Sliding sleeve type subsurface safety valve

A technology of safety valve and sliding sleeve, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of untimely closure of passageway, failure of rubber body to lock, failure to contain blowout, etc. , to achieve the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

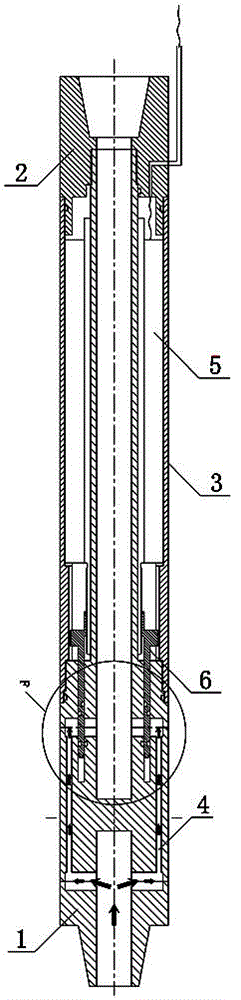

[0025] Such as figure 1 and figure 2 As shown, a sliding sleeve type downhole safety valve includes a lower joint 1, an upper joint 2, a casing 3, a power unit 5 and a sliding sleeve 6, an oil and gas channel 4 is arranged inside the lower joint 1, and the thin shaft on the upper part of the lower joint 1 The part is connected with the upper joint 2 through thread fit, the thick shaft part at the lower part of the lower joint 1 is connected with the shell 3 through thread fit, and the upper joint 2 and the shell 3 are clearance fit, such as Figure 4 As shown, the lower joint 1 is provided with an annular slot 11 along the axial direction, and the power unit 5 is installed in the airtight cavity formed between the lower joint 1, the upper joint 2 and the shell 3, as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com