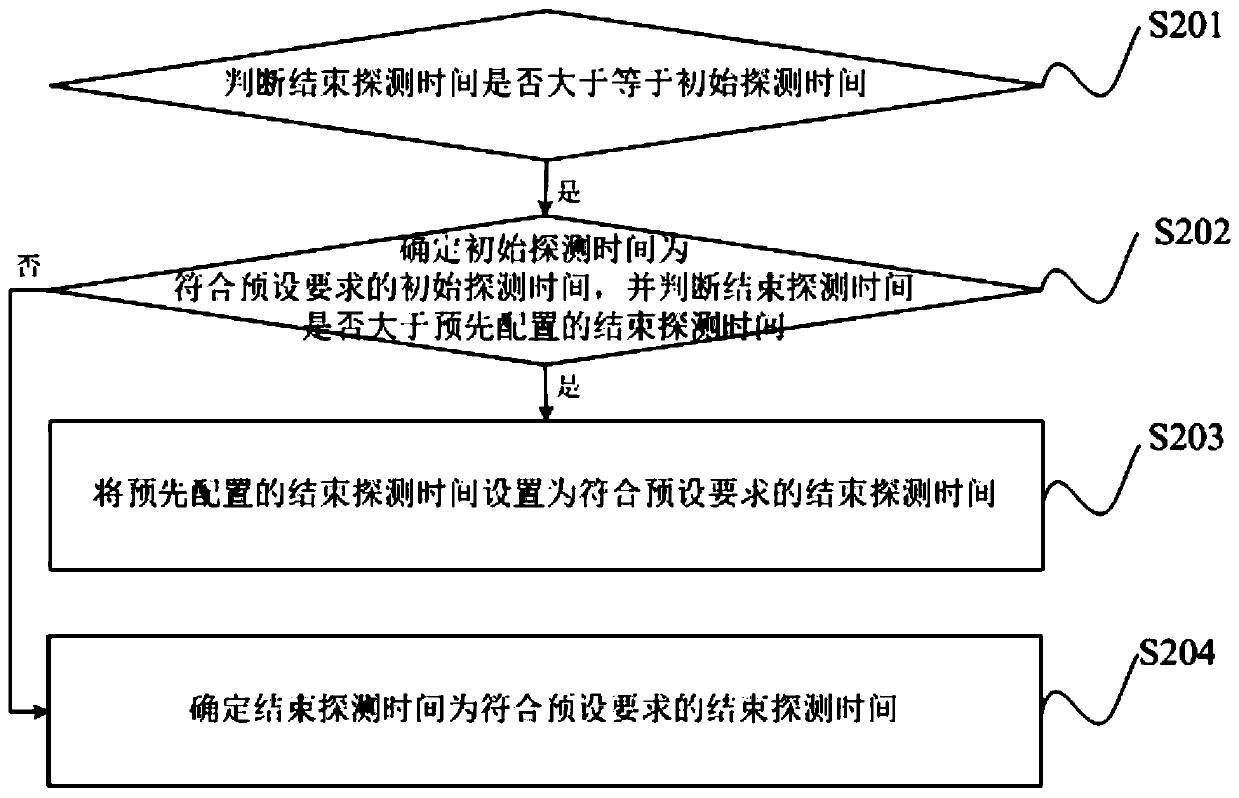

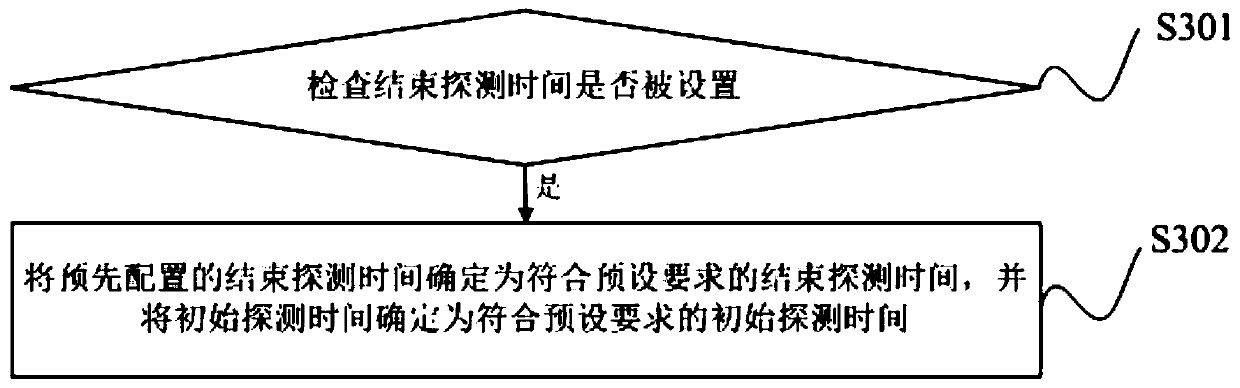

Container state inspection method and device

The invention provides a container state inspection method and a device. The method comprises the steps that whether initial detection time and end detection time meet preset requirements is determined; if both the initial detection time and the end detection time meet the preset requirements, when the waiting time of the container reaches the initial detection time, whether the application is normally started is checked before the detection ending time is up, and if it is determined that the application is normally started, new detection ending time is set based on the normal starting time ofthe application and preset first delay time, and the health check state of the container is recorded; and if it is determined that the application is not started normally, new detection ending time is set based on the current detection ending time and preset second delay time, and the container is restarted. According to the method, the end detection time is reset by determining whether the application is normally started, so that the application starting time can be accurately estimated, and the application can normally receive the service access request.

Owner:北京浪潮数据技术有限公司

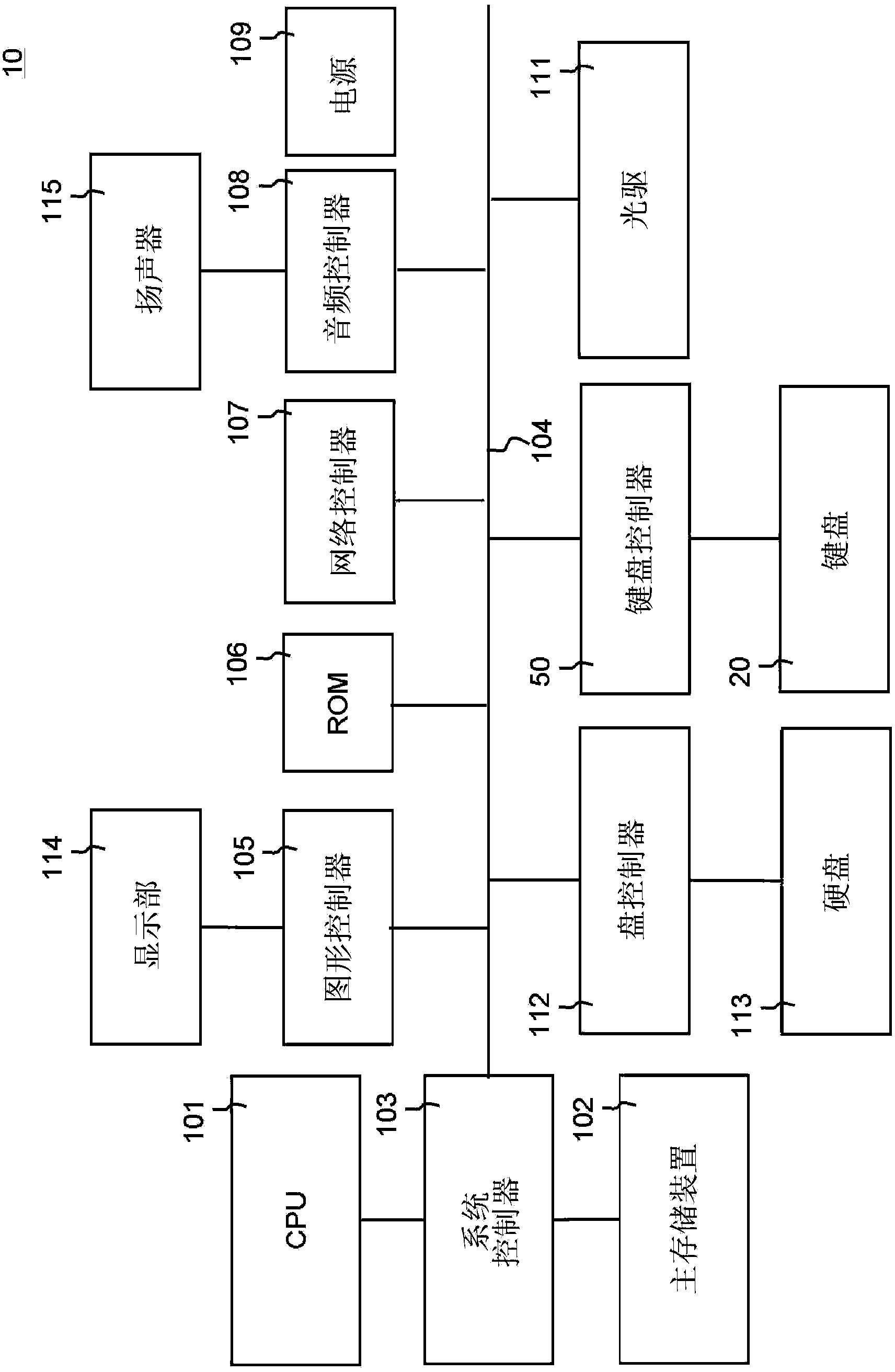

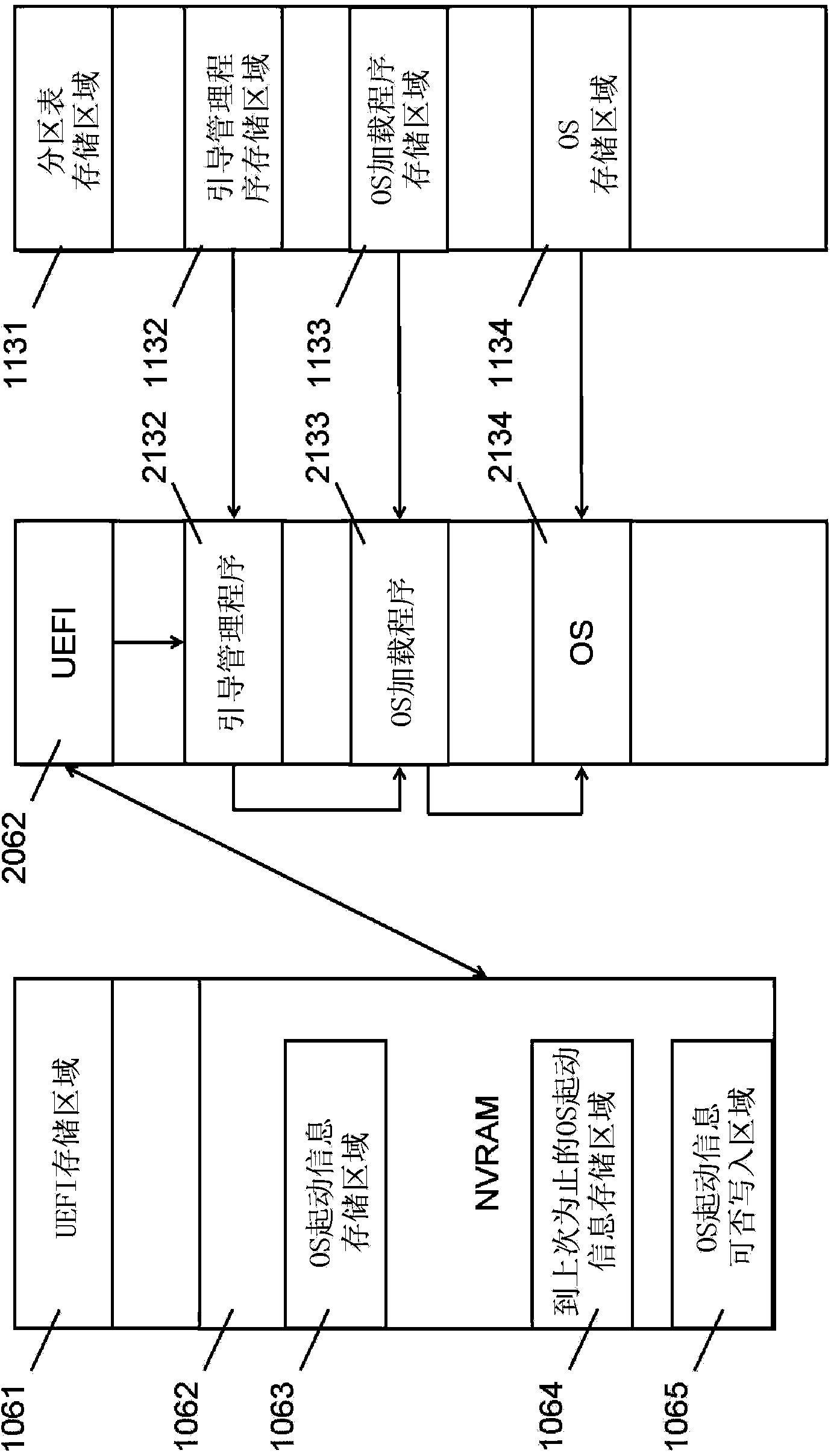

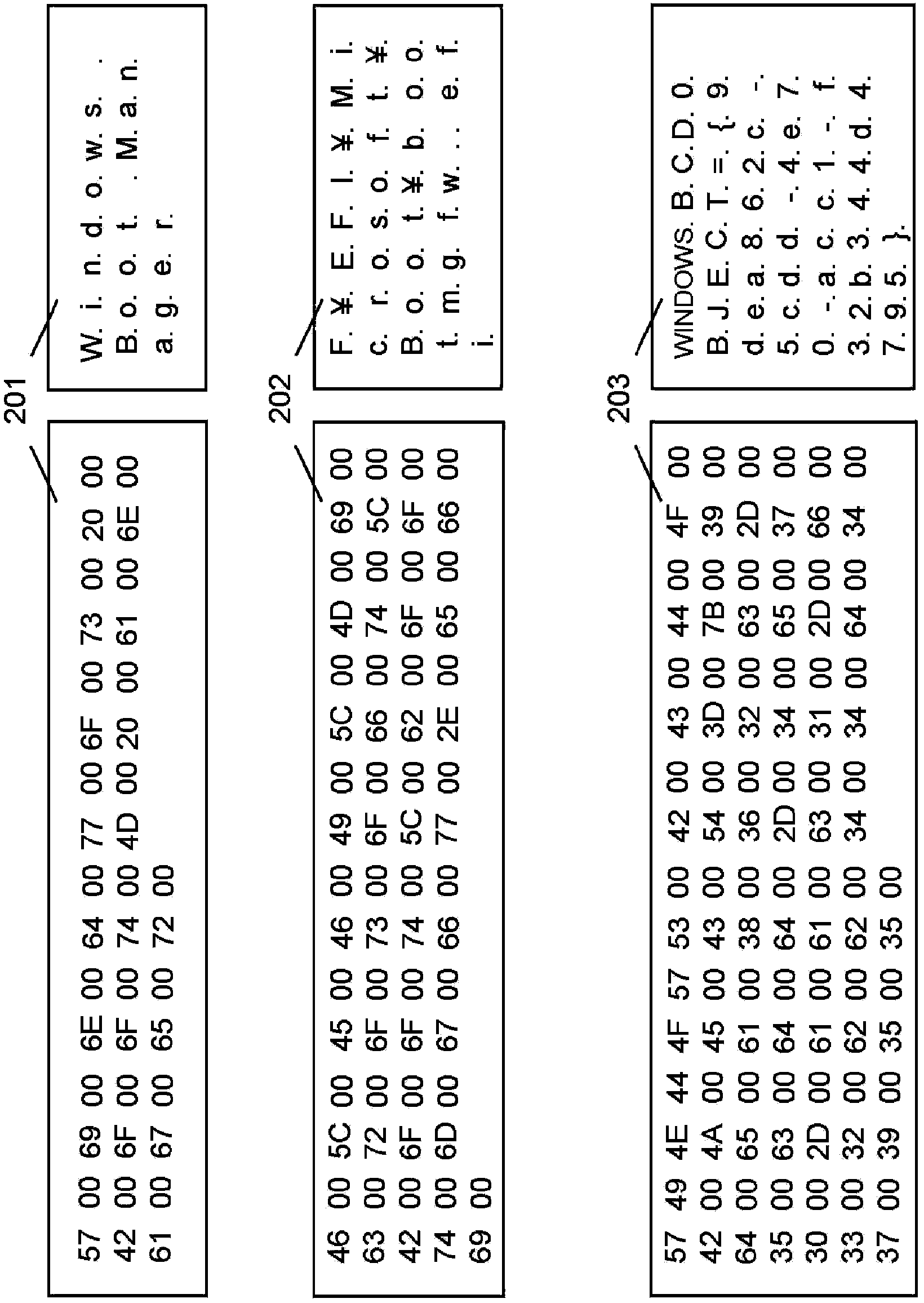

Information processing device and method for controlling information processing device

To solve the problem of providing an information processing device that can start up a system in a normal manner, the information processing device comprises: a first storage unit for storing an OS program; a second storage unit having a storage area for storing a boot program, a first area for storing first path information that indicates the location of the OS program in the first storage unit, and a second area for storing second path information that indicates the location of the OS program previously used for startup, the second area being set so as to be accessible only by the boot program; and a processor. The processor writes to the second area the first path information used for starting up the OS program during a first startup; and during a second startup after the first startup, the processor uses the boot program to compare the first path information stored in the first area and the second path information stored in the second area, and determines whether to start up the OS program indicated by the first path information on the basis of the comparison results.

Owner:FUJITSU CLIENT COMPUTING LTD

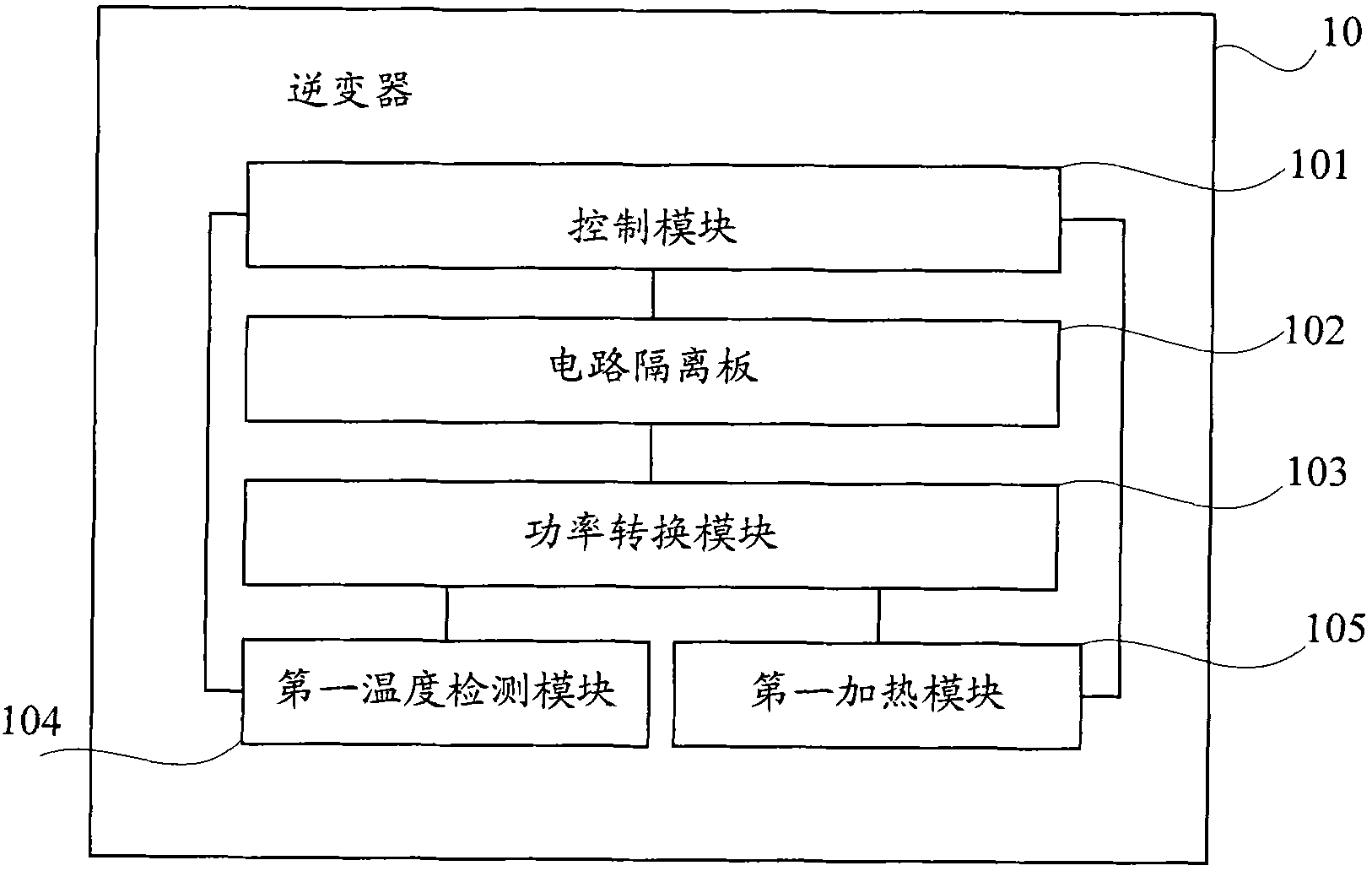

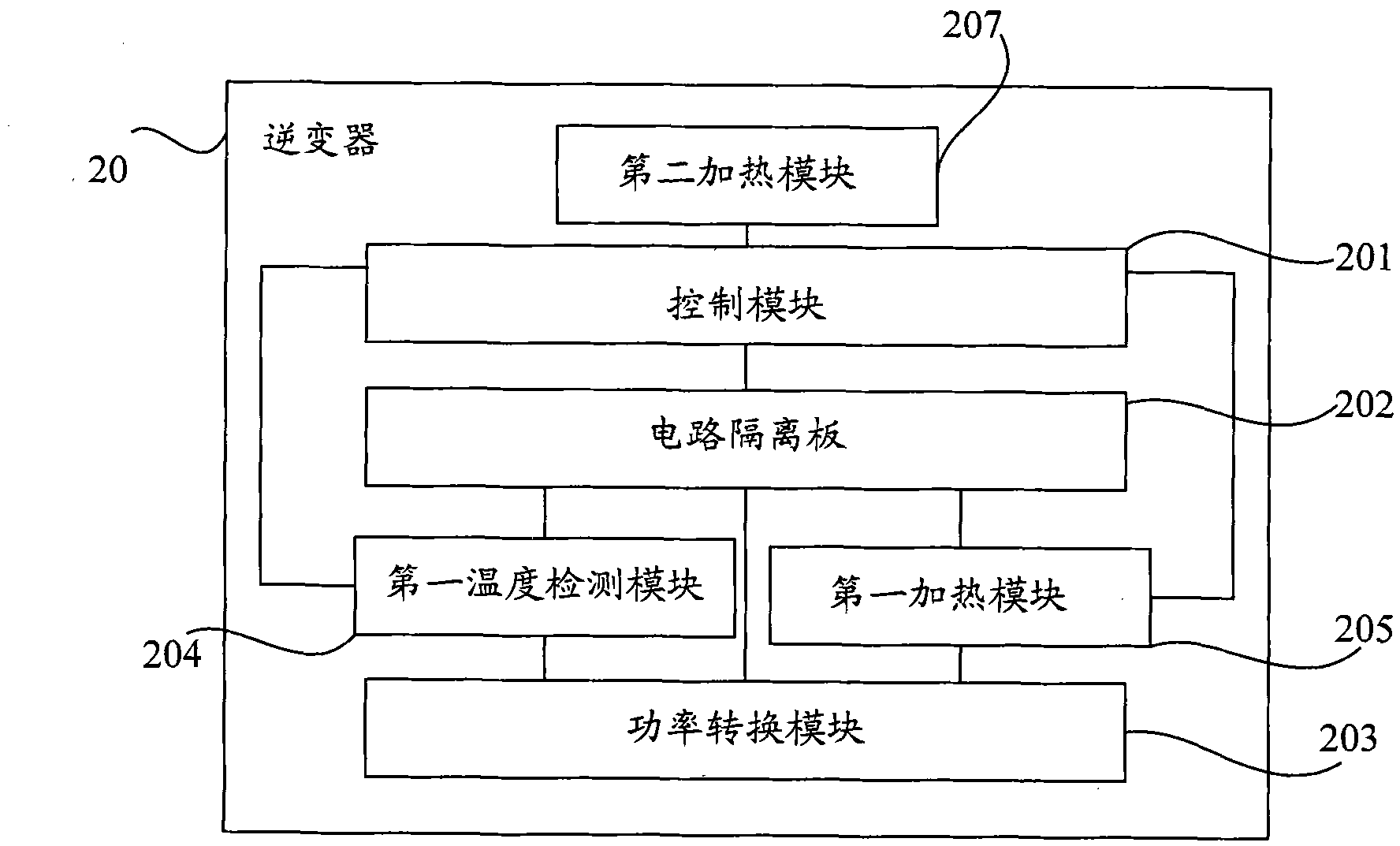

Inverter used in low temperature environment and photovoltaic system

ActiveCN102468776ANormal startUptimePhotovoltaic energy generationDc-ac conversion without reversalComputer moduleEngineering

The invention discloses an inverter used in a low temperature environment, and a photovoltaic system. The inverter comprises a control module, a circuit separator connected with the control module, a power conversion module connected with the circuit separator, a first temperature detection module connected to the control module and used for detecting the temperature of the power conversion module, and a first heating module connected to the control module and used for heating the power conversion module; if the control module is started, the first temperature detection module detects the temperature of the power conversion module, and whether the power conversion module can be normally started and / or normally work is judged according to the detected temperature of the power conversion module; and if the power conversion module is not normally started and / or does not normally work, the first heating module is started. The inverter can be normally started and normally work in the low temperature environment, and can effectively improve the generating efficiency of the photovoltaic system.

Owner:CRRC YONGJI ELECTRIC CO LTD

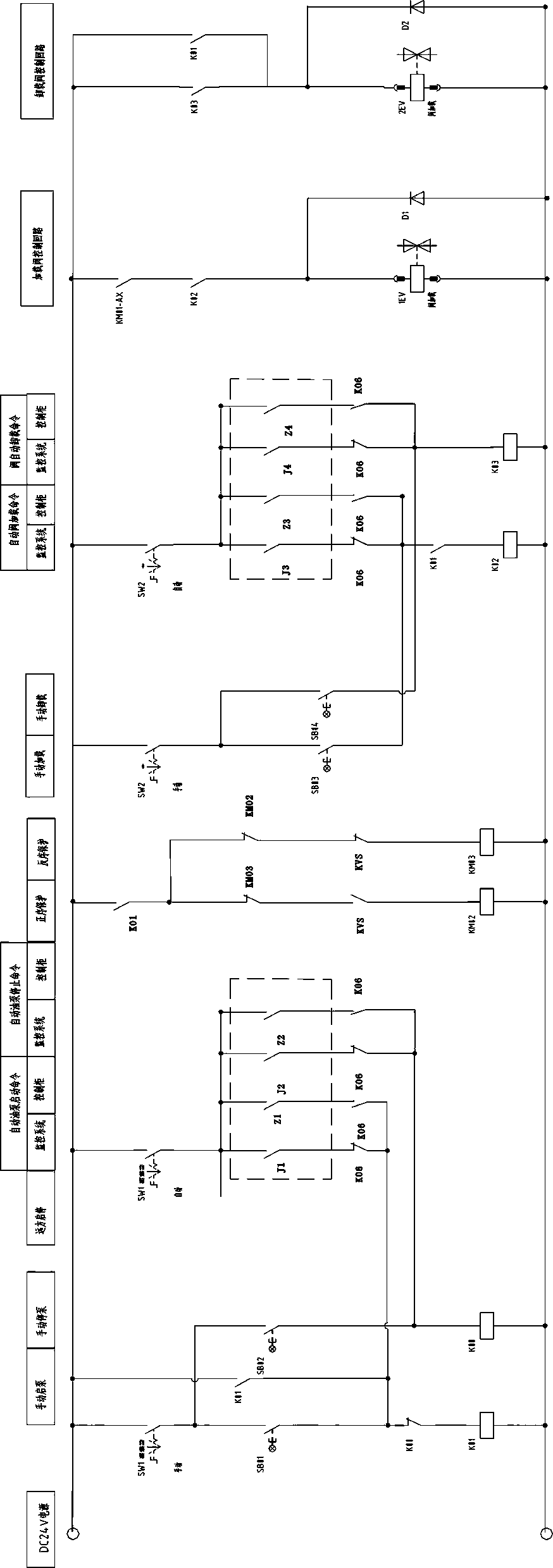

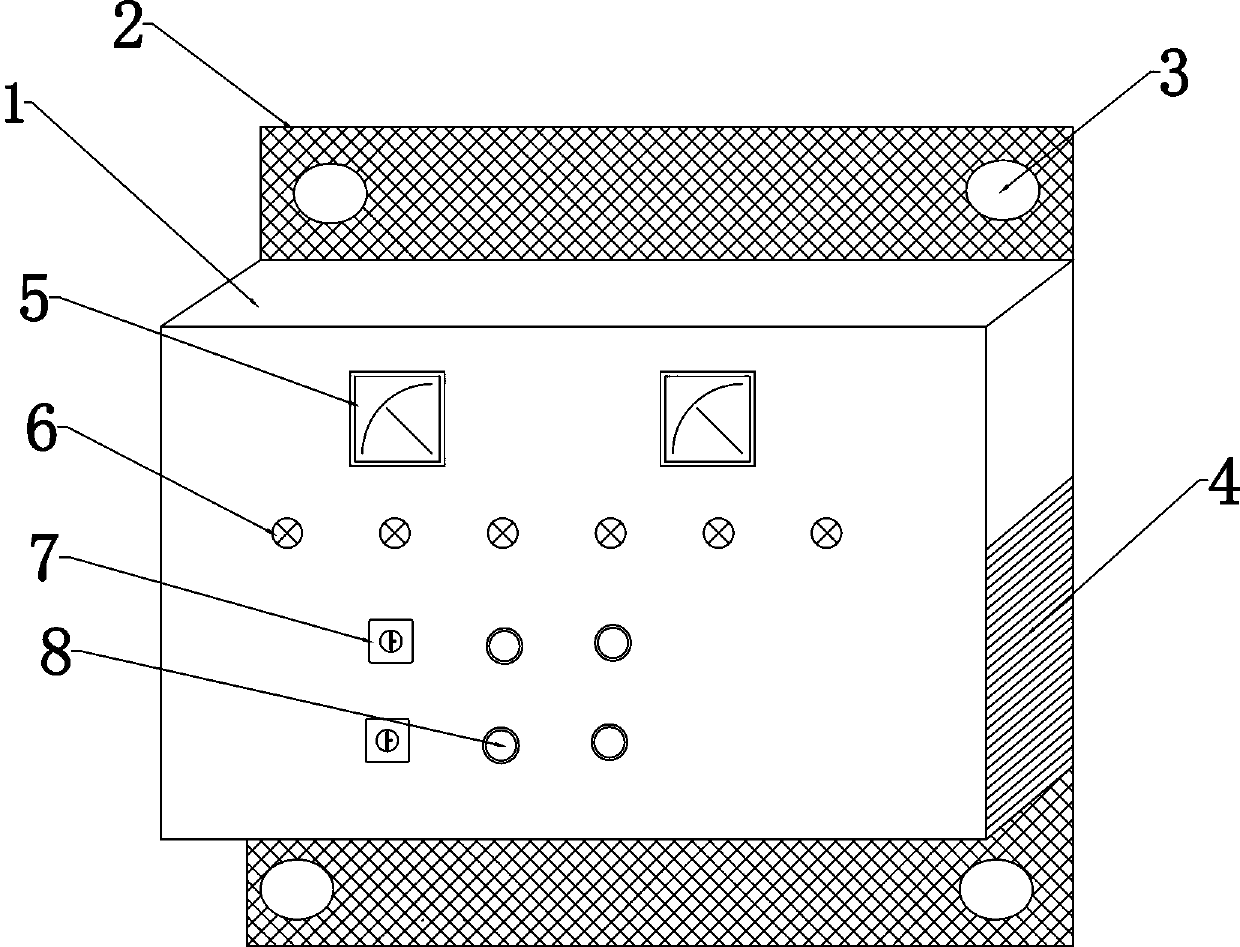

Electrical control device and method for pressure oil pump

PendingCN109751231AReduce shockReduce noisePump controlPositive-displacement liquid enginesControl mannerCircuit breaker

The invention relates to an electrical control device and method for a pressure oil pump. The electrical control device comprises a primary loop and a secondary loop. The primary loop comprises a circuit breaker QF01, a phase sequence protection device KVS, a positive sequence contactor KM02, a reverse sequence contactor KM03, a main contactor KM00, a bypass contactor KM01 and a soft starter RQ; and the secondary loop comprises a start button SB01, a stop button SB02, a loading button SB03, an unloading button SB04, a pump-starting relay K01, a pump-stopping relay K00, a loading relay K02, anunloading relay K03, a positive sequence contactor KM02, a reverse sequence contactor KM03, a loading valve 1EV, an unloading valve 2EV, a start-stop switching handle SW1, a loading-unloading switching handle SW2 and a control cabinet fault point relay K06. According to the electrical control device and method for the pressure oil pump, the control mode for the pressure oil pump of a speed regulator oil pressure device is technically optimized and studied so as to improve the operation reliability of the pressure oil pump.

Owner:CHINA YANGTZE POWER

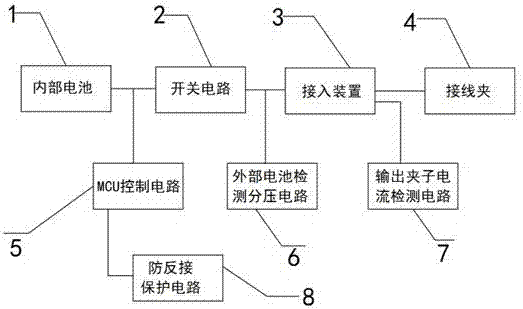

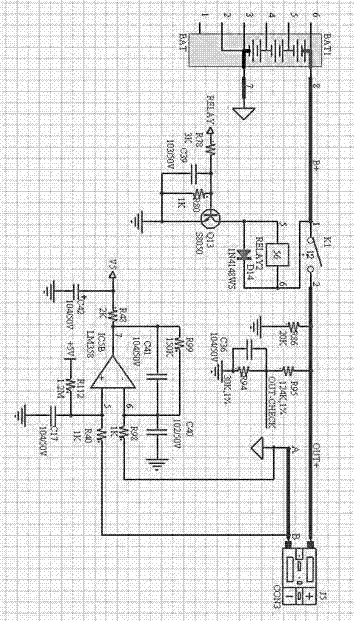

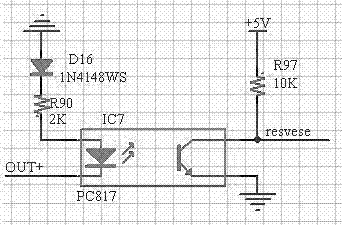

Fall protection and reverse-connection protection system and method for automobile starting power source wiring clamp

ActiveCN107069850AValid sense voltage conditionCheck voltage statusEmergency protection detectionElectric powerElectrical batteryFall protection

Owner:DONGGUAN ZHONGKANG TECH ELECTRONICS CO LTD

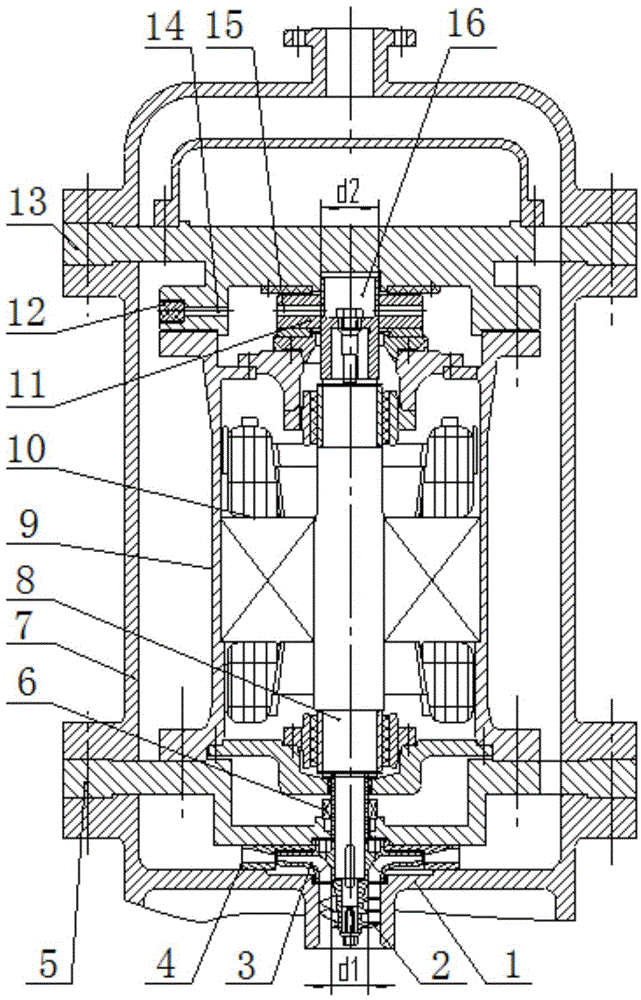

Deep mine submersible pump capable of balancing shaft head force of static rotor

ActiveCN104154003AEnsure normal startup and reliable operationNormal startPump componentsPump installationsBalance shaftEngineering

The invention provides a deep mine submersible pump capable of balancing shaft head force of a static rotor. The deep mine submersible pump comprises a motor top cover, a motor and a motor base which are connected sequentially from top to bottom. The deep mine submersible pump is characterized in that a thrust disc is fixed at the top of a shaft of the motor, a thrust disc cavity is arranged in the upper end of the thrust disc, the thrust disc is further provided with thrust disc through holes arranged in the radial direction and communicated with the thrust disc cavity, the motor top cover is provided with a radial motor top cover through hole, the motor is a wet motor, and the motor base is provided with an axial through hole. The deep mine submersible pump has the advantages that high pressure water is guided from the bottom end of the pump to the top of a rotor; reverse shaft head force is produced to balance shaft head force, and axial force of the rotor of the pump is nearly zero before startup; liquid guided in is filtered so as to ensure normal startup and reliable operation of the pump.

Owner:JIANGSU UNIV

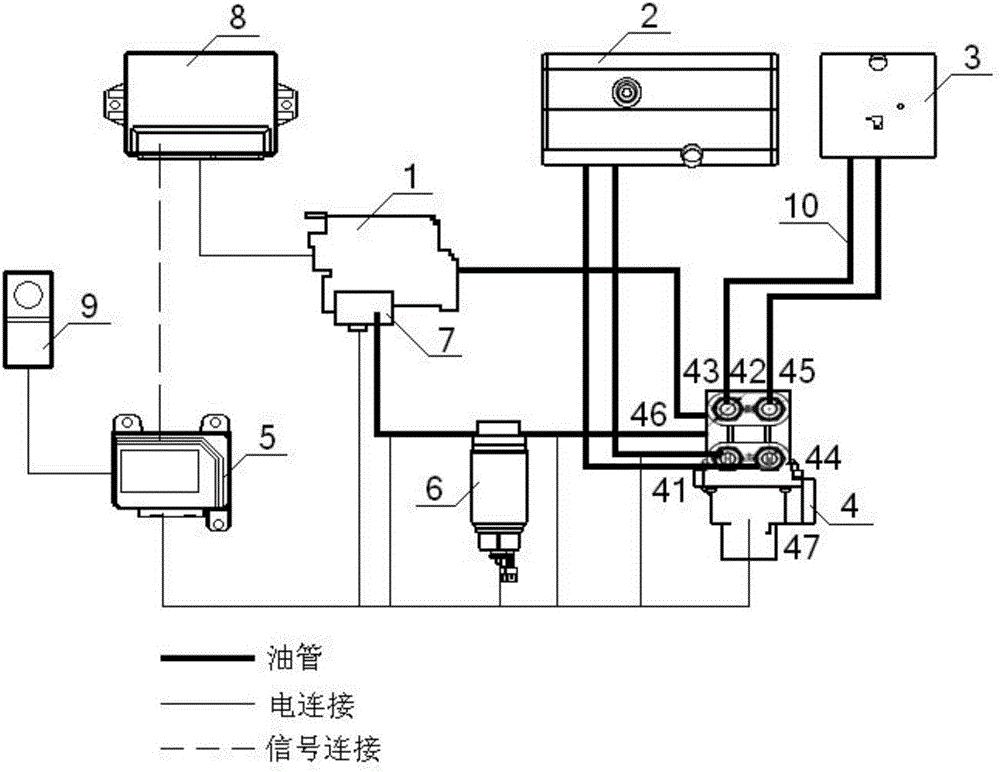

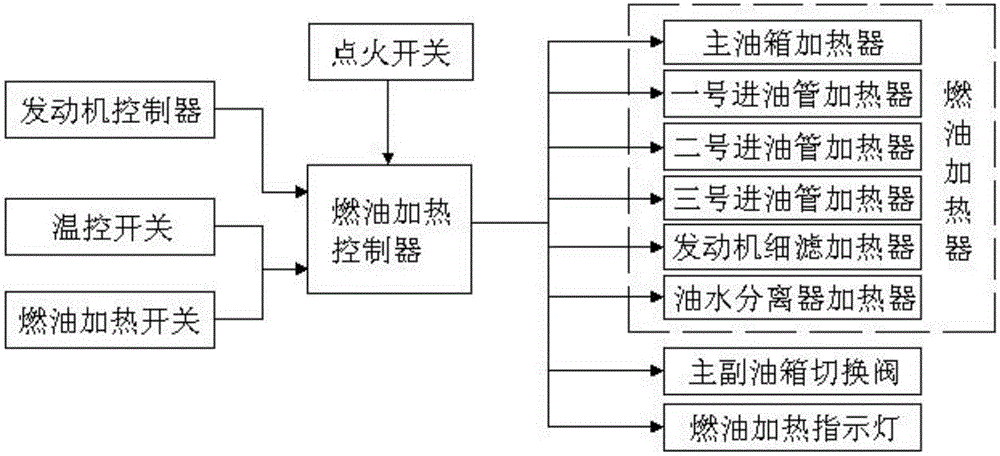

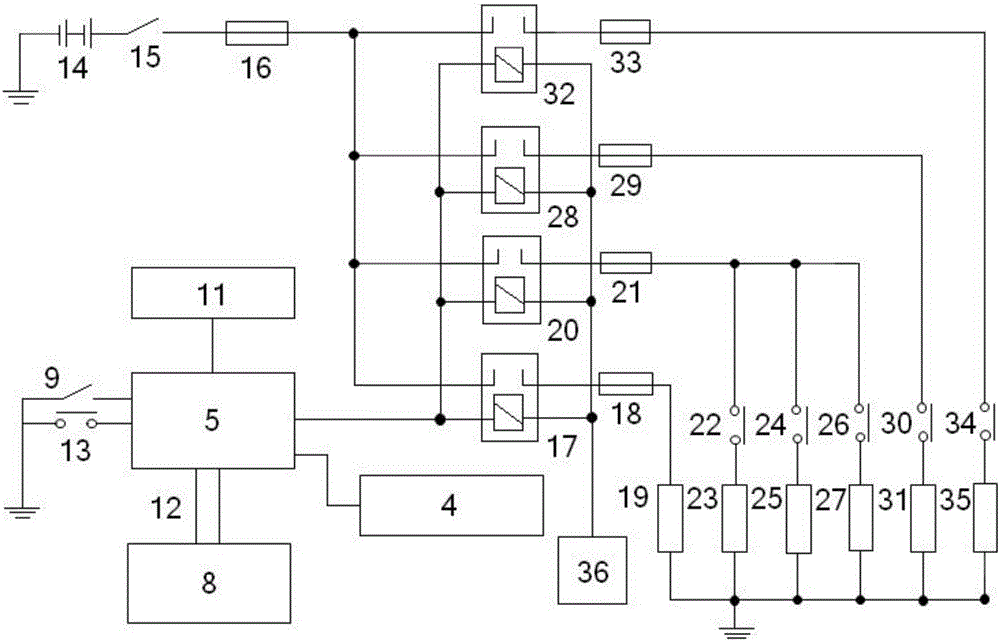

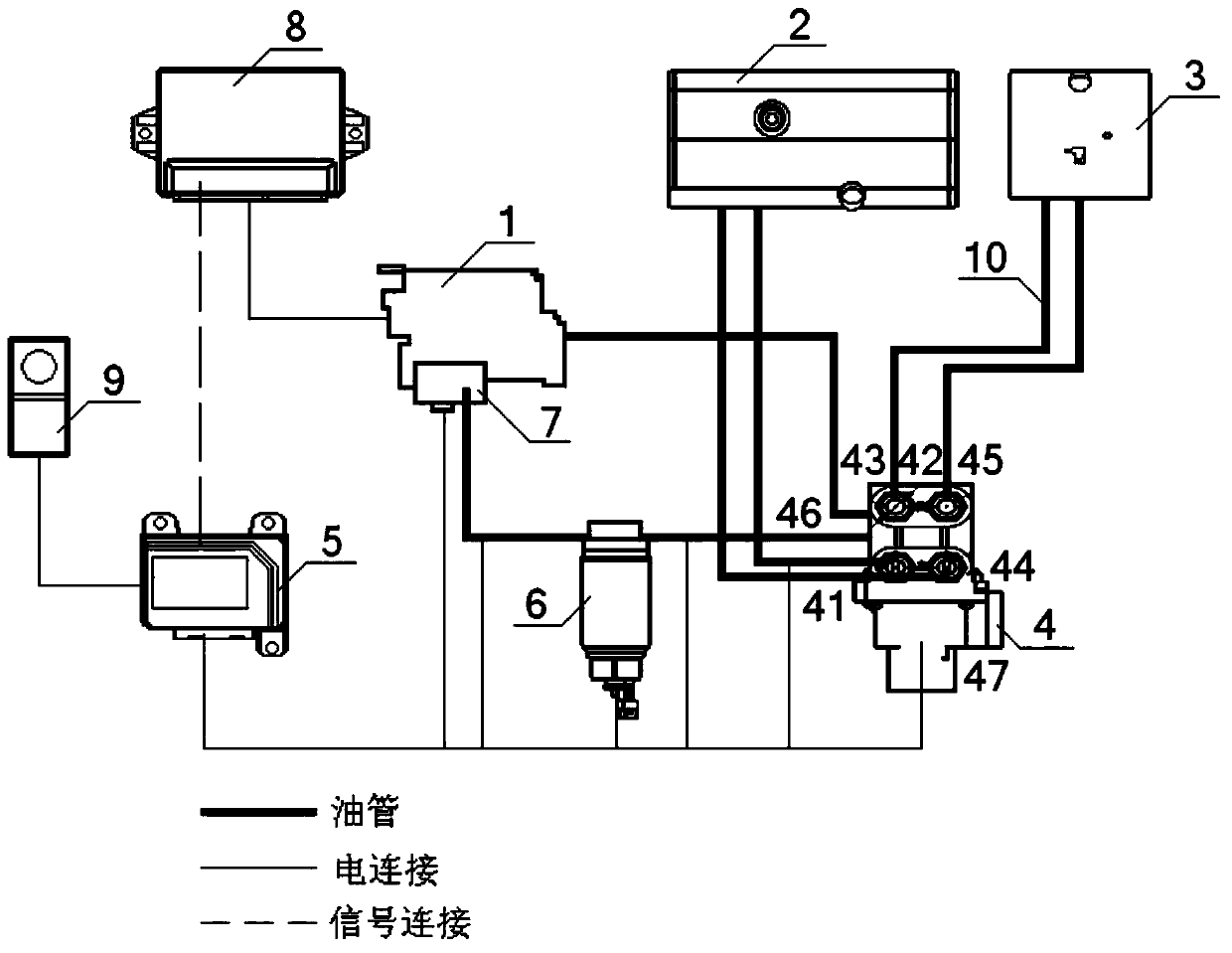

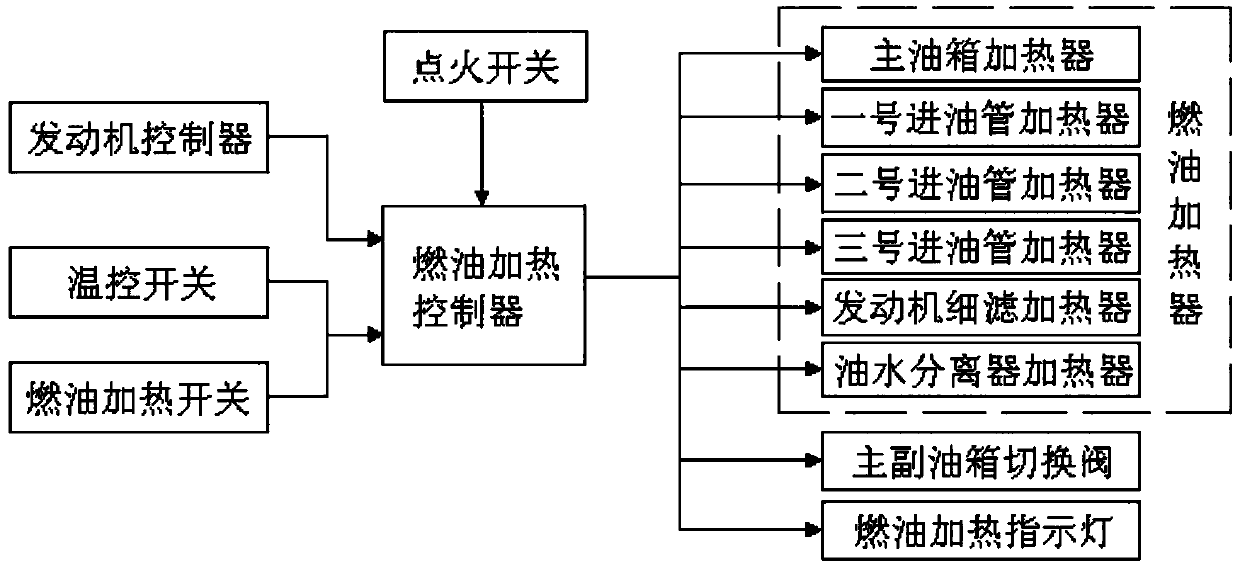

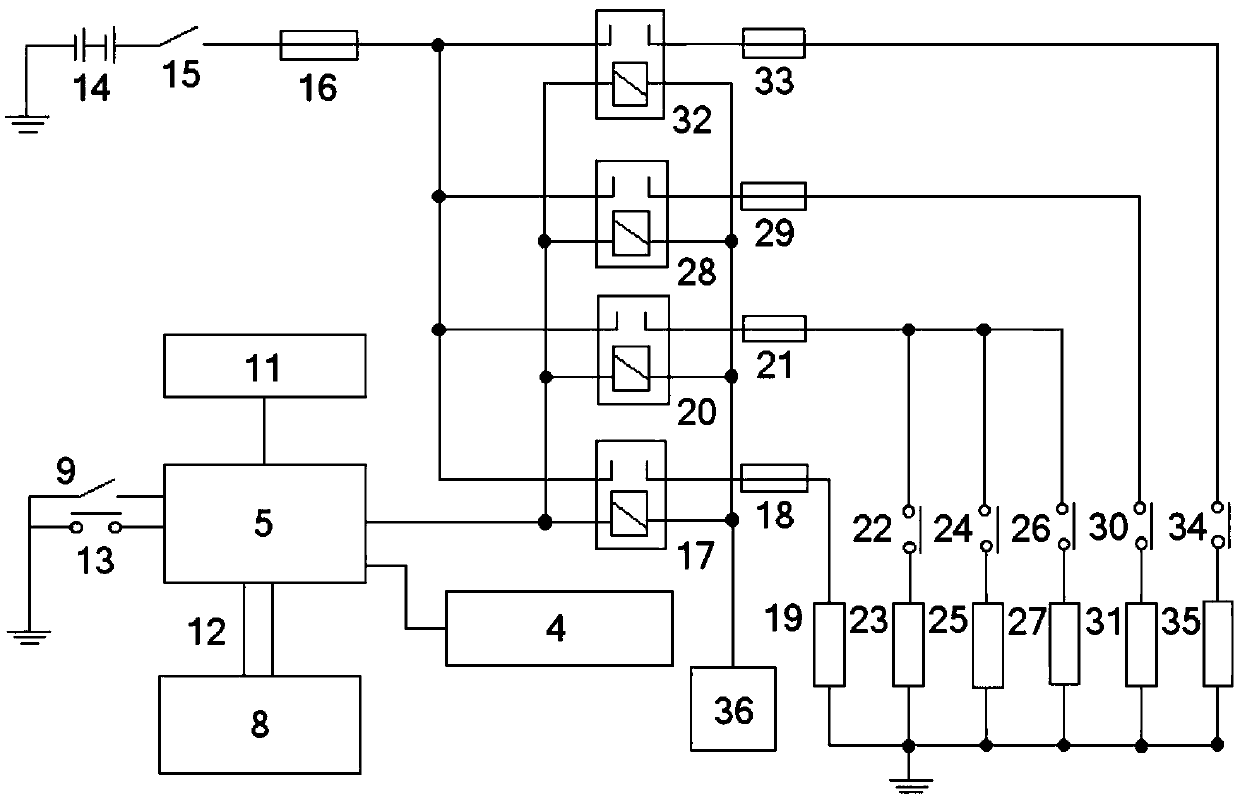

Intelligent control system and control method for fuel oil heating

ActiveCN106150779AImprove starting performanceAvoid the phenomenon of feedingMachines/enginesThermal treatment of fuelTemperature controlElectricity

The invention relates to an intelligent control system for fuel oil heating. The intelligent control system comprises an engine, an engine controller, a main oil tank, an auxiliary oil tank, a fuel oil heating controller and a storage battery. The main oil tank is communicated with the engine through a main oil tank switch valve, the auxiliary oil tank is communicated with the engine through an auxiliary oil tank switch valve, the engine controller is in signal connection with the fuel oil heating controller, and the fuel oil heating controller is electrically connected with an ignition switch, the main and auxiliary oil tank switch valves, a relay coil, a fuel oil heating switch and a temperature controlled switch; the positive pole of the storage battery is grounded through a battery main switch, a relay contact and a main oil tank heater in sequence, and the negative pole of the storage battery is grounded; when the temperature of an oil sucking opening of the main oil tank is lower than 5 DEG C, an oil way is switched to an auxiliary oil tank loop so as to start the engine, when the rotating speed of the engine reaches 700 rpm, the main oil tank heater starts to heat, when the temperature of the oil sucking opening of the main oil tank reaches 25 DEG C, heating is stopped, and the oil way is switched to a main oil tank loop. By means of the intelligent control system, the starting performance of the engine is improved, and the safety and the reliability are high.

Owner:DONGFENG COMML VEHICLE CO LTD

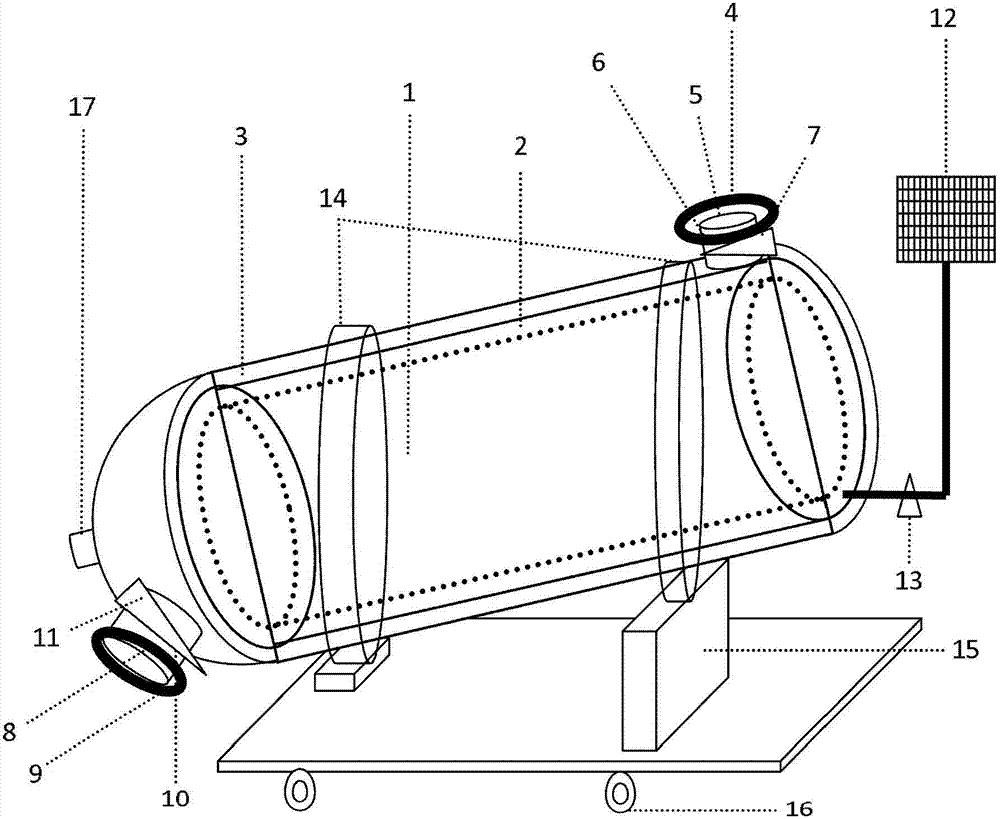

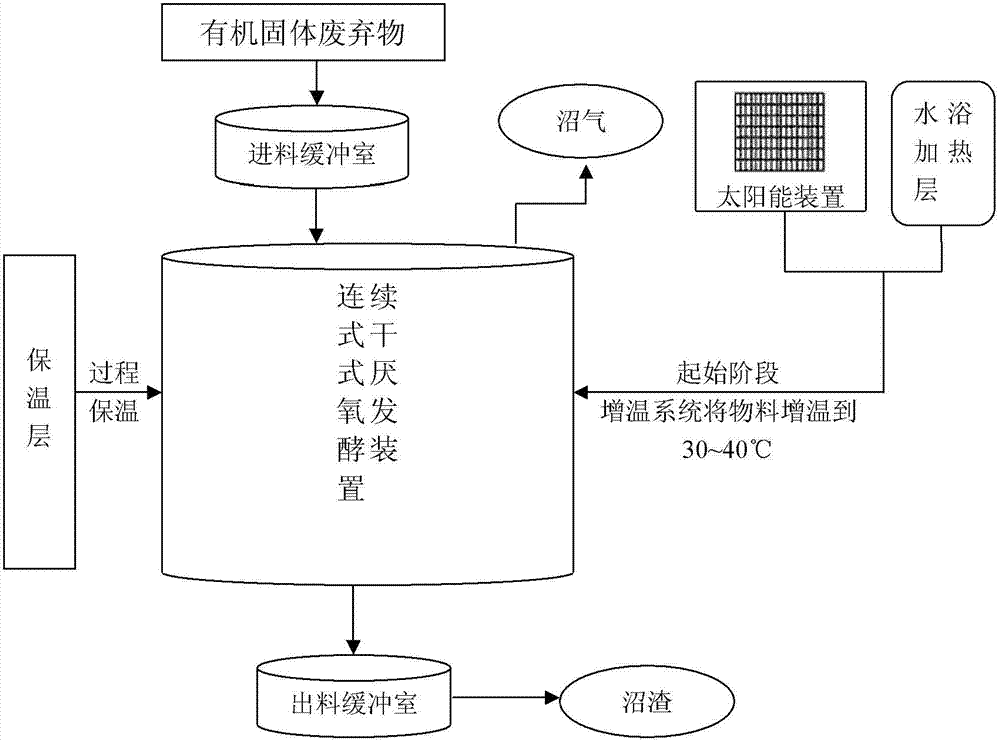

Continuous dry anaerobic fermentation method

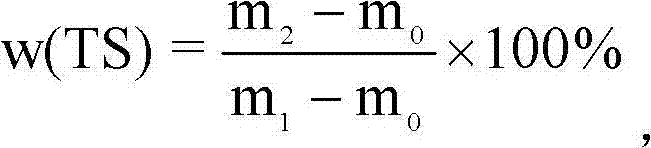

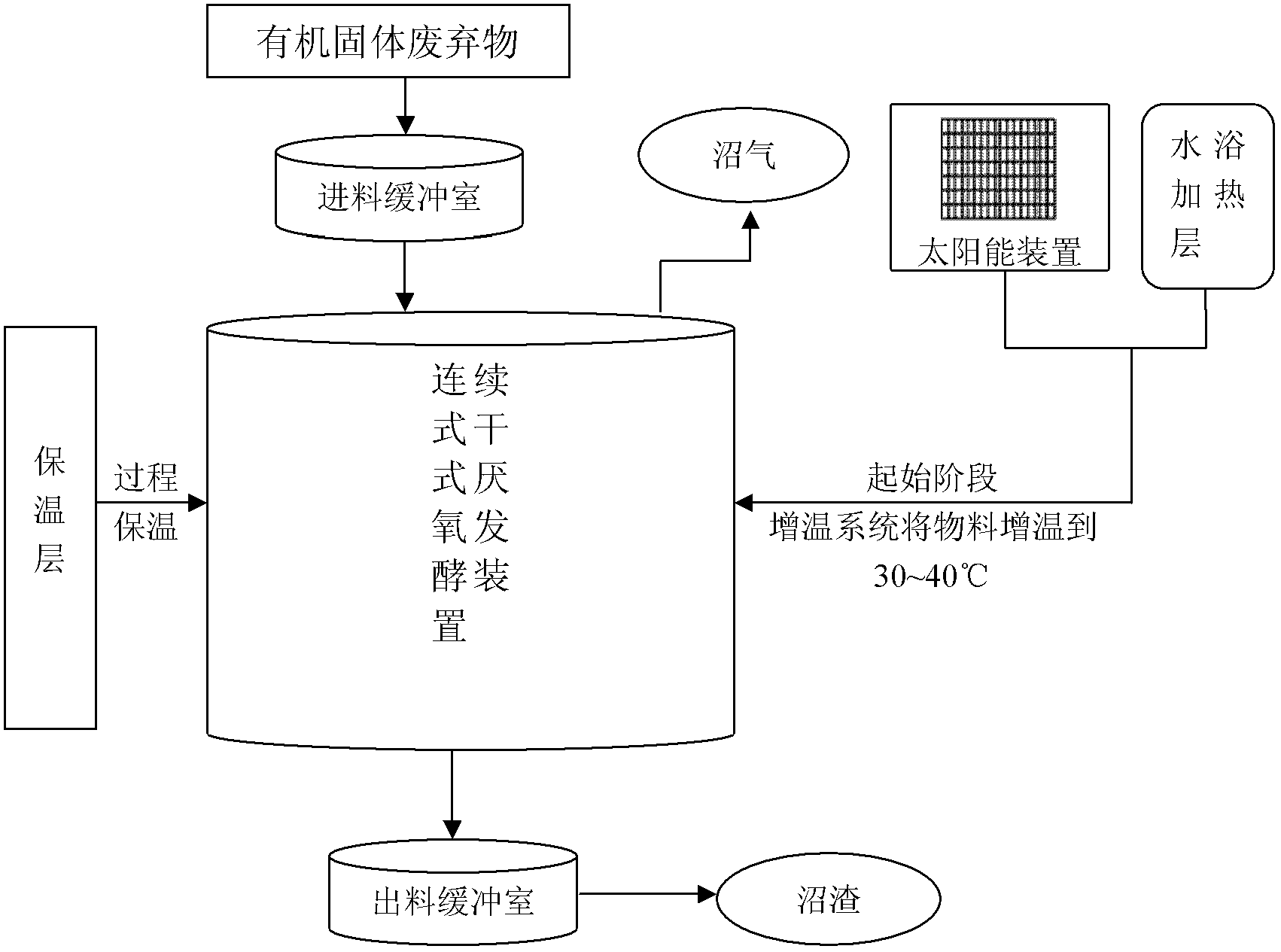

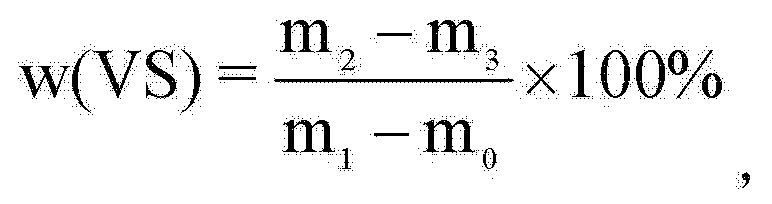

InactiveCN102795899BTimely and continuous rapid processingNormal startBio-organic fraction processingEnergy inputFermentationContinuous operation

The invention relates to a continuous dry anaerobic fermentation method which comprises the following steps: A) raw material filling: adding organic solid waste into a fermentation container; B) fermentation starting: sealing the fermentation container to carry out anaerobic fermentation; C) feeding: adding the fresh organic solid waste into the fermentation container with a feeding buffer unit or system; D) discharging: while carrying out the step C, taking out the fermented material with a discharging buffer unit or system; and E) continuous operation: repeating the steps C and D. In the whole anaerobic fermentation process, a solar device can be utilized to heat the fermentation device.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Continuous dry anaerobic fermentation method

InactiveCN102795899ATimely and continuous rapid processingNormal startBio-organic fraction processingEnergy inputFermentationContinuous operation

The invention relates to a continuous dry anaerobic fermentation method which comprises the following steps: A) raw material filling: adding organic solid waste into a fermentation container; B) fermentation starting: sealing the fermentation container to carry out anaerobic fermentation; C) feeding: adding the fresh organic solid waste into the fermentation container with a feeding buffer unit or system; D) discharging: while carrying out the step C, taking out the fermented material with a discharging buffer unit or system; and E) continuous operation: repeating the steps C and D. In the whole anaerobic fermentation process, a solar device can be utilized to heat the fermentation device.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

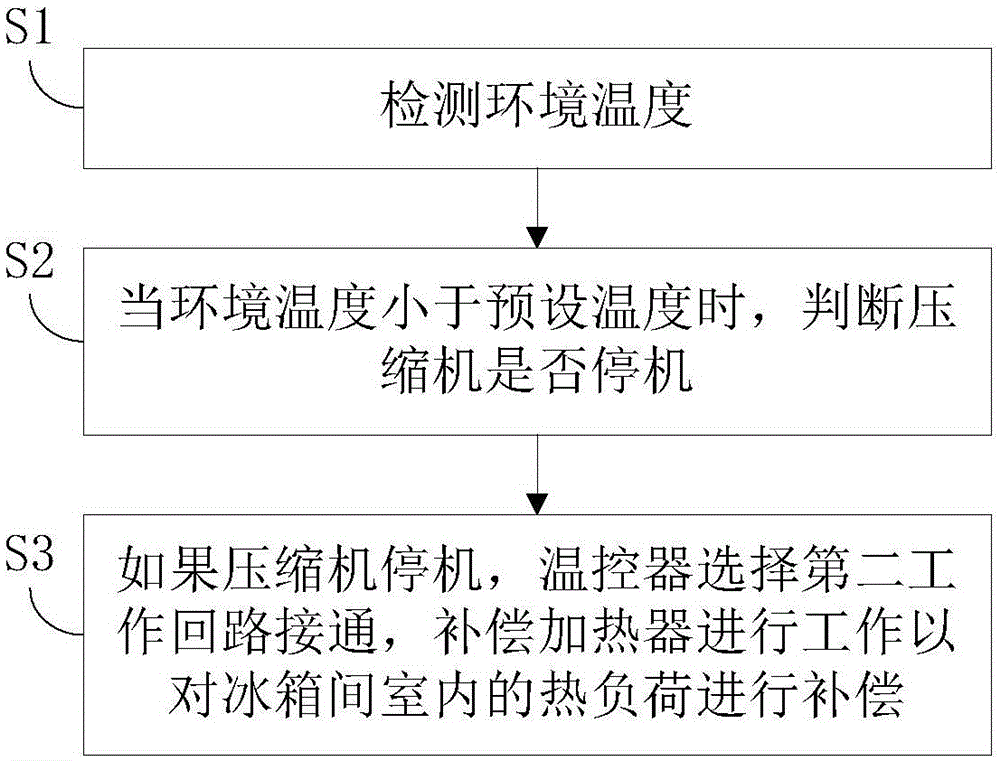

Inverter refrigerator, low-temperature compensation system thereof and low-temperature compensation control method

InactiveCN105043008AMeet cooling needsReduce downtimeLighting and heating apparatusRefrigeration devicesFrequency conversionEngineering

The invention discloses a low-temperature compensation system of an inverter refrigerator, the inverter refrigerator with the low-temperature compensation system and a low-temperature compensation control method. The low-temperature compensation system comprises a first working circuit, a second working circuit and a temperature controller. The first working circuit comprises a frequency conversion control panel and a compressor connected with the frequency conversion control panel. The second working circuit comprises a compensation heater. The temperature controller is connected with the first working circuit and the second working circuit. When the environment temperature is smaller than the preset temperature and the compressor is stopped, the temperature controller selects the second working circuit to be switched on, and the compensation heater works to compensate for heat loads in refrigerator chambers. The system can effectively solve the problem that the inverter refrigerator is not started under the low-temperature environment.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Oil supply type compressor

ActiveCN105612353AAvoid foamingRelieve pressureRotary piston pumpsRotary piston liquid enginesAtmospheric airDecreased pressure

Owner:HITACHI IND EQUIP SYST CO LTD

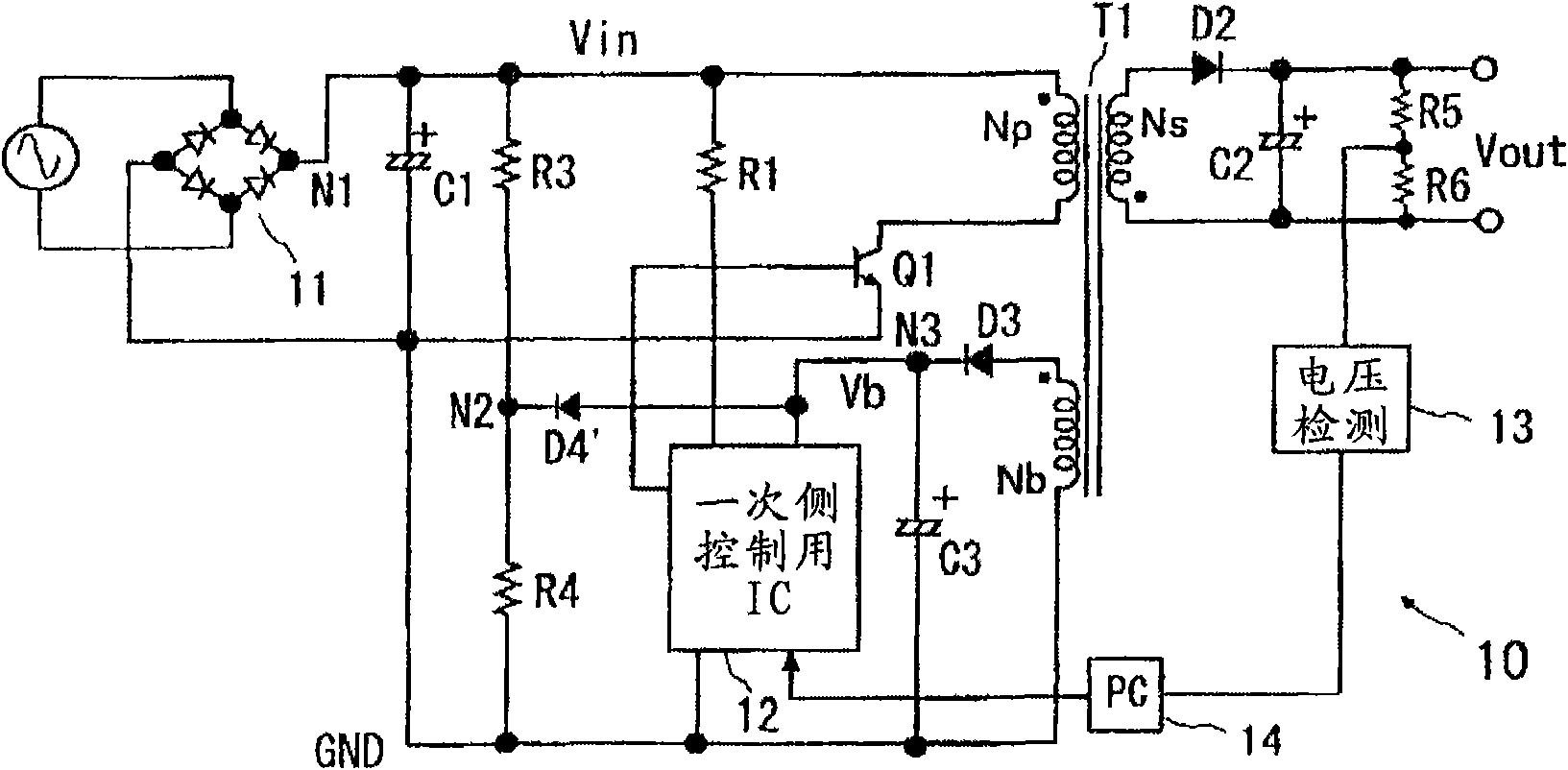

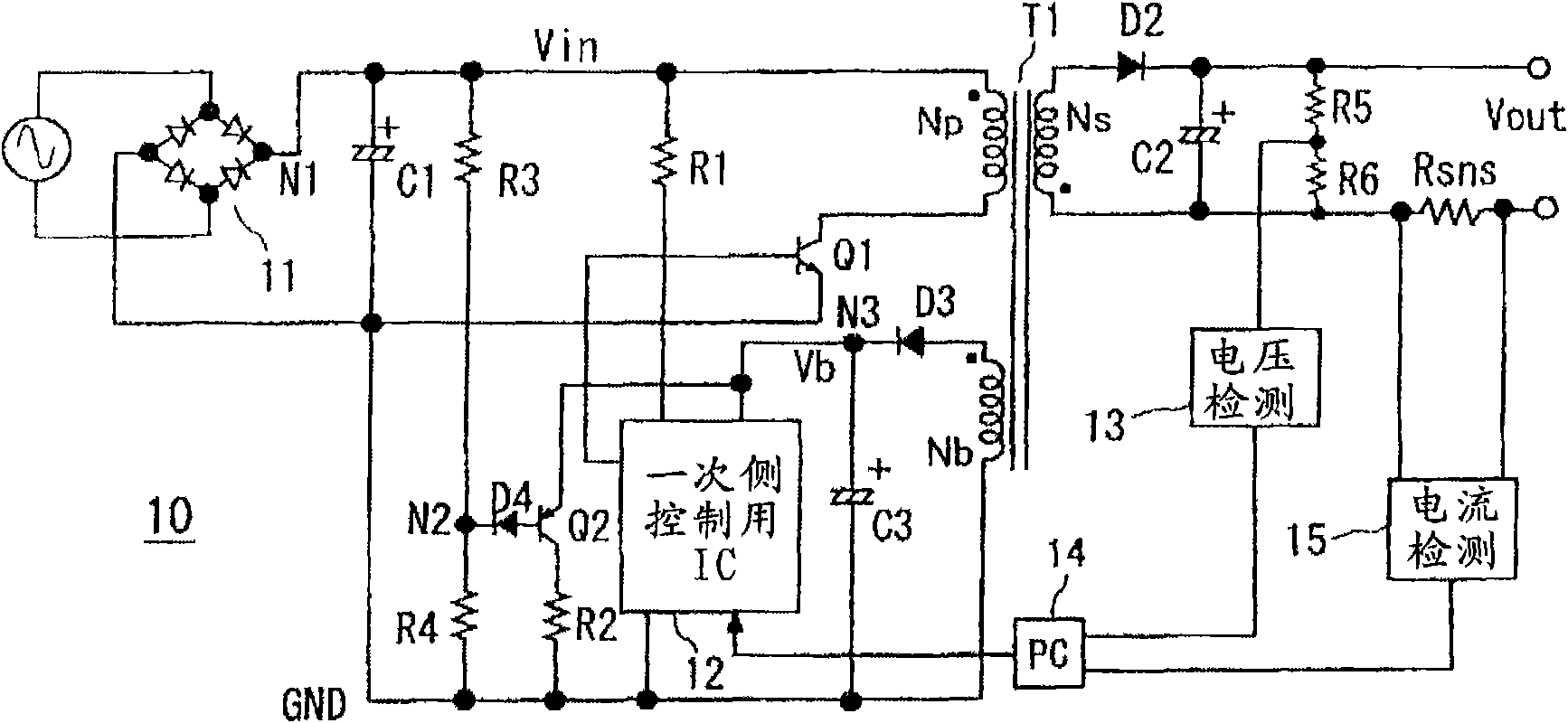

Direct current power unit

InactiveCN101615852ANormal startNo malfunctionAc-dc conversion without reversalApparatus with intermediate ac conversionConductor CoilTransformer

The invention provides a direct current power unit for avoiding wrong operation when utilizing IC and guaranteeing normal startup of a system when losing an input voltage and then communicating again. The direct current power unit comprises a transformer (T1) for voltage change with an auxiliary coil; a control circuit (12) for controlling current of a primary side winding of the transformer; and a rectifying circuit (D3) of a rectifying unit and a filter capacitor used for changing alternating current induced in the auxiliary coil into direct current. The control circuit can use a voltage generated by the rectifying circuit as a power supply voltage to work. Voltage stepping units (R3, R4, Q2) are arranged in the direct current power unit. When the input voltage (Vin) of the primary side winding of the transformer is lower than a given potential, a charge in the filter capacitor of the rectifying circuit is released to reduce the voltage supplied to the control circuit.

Owner:MITSUMI ELECTRIC CO LTD

A fuel heating intelligent control system and its control method

ActiveCN106150779BImprove starting performanceAvoid the phenomenon of feedingMachines/enginesThermal treatment of fuelElectricityTemperature control

The invention relates to an intelligent control system for fuel oil heating. The intelligent control system comprises an engine, an engine controller, a main oil tank, an auxiliary oil tank, a fuel oil heating controller and a storage battery. The main oil tank is communicated with the engine through a main oil tank switch valve, the auxiliary oil tank is communicated with the engine through an auxiliary oil tank switch valve, the engine controller is in signal connection with the fuel oil heating controller, and the fuel oil heating controller is electrically connected with an ignition switch, the main and auxiliary oil tank switch valves, a relay coil, a fuel oil heating switch and a temperature controlled switch; the positive pole of the storage battery is grounded through a battery main switch, a relay contact and a main oil tank heater in sequence, and the negative pole of the storage battery is grounded; when the temperature of an oil sucking opening of the main oil tank is lower than 5 DEG C, an oil way is switched to an auxiliary oil tank loop so as to start the engine, when the rotating speed of the engine reaches 700 rpm, the main oil tank heater starts to heat, when the temperature of the oil sucking opening of the main oil tank reaches 25 DEG C, heating is stopped, and the oil way is switched to a main oil tank loop. By means of the intelligent control system, the starting performance of the engine is improved, and the safety and the reliability are high.

Owner:DONGFENG COMML VEHICLE CO LTD

Automatic water diversion device

InactiveCN101761486AAvoid physical laborEasy to automatePriming pumpNon-positive displacement fluid enginesCentrifugal pumpWater diversion

The invention relates to an automatic water diversion device which belongs to an auxiliary facility of a water pump. The automatic water diversion device comprises a water inlet pipe (1) of a centrifugal water pump, a water storage tank (2) and a water storage tank water diversion pipe (3), wherein the water inlet pipe (1) of the centrifugal water pump is communicated with the bottom side of the water storage tank (2); the water storage tank water diversion pipe (3) is communicated with the higher end of the water storage tank (2); the top of the water storage tank (2) is communicated with a water injection pipe (4); and the water injection pipe is provided with a control valve (5). The invention solves the problem that water injection is needed before the centrifugal water pump is started, and can fully inject the water storage tank when the centrifugal water pump is used for the first time, thereby enhancing the vacuum degree of a working system and increasing the water diversion height of the water diversion pipe.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

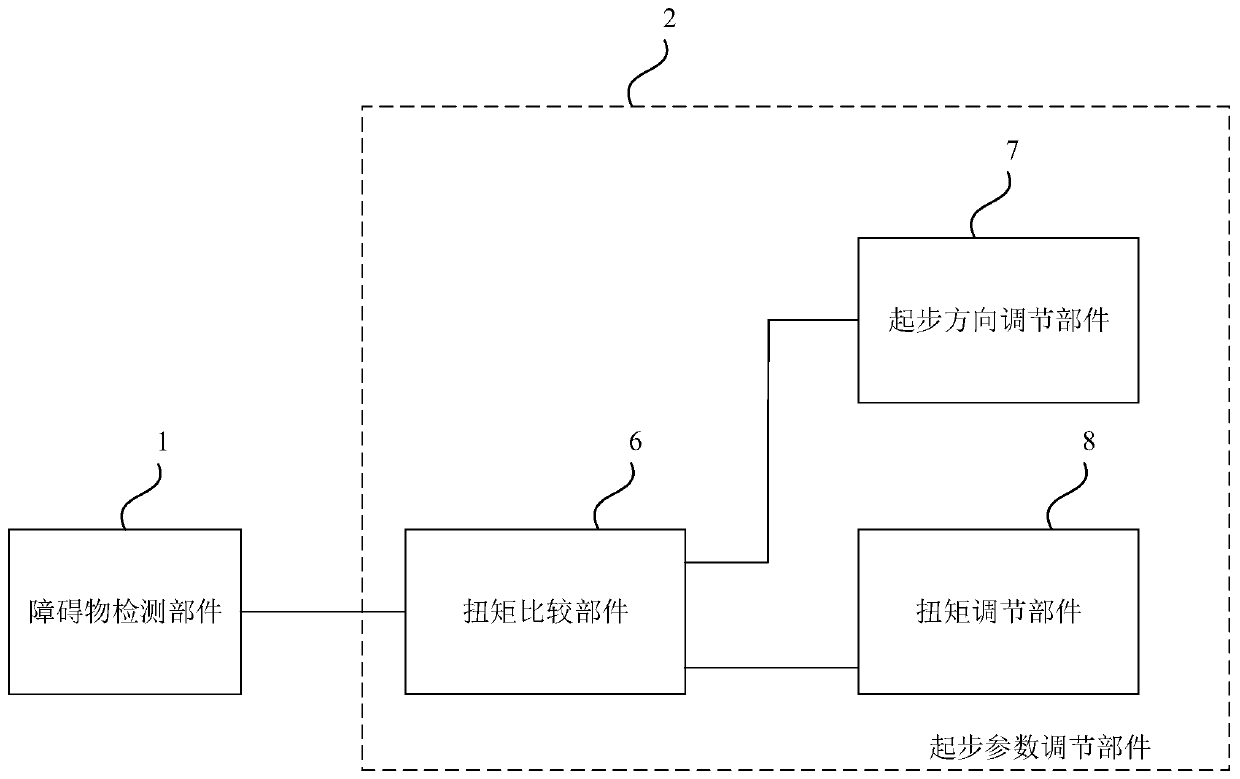

Automatic driving vehicle and obstacle feedback adjusting method thereof

The invention discloses an automatic driving vehicle and an obstacle feedback adjusting method thereof and belongs to the field of unmanned vehicles (or automatic driving or unmanned driving). The automatic driving vehicle comprises obstacle detection components and a starting parameter adjusting component; at least one tire of the automatic driving vehicle is correspondingly provided with the obstacle detection components; the obstacle detection components are used for detecting obstacles in front of and / or behind the corresponding tires in parking states; and the starting parameter adjustingcomponent is electrically connected with the obstacle detection components and used for adjusting the driving starting parameters of the automatic driving vehicle according to obstacle detection results sent by the obstacle detection components. By means of the automatic driving vehicle and the obstacle feedback adjusting method thereof provided by the technical schemes of the invention, the automatic driving vehicle can cross over or bypass an obstacle when starting, and it is guaranteed that the automatic driving vehicle can start normally.

Owner:NEOLIX TECH CO LTD

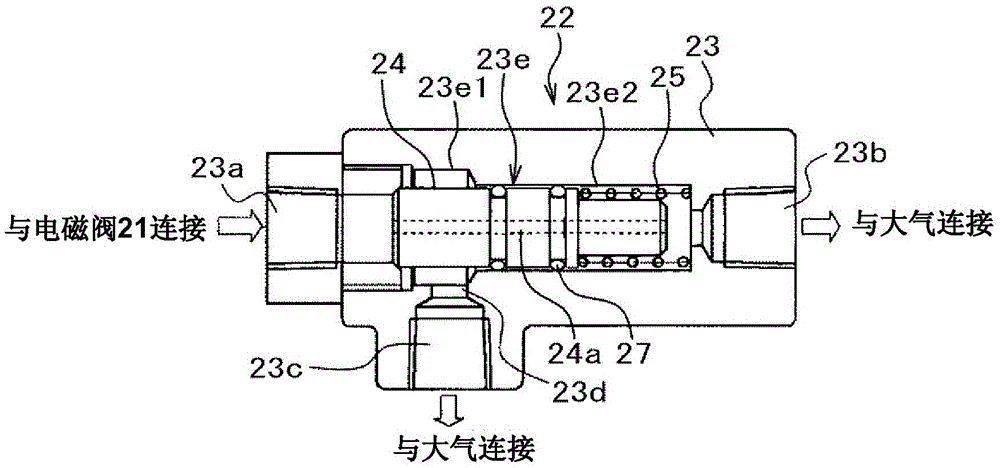

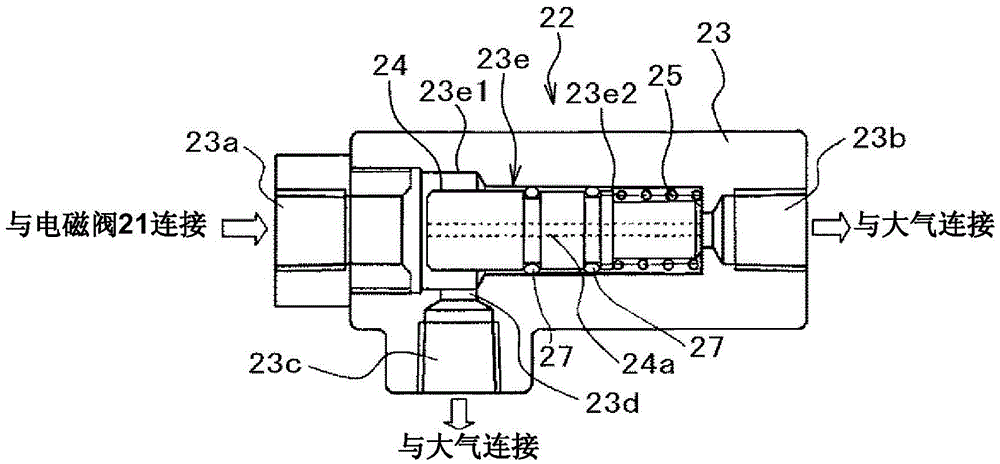

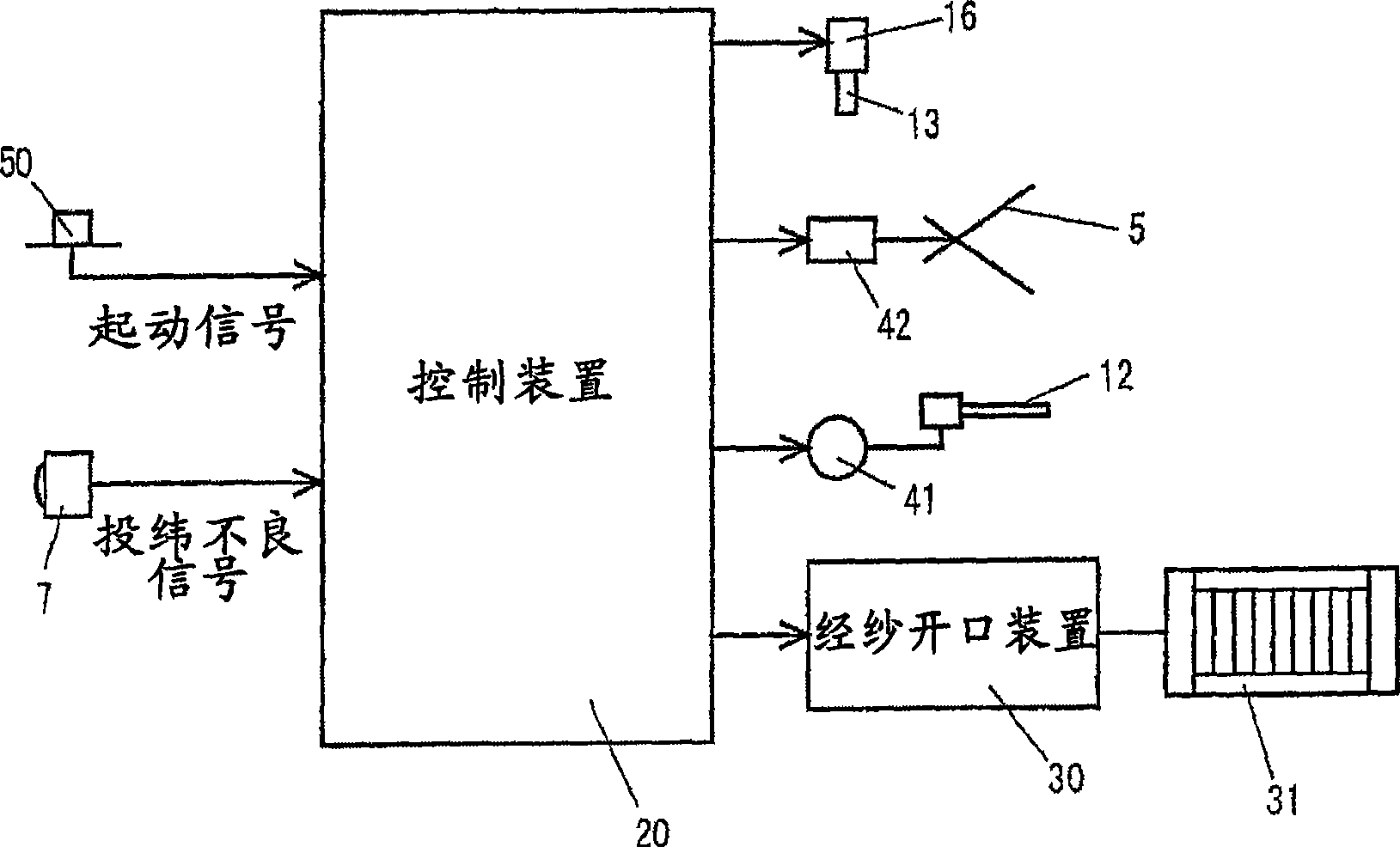

Jet loom

This invention relates to an air jet weaving machine, which preventes weft yarn loosing, detwisting and being blown down from wefting nozzle during weaving machine halting through using simple structure of the weaving machine in existence. The weaving machine is stopped, at the state that the weft yarn wefted just before the weaving machine is about to stop is the by fiber payoff cutter is cut, comprising: control device for controlling weft yarn holding, relieving action of distance measuring and stocking arrangement, spraying action of wefting nozzle and opening action of warp opening device. After the weaving machine stops, the opening device is controlled to make the warp thread at waiting state, and then the hold mode to weft yarn at the distance measuring and stocking arrangement isrelieved, and the compressed air is jetted using the said wefting nozzle, at last the weft yarn of the preset length is emitted from the wefting nozzle towards warp. The invention also comprises a starting method of weaving machine. After the above action, a part of the said weft yarn ejected and extended from the front end of the wefting nozzle is fixed on the textile, and the ejected weft yarn is installed on the front of the said fiber payoff cutter.

Owner:TSUDAKOMA KOGYO KK

Auxiliary electric heater of central air-conditioner

InactiveCN103196220ANormal startUptimeWater heatersAir conditioning systemsTemperature controlEngineering

The invention relates to a heating device and particularly relates to an auxiliary electric heater of a central air-conditioner. The technical scheme includes that the auxiliary electric heater comprises a heating box body, a heating coil, a terminal box, a temperature controller, a temperature measuring device, a water inlet, a pressure reducing valve, a water outlet and a drain outlet, wherein the terminal box is connected to one side of the heating box body, the water inlet and the water outlet are arranged on the heating box body, the drain outlet is arranged at the bottom of the heating box body, the heating coil is fixed inside the heating box body, the heating coil is connected with the terminal box, the temperature controller is arranged inside the terminal box and is connected with the temperature measuring device, and the pressure reducing valve is arranged at the top of the heating box body. The auxiliary electric heater has the advantages that preheating is conducted on an aqueous medium through the auxiliary electric heater of the central air-conditioner, the water temperature is increased, the normal starting and operation of an air conditioning unit can be guaranteed, and the heat supply efficiency and the heat supply effect of a main machine can be improved.

Owner:张敬敏

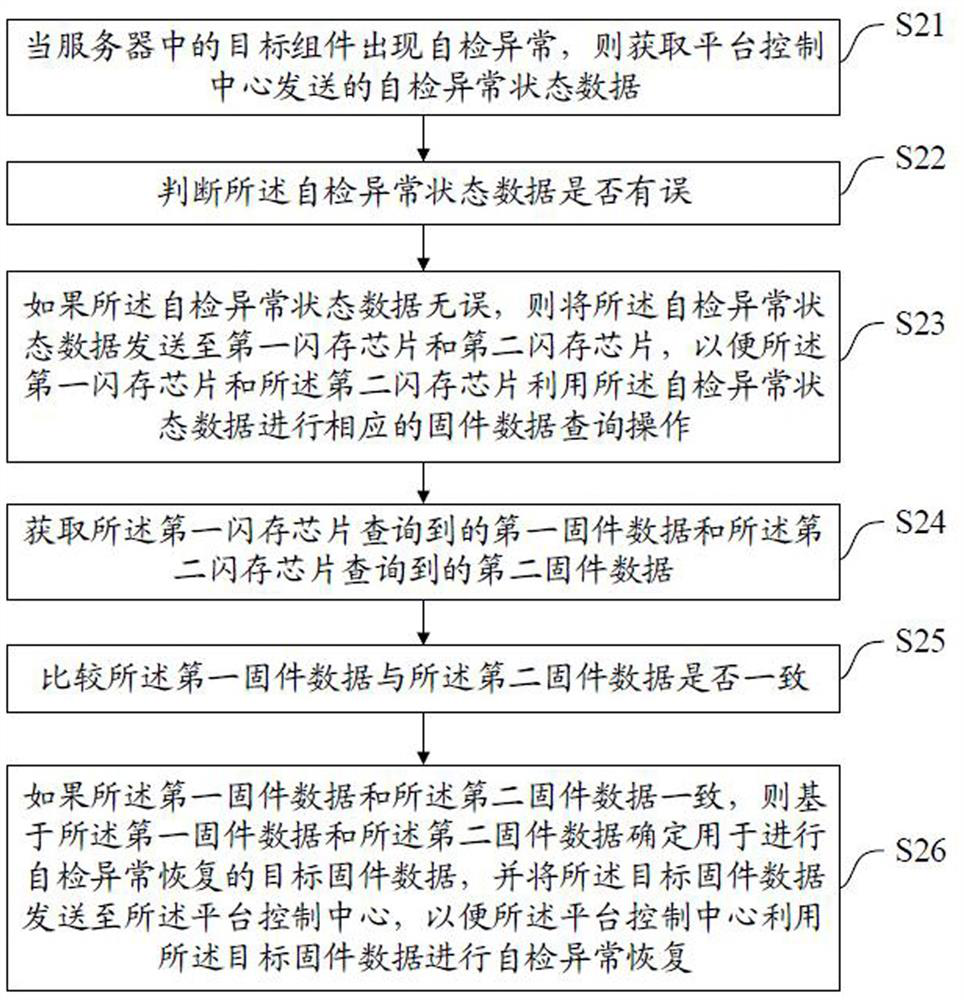

Server component self-test anomaly recovery method and device, system and medium

ActiveCN113672306AIncrease success rateStart fastNon-redundant fault processingProgram loading/initiatingServerReliability engineering

The invention discloses a server component self-test exception recovery method and device, a system and a medium, and the method comprises the steps: obtaining self-test abnormal state data sent by a platform control center when a target component in a server has a self-test anomaly; querying corresponding first firmware data and second firmware data from a first flash memory chip and a second flash memory chip based on the self-test abnormal state data; determining whether the first firmware data is consistent with the second firmware data or not; and if the first firmware data is consistent with the second firmware data, determining target firmware data used for performing self-check anomaly recovery based on the first firmware data and the second firmware data, and sending the target firmware data to a platform control center, so that the platform control center performs self-check anomaly recovery by using the target firmware data. According to the method and the device, the target firmware data used for performing self-test anomaly recovery is determined from the two flash memory chips based on the self-test abnormal state data, so that the labor and time cost caused by self-test anomaly recovery is saved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com