Double-skewed-slot rotor, and stator-rotor equal-slot matching structure based on rotor

A double-chute, stator-rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, electrical components, etc., can solve the problem that the straight-slot cage rotor induction motor cannot start and weaken the harmonic magnetic field of the stator teeth Electromotive force, weakening of synchronous additional torque and other problems, to achieve good starting characteristics, small asynchronous additional torque, and small additional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

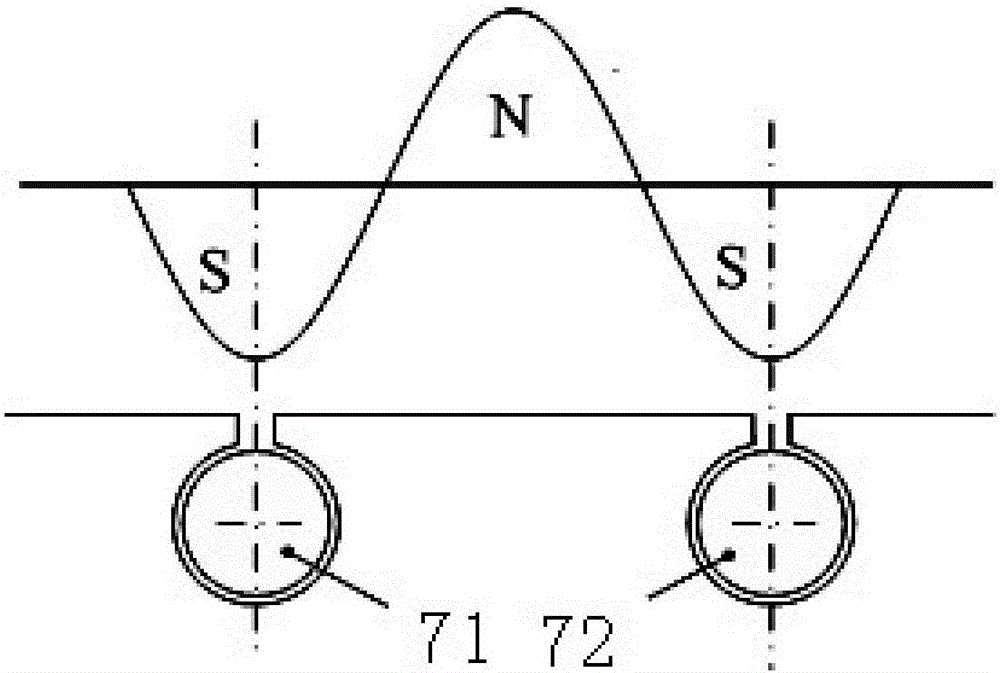

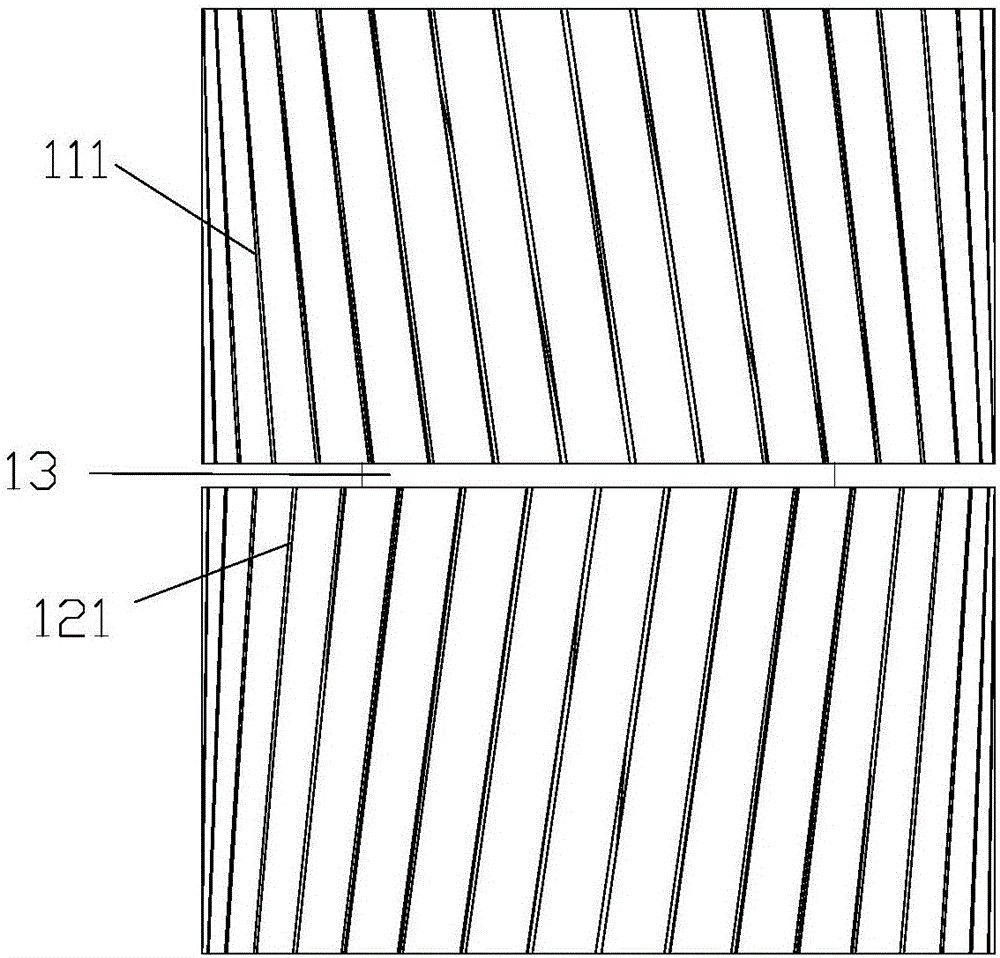

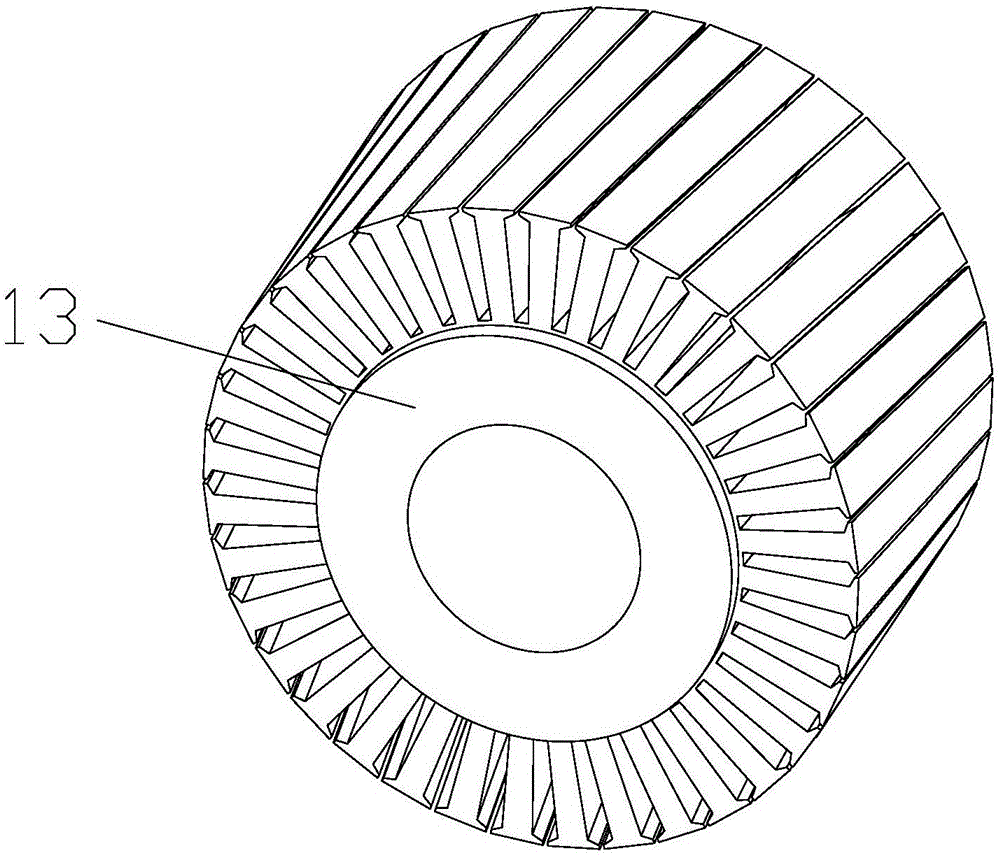

[0047] Such as Figure 2-3 As mentioned above, this embodiment discloses a double-sloped rotor, the number of slots of the double-sloped rotor is equal to the number of slots of the stator matched with it; the double-sloped rotor includes the first rotor, the second Two rotors; the groove body 111 of the first rotor is oppositely twisted to the corresponding groove body 121 of the second rotor;

[0048] The distance between the chute of the first rotor and the second rotor is:

[0049]

[0050] The chute angles of the first rotor and the second rotor are both:

[0051]

[0052] Among them, Z 1 is the number of stator slots, p is the number of pole pairs of the motor, D i1 is the inner diameter of the stator;

[0053] The stagger distance between the slot body of the first rotor and the corresponding slot body in the second rotor is:

[0054]

[0055] The stagger angle between the slot body of the first rotor and the corresponding slot body in the second rotor is:...

Embodiment 2

[0066] This embodiment discloses a cage-type rotor induction motor with 24-24 stator and rotor slots. The rotor is a built-in rotor, which is built into the cavity of the stator. Straight-slotted rotors, skewed-slotted rotors, and double-sloped-slotted rotors are used respectively. The main parameters of the motors are shown in Table 1.

[0067] Table 1 Main parameters of the motor

[0068] Rated power (kW) 1.5 Number of parallel branches 1 Stator outer diameter (mm) 130 Stator inner diameter (mm) 80 Core length (mm) 105 Air gap length(mm) 0.25 Number of stator slots 24 Number of rotor slots 24 Winding connection form star shape number of poles 4

[0069] Among them, the chute angle of the chute rotor is 15°, the chute distance is 10.4mm; the chute angle of each segment of the double chute rotor is 15°, the chute distance of each rotor segment is 10.4mm, the stagger angle is 7.5°, and the stagger distance i...

Embodiment 3

[0080] This embodiment discloses a cage-type rotor induction motor with 36-36 slots in the stator and rotor. The parameters are shown in Table 4.

[0081] Table 4 Main parameters of the motor

[0082] Rated power (kW) 11 Number of parallel branches 1 Stator outer diameter (mm) 260 Stator inner diameter (mm) 170 Core length (mm) 155 Air gap length(mm) 0.5 Number of stator slots 36 Number of rotor slots 36 Winding Connection triangle number of poles 4

[0083] Among them, the chute angle of the chute rotor is 10°, and the chute distance is 11.8mm; the chute angle of each segment of the double chute rotor is 10°, the distance of each rotor electric chute is 11.8mm, and the stagger angle of the two rotor segments is 5 °, the stagger distance is 5.9mm.

[0084] When the stator and rotor slot fit is 36-36, the stator and rotor harmonic spectrum is shown in Table 5.

[0085] Table 5 When the groove fit is 36-36,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com