Double-layer air filter

An air filter, double-layer technology, applied in the field of vehicle air filters, can solve the problems of containing, insufficient adsorption capacity of fine particles, unable to meet the requirements of engine air supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

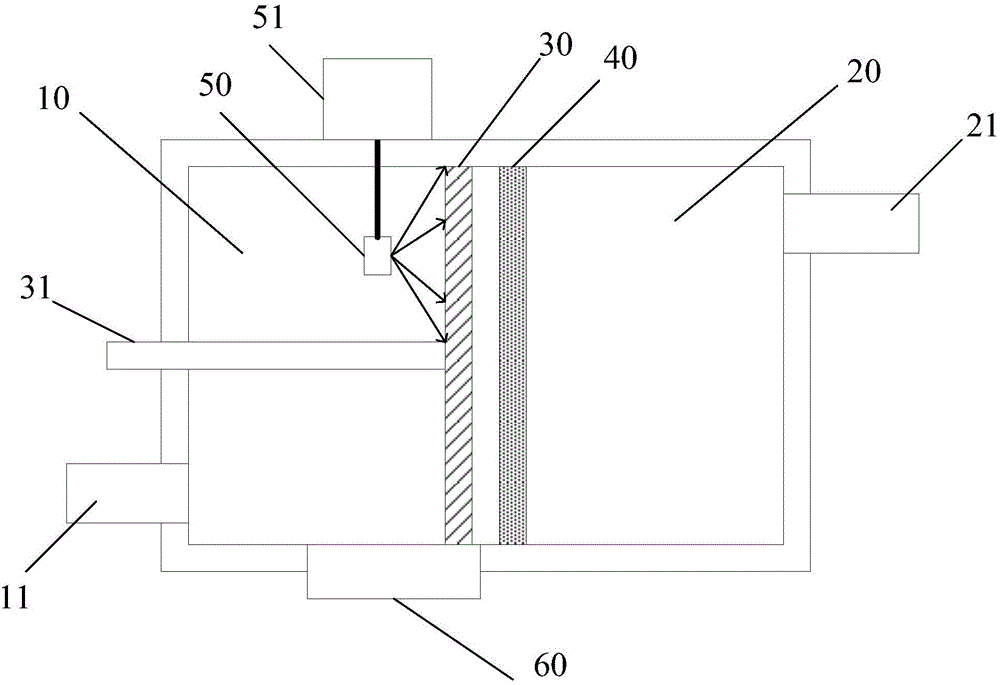

[0016] Such as figure 1 As shown, the embodiment of the present invention proposes a double-layer air filter, including a casing and a filter element, the casing forms an inner cavity with a circular cross section, and the filter element divides the inner cavity into an air intake cavity 10 and a filter element. An air outlet chamber 20, an air inlet 11 is arranged in the air inlet chamber 10, an air outlet 21 is arranged in the air outlet chamber 20, and the air entering through the air inlet 11 is filtered and supplied to the engine from the air outlet 21.

[0017] Wherein, the filter element includes: a first filter element layer 30, located on the side of the filter element facing the air inlet 11, with a gap diameter of 0.05-0.1um; a second filter element layer 40, located on the side of the filter element facing the air outlet 21, for absorbing water material, such as activated carbon fiber, etc.; the first filter element layer 30 is installed in the inner cavity through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com