Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "No air leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

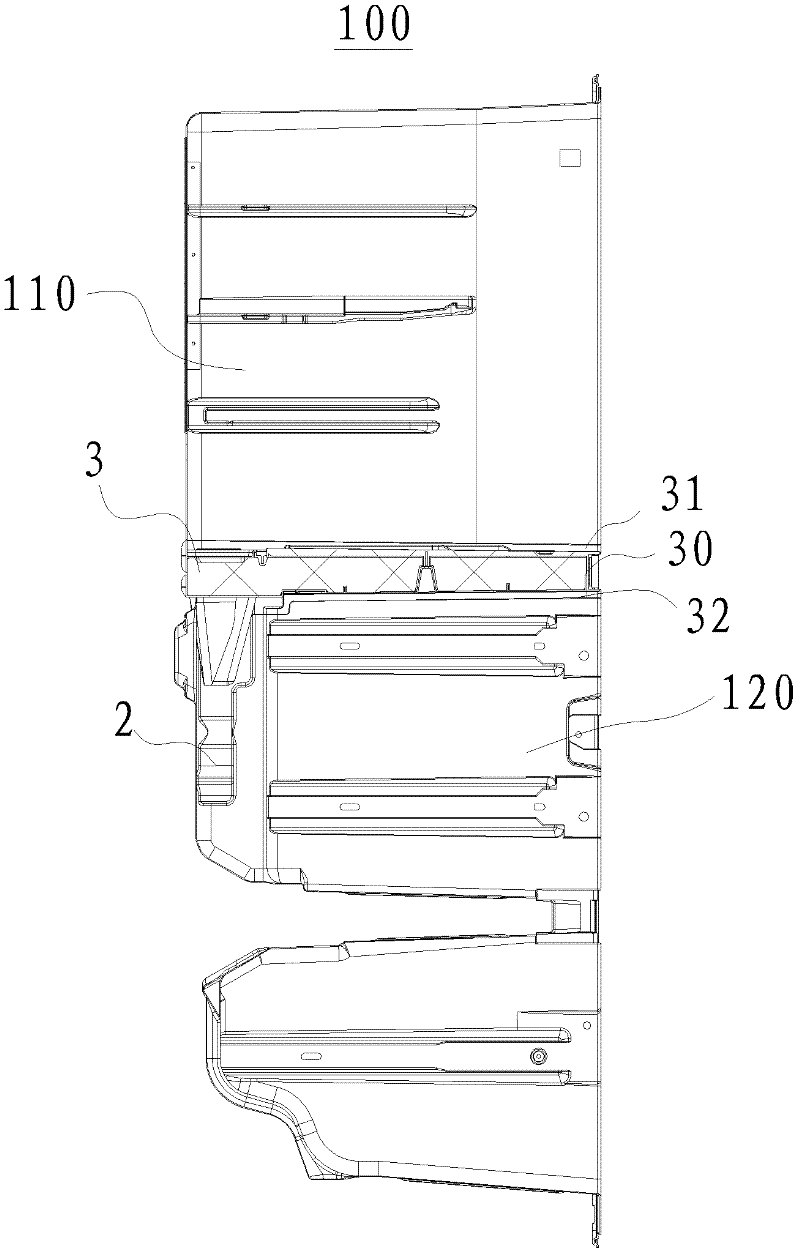

Refrigerator and assembly method thereof

ActiveCN102506537AImprove performanceLow costLighting and heating apparatusDomestic refrigeratorsRefrigerated temperatureEvaporator

The invention discloses a refrigerator and an assembly method thereof. The refrigerator comprises a refrigerator body, an evaporator, a fan and an intermediate air channel component, the intermediate air channel component comprises a main body, an upper cover plate and a lower cover plate, the upper cover plate is arranged on the upper surface of the main body, a first air outlet and a first air inlet which are spaced from each other are formed on the upper cover plate, a plurality of first fastening portions which are spaced along a front and back direction are disposed on both the left side and the right side of the upper cover plate, the lower cover plate is disposed on the lower surface of the main body, an air channel and a foam space are limited and separated among the upper cover plate, the lower cover plate and the main body, a second air inlet and a second air outlet which are spaced from each other are formed on the lower cover plate, a plurality of second fastening portions which are spaced along a front and back direction are disposed on both the left side and the right side of the lower cover plate, and the air channel is communicated with a first room via the first air outlet and the first air inlet, and is communicated with a second room via the second air inlet and the second air outlet. In the refrigerator of an embodiment of the invention, the air channel is sealed, air is not easy to leak, performances are stable, and production cost is low.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

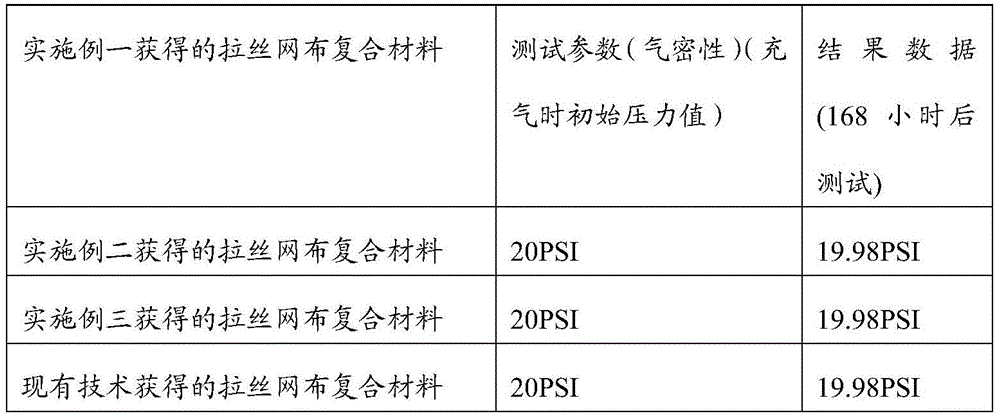

Wire-drawing screen cloth composite material and preparing method thereof

InactiveCN105666963APrevent penetrationSolve sticking problemsSynthetic resin layered productsCoatingsPolyvinyl chlorideEngineering

The invention relates to a wire-drawing screen cloth composite material which comprises a PVC layer, a wire-drawing screen cloth layer, a first coating and a second coating. The first coating and the second coating are arranged on the two side faces of the wire-drawing screen cloth layer respectively so as to form a pre-compositing layer. The two side faces of the pre-compositing layer are attached to the PVC layer respectively to form the wire-drawing screen cloth composite material. The first coating and the second coating are each prepared from, by weight, 60-80 parts of diisononyl phthalate or dioctyl phthalate, 95-105 parts of polyvinyl chloride and 2-4 parts of a stabilizer. Viscosity of the first coating and viscosity of the second coating each range from 10000 cps to 12000 cps. The invention further relates to a preparing method of the wire-drawing screen cloth composite material. The wire-drawing screen cloth composite material can effectively solve the problem of bonding of the wire-drawing screen cloth and has the advantage of effectively improving air tightness.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

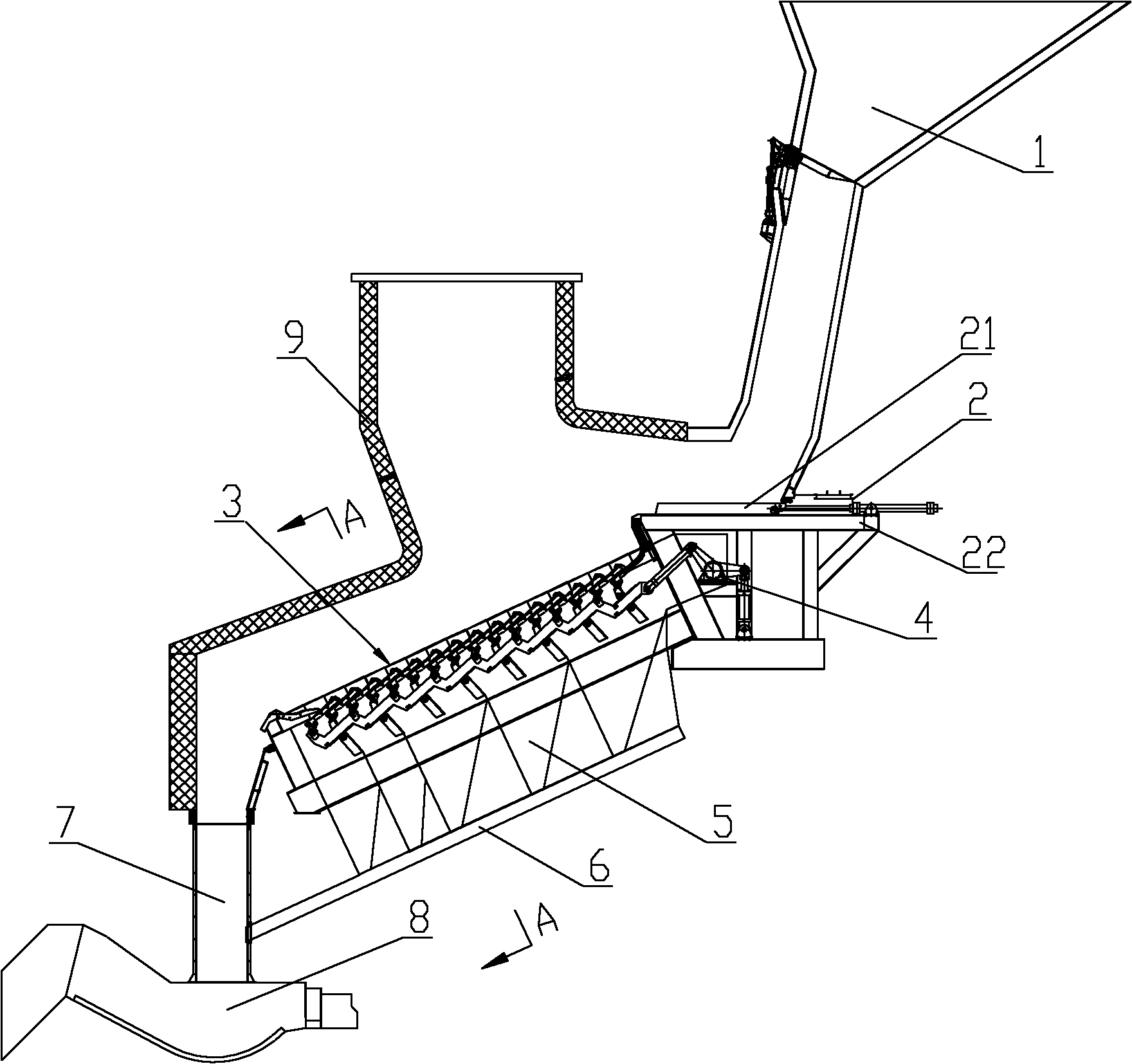

Reciprocating inverse-pushing type garbage incinerator

The invention discloses a reciprocating inverse-pushing type garbage incinerator which comprises a hearth wall body, a hopper device arranged on an upper port of the hearth wall body, a residue falling groove arranged at a lower port of the hearth wall body and a residue discharging machine positioned below the residue falling groove, wherein a reciprocating inverse-pushing type fire grate is arranged in the hearth wall body, a primary air chamber and an ash discharging device are sequentially arranged below the fire grate, a closed rotating shaft fire grate drive device is arranged below thefeeding device; the fire grate comprises a fire grate frame, a plurality of fixed beams used for supporting and fixing fire grate sheets, and a plurality of movable beams used for driving movable fire grate sheets; the fixed beams and the movable beams are arranged on the fire grate frame at intervals laterally, the corresponding fixed fire grate sheets and the movable fire grate sheets are arranged and overlapped at intervals laterally, the fire grate is inclined downwards along the advancing direction of rubbish, the fire grate is divided into 2-6 lines of fire grate units along the direction vertical to the advancing direction of rubbish, and the movable beam of each line of fire grate units is driven by the corresponding primary closed rotating shaft drive device through a movable beam frame. The reciprocating inverse-pushing type garbage incinerator ensures that the rubbish can be effectively conveyed, stirred, loosened, crushed and fully combusted in a process of incinerating the rubbish, and has the advantages of good sealing property, and no air and ash leakage and dropping and permeating phenomena.

Owner:SHENZHEN DINGZHU ENVIRONMENTAL PROTECTION TECH

Processing method of nonmetal isolating sleeve for magnetic pump

The invention relates to a processing method of a nonmetal isolating sleeve for a magnetic pump, comprising the following steps of: uniformly stirring 65%-70% of polybenzimidazole and 30%-35% of polyetheretherketone, wherein the heating temperature is controlled to 350-370 DEG C, and the time is controlled to 1.2-1.8 hours; injecting the melted ingredients into a mould cavity to be formed, wherein the injection pressure is 7.0-8.0 MPa, and the injection time is 8-12 seconds; carrying out pressure-maintaining formation and then cooling 6-8 minutes along with air; taking out a formed product blank, cutting off burrs and flashing and smoothly grinding and finishing; inspecting according to the requirements of a drawing; performing a hydrostatic-pressure test of 3.0-5.0 MPa on the isolating sleeve on a special fixture, wherein the pressure-maintaining time is 15-25 minutes, and the phenomena of leakage and sweating do not exist; and then performing an air-tight sealing test on the isolating sleeve, if the isolating sleeve has no the phenomenon of air leakage, and then the product is a qualified product. The product enables the heat of magnetic force to not be gathered so that the demagnetization of magnetic steel can not be caused and the service life of the pump is prolonged.

Owner:江苏海天科技有限公司

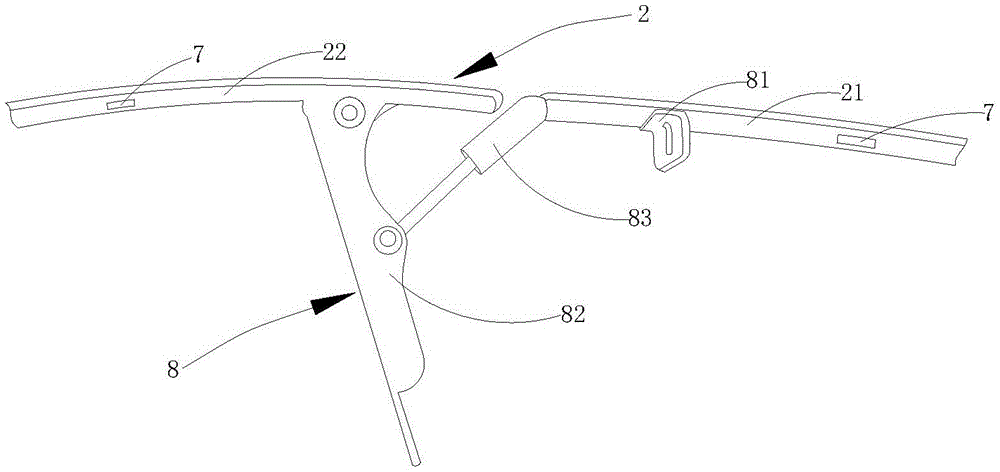

Heating ventilating and air conditioning (HVAC) inner and outer circulation air door capable of regulating fresh air and return air ratio and regulation method of HVAC inner and outer circulation wind door

InactiveCN102022809AMeeting Hygiene NeedsReduce energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusFresh airEngineering

The invention relates to a heating ventilating and air conditioning (HVAC) inner and outer circulation air door capable of regulating fresh air and return air ratio, comprising an outer circulation air inlet, an inner circulation air inlet, an original fixed air door and an air blower pipeline, wherein the outer circulation air inlet and the inner circulation air inlet are connected with one end of the original fixed air door, and the other end of the original fixed air door is communicated with the air blower pipeline; a moveable air door is arranged in the middle of the original fixed air door; and the moveable air door moves in the original air door through a control device and leads the fresh air in the outer circulation air inlet and the return air in the inner circulation air inlet to respectively enter the air blower pipeline, so that the area changes. In the HVAC inner and outer circulation air door, because the moveable air door capable of regulating the fresh air and the return air ratio is arranged, reliable fresh air and return air ratio are selected according to the number of passengers in a vehicle and the temperature of outdoor environment, thereby meeting the sanitation requirement of the passengers in the vehicle and saving energy consumption.

Owner:CHERY AUTOMOBILE CO LTD

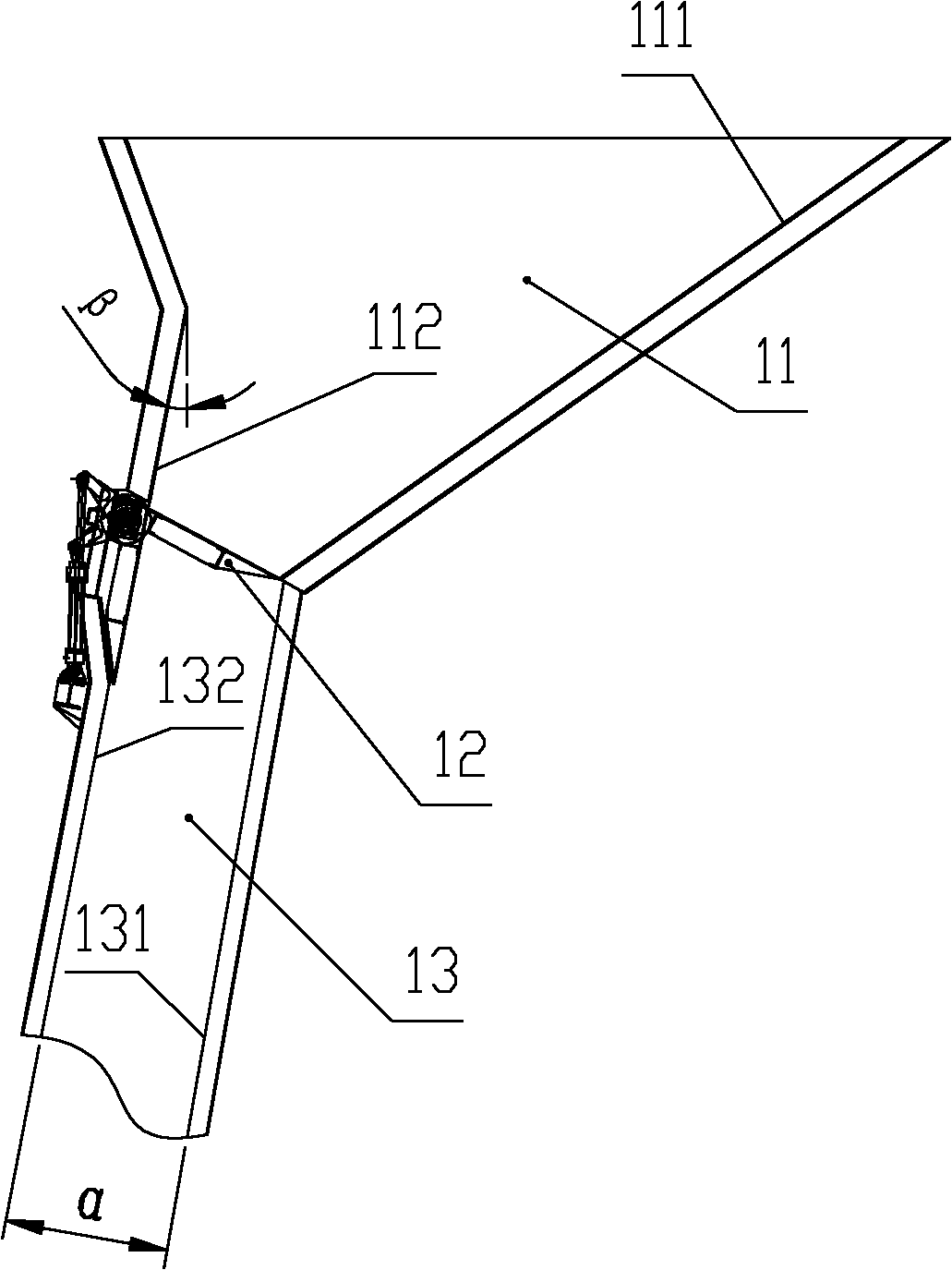

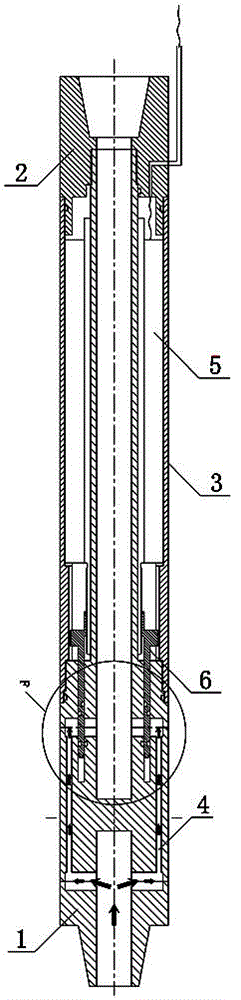

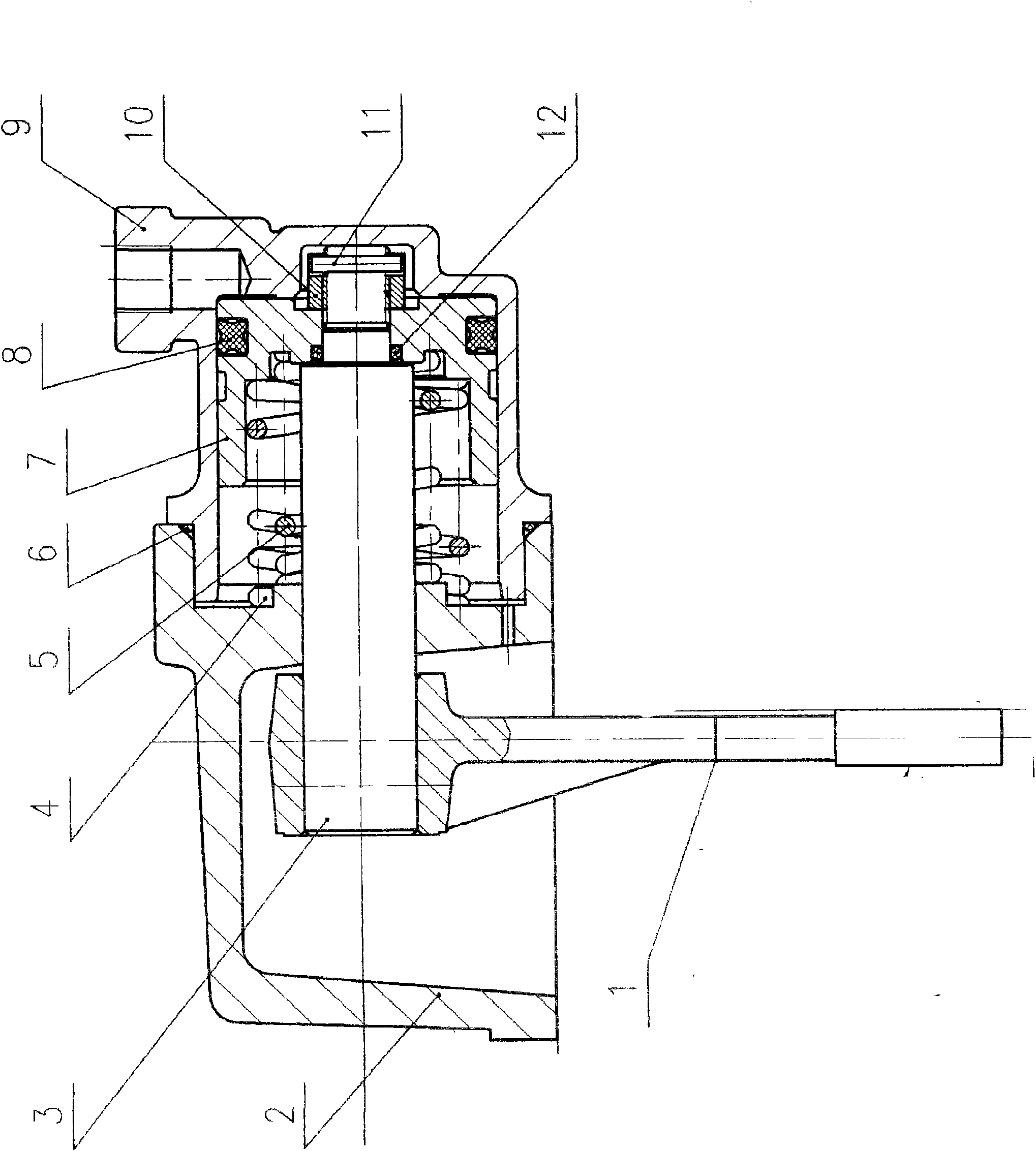

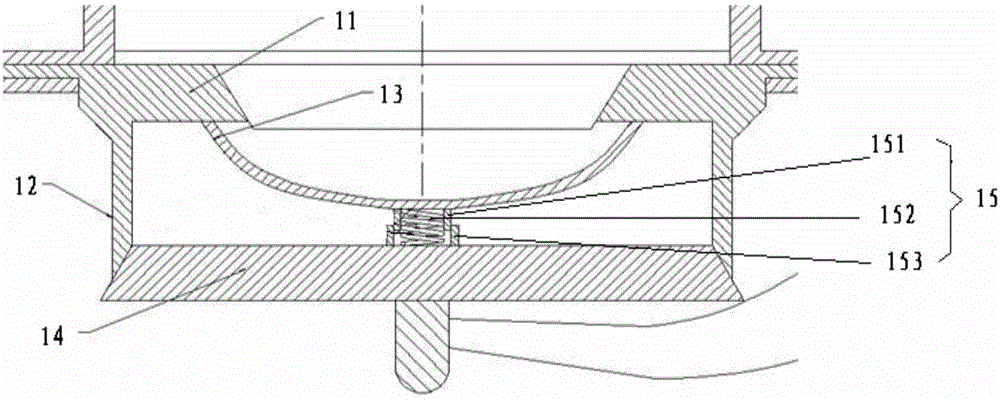

Sliding sleeve type subsurface safety valve

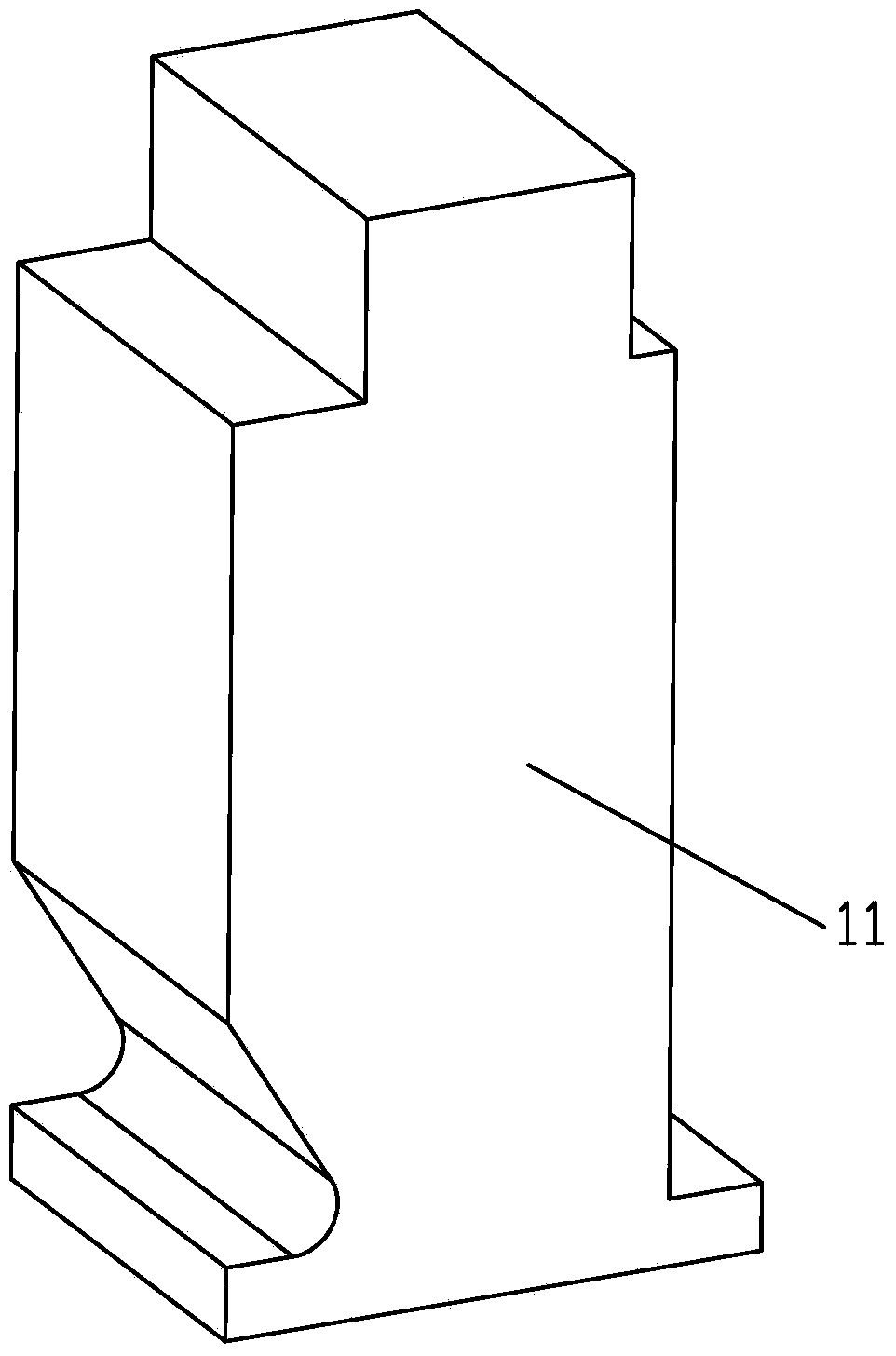

InactiveCN104314520AQuick responseNo air leakageConstructionsWell/borehole valve arrangementsDownhole safety valveEngineering

The invention relates to a sliding sleeve type subsurface safety valve. The sliding sleeve type subsurface safety valve comprises a lower joint (1), an upper joint (2), a housing (3), a power device (5) and a sliding sleeve (6), wherein an oil gas passage (4) is arranged inside the lower joint (1); a thin shaft part at the upper part of the lower joint (1) is matched and connected with the upper joint (2) through threads; a thick shaft part at the lower part of the lower joint (1) and the upper joint (2) are respectively matched with the housing (3); an annular inserting groove (11) is formed in the inner part of the lower joint (1) in the axial direction; the power device (5) is mounted in a closed cavity formed by the lower joint (1), the upper joint (2) and the housing (3); the sliding sleeve (6) comprises a connecting part (6) and an isolating part (10); the connecting part (9) is connected with the output end of the power device (5); the isolating part (10) is matched with the annular inserting groove (11) in an inserting connection mode. The sliding sleeve type subsurface safety valve has the advantages of rapid and sensitive reaction, complete isolation and reusing.

Owner:SOUTHWEST PETROLEUM UNIV

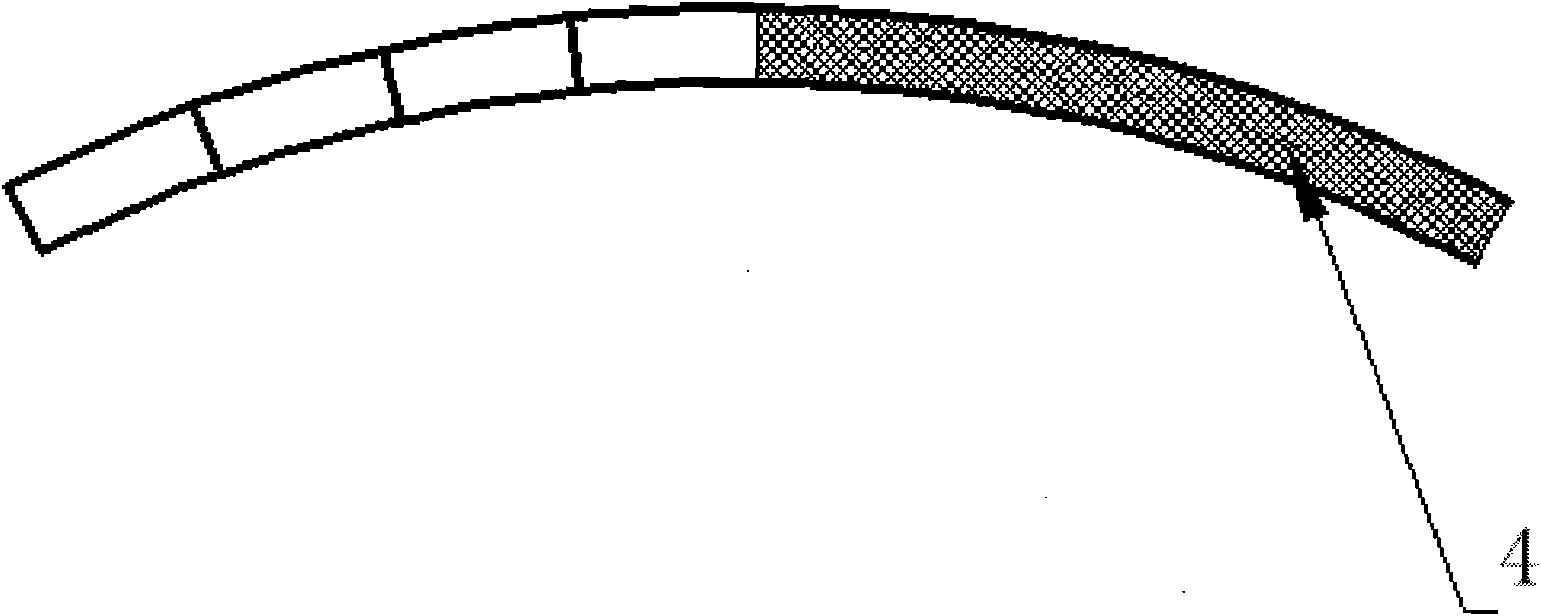

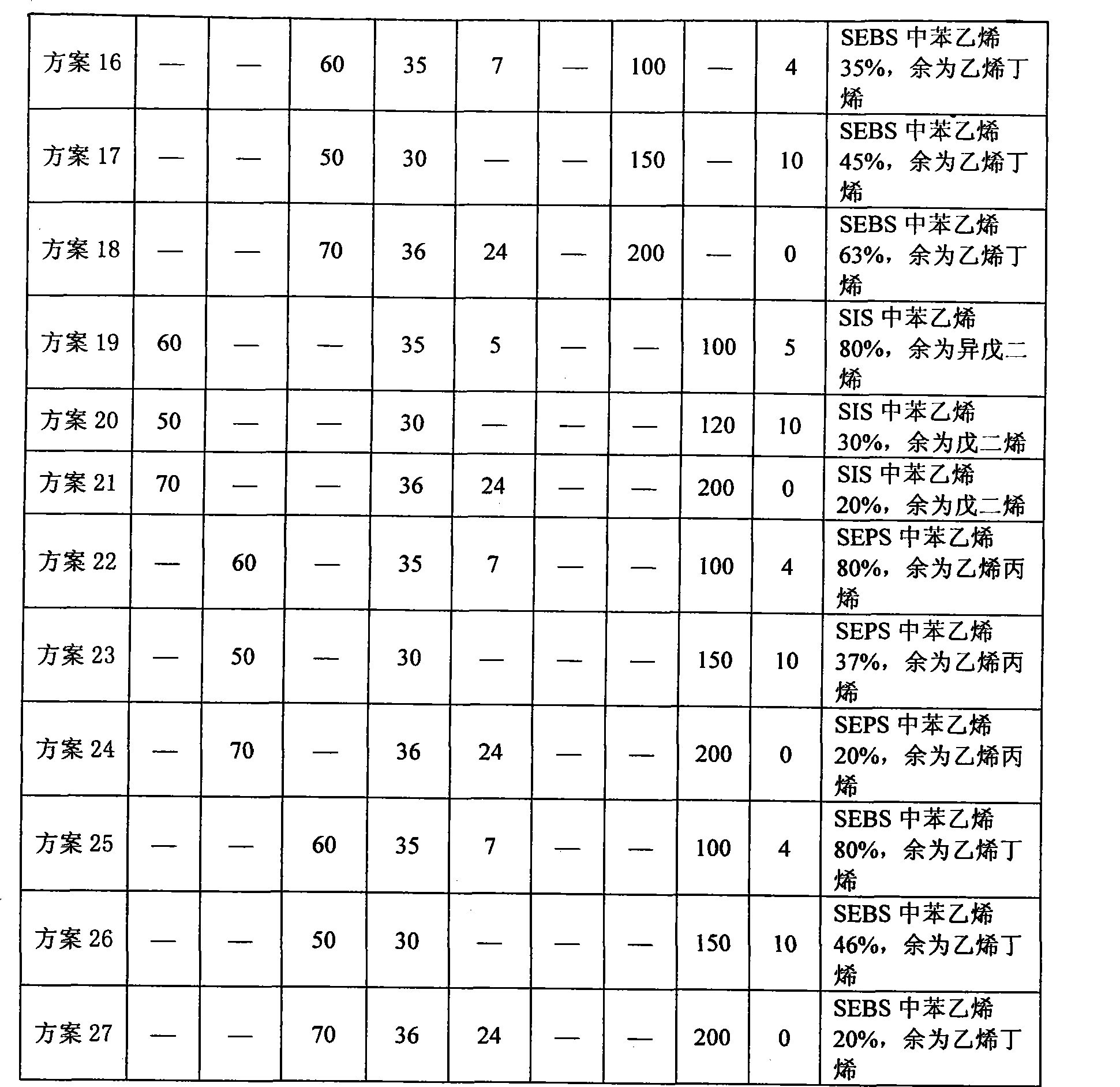

Leakproof tire and preparation method thereof

InactiveCN101480903ANormal tire pressureNo air leakageTyre partsRolling resistance optimizationForeign matterElastomer

The invention relates to an anti-leakage tyre and a production method thereof, belonging to the technical field of vehicle tyres. The anti-leakage tyre comprises a tyre surface, a tyre shoulder and a coating layer in the tyre, and is characterized in that the coating layer in the tyre is formed by solidifying elastomer materials in a gel state, and the elastomer materials in a gel state are mainly formed by mixing following raw materials by weight: 50 to 70 portions of thermoplastic elastomer, 100 to 200 portions of softening oil, 30 to 60 portions of perduren powder and 0 to 10 portions of resin. The coating layer in the anti-leakage tyre cannot be softened to flow into a conglobation at higher ambient temperature or during high-speed driving of the tyre or the increase of heat accumulation temperature. The anti-leakage tyre can keep elasticity at lower temperature and has good self-sealing effect. When the tyre is broken by unctuous foreign matters at normal temperature, the tyre cannot leak and can be continuously used, thereby being safe and convenient.

Owner:刘锦磊

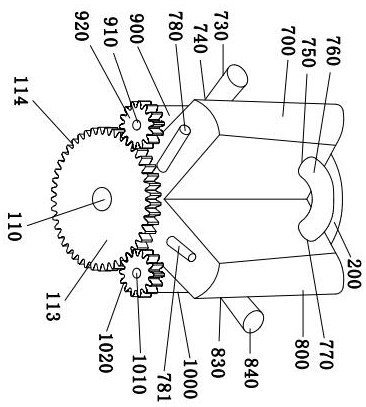

Differential lock assembly

InactiveCN101634358ANo air leakageNo sticking phenomenonDifferential gearingsControl devicesEngineeringPiston

The invention discloses a differential lock assembly, which consists of a shifting fork, a shifting fork shaft, an air cylinder and a piston. A small end of the shifting fork shaft is provided with an O-shaped sealing ring, passes through the piston, is locked by a small hexangular groove-shaped flat nut, and is fixed by an elastic cylindrical pin; the shifting fork shaft in an inner cavity of the piston is provided with two return springs; the inside of a cylindrical groove at the right end of the piston is provided with a leather cup; the left end of the shifting fork shaft passes through a base and is sleeved with the shifting fork; the air cylinder sleeves the piston in the inner cavity; and a connecting position of the cylindrical surface at the left end of the air cylinder and the base is provided with an O-shaped sealing ring. When performing gas tightness check under 0.35-0.8MPa, the differential lock assembly has no gas leakage; the shifting fork has flexible action and return, no blockage phenomenon, and working effective stroke more than 20; and the differential lock assembly meets various technical indexes, and ensures product quality.

Owner:鞠小平

Preparation method of vacuum heat-insulation material used at high temperature of 1,000 to 2,200DEG C

ActiveCN105198468ANo air leakageDense surfaceThermal insulationPipe protection by thermal insulationCarbon fibersSilanes

The invention discloses a preparation method of a vacuum heat-insulation material used at the high temperature of 1,000 to 2,200DEG C. The preparation method comprises the following steps of firstly, winding a carbon fiber casing on the outer surface of a core material of a low-heat-conduction-coefficient material to form a prefabricated member; secondly, placing the prefabricated member into a vacuum chemical vapor deposition furnace; enabling the casing to be turned into a C / C composite material framework by using a chemical vapor infiltration method, sequentially introducing chloromethylsilane, dichloromethylsilane and trichloromethylsilane; infiltrating carbon and silicon generated by decomposing silicane into the C / C composite material framework by the chemical vapor infiltration method; fully densifying the casing to obtain a test piece. The material prepared by the preparation method has no air leakage phenomenon, is dense in surface and is free from defects; in a process of low pressure chemical vapor infiltration, the inside is enabled to reach the vacuum state while an outer-layer structure is densified, and no after treatment is needed.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

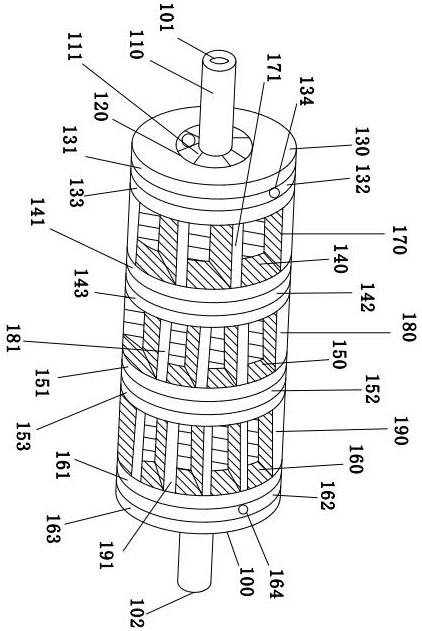

High-efficiency multistage demister

The invention discloses a high-efficiency multistage demister. The high-efficiency multistage demister comprises a plurality of demisting components; each demisting component comprises a gas riser pipe and an outer barrel; the outer barrel is arranged on the outer side of the gas riser pipe and located on the same axis as the gas riser pipe; the inner surface of the outer barrel is provided with spiral fins; the gas riser pipe is fixed on a tray; the top of the gas riser pipe is provided with a sealing cover; and a rectifying passage is arranged on the circumference of the gas riser pipe. Thedemister of the invention realizes the separation of droplets from gas by rectification, acceleration and scraping effect in the flowing process of fluids. The demister of the invention has the advantages of simple structure, convenient installation and small possibility of scale formation, and can effectively realize gas-liquid separation and reduce entrainment of mist.

Owner:CHINA PETROLEUM & CHEM CORP +1

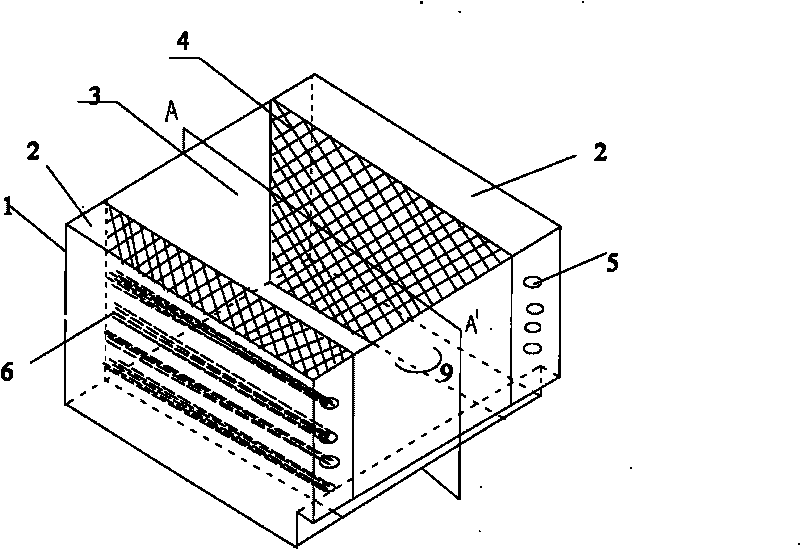

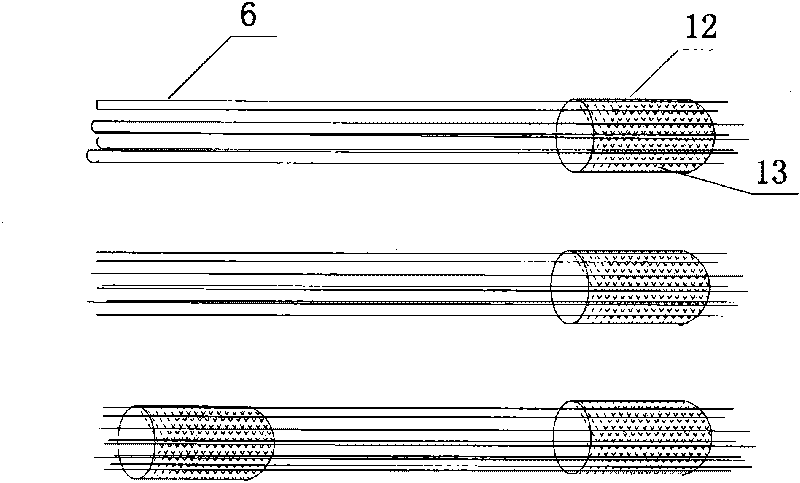

Membrane oxygenation type container for transporting aquatic living bodies

InactiveCN101731175AImprove survival rateGuaranteed dissolved oxygenPisciculture and aquariaFiberAquatic product

The invention discloses a membrane oxygenation type container for transporting aquatic living bodies, comprising a box body on which a sealing cover, a water inlet pipe and a water outlet pipe are arranged. The membrane oxygenation type container for transporting aquatic living body is characterized in that the box body mainly comprises an oxygen supplying area and a fish culturing area which are separated from each other by a grid-like partition board, the oxygen supplying area is arranged on the side of the box body, at least one hollow fiber is laid in the oxygen supplying area, the wall of the hollow fiber is provided with micropores, one end of the hollow fiber penetrates through an air inlet hole so as to be connected with an outside oxygen supplying pipe, and a sealing device is fixed between the outer wall of the hollow fiber and the air inlet hole. Adopting the membrane oxygenation, the membrane oxygenation type container for transporting aquatic living body can realize the bubble-free oxygen supply, improve the oxygen dissolving efficiency, ensure the waterbody oxygen dissolving degree during the transportation of the aquatic living bodies and provide the environment suitable for the aquatic living bodies to live, thereby greatly improving the survival rate of the aquatic living bodies.

Owner:NINGBO UNIV

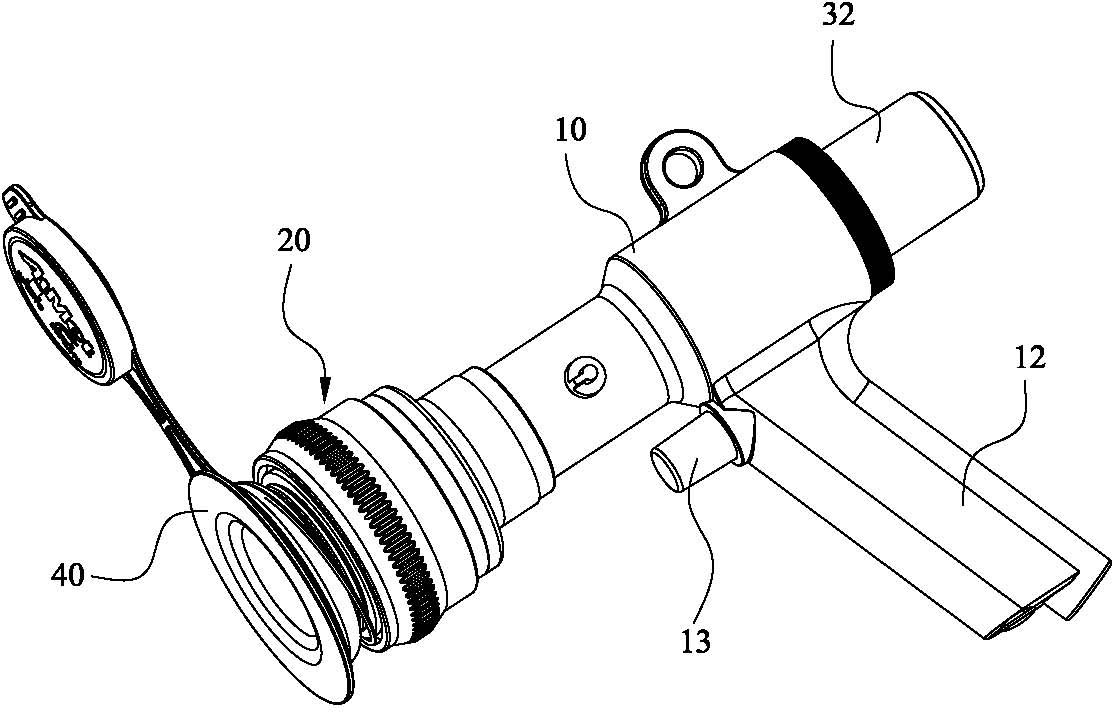

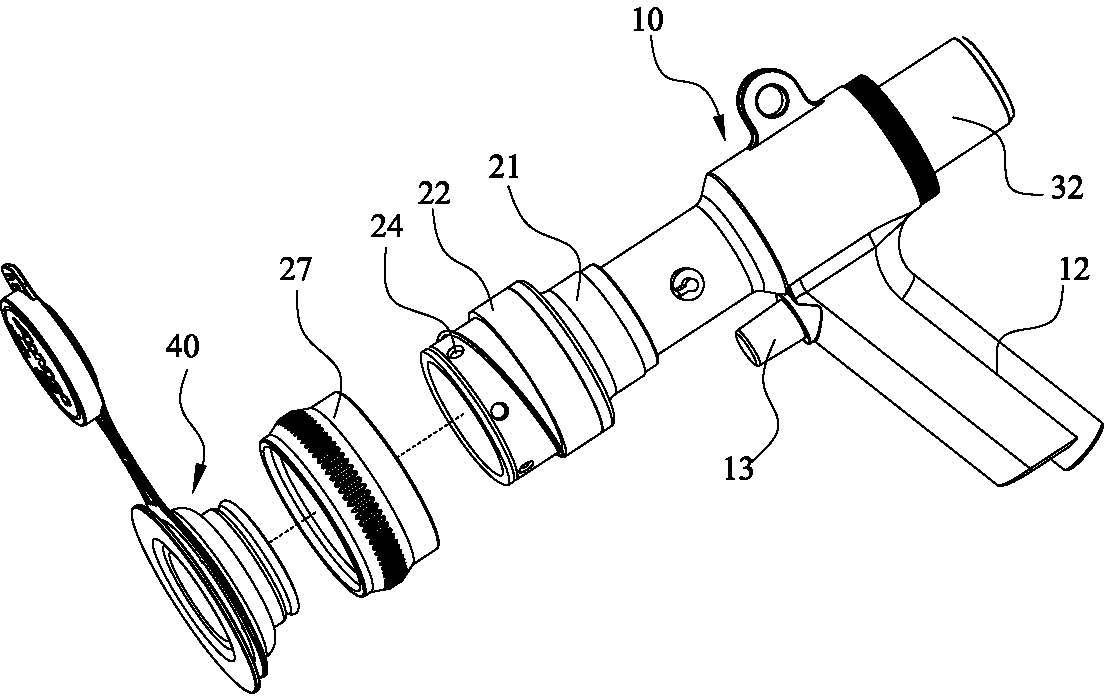

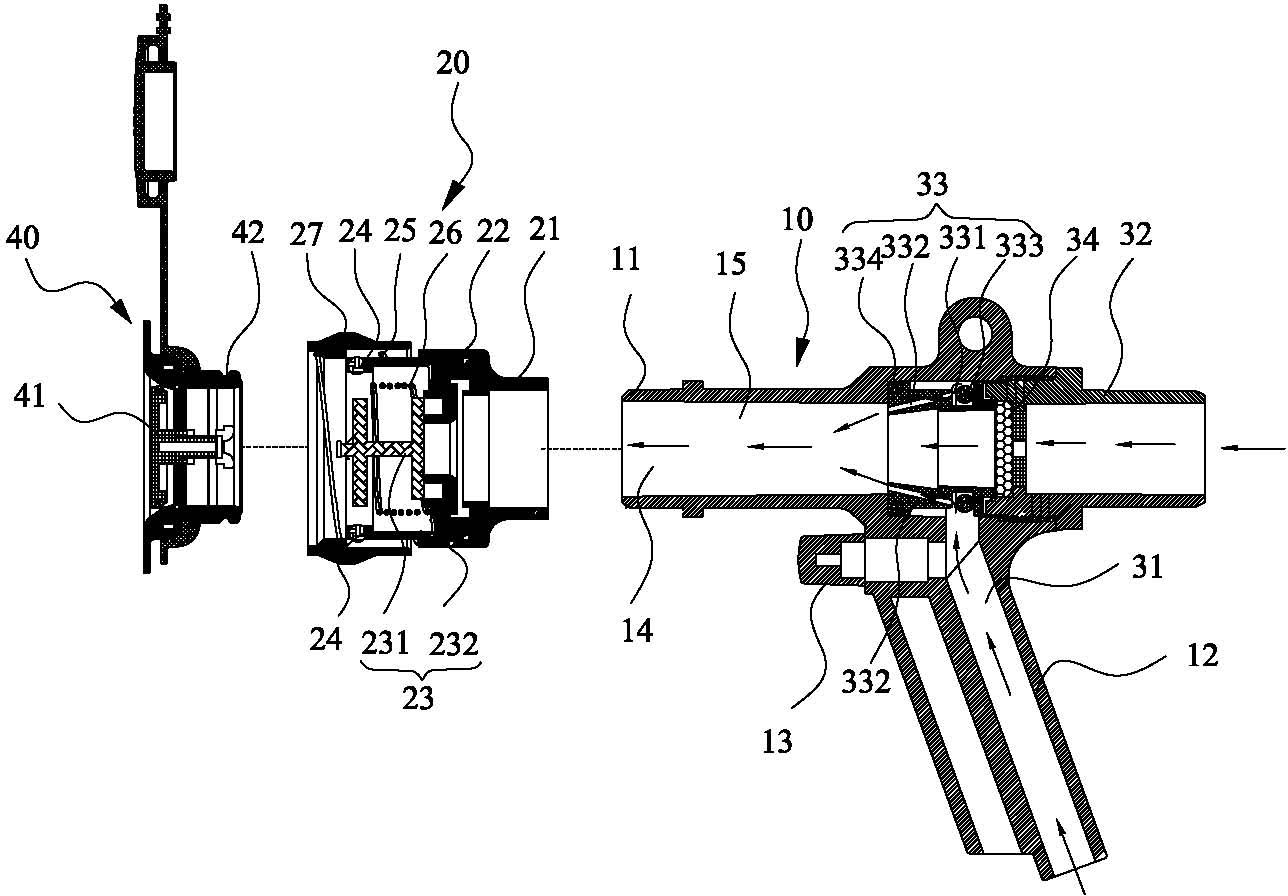

Rapid inflation gun

InactiveCN102352956AFast inflationImprove inflation efficiencyCheck valvesCouplingsEngineeringInlet channel

The invention discloses a rapid inflation gun, which comprises a gun body, a first air inlet pipe, a second air inlet pipe, an air source collector and an air outlet, wherein the first air inlet pipe is arranged in the gun body, and is connected with external active air supply equipment; the second air inlet pipe is communicated with external atmospheric air; the air source connector is arranged in the gun body; the air outlet is formed at the other end of the gun body; the air source connector is provided with a passive air inlet channel and an active air inlet channel for bringing atmospheric air of the passive air inlet channel to the air outlet; the active air inlet channel is communicated between the first air inlet pipe and the air outlet; and the passive air inlet channel is communicated between the air outlet and the second air inlet pipe. When air is supplied to the first air inlet pipe, external atmospheric air can be brought into the inflation gun through the second air inlet pipe, so that the inflation amount is multiple times of the air source supply amount within the same inflation time, and the high inflation speed and high efficiency are achieved.

Owner:上海奥特玛特物流设备有限公司

High-efficiency defogging device

ActiveCN108499227ASimple structureSmall pressure dropDispersed particle separationProduct gasEngineering

The invention discloses a high-efficiency defogging device. The high-efficiency defogging device comprises a plurality of parallel defogging components; each defogging component comprises a gas riserpipe and an outer barrel; the outer barrel is arranged on the outer side of the gas riser pipe and located on the same axis as the gas riser pipe; the gas riser pipe is axially divided into an upper part and a lower part, the upper part is a gas riser pipe I, the lower part is a gas riser pipe II, the gas riser pipe II is fixed on a tray, and the gas riser pipe I and the gas riser pipe II are connected with each other by a bearing; the top of the gas riser pipe I is provided with an upper capping plate; the gas riser pipe I is circumferentially provided with a plurality of slits; and vanes arecircumferentially arranged on the gas riser pipe I at positions close to the slits. The high-efficiency defogging device of the invention realizes the separation of droplets from gas by multiple baffling, acceleration and scraping effect in the flowing process of fluids. The high-efficiency defogging device of the invention has the advantages of simple structure, small pressure drop, small possibility of scale formation, convenient installation, reduced mist entrainment and capacity of effectively realizing gas-liquid separation, and is especially applicable to occasions with large gas flow fluctuations.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound vacuum glass

The invention discloses compound vacuum glass, comprising upper-layer flat plate glass, lower-layer flat plate glass and toughened glass, wherein the lower-layer flat plate glass is arranged between the upper-layer flat plate glass and the toughened glass; the vacuum glass is formed by the upper-layer flat plate glass and the lower-layer flat plate glass; the lower-layer flat plate glass is exposed from the peripheries of the upper-layer flat plate glass and the toughened glass; a plurality of supporting columns, which are uniformly arrayed, are arranged between the upper-layer flat plate glass and the lower-layer flat plate glass; a connecting piece made of the glass is spliced between the peripheries of the upper-layer flat plate glass and the toughened glass; the connecting piece is stuck with the upper-layer flat plate glass and the toughened glass through a photosensitive adhesive, so that the upper-layer flat plate glass and the toughened glass are firmly sealed together and a phenomenon of leaking gas is not generated; gas and water cannot enter a hollow layer and water fog is not generated, so that the visual effect is good; and each part of the compound vacuum glass has one color and the vision effect is good.

Owner:WEIFANG YATONG GLASS PRODS

Water absorption rake structure of automatic ground washing machine

ActiveCN105125145AEasy to assemble and disassembleNo air leakageMachine detailsFloor-scrubbing machinesFluoroplastStructural engineering

The invention discloses a water absorption rake structure of an automatic ground washing machine. The water absorption rake structure of the automatic ground washing machine comprises a front pressing bar, a front rubber sheet, a main body support, a rear rubber sheet and a rear pressing bar which are sequentially arranged in the front and rear direction. The main body support comprises an upper side plate and a lower side plate, the front side face and the rear side face of the lower side plate are each provided with inserting connection heads, and the front pressing bar, the front rubber sheet, the rear rubber sheet and the rear pressing bar are each correspondingly provided with inserting holes matched with the inserting connection heads; the main body support further comprises a seal plate which is arranged under the lower side plate and used for preventing air leakage occurring between the inserting connection heads and the inserting holes in the water absorption process of the water absorption rake. Due to the fact that the sealing plate is additionally arranged, in the water absorption process of the water absorption rake, the air leakage does not occur between gaps of the inserting connection heads and the inserting holes, and the water absorption capacity of the water absorption rake is improved; meanwhile, the main body support is made of ferrous materials coated with fluoroplastic, and the main body support is low in manufacturing cost, good in anti-corrosion effect and long in service life.

Owner:张家港高格清洁设备有限公司

Horizontal push-flow anaerobic dry fermentation device and process for organic waste

PendingCN108660075AReduce heat consumptionIncrease gas production rateBioreactor/fermenter combinationsBiological substance pretreatmentsDry matterBiogas

The invention relates to a horizontal push-flow anaerobic dry fermentation device and process for organic waste, and belongs to the technical field of anaerobic fermentation. The concentration of drymatter in a tank can be increased to 30%-60%, heat consumption is effectively reduced, and gas production rate is increased. Water spraying pipes are arranged at a feed end and a discharge end of a pretreatment pool, a feeder is arranged at the discharge end of the pretreatment pool and communicated with feed ports of an anaerobic fermentation tank, discharge ports of the anaerobic fermentation tank are communicated with inlets of pressers, a conveyor belt II is arranged in the position of the pressers and conveys biogas residues discharged from solid outlets of the pressers outwards, a biogasslurry tank conveys biogas slurry into a cow dung tank through a conveying pipe, the cow dung tank is communicated with inlets of the water spraying pipes, and a push-flow stirring shaft is arrangedin the anaerobic fermentation tank. The concentration of the dry matter inside can be increased to 30%-60% by the anaerobic fermentation tank, heat consumption is effectively reduced, the gas production rate is increased and the yield is increased.

Owner:黑龙江乾进能源科技有限公司

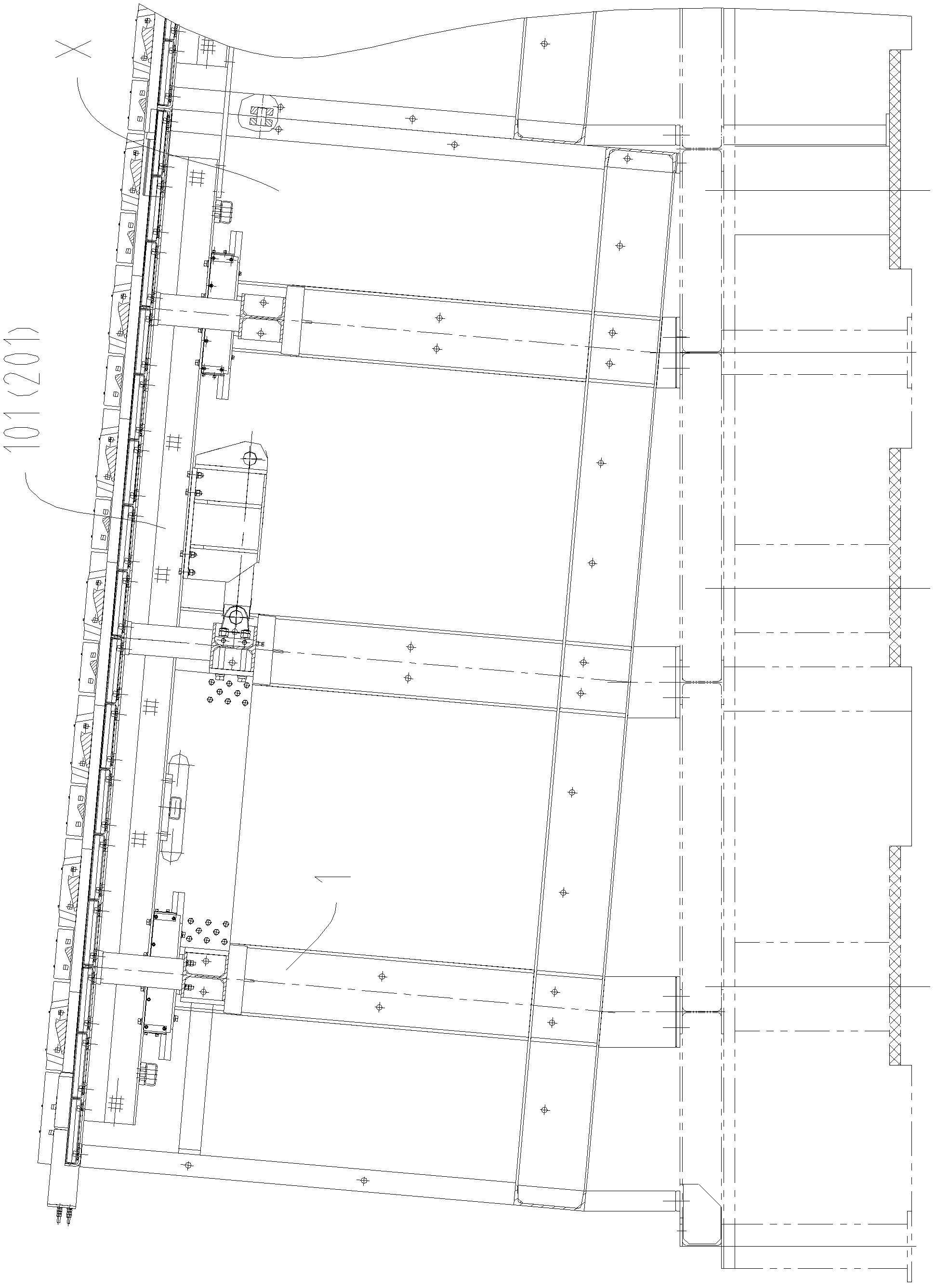

Carton taking method and device for ceramic tile packaging machine

The invention relates to a carton taking method and device for a ceramic tile packaging machine, belonging to the field of tile packaging machinery. Cartons are placed in a carton bin, the carton bin is arranged at one side of a tile packaging station, the carton is caught up and pulled backward to the tile packaging station by adopting a sucking disc, then the carton is placed down, and the carton taking device is characterized in that the cartons are placed at least two side positions of the tile packaging station, the cartons are vertically placed in the carton bin, the headmost carton is caught up by adopting the sucking disc, then the sucking disc moves toward the direction far away from the carton bin while the sucking disc rotates around the rotating shaft of the sucking disc, when the sucking disc rotates to a horizontal position, the sucking disc cuts off gas, and the cartons fall onto the tile packaging station. A carton taking process in the invention is reliable, the cartons can not deviate, the defect that the cartons are instantly blocked after being pulled out can be avoided, construction of equipment is greatly simplified, and occupying area and occupying length of equipment are reduced.

Owner:山东润科机电设备有限公司

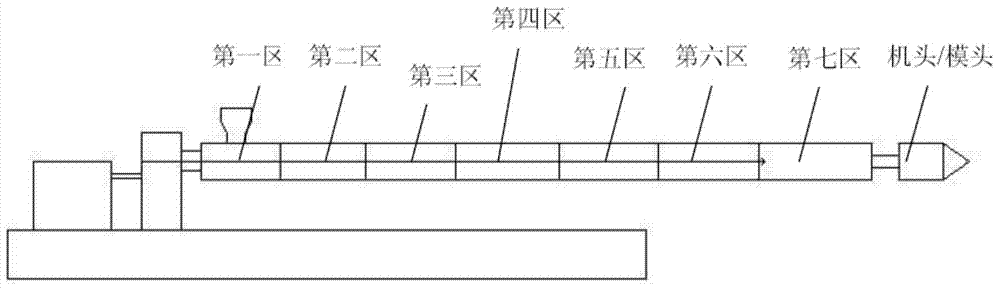

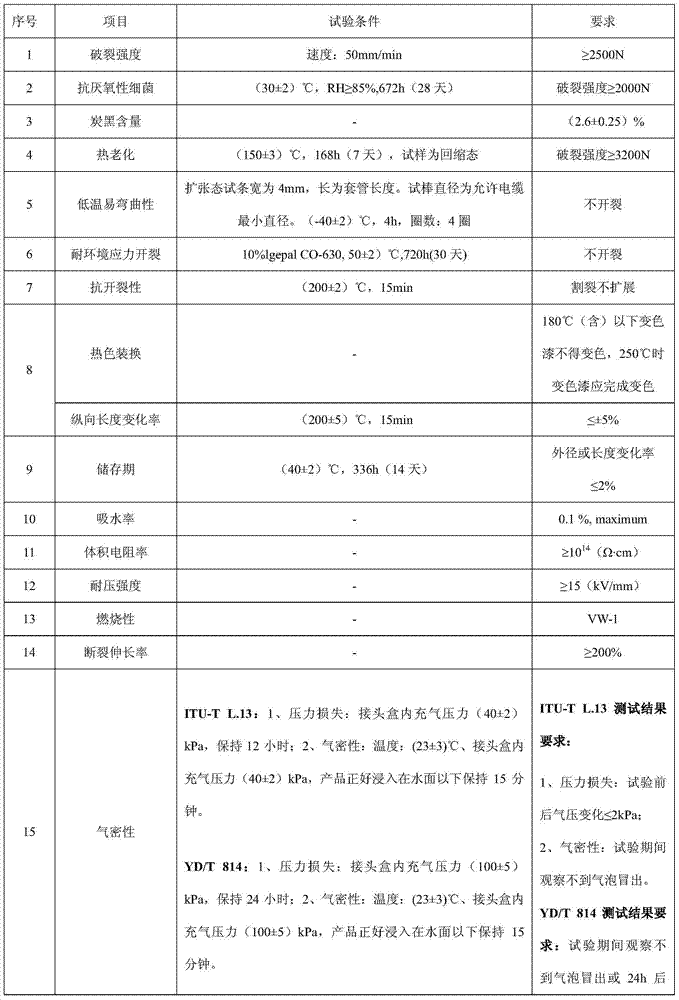

Diesel and kerosene resistant high-shrinkage heat-shrinkable tube for optical fiber splicing and sealing and preparation method thereof

ActiveCN103897243AAffect the transmission effectNo air leakageRigid pipesAdhesivesPolyolefinKerosene

The invention provides a diesel and kerosene resistant high-shrinkage heat-shrinkable tube for optical fiber splicing and sealing and a preparation method thereof. Firstly a formula of a radiation crosslinking polyolefin base material is broken through, high density polyethylene with high mechanical strength and high crystallization property is selected as a main ingredient, a small amount of flexible medium density polyethylene with excellent low temperature performance and linear low density polyethylene with good processability are taken as auxiliary materials, and working procedures such as preparing, mixing, pelletizing by extrusion, sheet extruding and irradiating are carried out, so that the heat-shrinkable tube is obtained. The heat-shrinkable tube can realize the shrinkage requirement reaching 6 times according to deviation between an optical fiber splice closure and the diameter of an optical fiber and can be used normally after being soaked by diesel and kerosene for a long time.

Owner:CYG CHANGTONG NEW MATERIAL

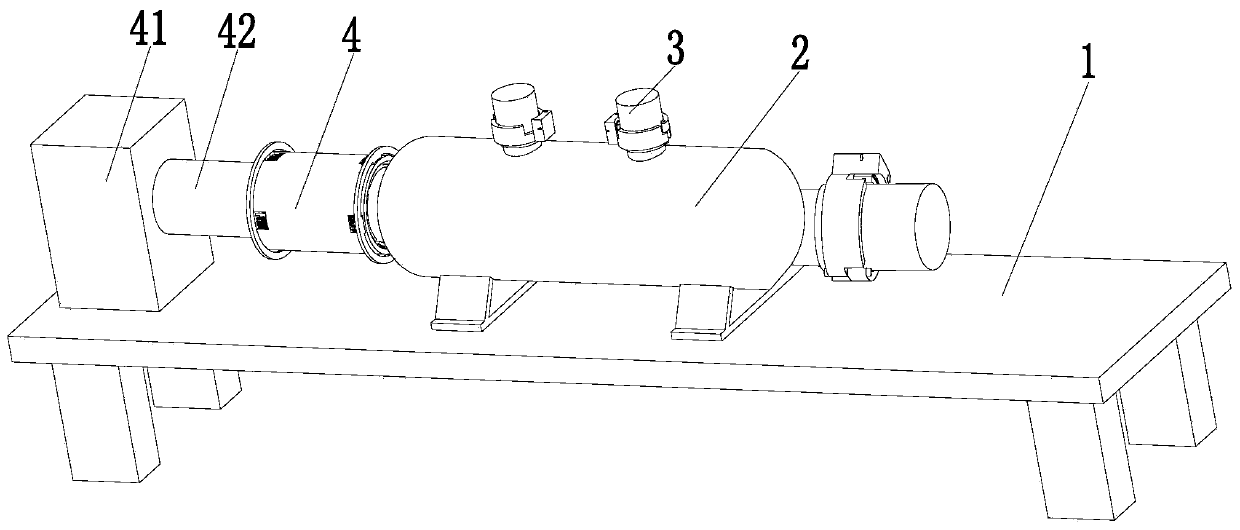

Airtightness detection system of pressure vessel

InactiveCN111337199AReduce laborEasy to useDetection of fluid at leakage pointEngineeringAir tightness

The invention relates to an air tightness detection system for a pressure vessel. The system comprises a test platform, a pressure vessel body, a sealing device and a gas transmission device, and thepressure vessel body is placed on the test platform. The gas transmission device is arranged on the test platform; the upper end of the pressure vessel body is connected with the sealing device. According to the invention, the following problems existing in air tightness detection of a conventional pressure vessel can be solved: a, gas is introduced into a pressure container for detection in mostmethods adopted at the present stage, but often inaccurate detection results exist due to the fact that the leaked gas affects the judgment of detection personnel due to improper sealing treatment ata joint; and b, when the air tightness of the existing pressure vessel is detected, a clamping tool at the interface of the pressure vessel is complex in structure and inconvenient to use and maintain. The air tightness detection system can be suitable for detecting a large batch of pressure vessels, the detection effect can be ensured, and the labor amount of staff is reduced.

Owner:张康乐

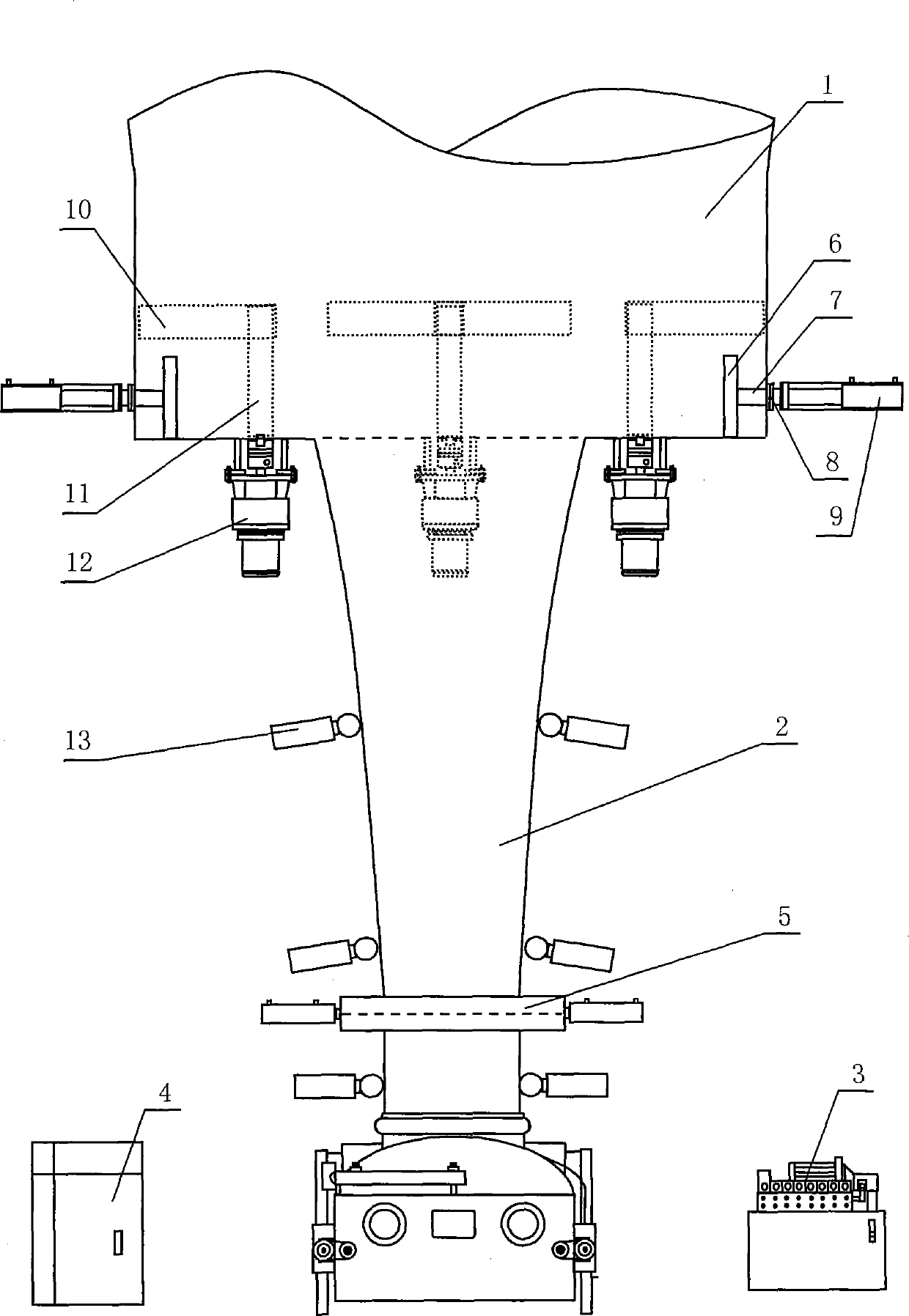

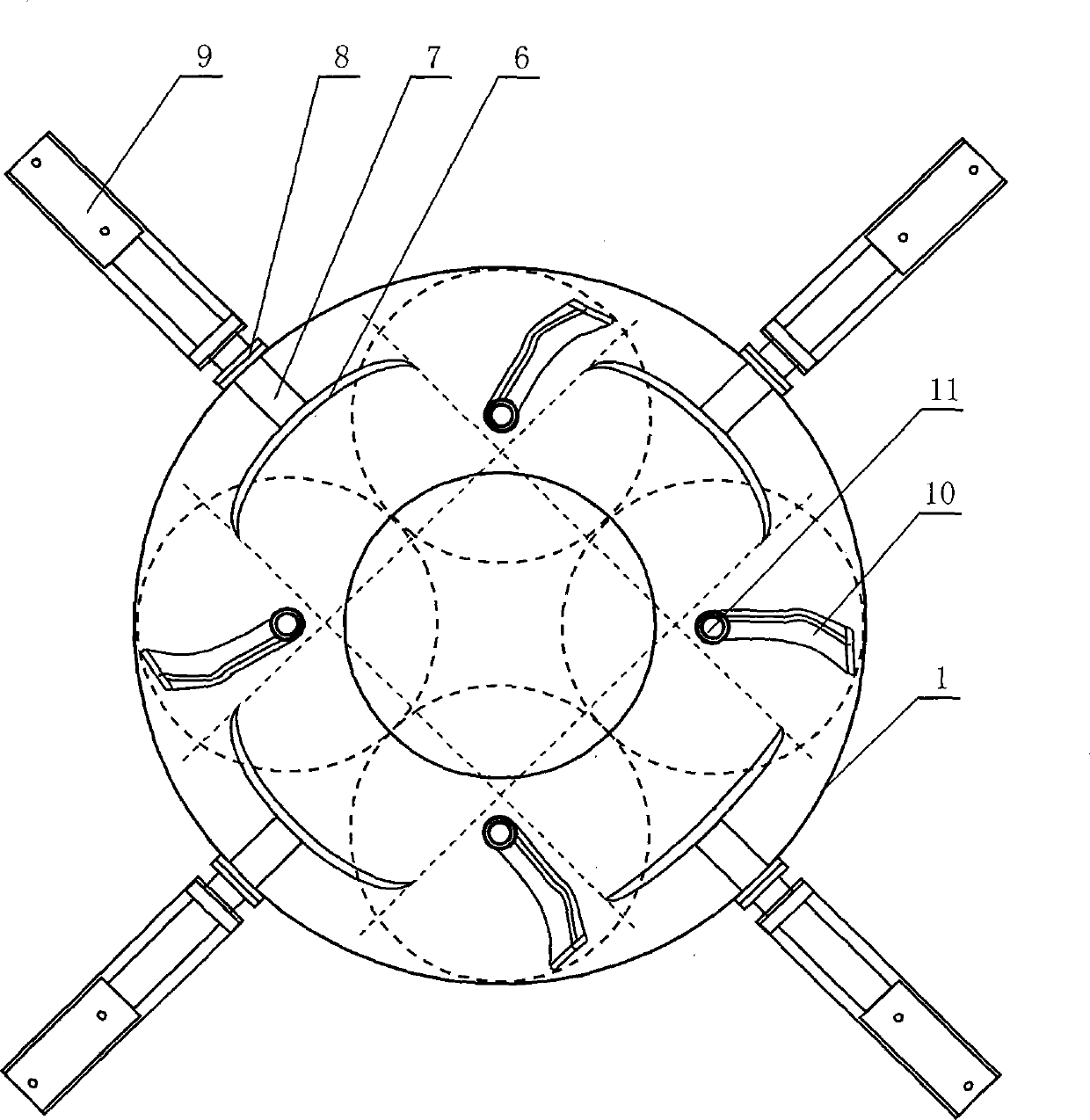

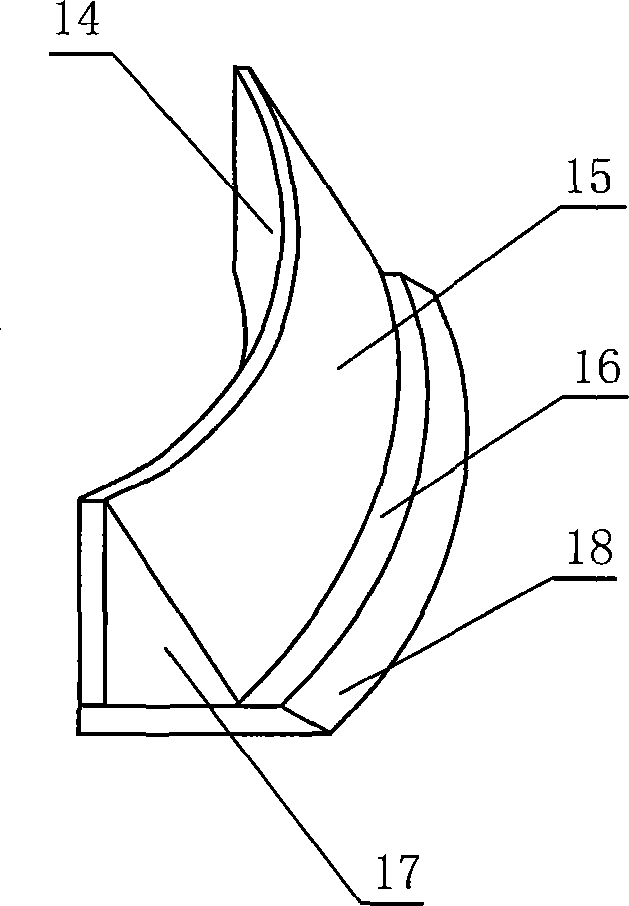

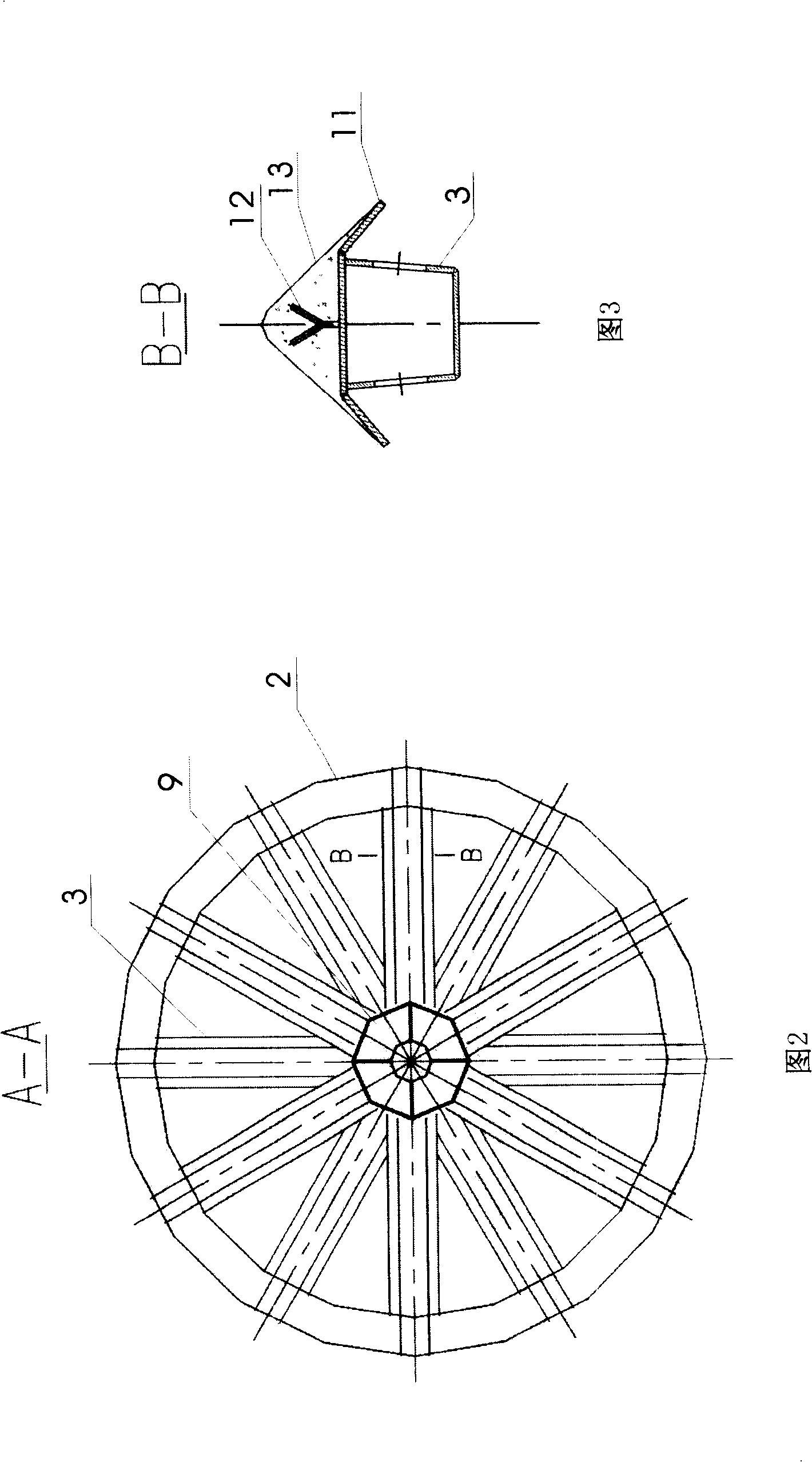

Integrated central feeder

ActiveCN103129980ASolve the blockageSolve a series of problems such as poor coal loadingLarge containersLoading/unloadingEngineeringEnergy consumption

The invention discloses an integrated central feeder which solves the problem that existing devices are huge in structure and large in energy consumption. The integrated central feeder is characterized by comprising a straight-barrel feeding bin, a central discharging pipe, a hydraulic oil station and four hydraulic pushing devices, wherein the hydraulic pushing devices are uniformly arranged around a lower wall of the straight-barrel feeding bin, each hydraulic pushing device comprises a pushing plate, a pushing rod, a sealer and an oil jack, the pushing plates are mounted on the pushing rods which penetrate through a wall of the straight-barrel feeding bin to be connected with piston rods of the oil jacks through the sealers, the oil jacks are fixed on the wall of the straight-barrel feeding bin, and each pushing plate comprises an arc-shaped plate, a wedge-shaped scraping plate, a straight-plate scraper and a retaining plate. The integrated central feeder is good in sealability, convenient to repair and maintain, low in energy consumption, supportive of automatic start during material blockage, reasonable in design, simple in structure, obvious in dredging effect, energy-saving, environment-friendly, high in adaptability, suitable for solving problems of blockage of a raw coal bin, unsmooth coal unloading and the like of a thermal power plant, and also suitable for storage bins for material conveying of other industries.

Owner:赵东楼

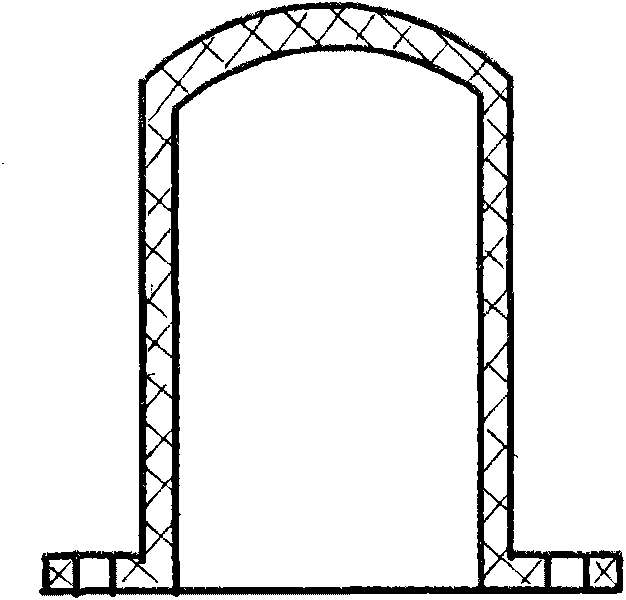

Composite material connecting structure for railway vehicle and forming method

The invention provides a composite material connecting structure for a railway vehicle and a forming method. The structure comprises a first top plate skin, a second top plate skin, a main beam carbonplate and a carbon fiber cover plate, wherein the first top plate skin and the second top plate skin are glued on the top surface of the main beam carbon plate; the first top plate skin is spliced with the second top plate skin; at least one row of holes located in the two sides of the splicing position are formed in the top face of the main beam carbon plate; the first top plate skin is providedwith at least one row of first through holes in one-to-one correspondence with the at least one row of holes in one side; the second top plate skin is provided with two rows of second through holes in one-to-one correspondence with the at least one row of holes in the other side; the first top plate skin and the main beam carbon plate are riveted with the corresponding holes through the first through holes, and the second top plate skin and the main beam carbon plate are riveted with the corresponding holes through the second through holes; and the carbon fiber cover plate is arranged on theouter surface of the splicing position of the first top plate skin and the second top plate skin in an adhesive covering mode. The connecting structure can adapt to connection of rail vehicle composite materials, and the air tightness and the structural strength of connection can be guaranteed.

Owner:CRRC QINGDAO SIFANG CO LTD

Girder-like even wind radiator

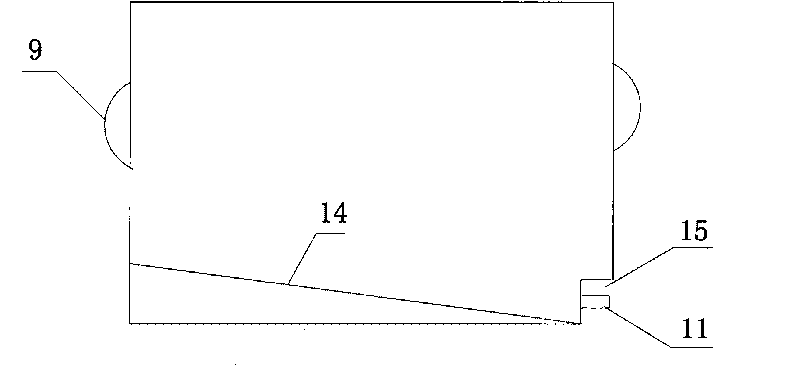

InactiveCN101245970ASimple structureReduce weightRotary drum furnacesCooling effectDistribution system

The invention discloses a beam-typed uniform wind cooler, comprising a connecting cover (1), a mainbody device (2), a wind distribution system, a pipeline system, a fan (8), a material hopper (5) and a material outlet device (7). The connecting cover (1) is connected with the kiln head cover of a rotary kiln and the mainbody device (2) of the cooler. The mainbody device is internally provided with the wind distribution system which is connected with the fan (8) by the pipeline system. The lower part of the mainbody device is the material hopper (5). The bottom of the material hopper (5) is connected with the material outlet device (7). The wind distribution system comprises a wind cap (9) and a wind distribution beam (3). The wind cap (9) is positioned at the central position of the cooler, and a plurality of wind distribution beams (3) are arranged below the cooler. The wind distribution beams are radially arranged from the center of the mainbody device (2) to the internal wall and are provided with wind outlets. The beam-typed uniform wind cooler has the advantages of simple structure, light weight, easy manufacture, convenient installation and maintenance, being difficult to blocking the material, good cooling effect, low energy consumption, environmental protection, and can be widely applied to various industries.

Owner:CITIC HEAVY INDUSTRIES CO LTD

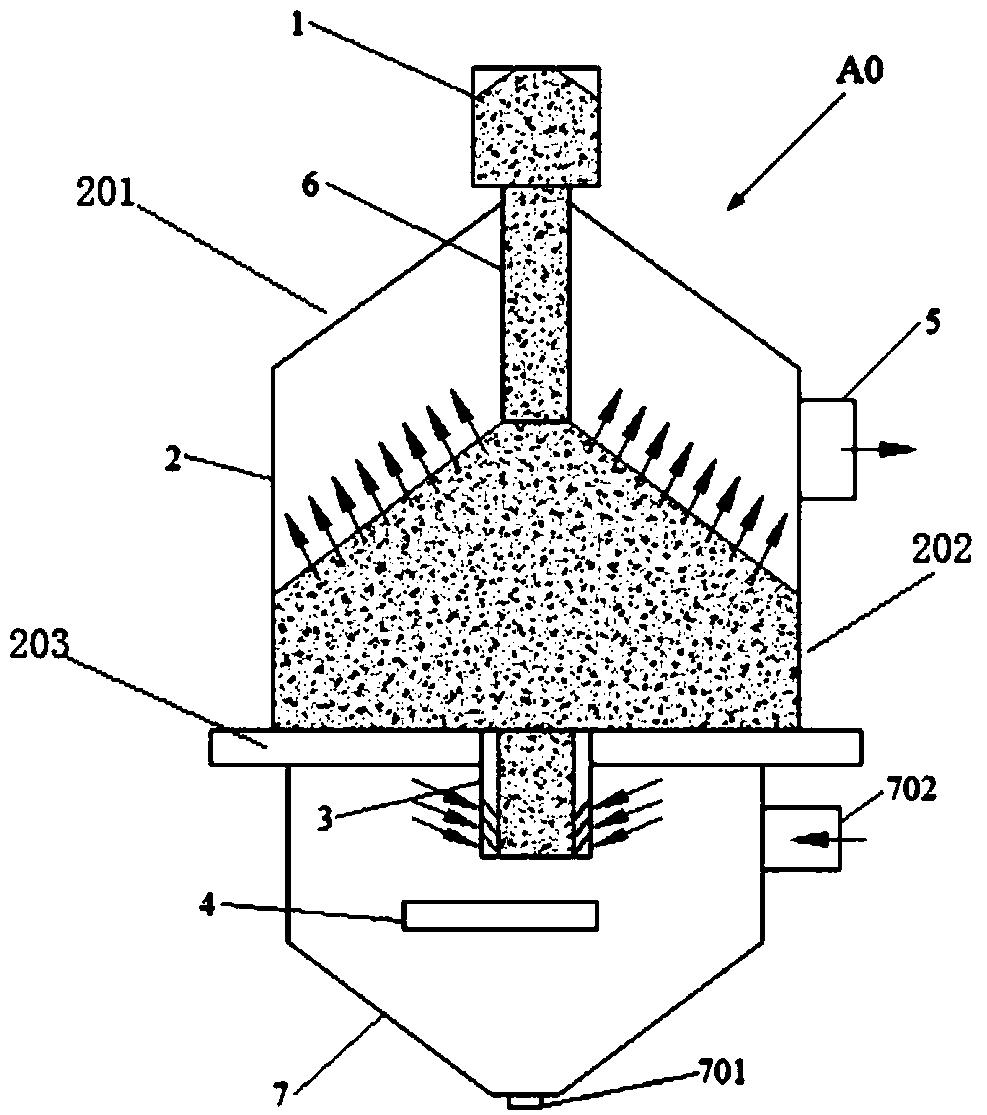

Vertical type sinter cooler and sinter cooling method

PendingCN108267019AImprove cooling effectRaise the hot air temperatureCharge treatment typeHandling discharged materialEngineeringMaterial distribution

The invention discloses a vertical type sinter cooler and a sinter cooling method. A plate type ore feeder unloading type vertical cooler comprises a material bin (1), a material distribution pipe (2), a tower, a plurality of discharge conical hoppers (5), an air ring (H), an air cap (M) and a hot air outlet (8). The tower comprises a tower top cover (3) and a tower wall (4). The discharge conicalhoppers (5) are located below the tower wall (4). The hot air outlet (8) is formed in the upper portion of the tower wall (4) or in the tower top cover (3). The top cover (3) is fixedly connected with the upper end of the tower wall (4). The material bin (1) is arranged above the top cover (3). The upper end of the material distribution pipe (2) is connected with the bottom of the material bin (1). The lower end of the material distribution pipe (2) stretches into the place below the top cover. The multiple discharge conical hoppers (5) are distributed annularly at the lower end of the towerwall (4) or are distributed evenly in the peripheral direction. A circle of fixed gap is formed between the lower portion of the tower wall and the tops of the multiple discharge conical hoppers (5) and serves as the air ring (H). The air cap (M) upwards stretching into the inner space of the tower is arranged in the bottom center of the tower, and a plate type ore feeder (12) is arranged below each discharge conical hopper (5).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Sintering ore air draft type circulating cooling system and process thereof

PendingCN109425231ASlow coolingImprove thermal efficiencyIncreasing energy efficiencyFurnace coolingCold airEngineering

Provided is a sintering ore air draft type circulating cooling system. The system comprises an air draft type vertical cooling furnace, a waste heat boiler and power generation system, a circulating exhaust fan, a hot air conveying channel and a cold air conveying channel, wherein the air draft type vertical cooling furnace comprises a material bin, a tower body, an air inlet discharging device, adischarging unit and a discharging chute; an air draft type hot air outlet is formed in the upper portion of the tower body; a cold air inlet is formed in the side wall of the discharging chute; theair draft type hot air outlet is connected with an air inlet of the waste heat boiler and power generation system through the hot air conveying channel; and an air outlet of the waste heat boiler andpower generation system is connected with a cold air inlet through the cold air conveying channel. The cooling system and a cooling process can effectively cool sintering ores and are low in air leakage, and at the same time, after cooling air is subjected to heat exchange with the sintering ores, waste heat can be totally used to achieve circulation.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

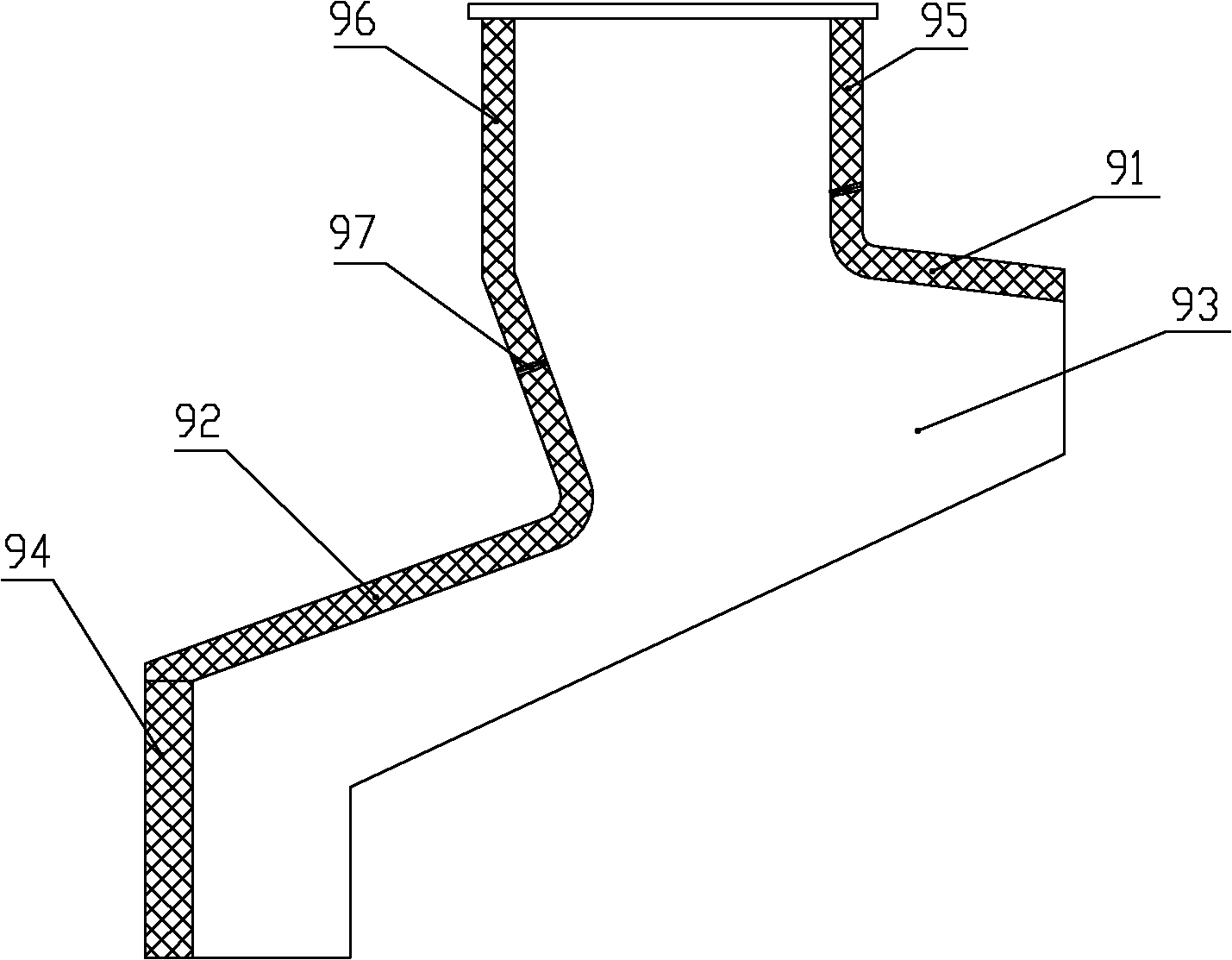

Non-equidirectional expansion membrane wall angle joint seal device

InactiveCN102353035AImprove working environmentGuaranteed uptimeFluid heatersSteam boilersEngineeringHearth

The invention relates to a non-equidirectional expansion membrane wall angle joint seal device, and relates to a membrane wall seal device, and the device is used for solving the problem of poor seal performance of a hearth because a front membrane water cooling wall and two side membrane water cooling walls of the existing boiler hearth have different expansion amount at high temperature, thus the welding lines of the front membrane wall cooling wall and two side membrane water cooling walls are disconnected. The device is positioned at the external part of two corners of the front side membrane water cooling wall of the boiler hearth, and comprises a plurality of steel connection pieces, namely a first steel connection piece, a second steel connection piece, a third steel connection piece, a fourth steel connection piece, a fifth steel connection piece and a sixth steel connection piece; a first empty cavity is defined by the first steel connection piece, the second steel connection piece, the third steel connection piece, a side membrane water cooling wall which is adjacent to the second steel connection piece in the two side membrane water cooling walls and the front membrane water cooling wall of the boiler hearth; and one end of the sixth steel connection piece is fixedly connected with the front membrane water cooling wall of the boiler hearth. The seal device provided by the invention is used for the seal of the boiler hearth.

Owner:HARBIN INST OF TECH

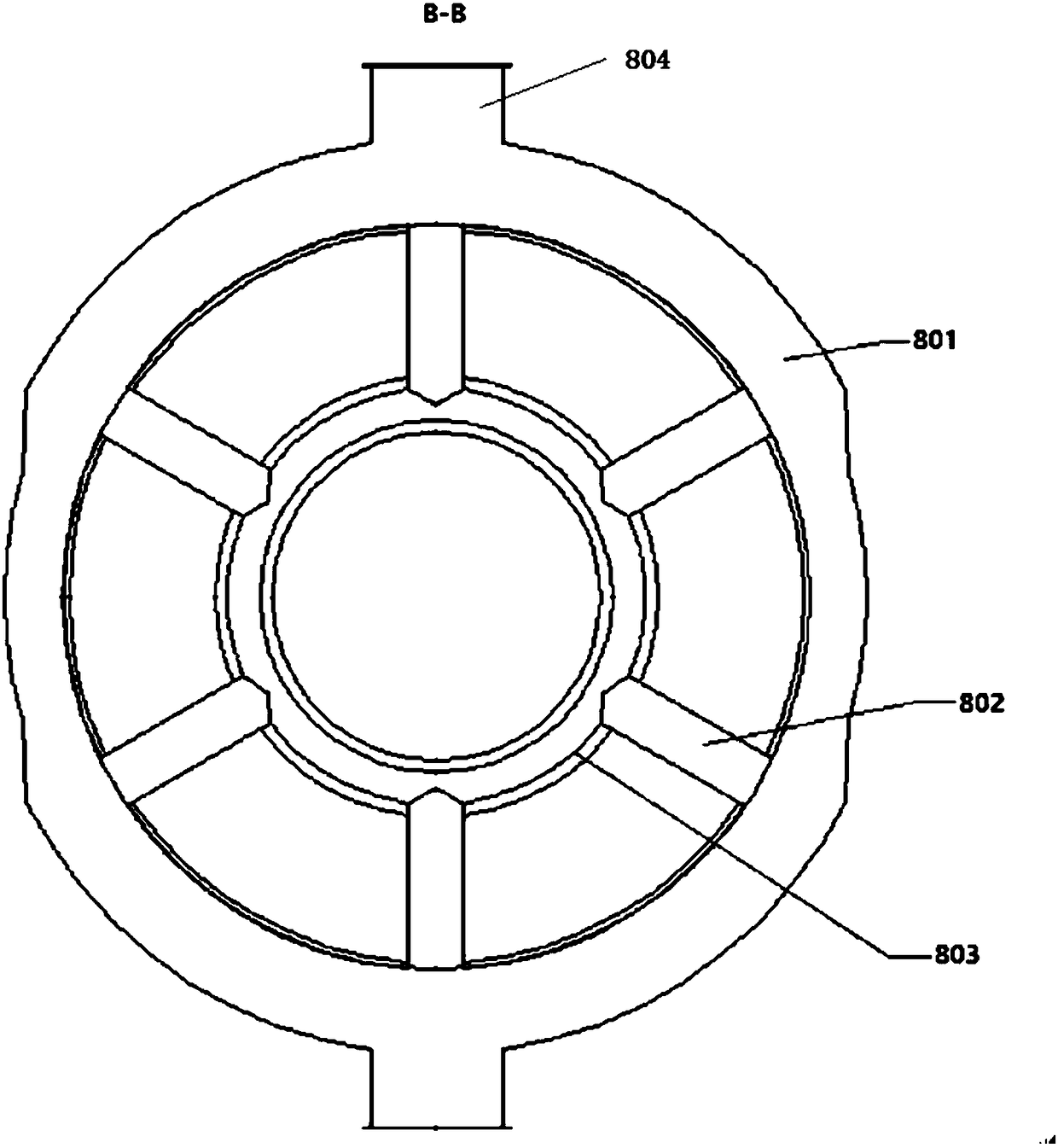

Valve structure and independent air-tight seal double-layer dust unloading valve

The invention relates to the technical field of metallurgical equipment, in particular to a valve structure and an independent air-tight seal double-layer dust unloading valve. A valve element of the double-layer dust unloading valve comprises an anti-leakage part on the upper layer, an air seal part on the lower layer and an elastic supporting part connected between the anti-leakage part and the air seal part. A valve body of the double-layer dust unloading valve comprises an inner base and an outer base. The inner base is connected to the inner wall of the outer base. The anti-leakage part is located below the inner base. The edge of the anti-leakage part makes contact with the inner base so as to cut off material flow. The air seal part makes contact with the outer base so as to cut off air flow. Corresponding functions of the anti-leakage part and the air seal part are independently brought into play, the air seal part is free of interference of solid materials even when the anti-leakage part is abraded or not well sealed due to other reasons, sealing is tight, and the whole valve body is high in air tightness, and air leakage is avoided.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

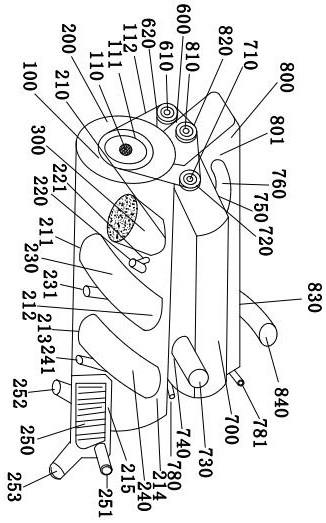

Auxiliary equipment of impeller cylinder combined engine

PendingCN113958408ALarge intake and exhaust volumeMeet gas supply requirementsRotary/oscillating piston combinations for elastic fluidsContinuous combustion chamberCombustion chamberHeat conservation

The invention discloses auxiliary equipment of an impeller cylinder combined engine. A cylinder is provided with a multi-stage air compressor for providing an air source for the engine and is provided with a high-pressure air storage tank; a first air injection hole outside the cylinder is provided with a heat preservation type combustion chamber and is connected with a group of air combustion switches for controlling; conditions are created for controlling the firepower and the air combustion ratio of the engine and doing work after air absorbs heat; one end of a first flow guide pipe and one end of a second flow guide pipe outside the cylinder are provided with a first flow guide branch pipe and a second flow guide branch pipe for heat preservation respectively; lubricating oil in the cylinder and the multi-stage air compressor is discharged into a first heat preservation type heat exchanger for heat exchange and then can be recycled; and a third exhaust hole outside the cylinder is provided with a second heat preservation type heat exchanger, and high-pressure air is subjected to heat absorption and pressurization by the two heat exchangers under the regulation and control of the air combustion switches and then returns into the cylinder through the two flow guide branch pipes for power assistance and work doing, so that the heat efficiency is higher. The heat engine belongs to an upgraded product of an internal combustion engine.

Owner:刘天锡

Grate cooler module of forming grate cooler

Owner:江苏羚羊机械有限公司

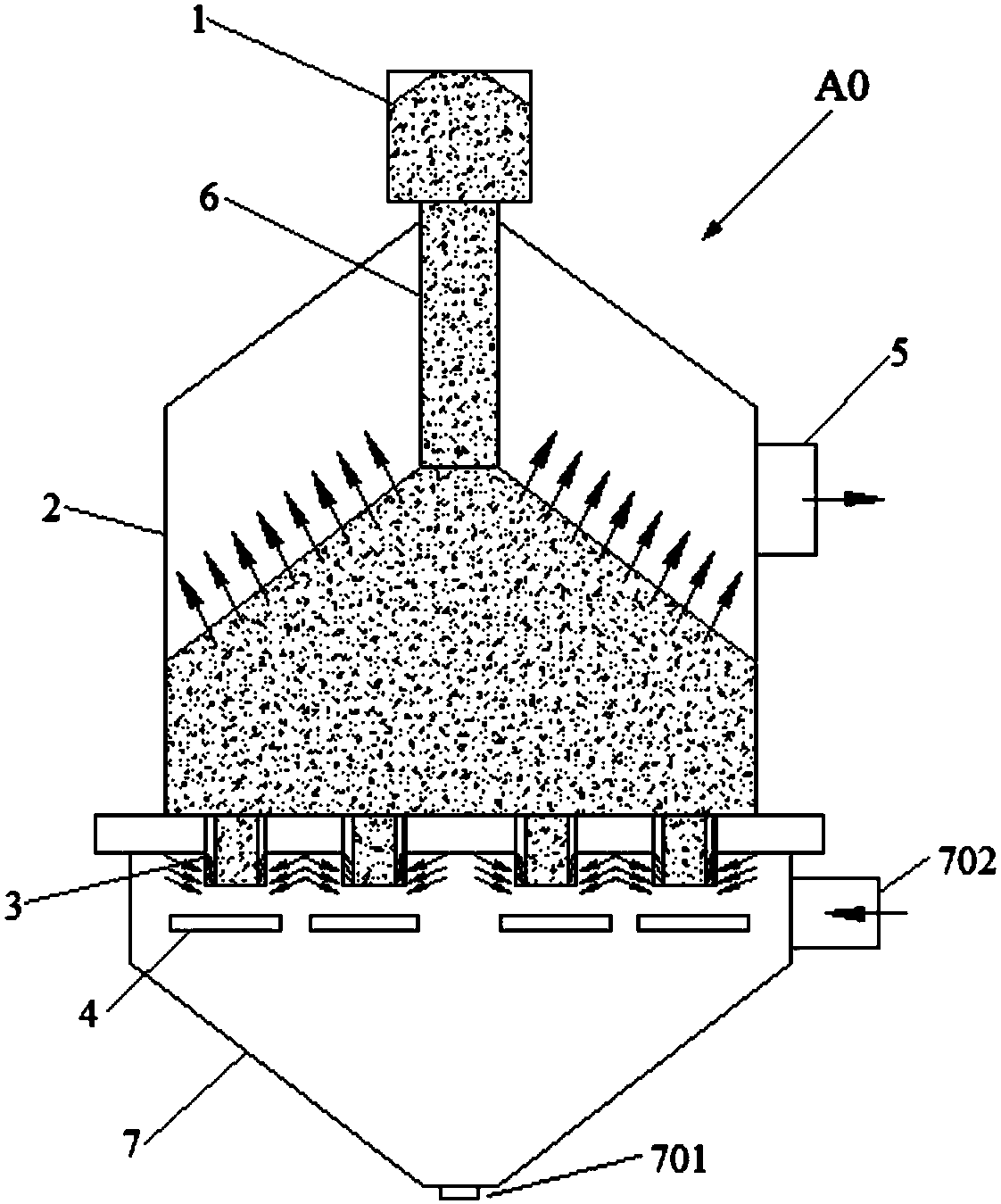

Vertical type sinter cooler with rotary distributing device and sinter cooling method

ActiveCN108955276ASimple structureImprove sealingIncreasing energy efficiencyHandling discharged materialTowerWaste management

A vertical cooling machine with a rotary distributing device comprises the rotary distributing device (1), an umbrella-shaped chute (2), vertical chutes (3), a tower body, a cooling section (6) and ahot air outlet (10), wherein the tower body is composed of a tower body top cover (4) and a tower body side wall (5), and the hot air outlet (10) is formed in the upper portion of the tower body top cover or the tower body side wall. The umbrella-shaped chute (2) comprises an upper overall section (201) and a lower separated section (202), the upper end of the overall section (201) is connected with the rotary distributing device (1), each branch of the lower separated section (202) is connected with one corresponding vertical chute (3) below, and a hot air channel (7) is formed above the cooling section (6) and in a gas space between the tower body and the vertical chutes (3). A uniform air inlet device (8) is arranged below the cooling section (6), and a plurality of discharging conicalhoppers (9) are arranged on the lower side of the uniform air inlet device (8). Discharging devices are arranged on the lower sides of the discharging conical hoppers (9). The vertical cooling machineis simple in structure, reliable in sealing and high in waste heat recovery efficiency.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method for manufacturing gas shutoff valve

The invention discloses a method for manufacturing a gas shutoff valve. The method includes steps of 1) extruding aluminum and forming; 2) cutting a blank piece; 3) processing; 4) cleaning; 5) assembling. The gas shutoff valve body is manufactured by extruding aluminum profile, so that the gas shutoff valve body is free of sand holes, the gas shutoff valve assembled by the gas shutoff valve body is good in air tightness and free of gas leak, potential safety hazards are eliminated, and safety is guaranteed. Furthermore, since the gas shutoff valve body is free of the sand holes, repair of the gas shutoff valve due to gas leak is greatly reduced, yield and production efficiency are improved, and social competitiveness of enterprises is enhanced.

Owner:谢启标

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com