Processing method of nonmetal isolating sleeve for magnetic pump

A processing method and technology of spacer sleeves, which are applied in the field of processing non-metallic spacer sleeves for magnetic pumps, can solve the problems of shortened service life, eddy current heat cannot be dissipated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

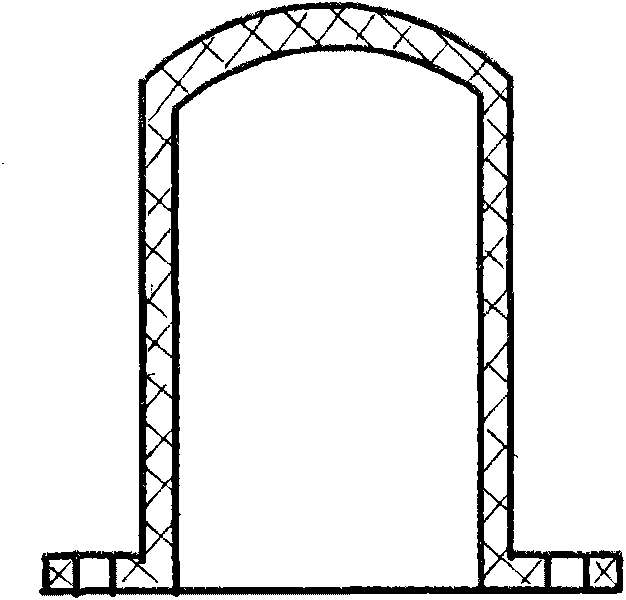

Image

Examples

Embodiment Construction

[0005] The processing method of the non-metal spacer sleeve for the magnetic pump is characterized in that: 65-70% of polybenzimidazole and 30-35% of polyether ether ketone are used for batching, and the mixture is evenly stirred and loaded into the feeding cylinder of the injection molding machine; Press the heating button on the injection molding machine to heat, the heating temperature is controlled at 350-370°C, and the heating time is controlled at 1.2-1.8 hours; press the mold clamping button, and then press the injection button to inject the melted ingredients into the mold Intra-cavity molding, the injection method is extrusion, the injection pressure is 7.0-8.0MPa, and the injection time is 8-12 seconds; after the injection is completed, the product is molded under pressure, cooled with the air for 6-8 minutes, and the demoulding button is pressed. The fixed mold is separated from the mold core, and the product is attached to the mold core; take out the formed product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com