Auxiliary equipment of impeller cylinder combined engine

A technology of auxiliary equipment and engine, applied in the direction of engine lubrication, mechanical equipment, engine components, etc., to achieve the effect of reducing heat conduction loss, large area and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

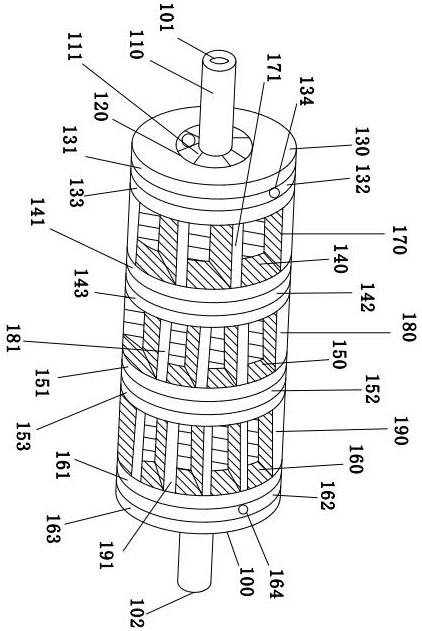

[0027] please see Figure 1-2, There are a plurality of connecting rods 111 connected to the inner peripheral surface of a cylindrical rotor 120 within the circumference of both ends of the main shaft 110 of the cylindrical impeller 100 . Both ends and the middle part of the rotor 120 are evenly provided with four annular partitions perpendicular to the rotor 120 , which are annular partition one 130 , annular partition two 140 , annular partition three 150 , and annular partition four 160 . Annular dividing plate one 130 outer edge two ends have retaining ring groove 131 and retaining ring groove 133, and in retaining ring groove 131 and retaining ring groove 133, the retaining ring that end has " Z " font groove is installed. There is also a first lubricating oil groove 132 between the gear ring groove 131 and the gear ring groove 133 . The two ends of the outer edge of the annular dividing plate 140 are provided with a retaining ring groove 141 and a retaining ring groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com