Integrated central feeder

A technology of central feeder and central unloading, which is applied in loading/unloading, containers, packaging, etc., can solve the problems of occupying effective storage capacity, material leakage, and poor sealing, and achieves convenient maintenance, good sealing, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

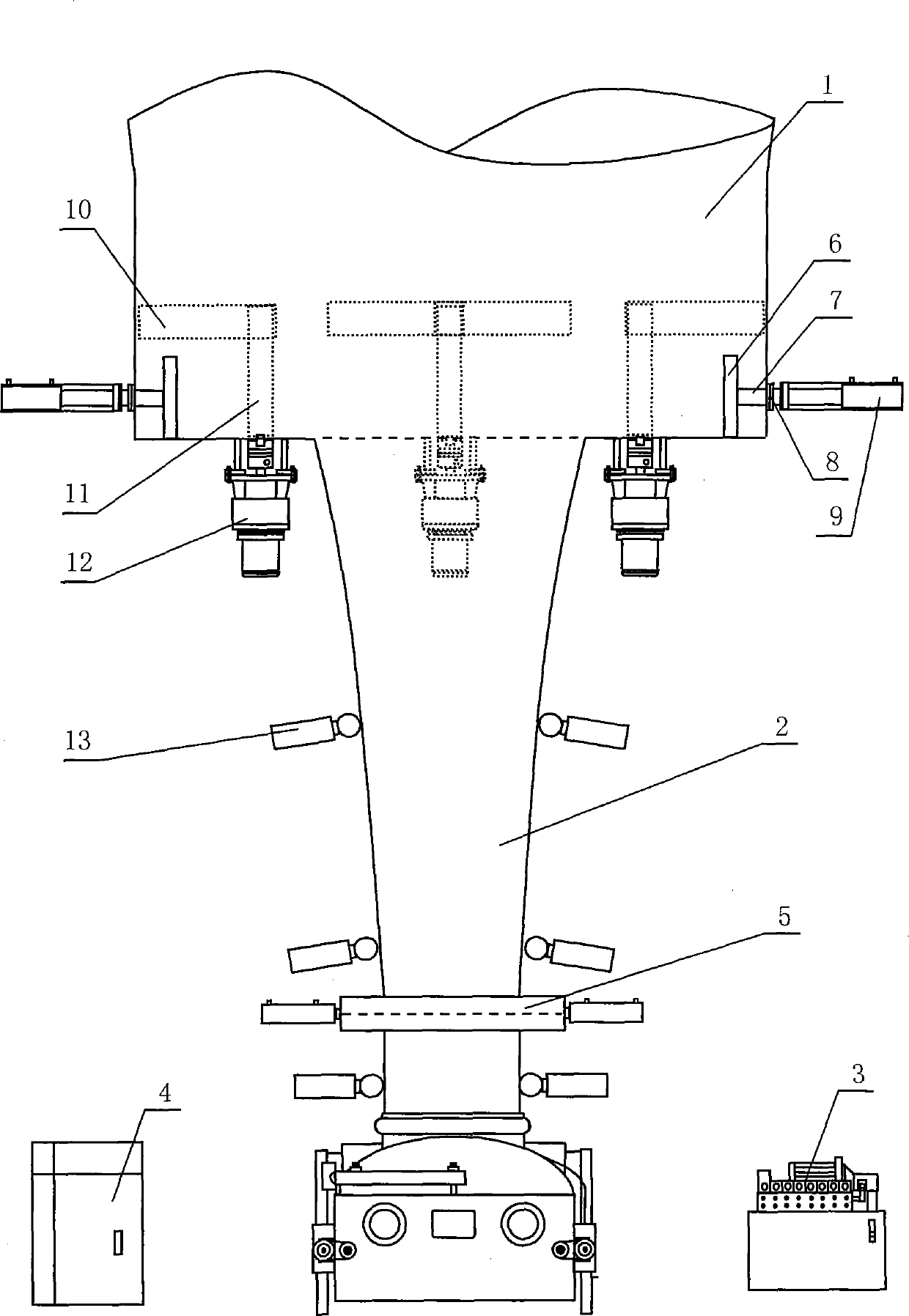

[0021] Such as figure 1 As shown, the present invention includes a rapping air hammer 13, a two-way hydraulic sliding door 5, an electric control box 4, a straight cylinder feeding bin 1, a central discharge pipe 2, a hydraulic oil station 3, 4 hydraulic pushing devices, 4 loose scraping device, etc. The center of the bottom of the straight tube feeding bin 1 is provided with a discharge port, the discharge port is connected to the central discharge pipe 2, and the two-way hydraulic sliding door 5 is installed above the outlet of the central discharge pipe 2; the hydraulic pushing device, The two-way hydraulic sliding door 5 is controlled by the hydraulic oil station 3 .

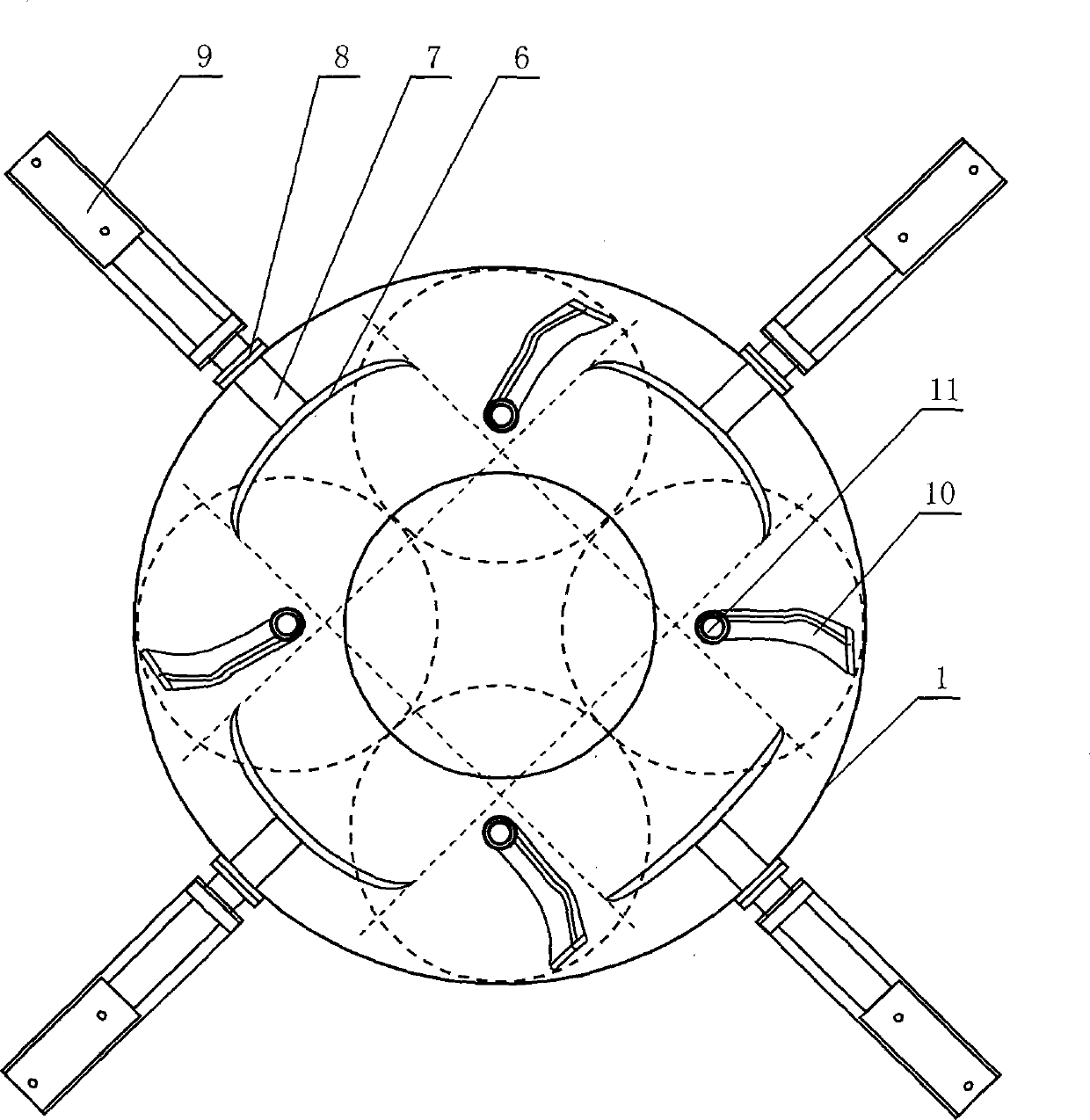

[0022] The hydraulic pushing device includes a pushing plate 6 , a pushing rod 7 , a sealer 8 and an oil top 9 . The pusher plate 6 is installed on the pusher rod 7, and the pusher rod 7 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com