Explosion prevention back-fire relief type separator for water and vapor

A gas-water separator, explosion-proof technology, applied in separation methods, dispersed particle separation, fire rescue, etc., to ensure stability, easy implementation, and improve the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

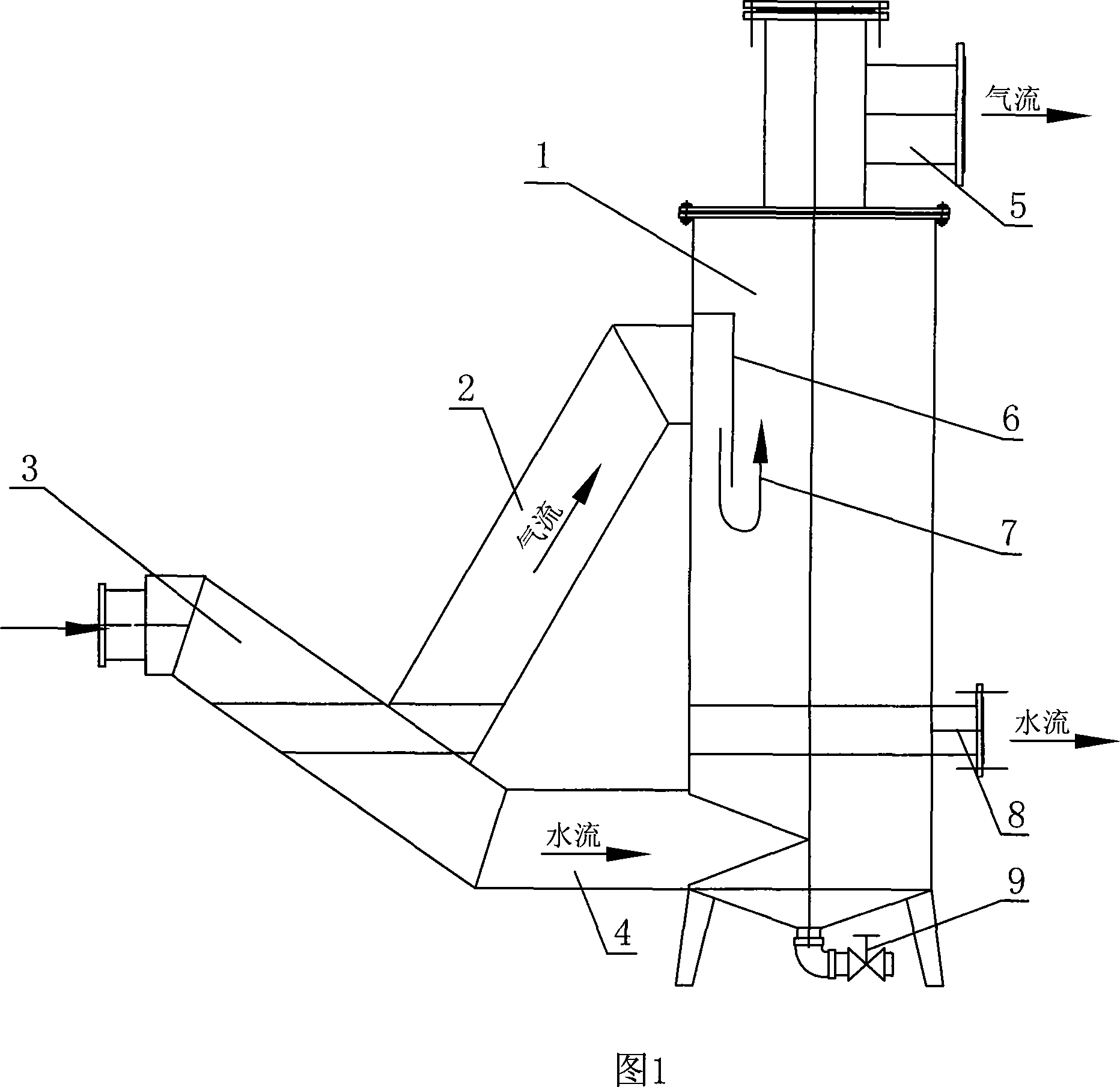

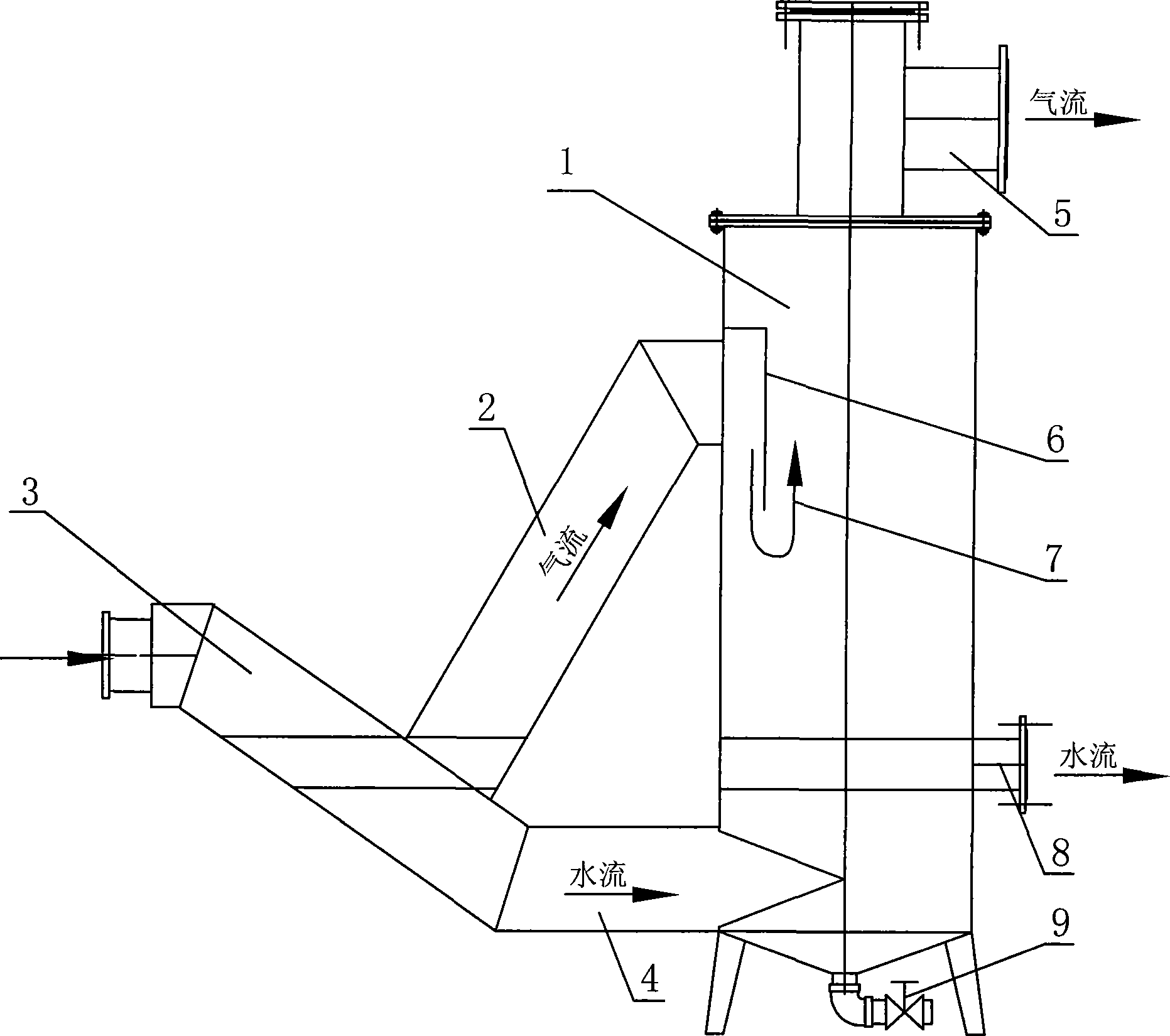

[0023] Referring to Figure 1, the gas-water two-phase mass flow input pipe 3 is arranged obliquely. The input pipe 3 enters the explosion-proof fire-proof gas-water separator buffer tank fire-stop tube 1 and is branched into two output channels, one of which is connected to the bottom. The water flow pipe 4 on the mouth, the other way is to be connected to the first-level dehydration air flow pipe 2 on its waist top;

[0024] An explosion-proof flame-retardant gas-water separator buffer tank fire arrester 1 is installed vertically, and the first-stage dehydration airflow pipe 2 is connected to the air inlet located on the upper side wall of the buffer tank fire arrester 1. On the inner side wall of the air inlet, a pair of inlet The first-stage dehydration airflow in the buffer tank fire arrester 1 forms a blocked second-stage dehydration baffle 6, which forms a second-stage dehydration airflow 7 after passing through the second-stage dehydration baffle 6; the water flow pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com