Girder-like even wind radiator

An air cooler and beam-type technology, applied in the field of beam-type uniform air coolers, can solve the problems of uneven cooling and complex structure, and achieve the effects of convenient maintenance, good cooling effect and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

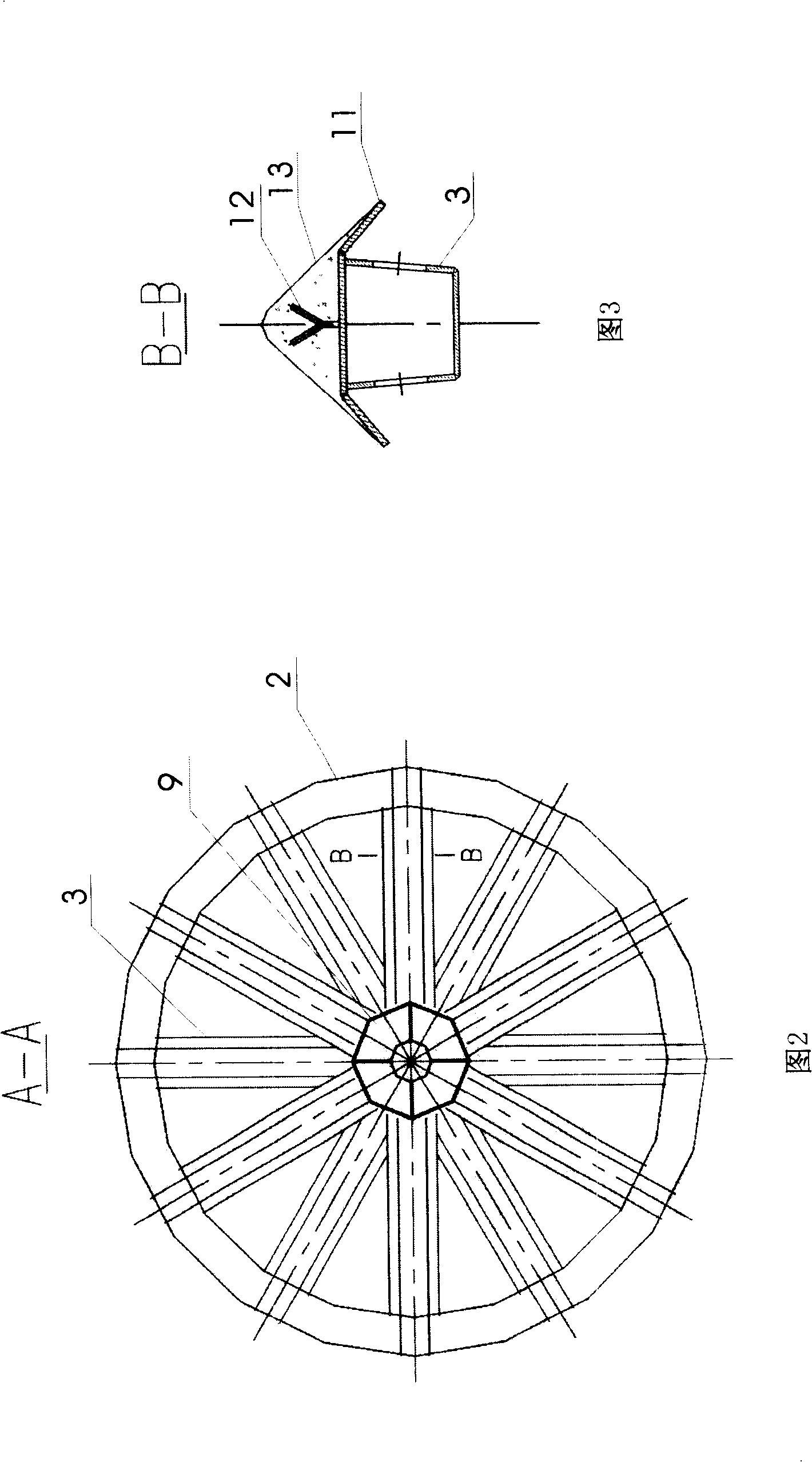

[0018] As shown in Figure 1: the beam-type uniform air cooler is an integral sealed structure, which consists of a connecting cover (1), a main device (2), an air distribution system, a pipeline system, a fan (8), a hopper (5) and a discharge Device (7) etc. are formed. The connecting cover (1) connects the kiln head cover of the rotary kiln and the main device (2) of the cooler to form a whole, guides the calcined material to enter the cooler, and guides the high-temperature secondary air to enter the rotary kiln for combustion. The high-temperature material from the rotary kiln is evenly filled into the main device (2), and gradually moves from top to bottom with its own weight; the main device (2) is equipped with an air distribution system, and the air distribution system is connected to the fan through the pipeline system (8), the fan distributes the cooling air through different pipeline systems, sends it into the air distribution system, and then blows it out from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com