Jet loom

A loom and nozzle technology, used in looms, textiles, textiles and papermaking, etc., can solve the problems of reduced driving rate, time required, and increased cost, and achieve the effect of simplifying structure and control and preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

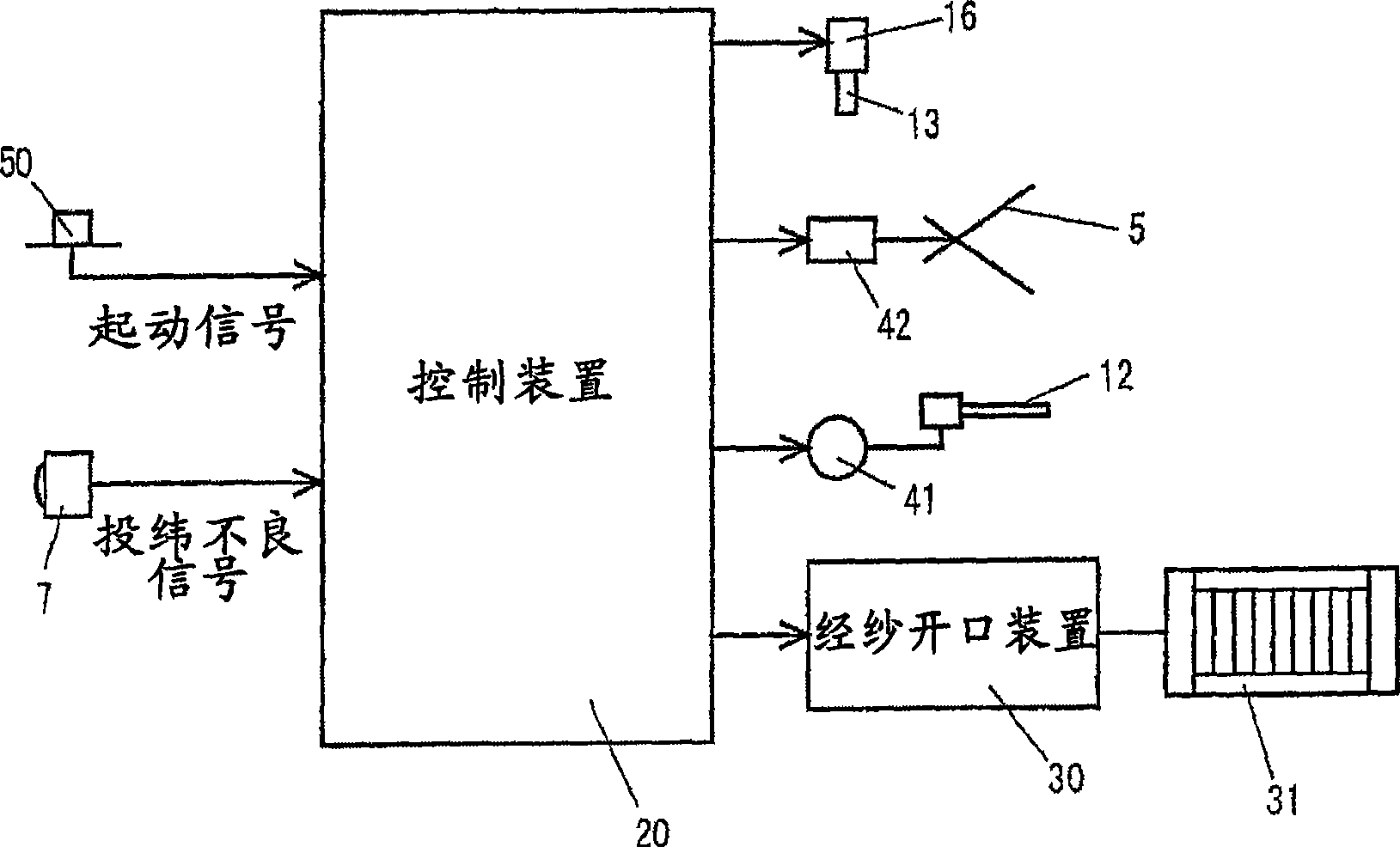

[0027] Fig. 1 is a structural view of the weft inserting device 10 and the vicinity of the cloth fell 8 of the air-jet loom 1 of the present invention. in addition, figure 2 It is a block diagram showing the relationship between a control device 20 that controls each device provided on the air jet loom 1 and devices connected to the control device 20 .

[0028] The air-jet loom 1 (hereinafter, referred to as the loom 1 ) has a weft insertion device 10 for inserting weft yarns 2 to warp yarns 3 using compressed air. The weft inserting device 10 is composed of a stationary drum type length-measuring storage device 11, a weft inserting nozzle 12, and a plurality of auxiliary nozzles (not shown) arranged side by side in the weaving web direction. In addition, the weft insertion nozzle 12 is fixed to an unshown sley.

[0029] An operation button 50 for outputtin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com