A fuel heating intelligent control system and its control method

An intelligent control system and heating controller technology, applied in the direction of charging system, fuel heat treatment device, liquid fuel feeder, etc., can solve the problems of poor starting performance of the engine, improve starting performance, reduce operating costs, and ensure The effect of normal starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

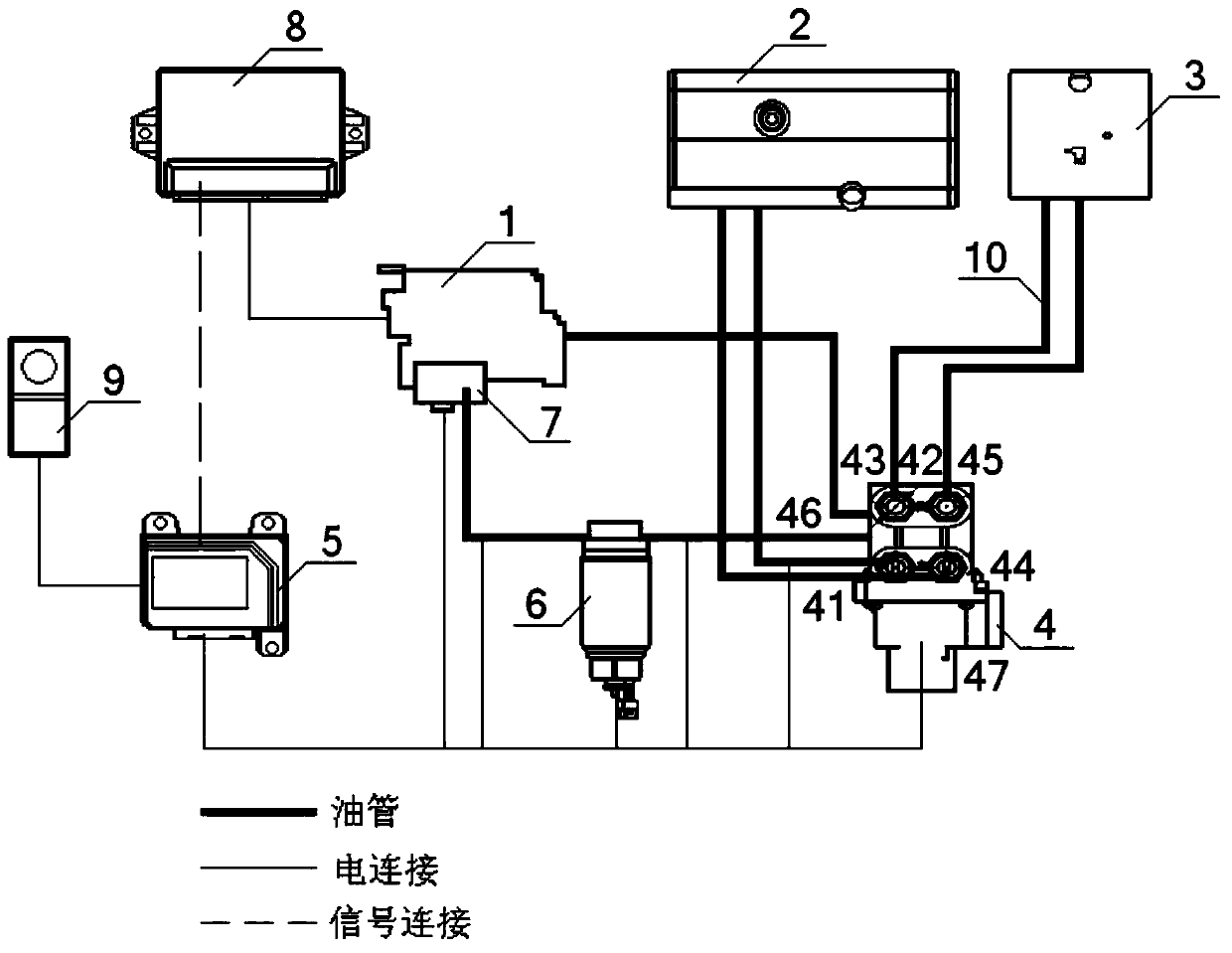

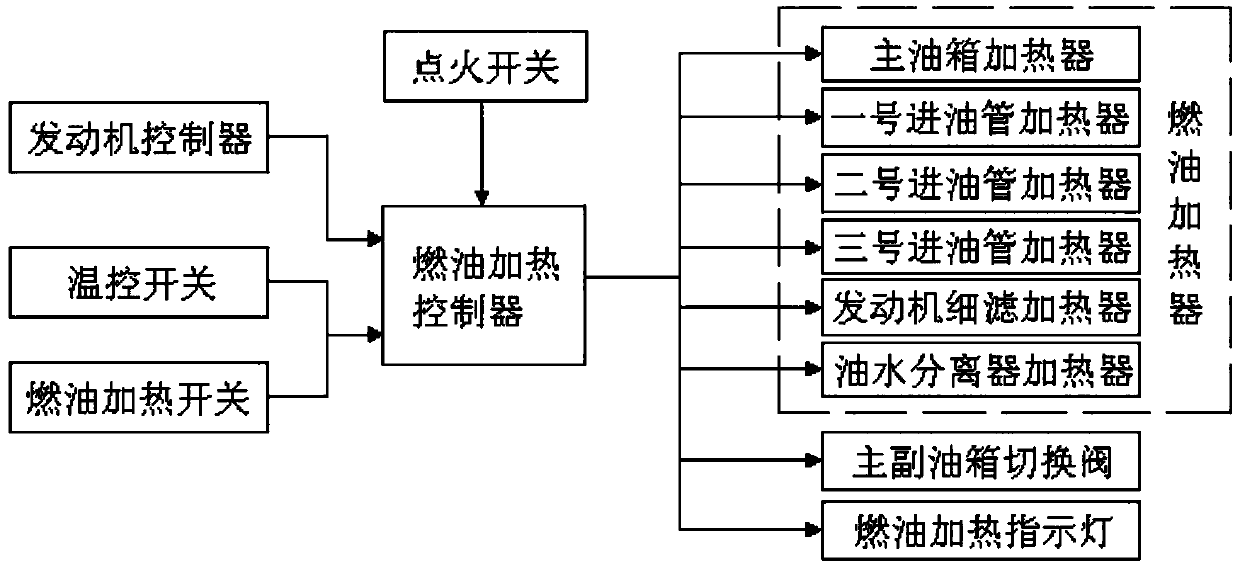

[0084] see Figure 1 to Figure 3 , an intelligent control system for fuel heating, comprising a fuel heater, a fuel heating controller 5, and a fuel heating switch 9, the fuel heater and the fuel heating switch 9 are respectively electrically connected to the fuel heating controller 5, and the fuel heating intelligent The control system also includes an engine 1, an engine controller 8, a main fuel tank 2, an auxiliary fuel tank 3, a main and auxiliary fuel tank switching valve 4, and an ignition switch 11; the fuel heating controller 5 is electrically connected to the ignition switch 11 and the main and auxiliary fuel tank switching valve 4 respectively, The engine 1 is electrically connected to the engine controller 8, and the engine controller 8 is connected to the fuel heating controller 5 for signals (the engine controller 8 performs signal transmission with the fuel heating controller 5 through the CAN bus 12); the main fuel tank 2 and the auxiliary fuel tank 3 The oil p...

Embodiment 2

[0087] Basic content is the same as embodiment 1, the difference is:

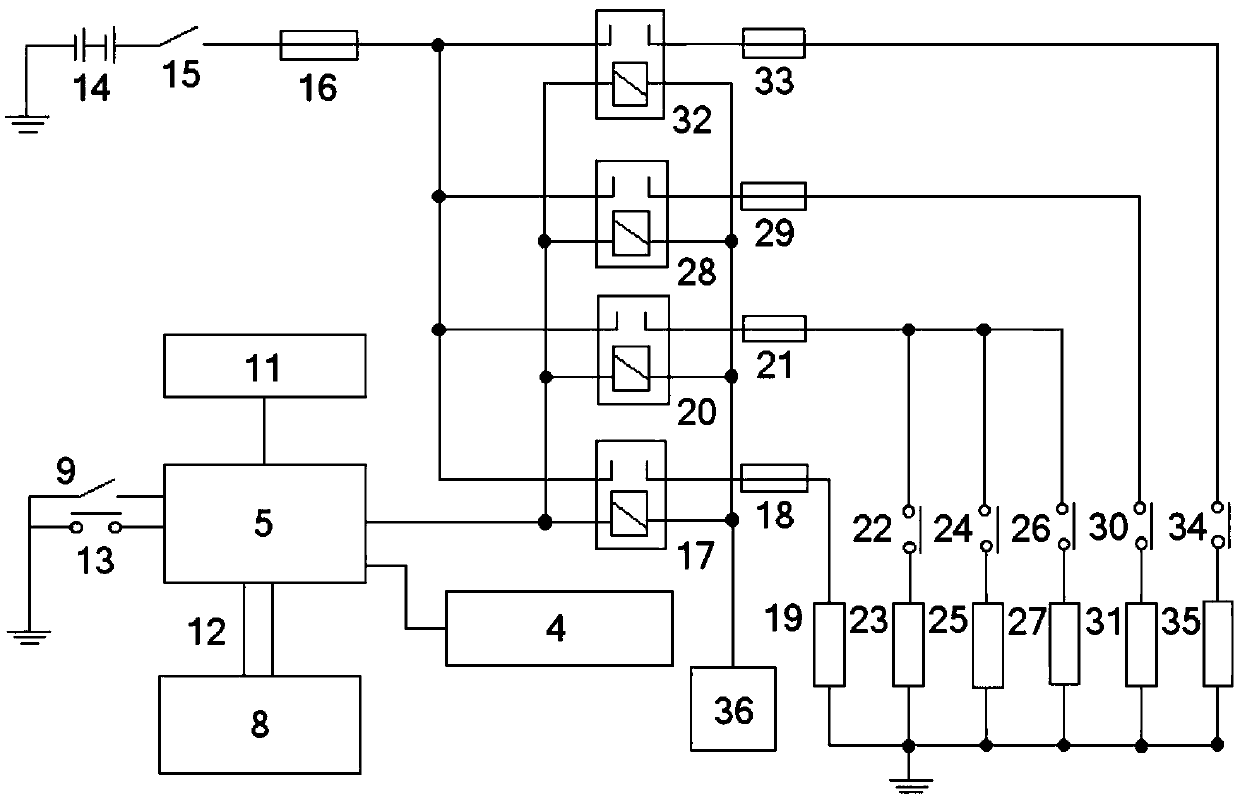

[0088] see Figure 1 to Figure 3 , the fuel heating intelligent control system also includes a storage battery 14, a main power switch 15, a No. 1 temperature control switch 13, and a No. 1 relay 17. The fuel heater includes a main fuel tank heater 19 for controlling the main fuel tank 2 The fuel is heated; the fuel heating controller 5 is grounded after the fuel heating switch 9, the fuel heating controller 5 is grounded after the No. 1 temperature control switch 13, and the fuel heating controller 5 is electrically connected with the coil of the No. 1 relay 17. The positive pole of the storage battery 14 is grounded successively through the main power switch 15, the first fuse 16, the contacts of the first relay 17, the second fuse 18, and the main oil tank heater 19, and the negative pole of the storage battery 14 is grounded;

[0089] The fuel heating intelligent control system also includes an oil-wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com