Method for manufacturing gas shutoff valve

A gas valve and main body technology, applied in valve details, valve device, valve shell structure and other directions, can solve problems such as reducing the production efficiency of gas valve production, gas valve main body easily containing trachoma, affecting the social competitiveness of enterprises, etc. Competitiveness, improving yield and production efficiency, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] refer to figure 1 Referring to Fig. 4, a method for making a gas valve includes the following steps:

[0020] 1) Extruded aluminum forming, first heat the aluminum rod to the hot forging temperature, and then put it into the extrusion machine for extrusion, so as to obtain a strip shape and its cross section is the same as the cross section of the gas valve body Similar to the aluminum profile 10, in the present invention, in addition to the above-mentioned hot extrusion method to produce the aluminum profile 10, the cold extrusion method can also be used to produce the required aluminum profile 10, which extrusion method can be used according to free choice according to the actual situation;

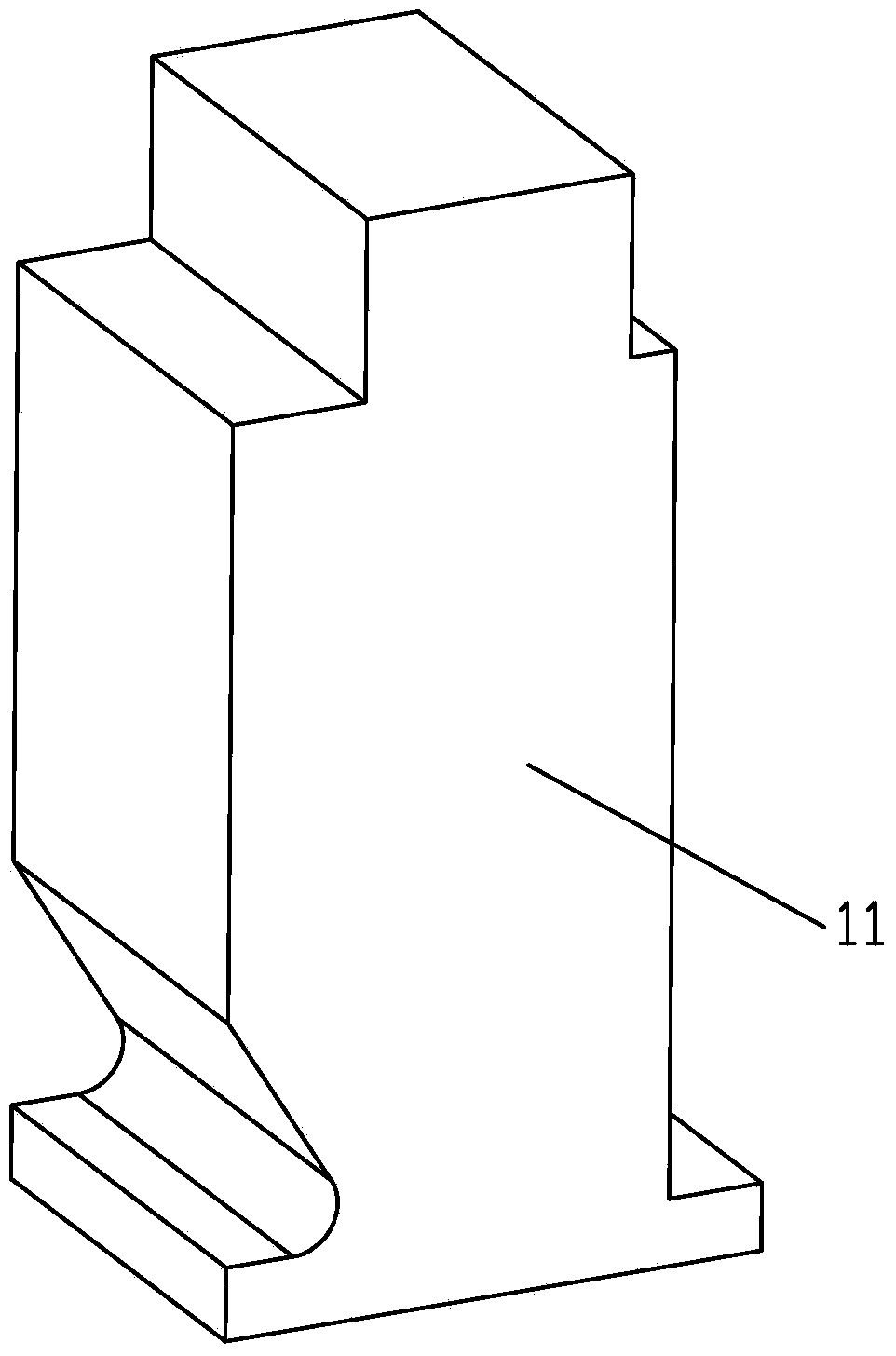

[0021] 2) Cutting the blank, using a cutting machine to cut the aluminum profile 10 obtained in step 1), so as to obtain several blanks 11 for making the main body of the gas valve, the thickness of the blank 11 is equal to or slightly greater than the thickness of the gas valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com