Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Long-term continuous and stable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously polymerizing nylon from bi-component monomer serving as raw material

The invention discloses a method for continuously polymerizing nylon from a bi-component monomer serving as a raw material. The method comprises the following steps of: reacting and rectifying a nylon salt aqueous solution serving as a raw material in a pre-condensing tower in which a liquid phase is a continuous phase, a gas phase is a dispersed phase and falling liquid and rising bubbles keep flat push flow respectively under a low pressure to generate a prepolymer of which the polymerization degree 5-50 (preferably 20-40) and a terminal carboxyl group, a terminal amino group and the like are of equal molar amounts; and pre-heating the pre-polymer to generate a polymer of which the polymerization degree reaches process indexes in the pre-condensing tower. In the pre-condensing tower, a film falling or strip falling method is adopted, so that evaporation of condensed water is accelerated, the reaction temperature is lowered, reaction time is shortened, and gel is reduced; and a kettle wall is coated with a falling liquid film, so that kettle wall scars are avoided. The method has the advantages of short flow, large mono-line scale, saving in investment, low running cost, good product quality, long continuous running period, environment friendliness and suitability for continually polymerizing nylon 66, nylon 56 and other nylon made of bi-component monomers serving as raw materials.

Owner:XCEED CHEMTECH

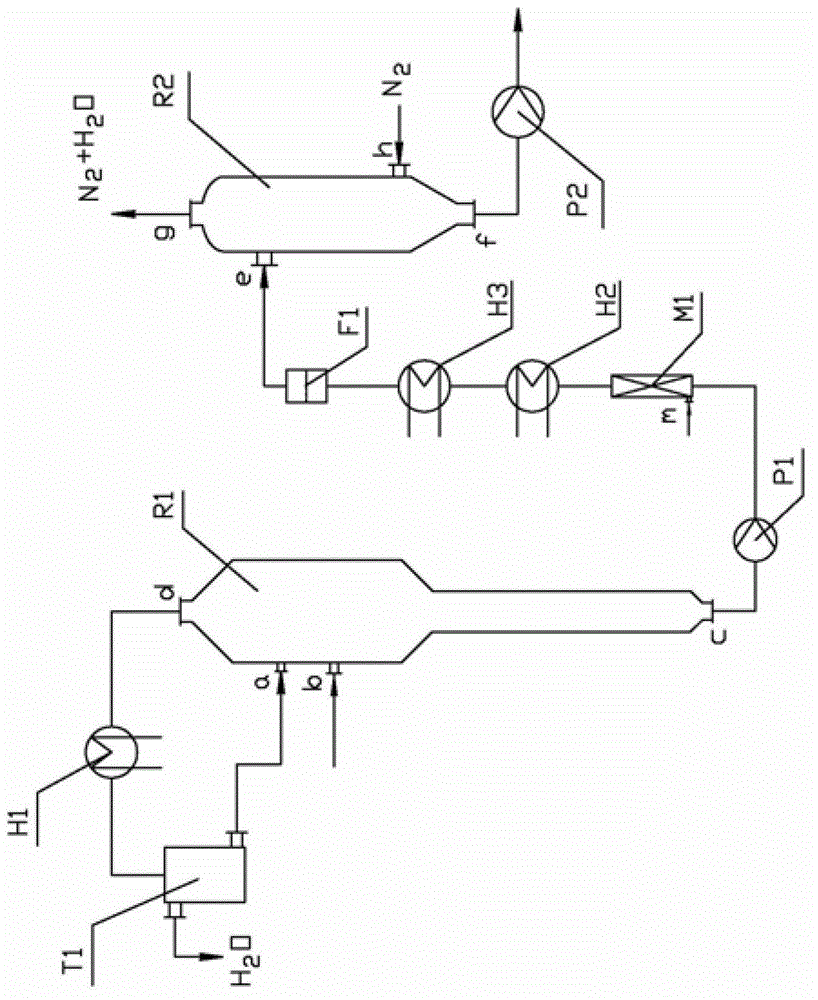

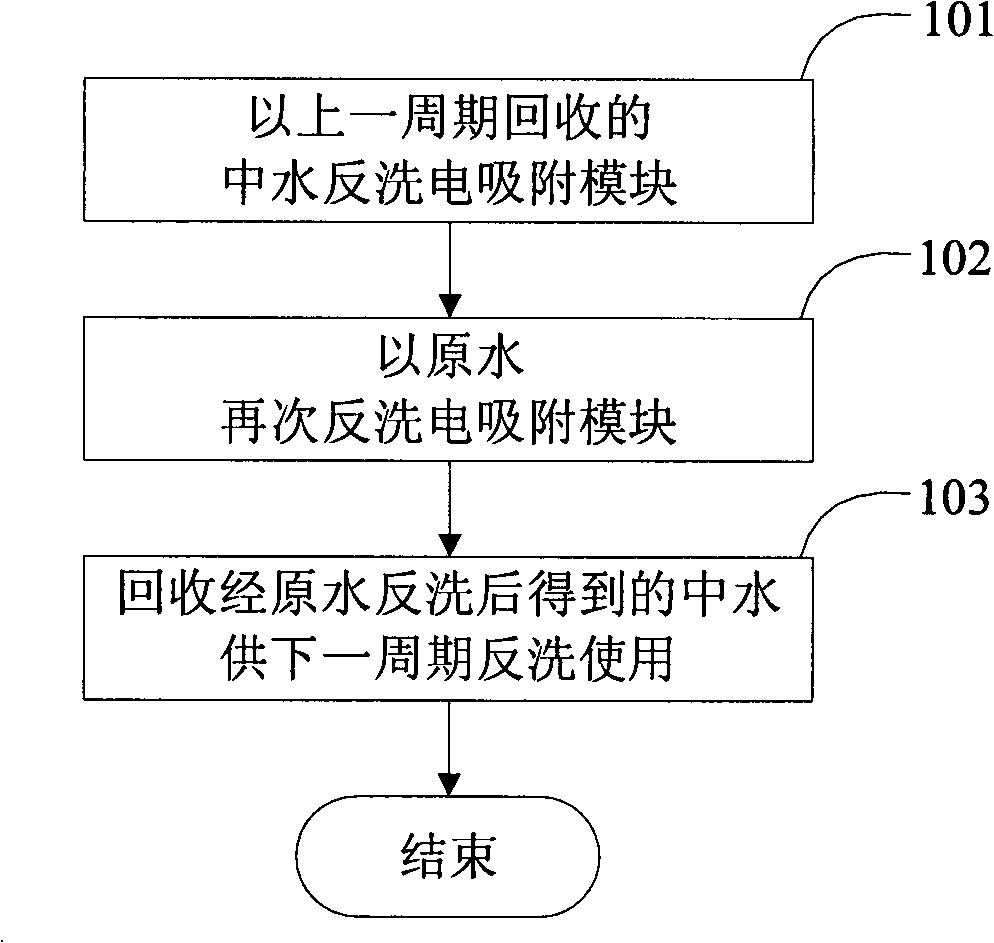

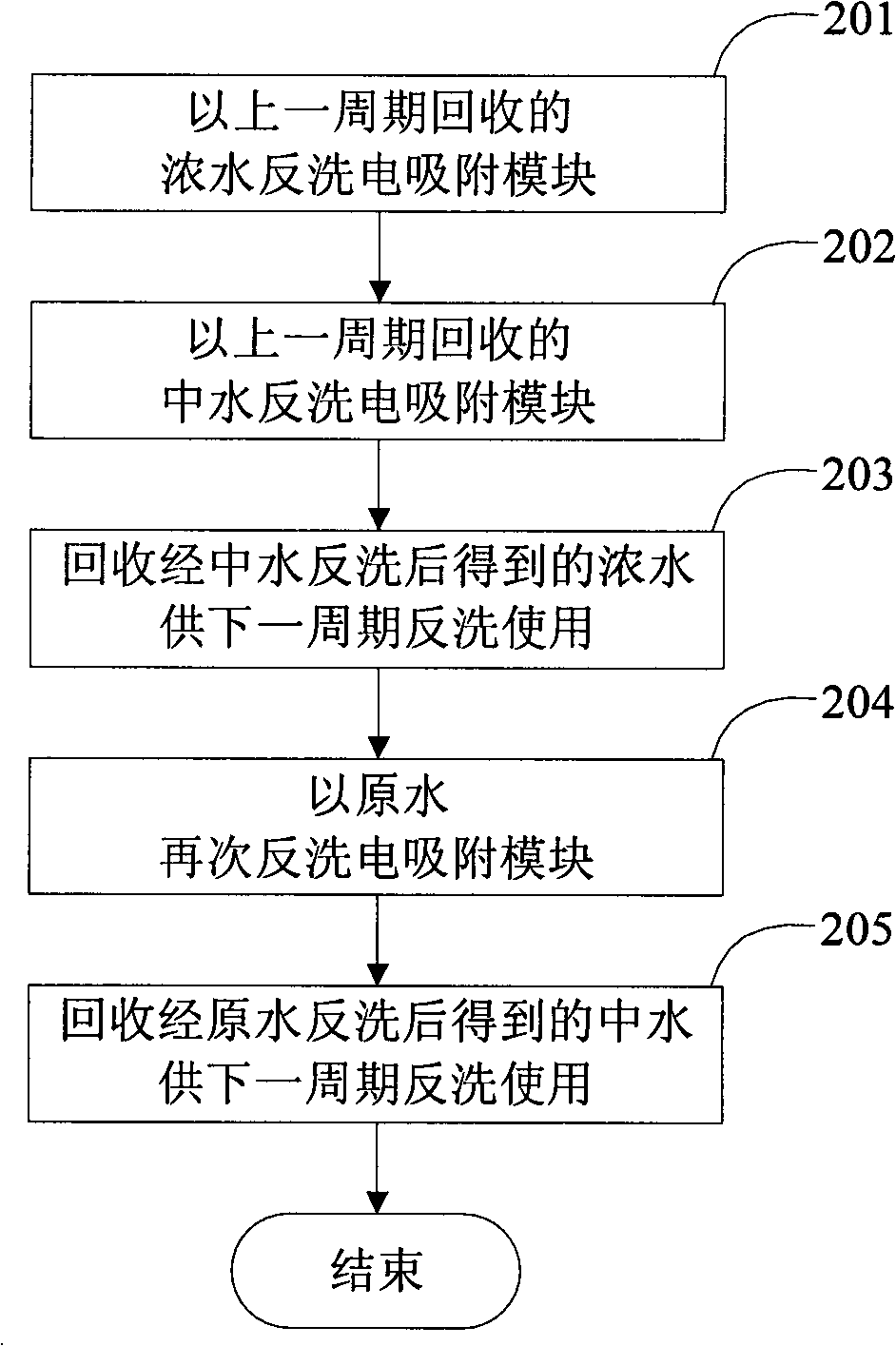

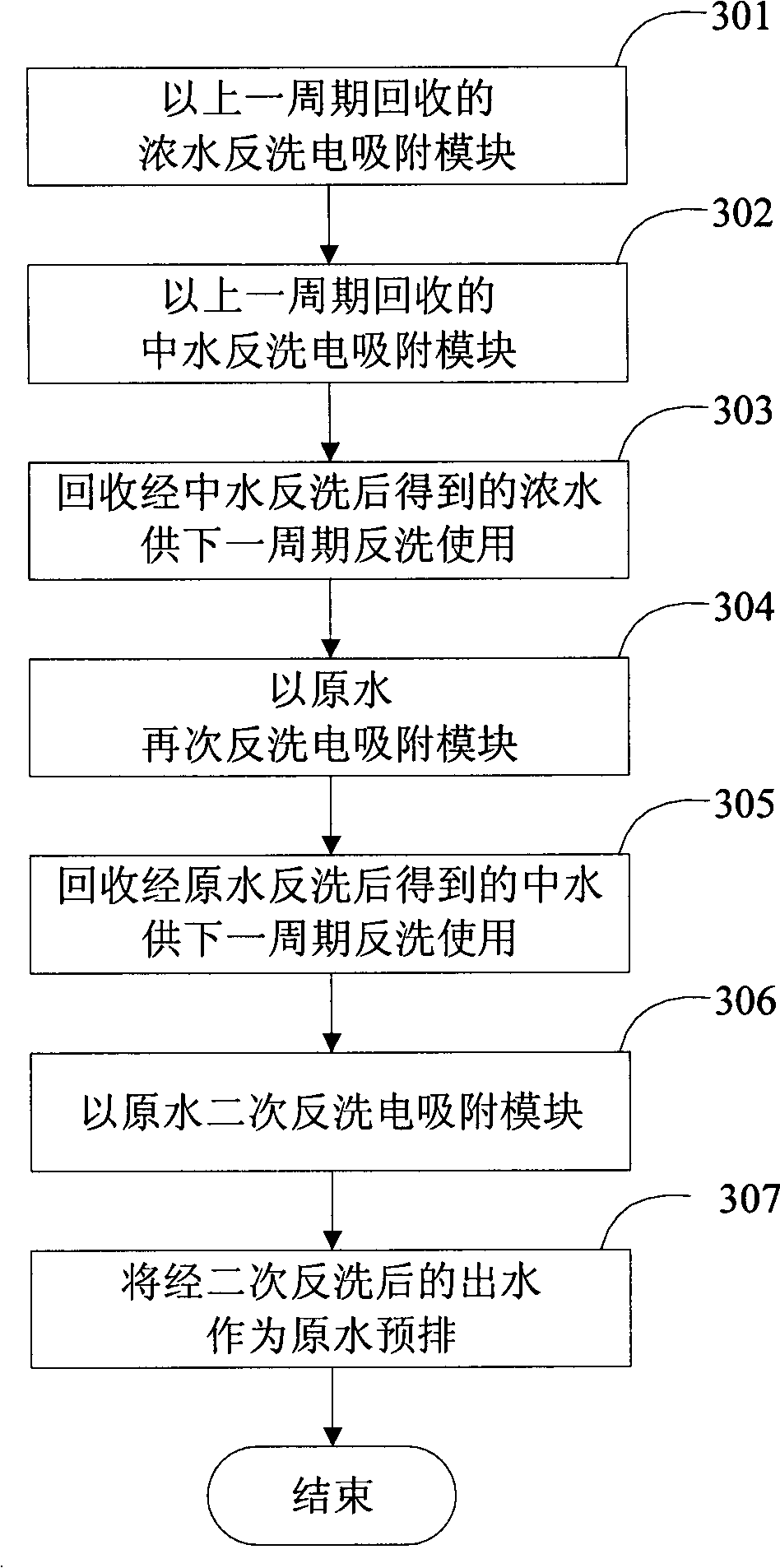

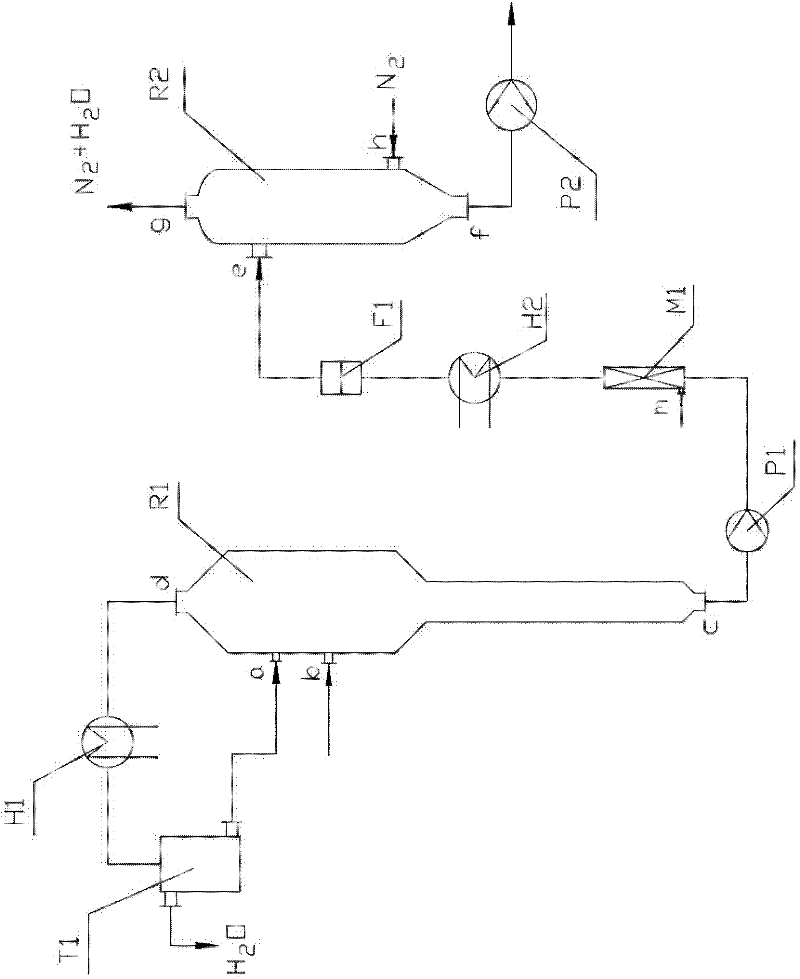

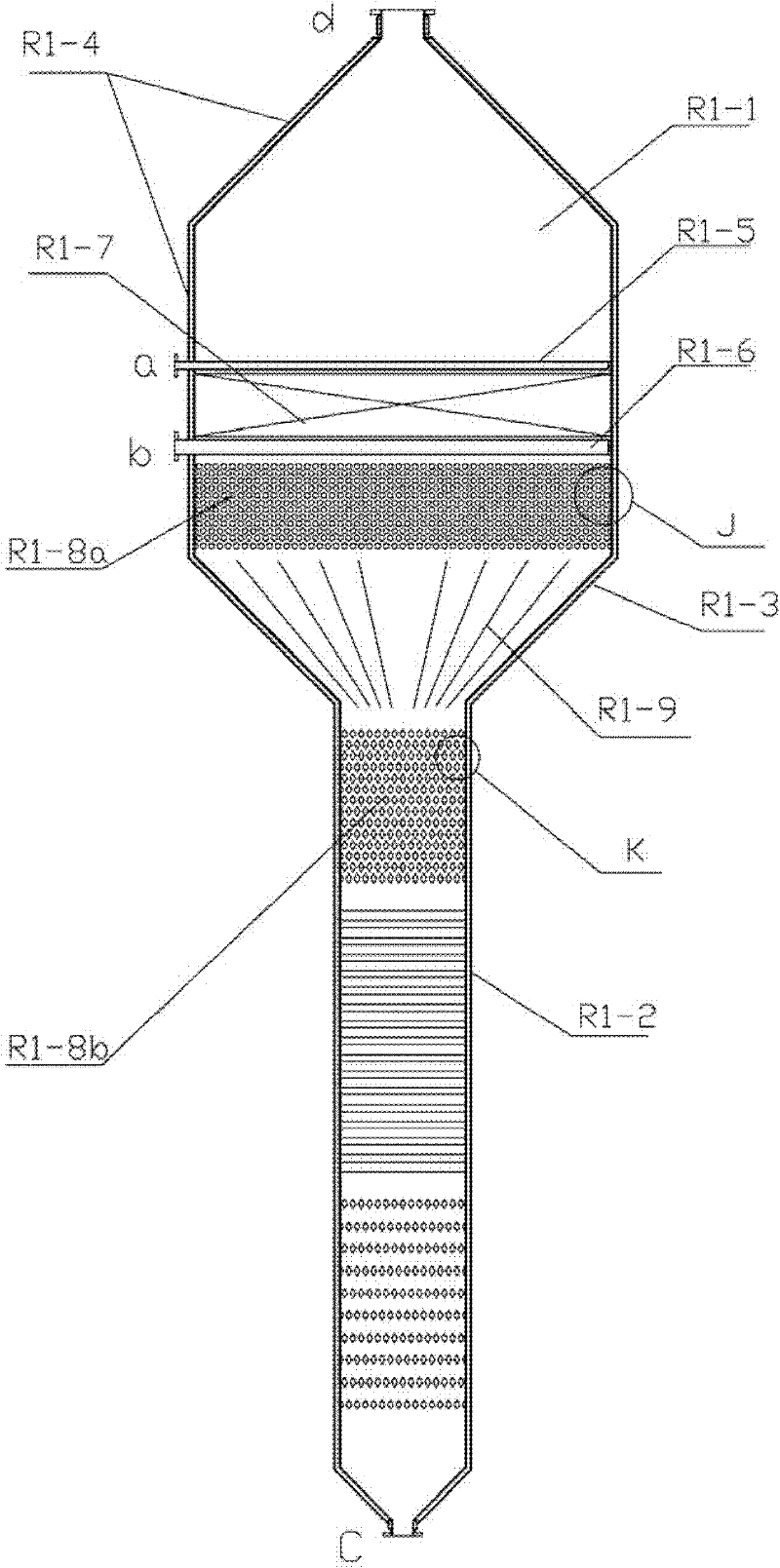

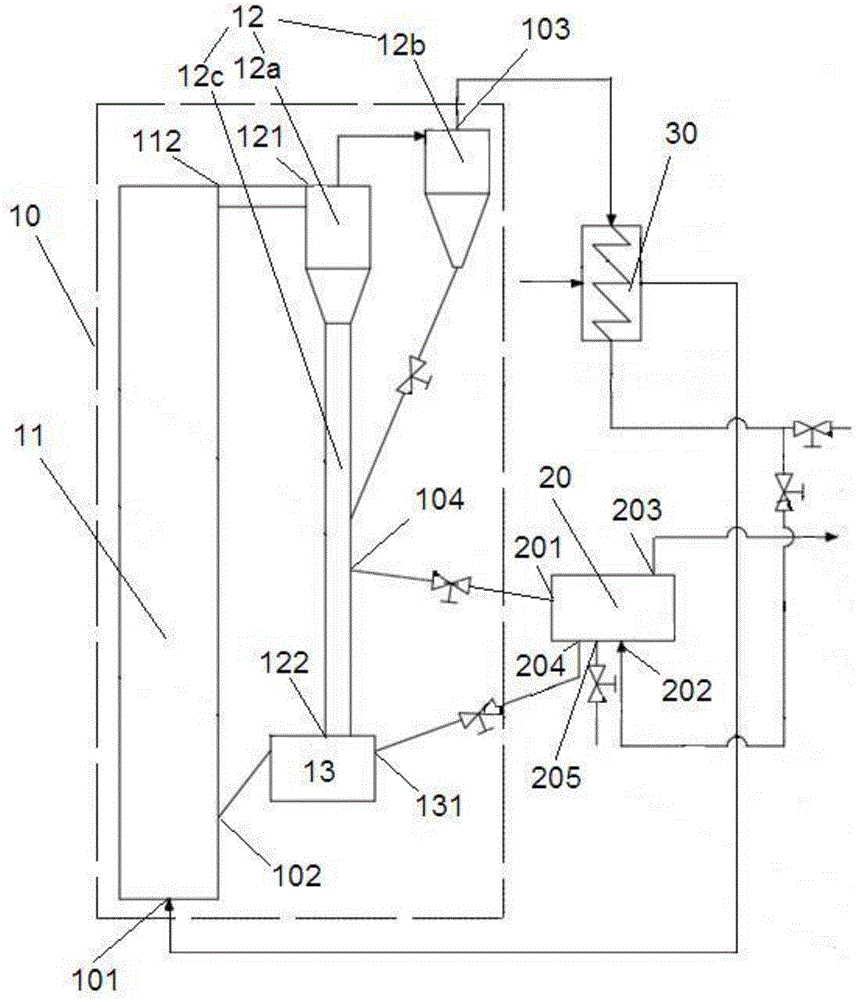

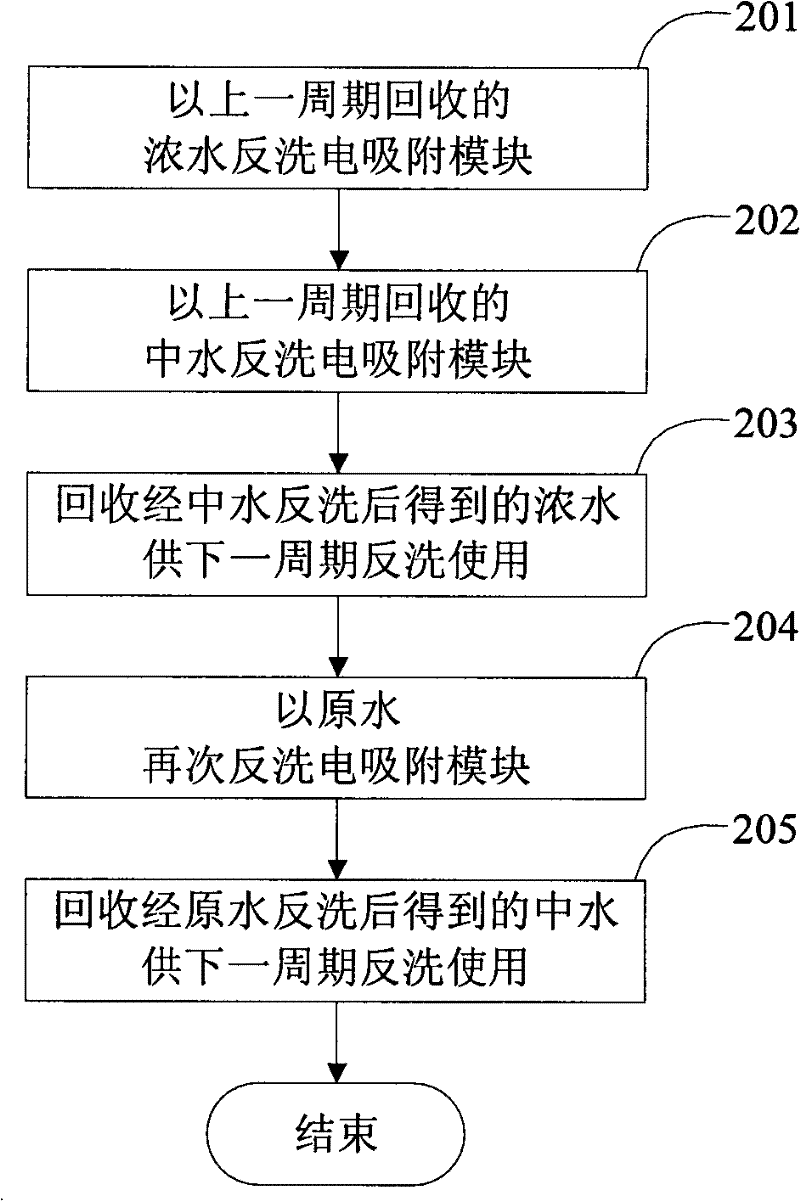

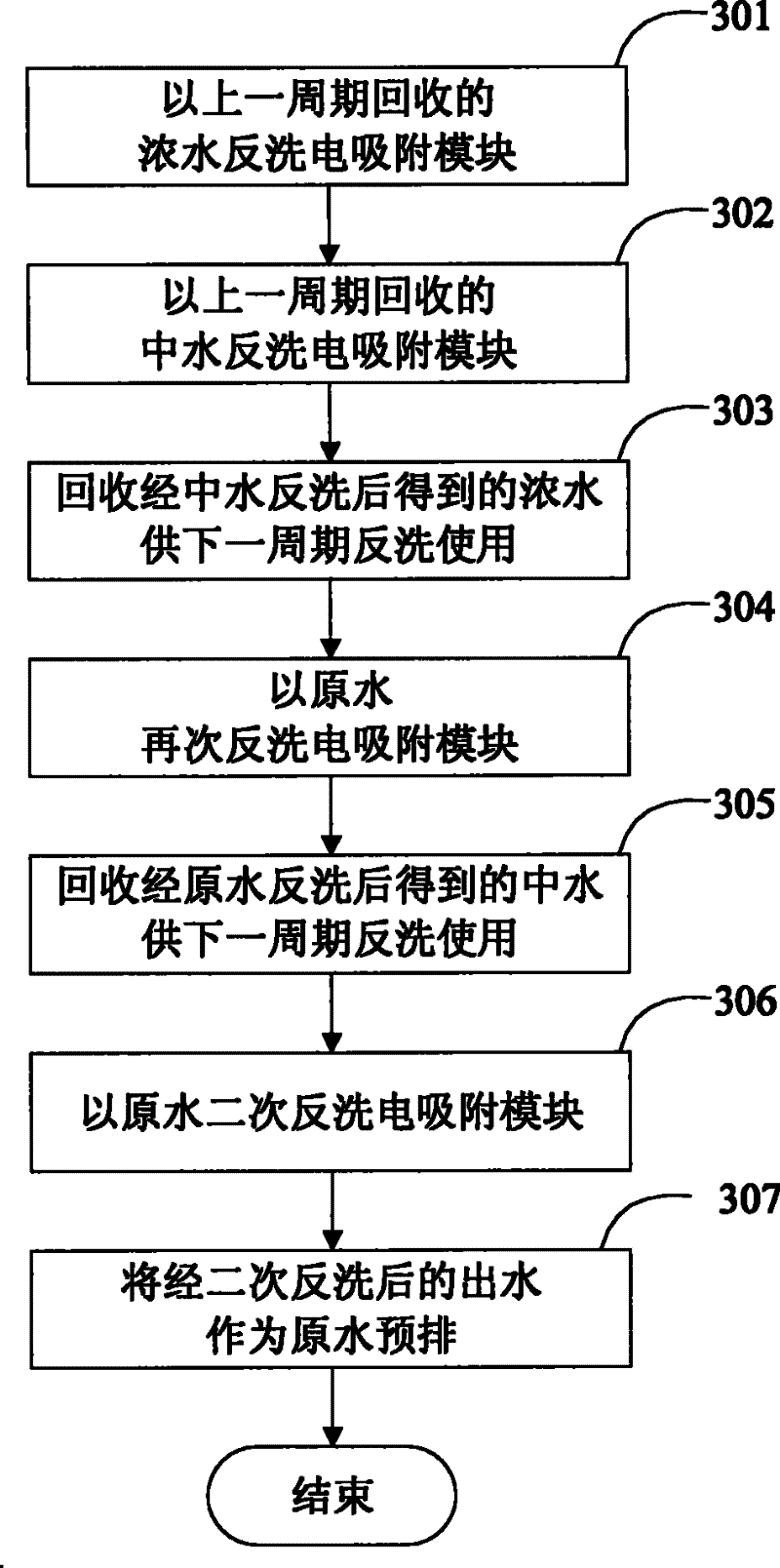

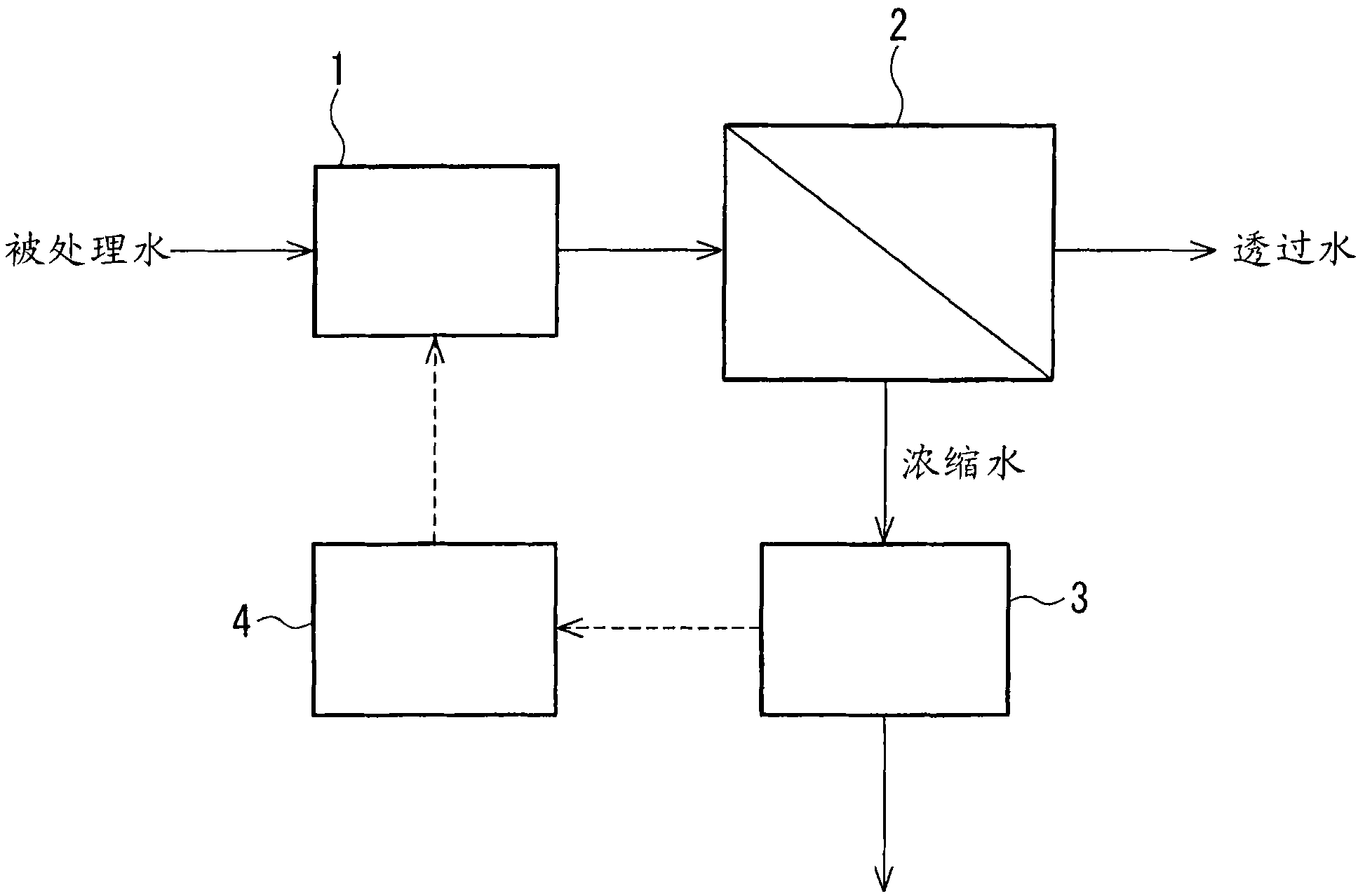

Method and system for desalting and backwashing through electric absorption

ActiveCN102010039ASave raw water consumptionIncrease water production rateDispersed particle separationRaw waterElectricity

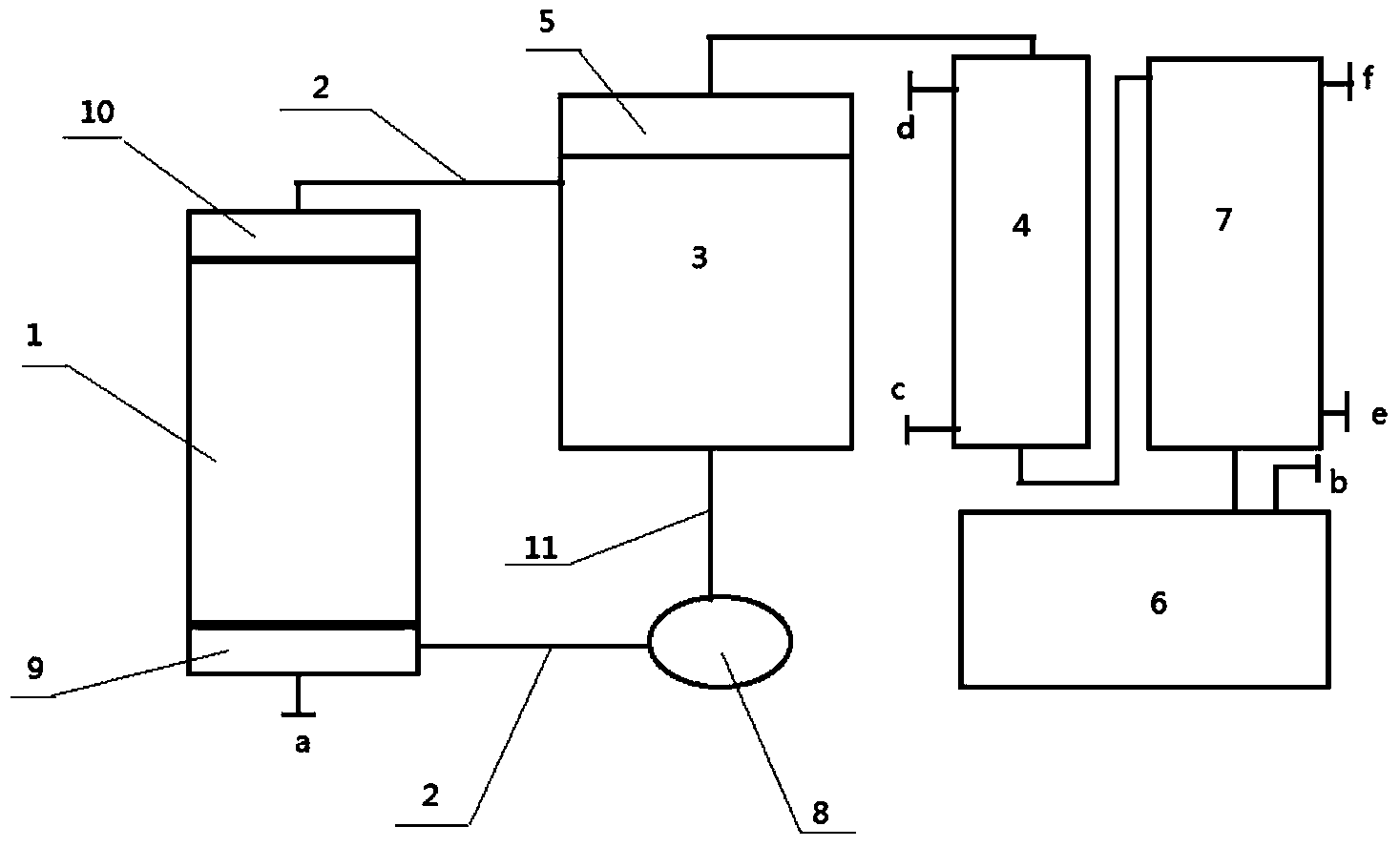

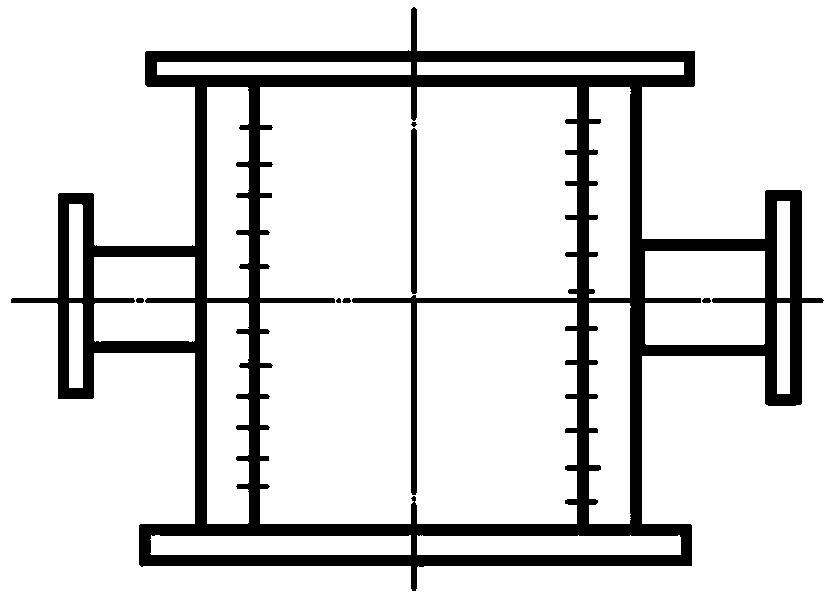

The invention discloses a method and a system for desalting and backwashing through electric absorption, belonging to the field of water treatment. The invention aims at solving the problem that the prior art can not ensure both the regeneration effect of an electric absorbing module and higher water yield. The method comprises the following steps of: backwashing the electric absorbing module by water recycled in the previous period, re-backwashing the electric absorbing module by raw water, and recycling water obtained by backwashing through the raw water for backwashing in the next period. The system comprises an electric absorbing module to be regenerated, a recycled water tank, a recycled water backwashing unit, a raw water tank, a raw water backwashing unit and a recycling water unit. By increasing the steps and units on the basis of the prior art, the invention realizes both the regeneration effect of the electric absorbing module and the higher water yield.

Owner:EST WATER & TECH

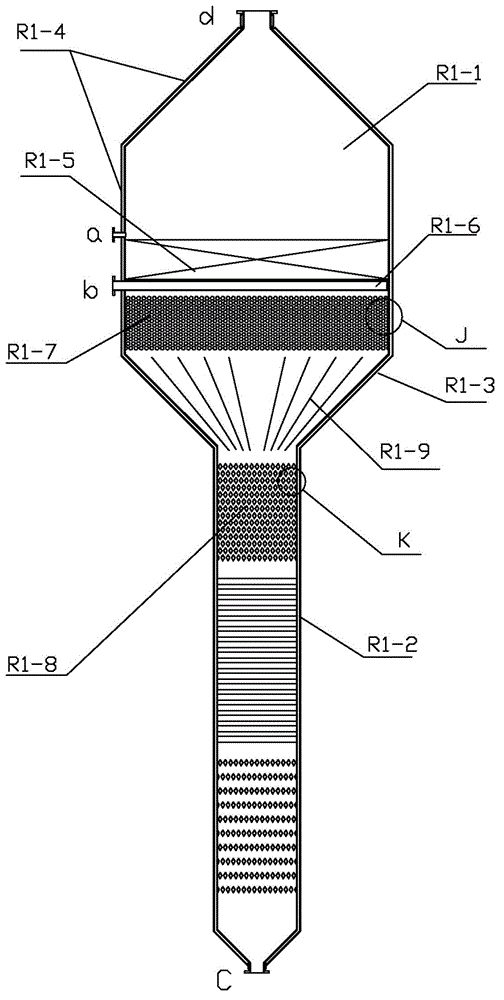

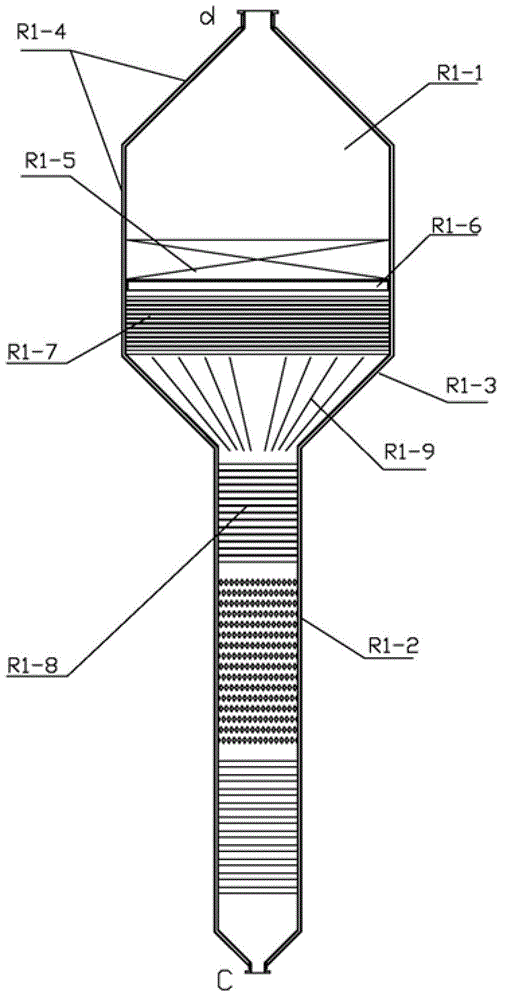

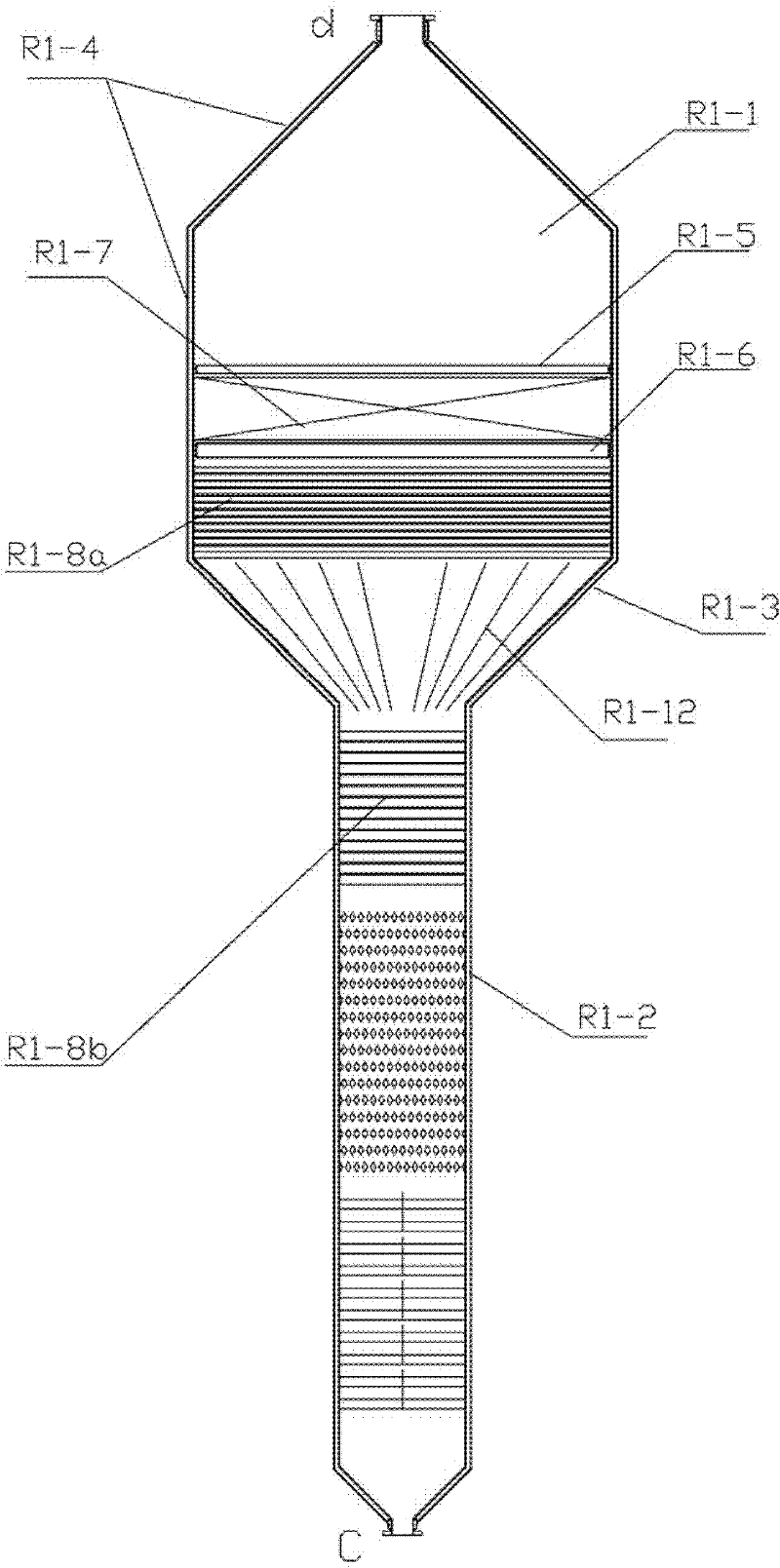

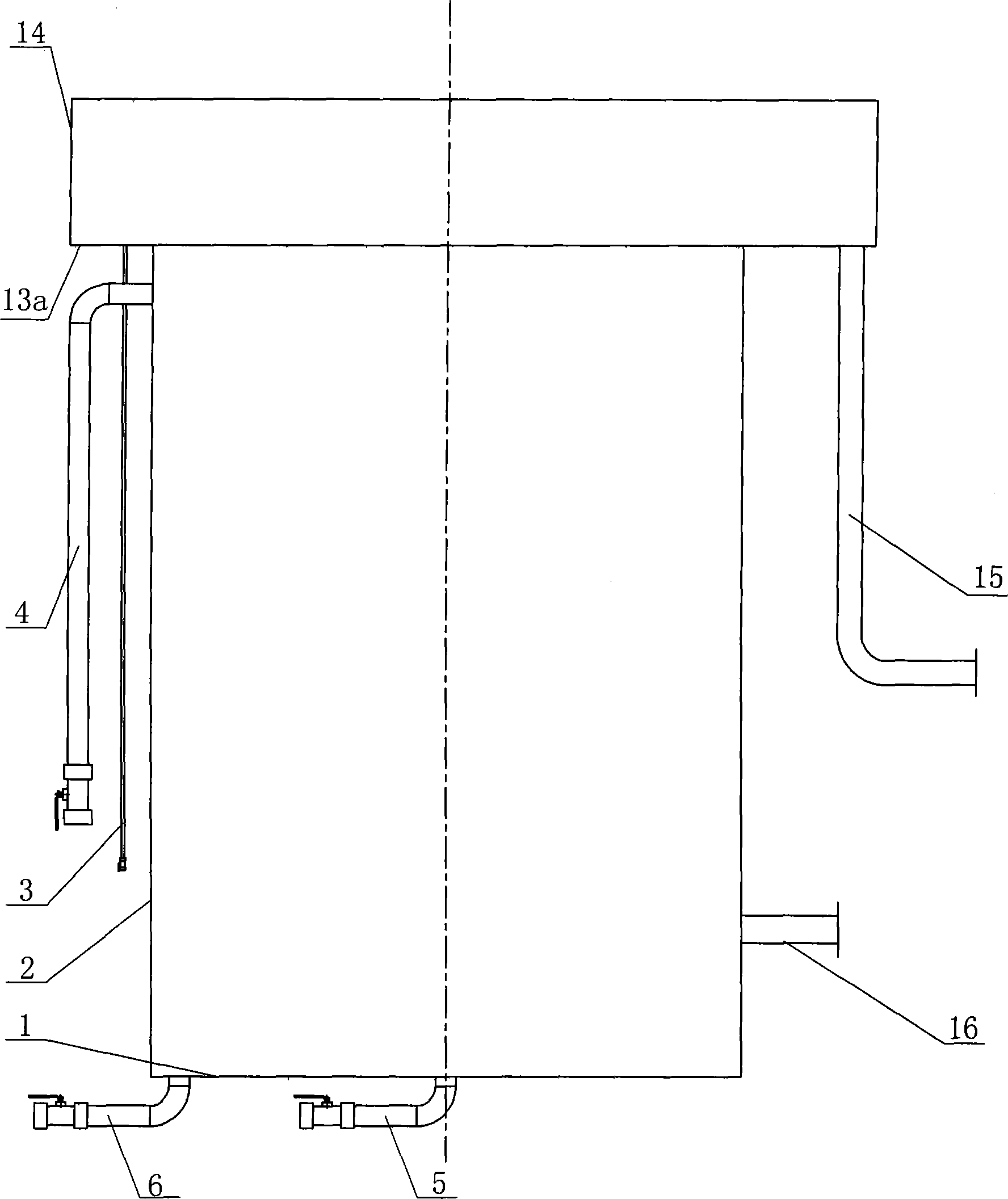

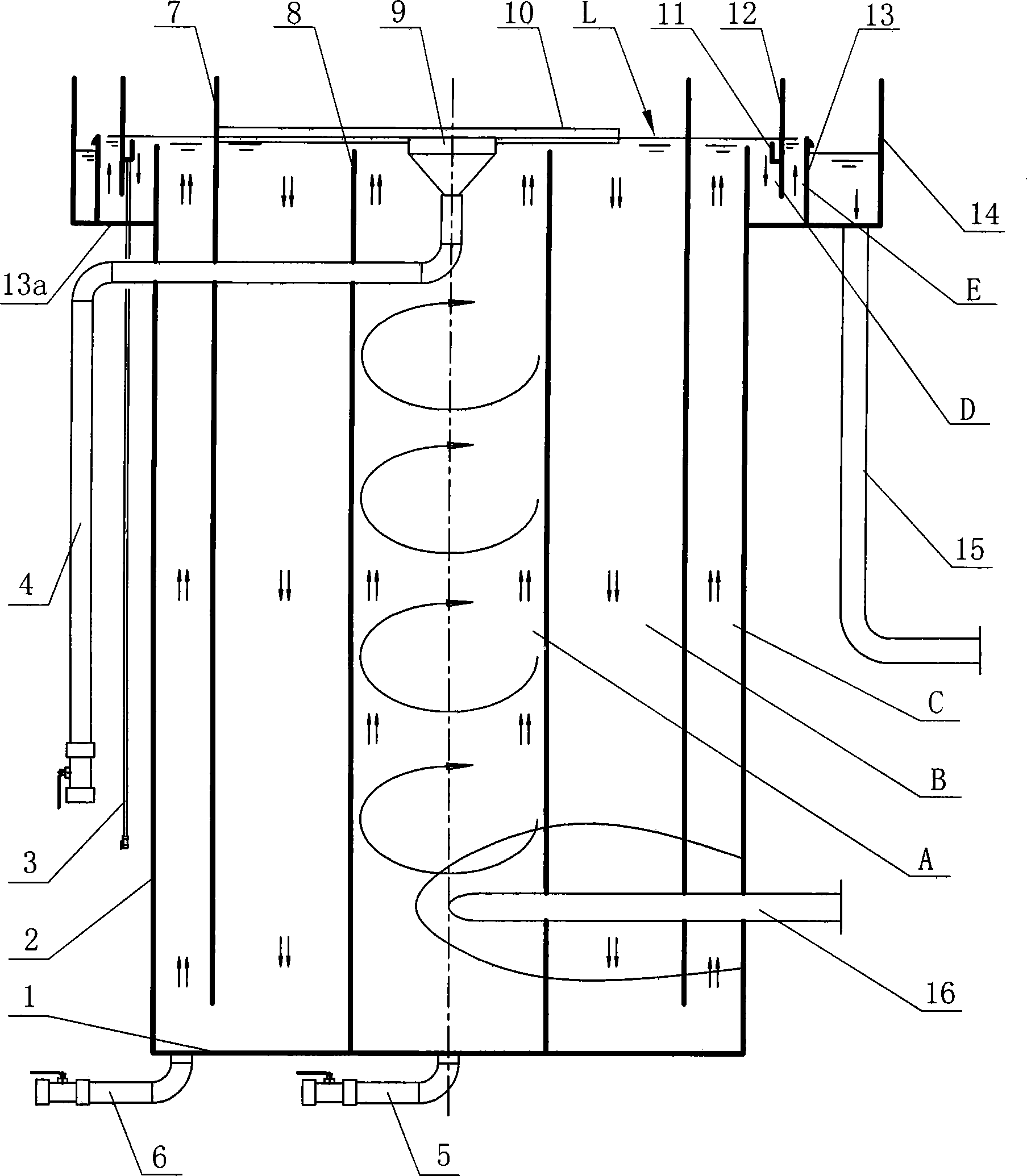

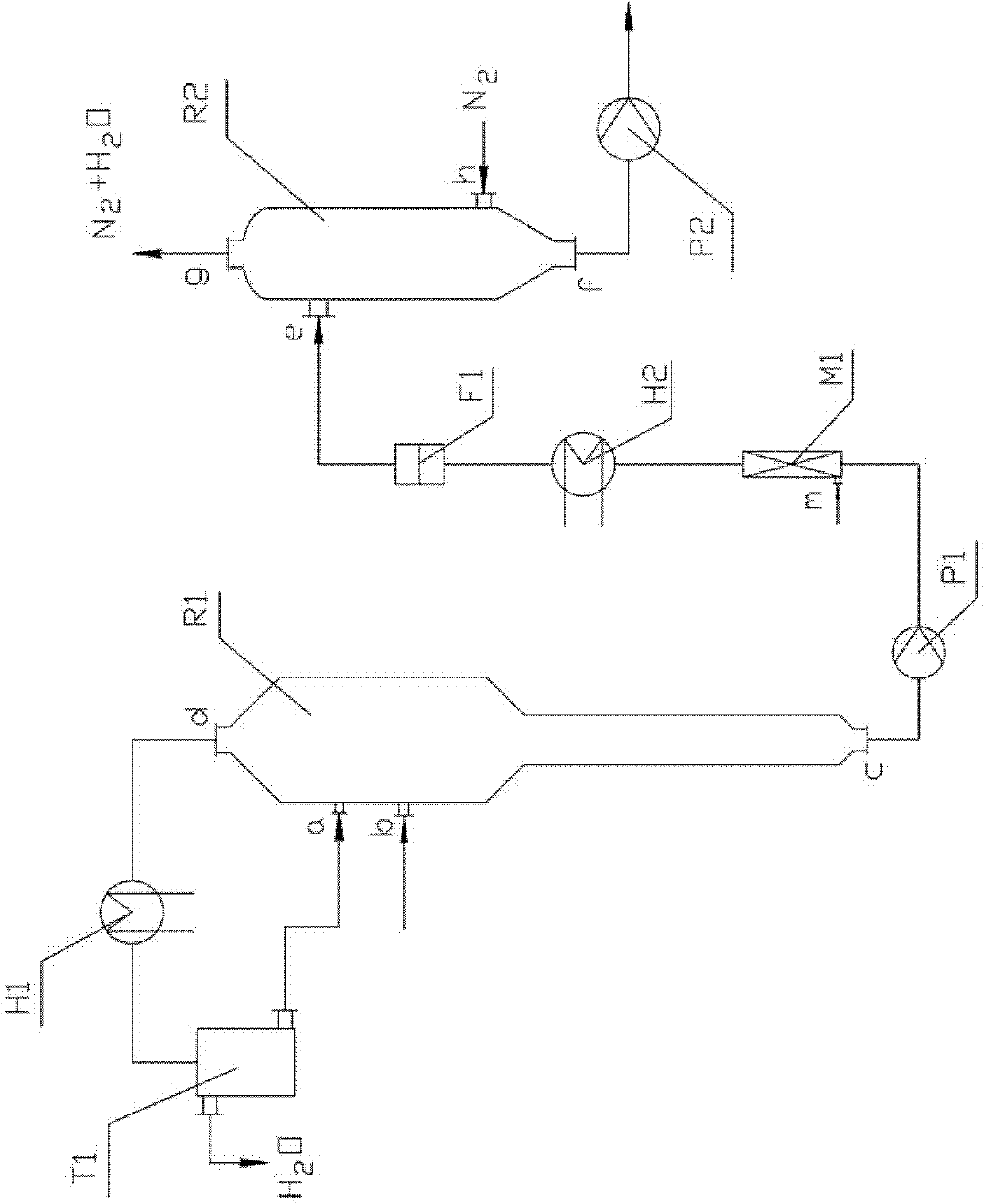

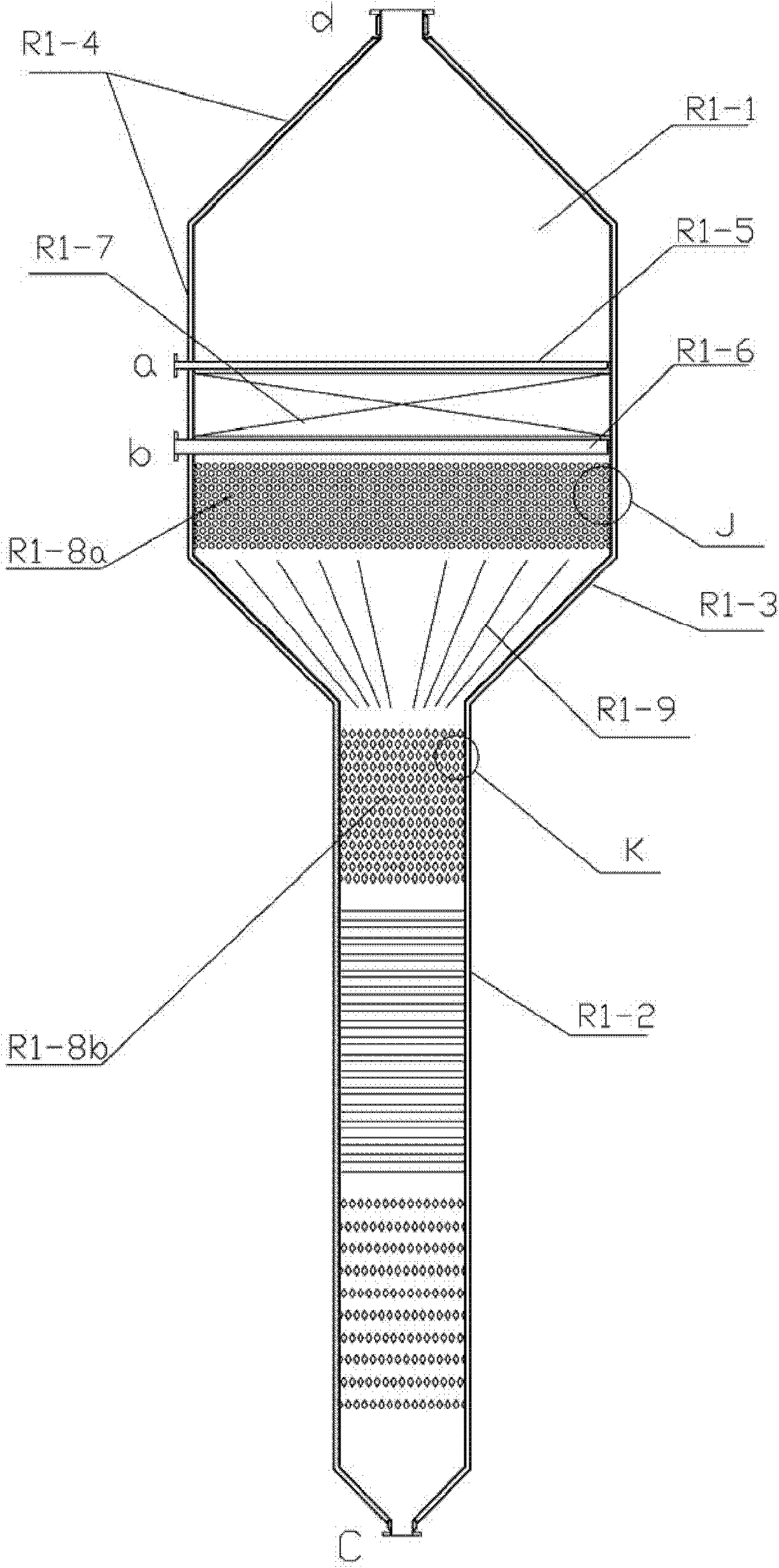

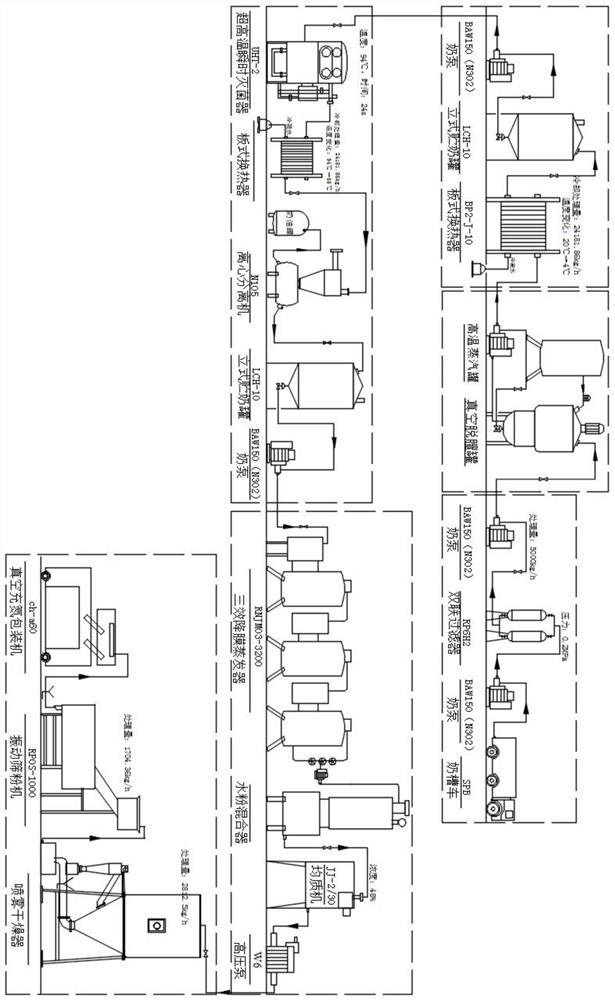

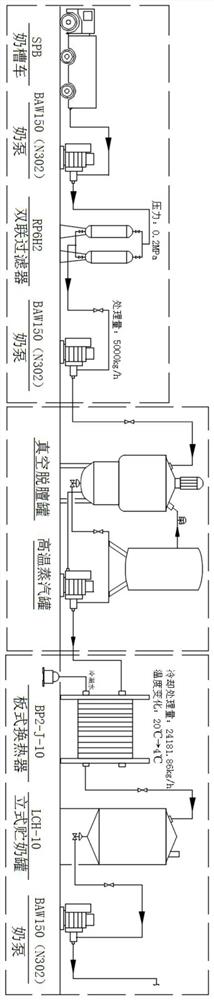

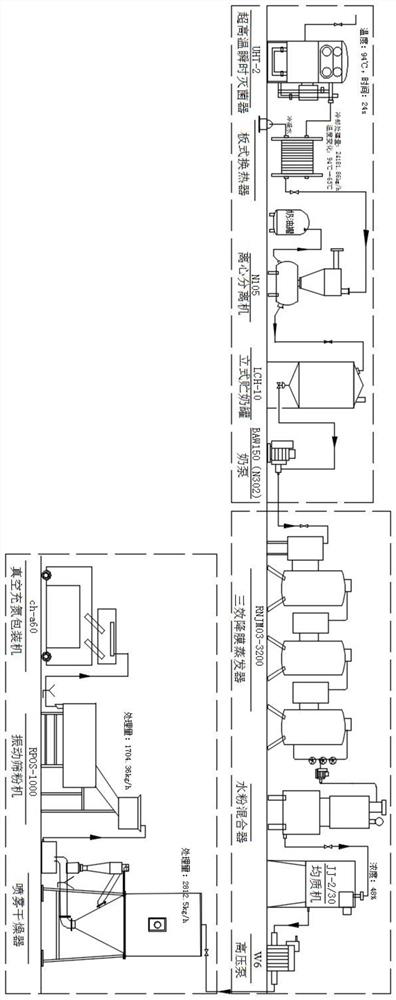

Method and equipment for nylon 66 short-flow continuous polymerization

The invention relates to a method and equipment for nylon 66 short-flow continuous polymerization. The method comprises the steps of carrying out heating, evaporation, concentration and polycondensation of 30-70% of a nylon 66 salt solution in a normal pressure pre-polypolycondensation tower by adopting a reaction distillation method to obtain a prepolymer with a polymerization degree of 5-50 (preferably 20-40) and equimolar terminal carboxy group and terminal amine group, and allowing the prepolyer to directly produce a polymer with a polymerization degree meeting technical indicators without flash distillation. A falling film devolatilization method is adopted in the polycondensation kettle to accelerate distillation out of condensation water, reduce reaction temperature, shorten reaction time and reduce gel; and the falling liquid film is used to seal and cover the kettle wall to avoid scarring of the kettle wall. Compared with the traditional nylon 66 continuous polymerization device, the method and the equipment provided by the invention has the advantages of short process, large single line scale, less investment, low operating cost, good product quality, long continuous operation cycle, and environmental friendliness.

Owner:XCEED CHEMTECH

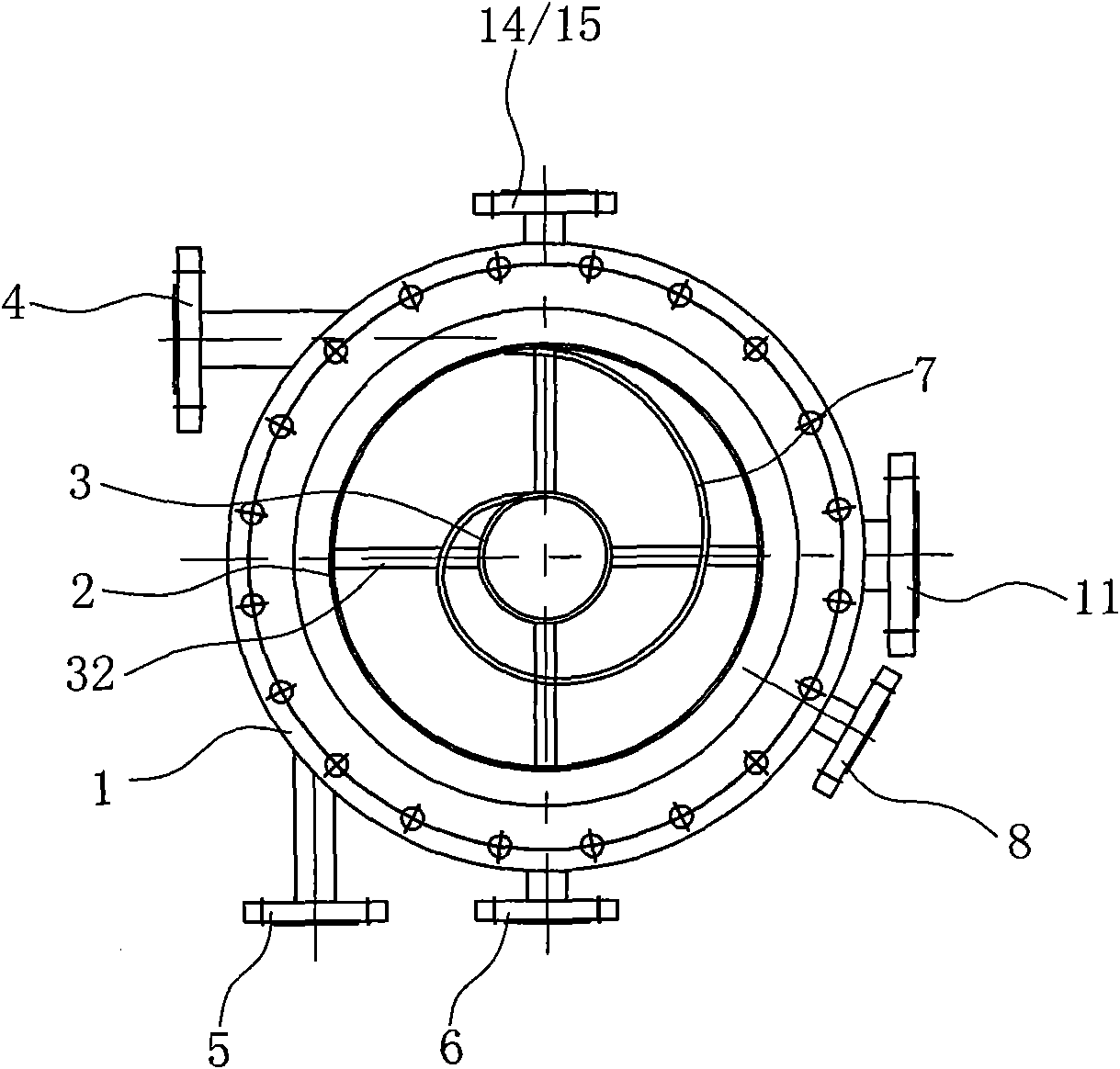

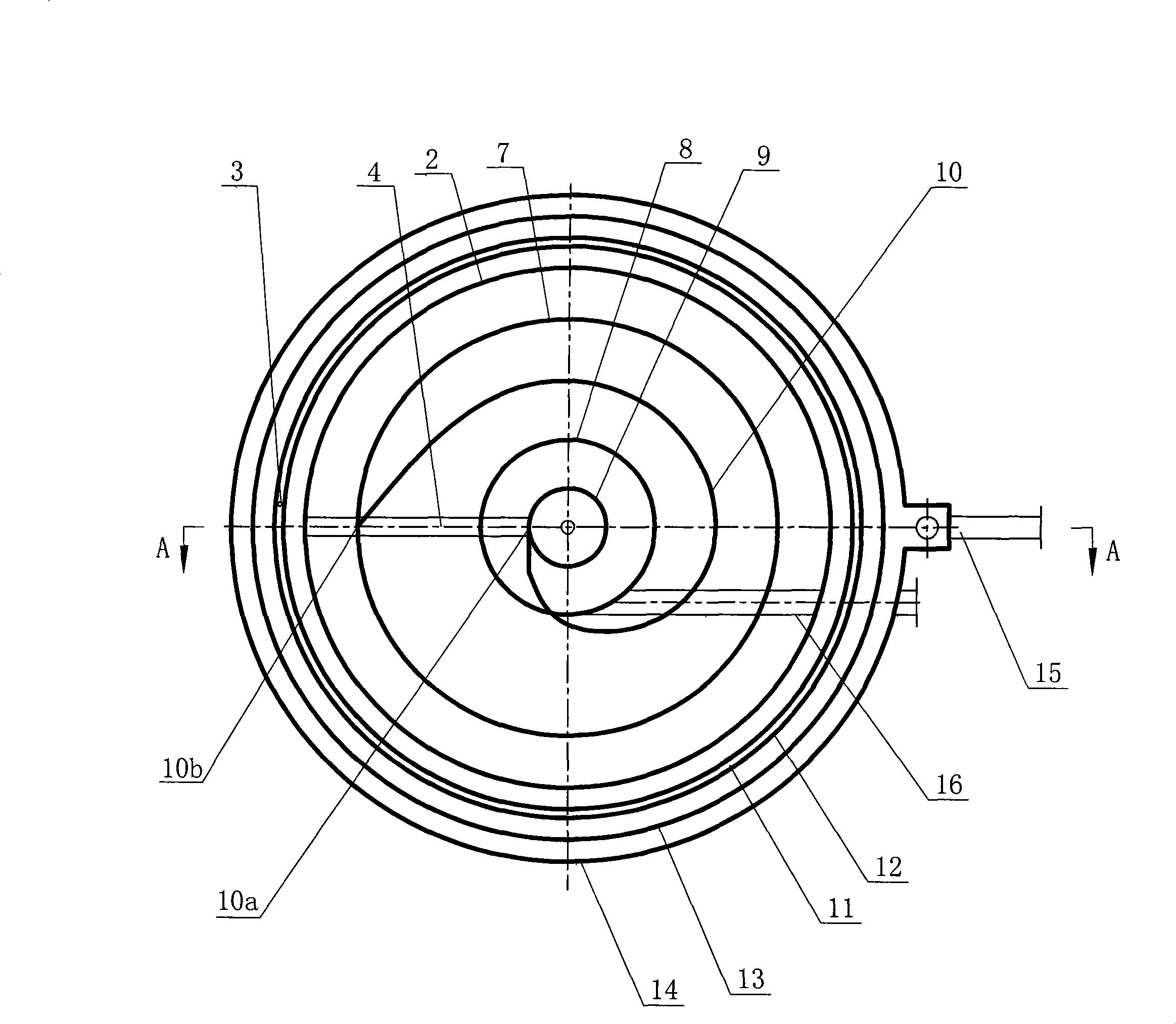

Gas floatation separation device

InactiveCN101417184ALong-term continuous stable distributionBetter even distributionFlotationLiquid separationExternal energyMicrobubbles

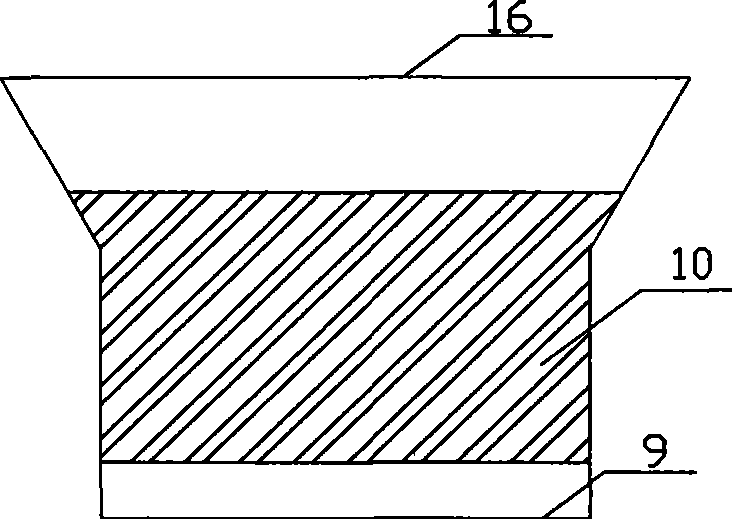

The invention discloses an air flotation separation device, comprising an external cylinder (2), a rotational flow mixed cylinder (8), a first slag-retaining cylinder (7), a first scum drainage pipe (4) and a scum collecting guide plate (10); wherein, the bottom end of the first slag-retaining cylinder (7) and the bottom of the external cylinder (2) have spacing so as to form a water passage; the bottom of the side wall of the rotational flow mixed cylinder (8) is connected with a water inlet pipe (16) which enters in tangent direction; the periphery of the top of the external cylinder (2) is provided with a clean water collecting trench (14); and the scum collecting guide plate (10) is a strip-typed plate in an involute shape, with the involute direction right opposite to the water rotational flow direction in the rotational flow mixed area (A). Compared with the prior art, the air flotation separation device does not need to add external energy cleaning systems, achieves the object of long-term continuously and stably running, and ensures that the requirement that the micro air bubbles adhere to the dispersed oil, emulsified oil and dissolved oil of small particle size as much as possible is met, thus achieving the object of high-efficiency separation of oil from water. The air flotation separation device is especially suitable for low-consistency water containing oil.

Owner:宁波威瑞泰默赛多相流仪器设备有限公司

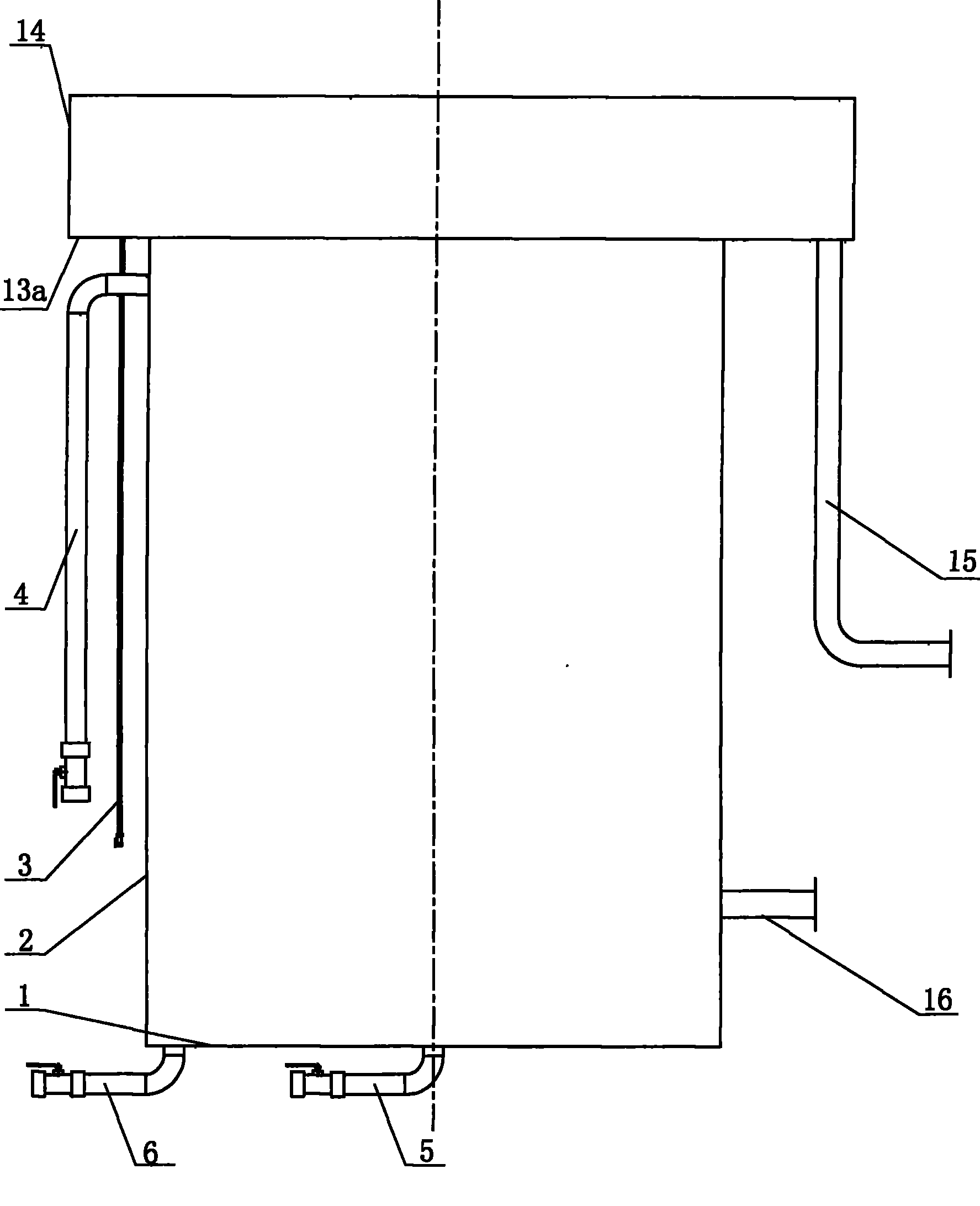

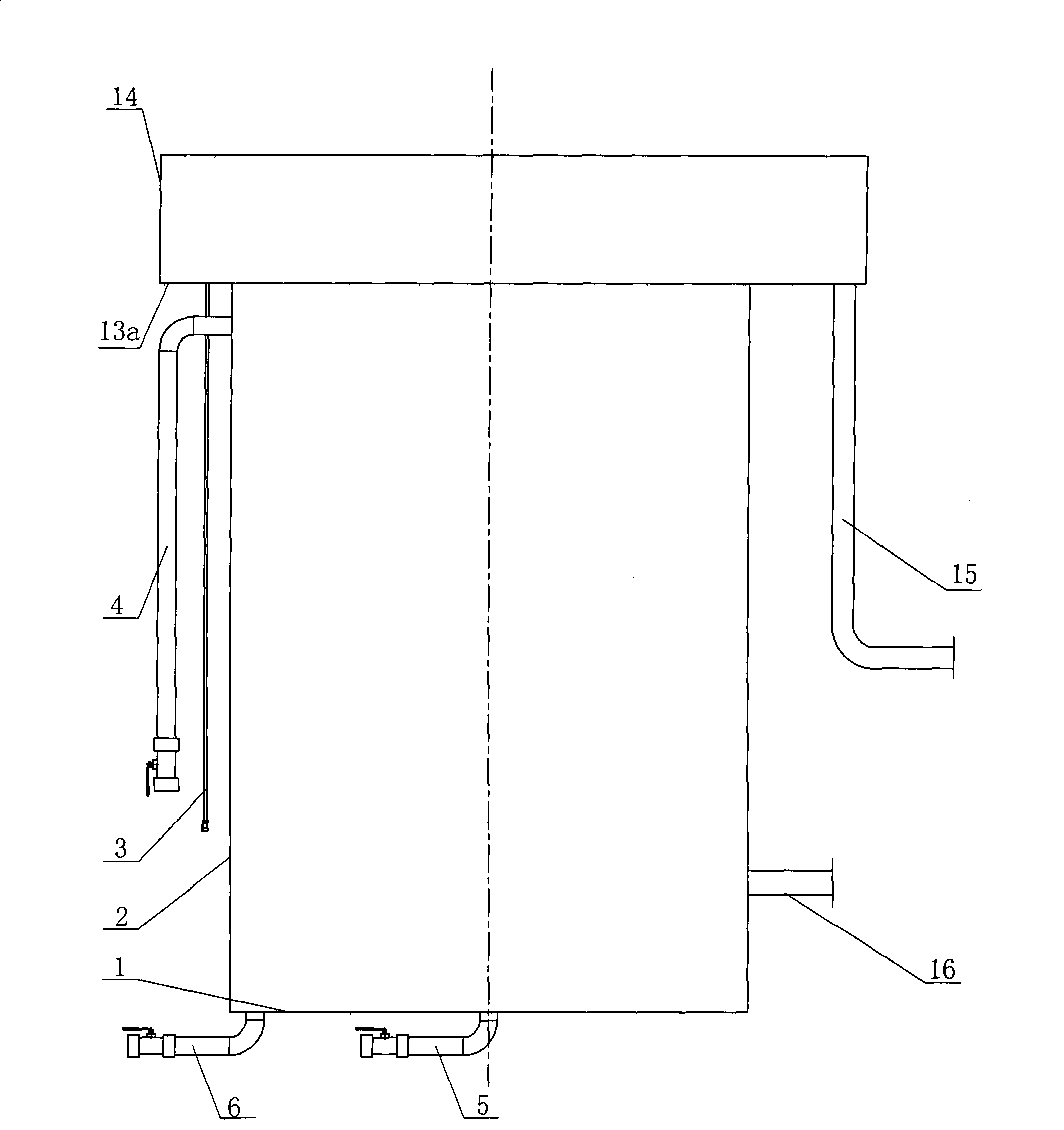

Pressure type air flotation separation device

ActiveCN101935081AAvoid interferenceThe separation interface is stableFatty/oily/floating substances removal devicesLiquid separationWater dischargeSmall particles

The invention discloses a pressure type air flotation separation device, which comprises a tank body (1), and an oil collecting barrel (3) and an air bubble flow rectifying barrel (2) which are arranged in the tank body (1), wherein an air bubble flow rectifying area (A) of which the bottom is sealed is formed between the outer side wall of the air bubble flow rectifying barrel (2) and the inner side wall of the tank body (1); a flotation separation area (B) of which the bottom is open is formed between the inner side wall of the air bubble flow rectifying barrel (2) and the outer side wall of the oil collecting barrel (3); an oil-containing water inlet pipe (4) and a gas-dissolving water inlet pipe (5) are arranged on the tank body (1) tangentially; and a water discharge pipe (11) is arranged at the bottom of the tank body (1). Compared with the prior art, the pressure type air flotation separation device has the advantages that: the interference of large air bubbles with the oil-water flotation separation area is avoided, the oil-water separation interface is more stable and the separation efficiency is high; mutual fusion of micro air bubbles is inhibited, so that the success rate of the contact and adhesion between the micro air bubbles and oil drops with small particle sizes is improved considerably; and thus, the oil-water separation effect is improved considerably. In addition, the device adopts a sealed tank body, so harmful gases are prevented from leaking to the outside.

Owner:浙江海牛海洋工程有限公司

VOC (Volatile Organic Compounds) enrichment device

InactiveCN106512648AFully contactedIncrease the adsorption rateGas treatmentDispersed particle separationDesorptionSorbent

The invention provides a VOC (Volatile Organic Compounds) enrichment device. The device comprises a circulating fluidized bed device and a desorption device, wherein the circulating fluidized bed device is provided with a low-concentration VOC mixed gas inlet, an adsorbent inlet, a purified gas outlet and a solid-phase material outlet; the desorption device is provided with an inlet to be desorbed, a fluidized gas inlet and an enriched gas outlet; the inlet to be desorbed is communicated with the solid-phase material outlet. In the VOC enrichment device, the circulating fluidized bed device is taken as an adsorption device so that system running energy consumption can be lowered remarkably, and the cost can be lowered. Meanwhile, more sufficient contact between low-concentration VOC mixed gas and an adsorbent can be realized, and the adsorption rate and efficiency of the VOC adsorbent are increased. Moreover, the circulating fluidized bed device is taken as the adsorption device, circular use of the adsorbent can be realized, so that long-term, continuous and stable running of a treating procedure is realized, and industrial production demands can be met.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

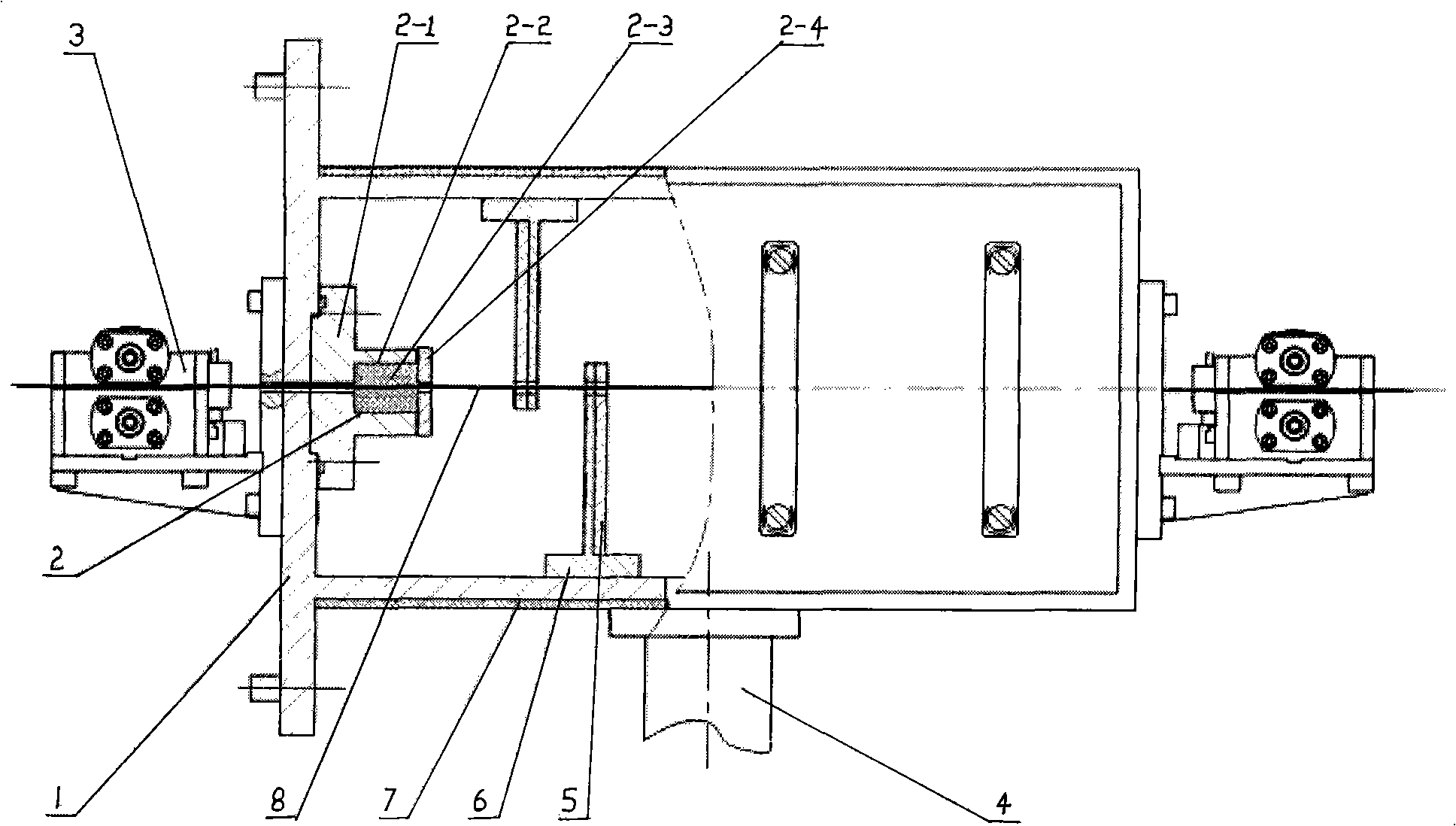

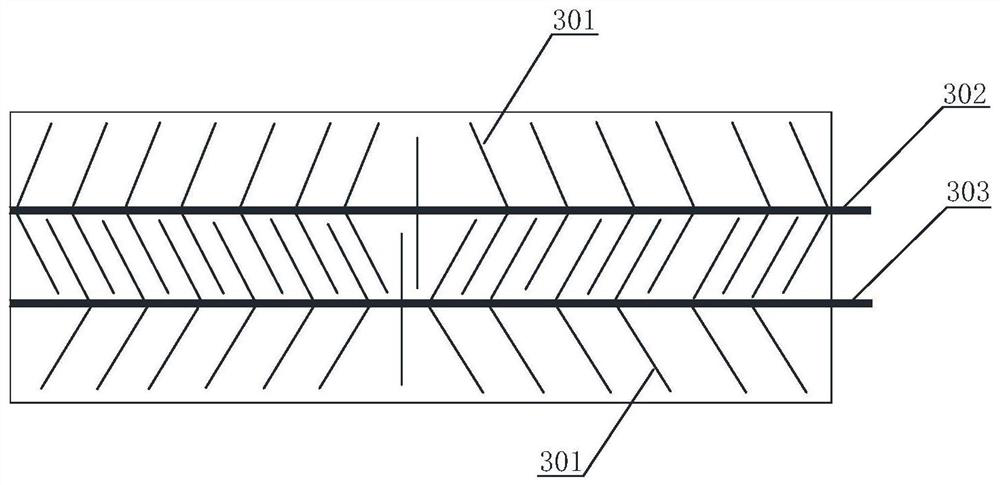

Continuous vacuum transition chamber with linear vacuum motive seal and X-ray radiation protection function

ActiveCN101403102AImprove work efficiencyReduce loadVacuum evaporation coatingSputtering coatingRadiation protectionLead plate

The invention discloses a continuous vacuum transition chamber with linear vacuum dynamic sealing and X ray protection functions, which is characterized in that: the continuous vacuum transition chamber consists of a transition chamber box body, more than two linear dynamic sealing devices arranged in the transition chamber box body, a guiding device at the two ends of the box body, a pipeline of the vacuum pumping pipe, lead baffles, a bracket for the lead baffles and protective lead arranged outside the transition chamber box body; an upper sealing block and a lower sealing block of the linear dynamic sealing device tightly press the sealing pressure plate, thus forming a vacuum-tight linear dynamic sealing channel; X ray protection lead baffles which are provided with lead plates and staggered up and down are arranged between the dynamic sealing devices, the vacuum transition chamber is coated with protection lead, and the vacuum pumping pipe is connected with a vacuum pump. The continuous vacuum transition chamber has the advantages as follows: the vacuum degree / pressure of the vacuum working chamber can be ensured to reach 0.5 to 1Pa under the running state of the continuous passing through of ribbon metal materials; X ray dose reaches safe dose at the inlet and outlet, the load of the vacuum pump is relatively small, the vacuum device can run continuously and stably for a long time and the work efficiency of processing equipment is high.

Owner:宿迁三鑫科技有限公司

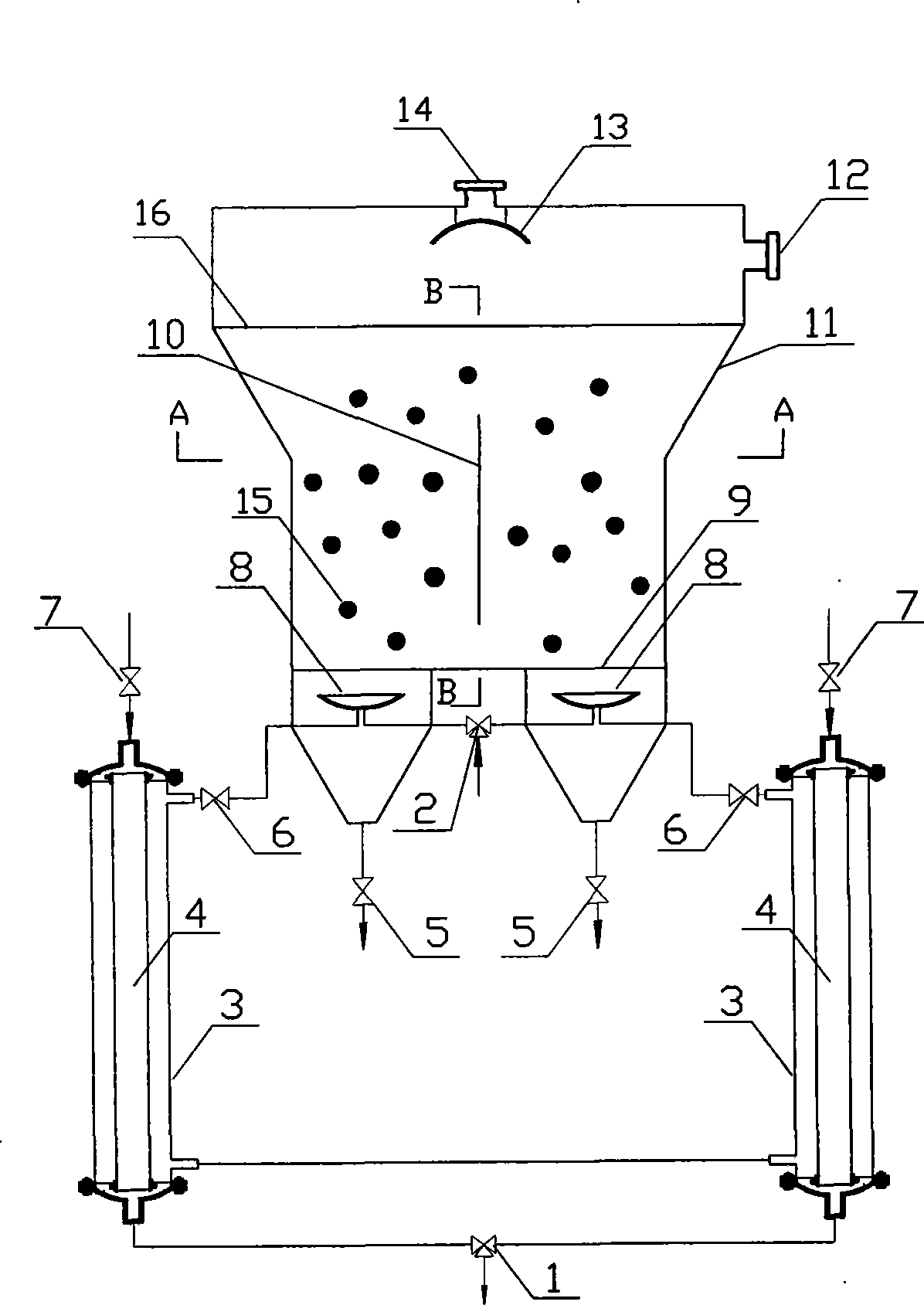

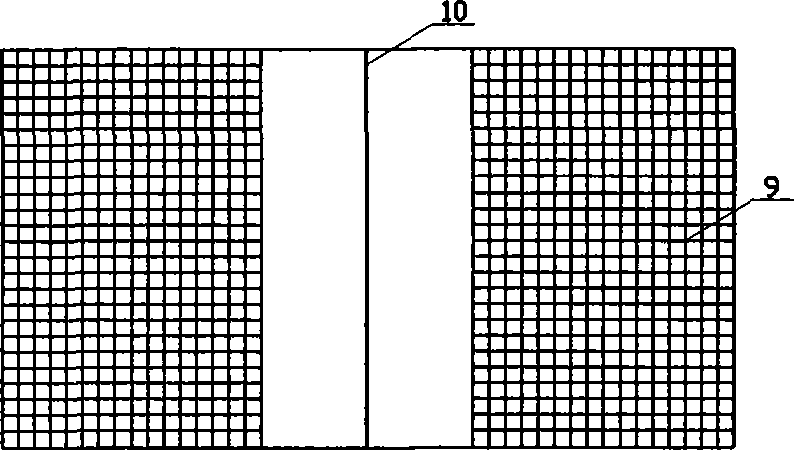

Double-circulating ceramic membrane bioreactor

InactiveCN101503245AEasy to handleImprove biochemical propertiesBiological water/sewage treatmentBiochemical engineeringInverted pyramid

The invention relates to a bicirculating ceramic membrane bioreactor which comprises a biological reaction tank internally installed with biological packing and a membrane module; wherein, both sides of the bottom of the biological reaction tank are symmetrically and respectively provided with the membrane module; the left and the right of the lower part of the biological reaction bank are symmetrically provided with two inverted pyramid bodies; the middle part of the biological reaction bank is vertically provided with a plate washer, the upper end and the lower end of the plate washer are provided with sieve meshes at intervals; thereby, the on-line back washing of the ceramic membrane pipe and the aeration of the biological reaction tank are reasonably and effectively coupled; namely, in the regeneration process of the on-line back washing of the ceramic membrane pipe, not only oxygenation and aeration can be carried out, but also both of the interior and the exterior of the biological reaction tank can form circular flow state to intensify the biochemistry effect; and meanwhile, the clean water is obtained; in addition, by alternately switching the back-washing aeration and suction filtration operation, the bioreactor can continously and stably run again and again. The bioreactor is characterized by high efficiency, energy-conserving, low cost and the like and is suitable for the effective treatment of the multiple waste waters.

Owner:JIUJIANG UNIVERSITY

Online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and operating method thereof

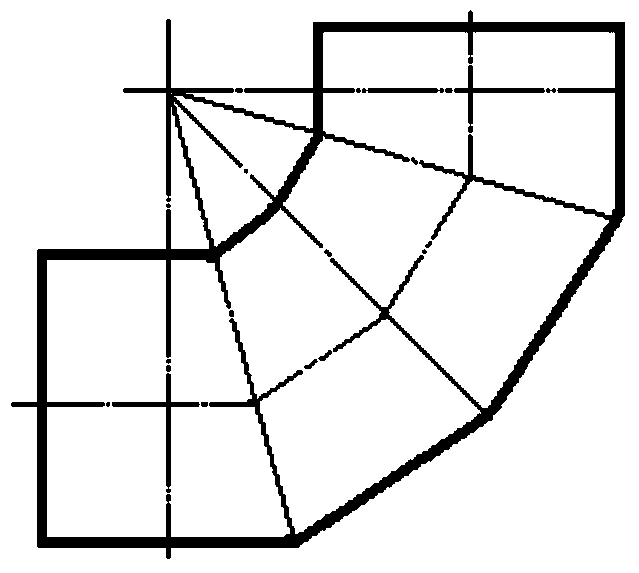

The invention provides an online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and an operating method thereof. A gas-liquid-solid three-phase natural circulation fluidized bed evaporation and concentration device in an industrial production scale in which the heating area of a heater is 18.9 m<2> and the evaporative power is 1100-1400 kg / h is determined. The inventions and innovations of a screen type discharging device, a 90-degree multi-section short-radius elbow connecting pipe and a demister on the upper part of a separation chamber are designed. At present, the production operation result of the industrial scale device of about 100-ton extracting solutions of Menopause Ease and other over ten traditional Chinese medicines proves that compared with a traditional two-phase flow evaporation concentrator with the heating area of 18 m<2> in a factory and an operating method thereof, the device and the method under approximate operation conditions have the advantages that the total heat transfer coefficient and evaporation intensity are improved, a wall hanging phenomenon of the two-phase flow evaporation concentrator is avoided, the wall hanging phenomenon existing in a traditional Chinese medicine extracting solution evaporation concentrator is eliminated, and high-efficiency continuous and stable operation is realized.

Owner:TIANJIN UNIV

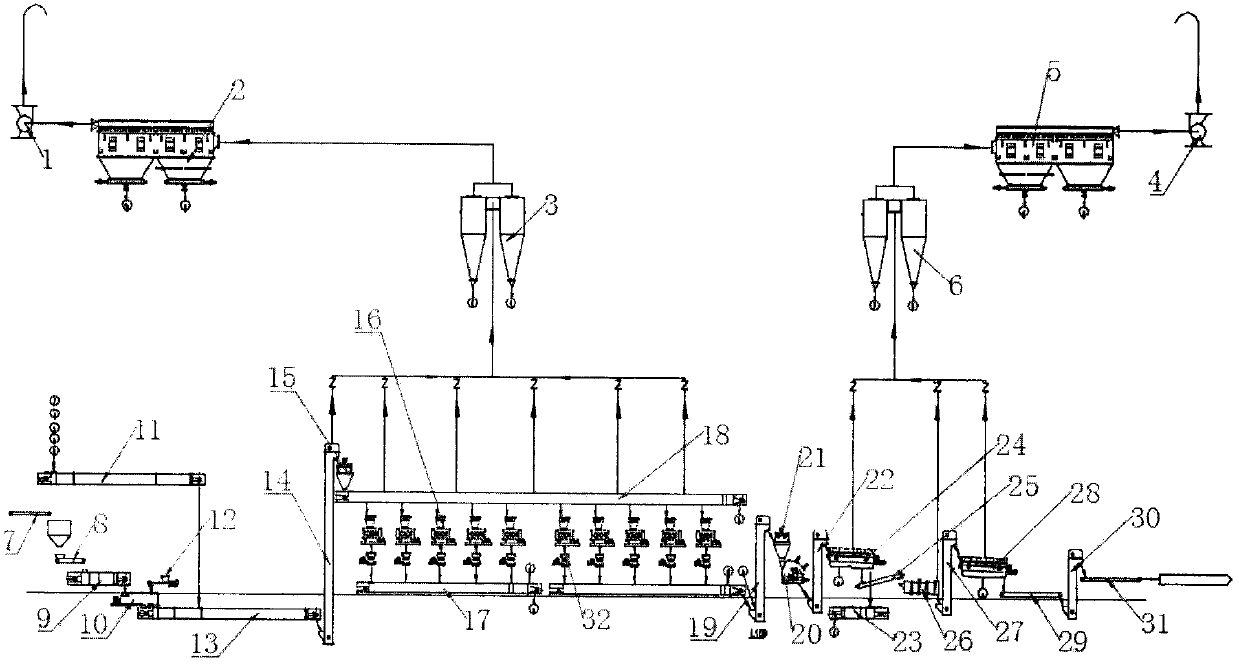

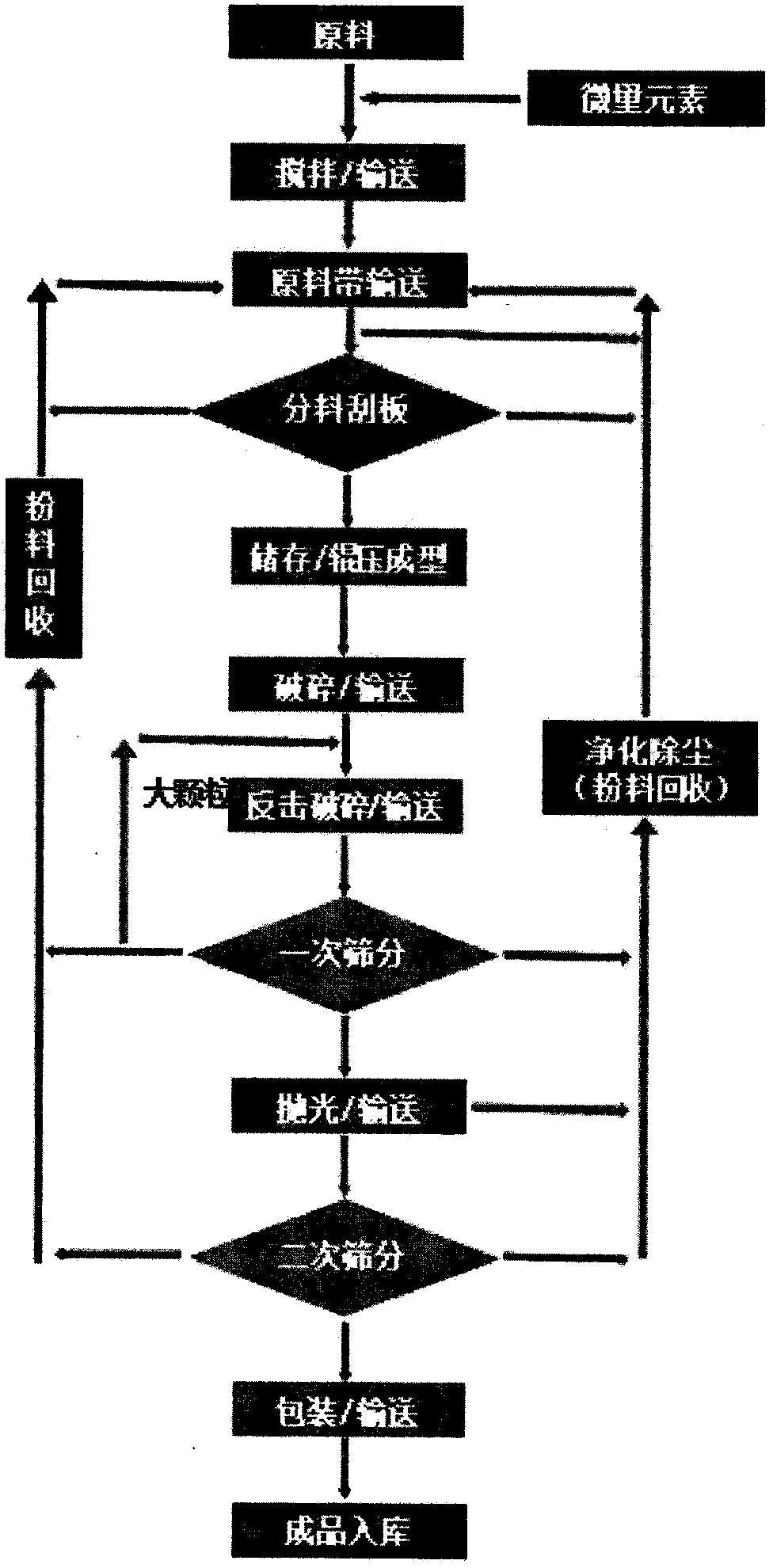

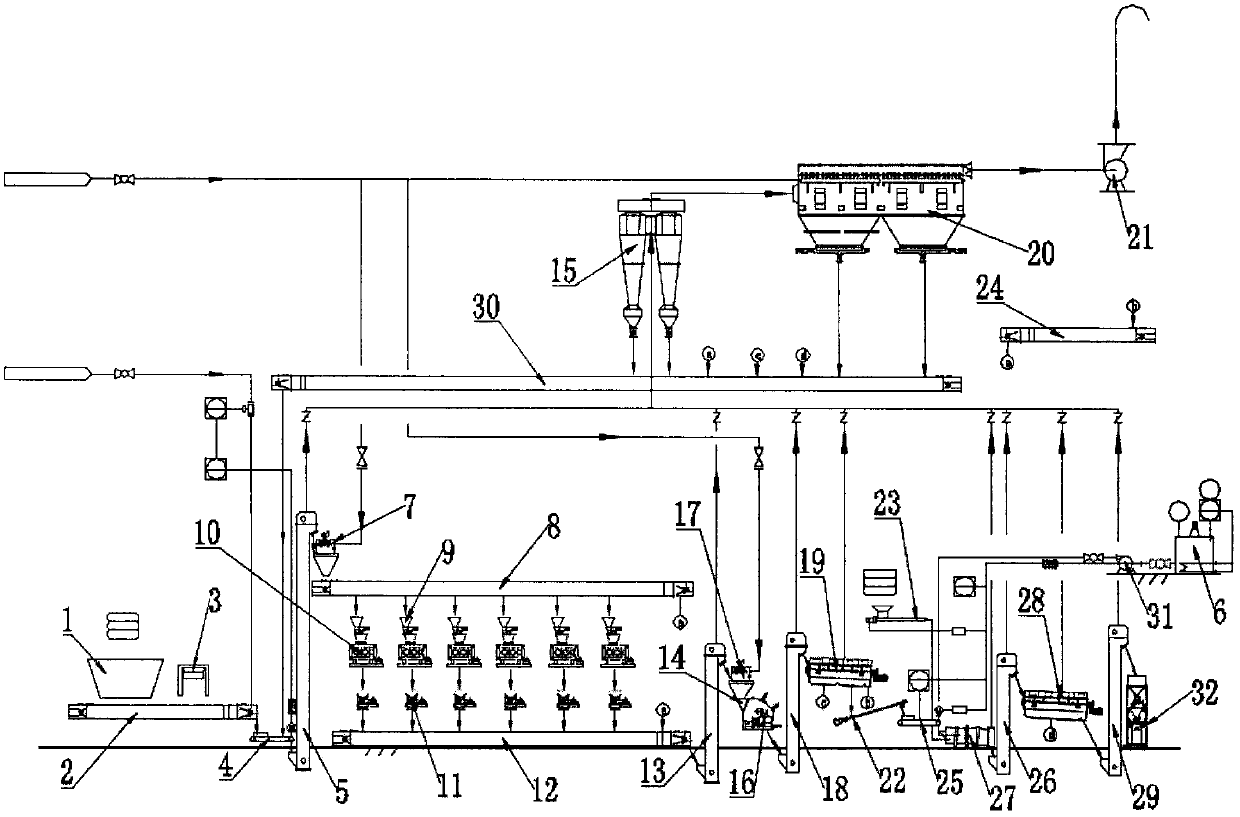

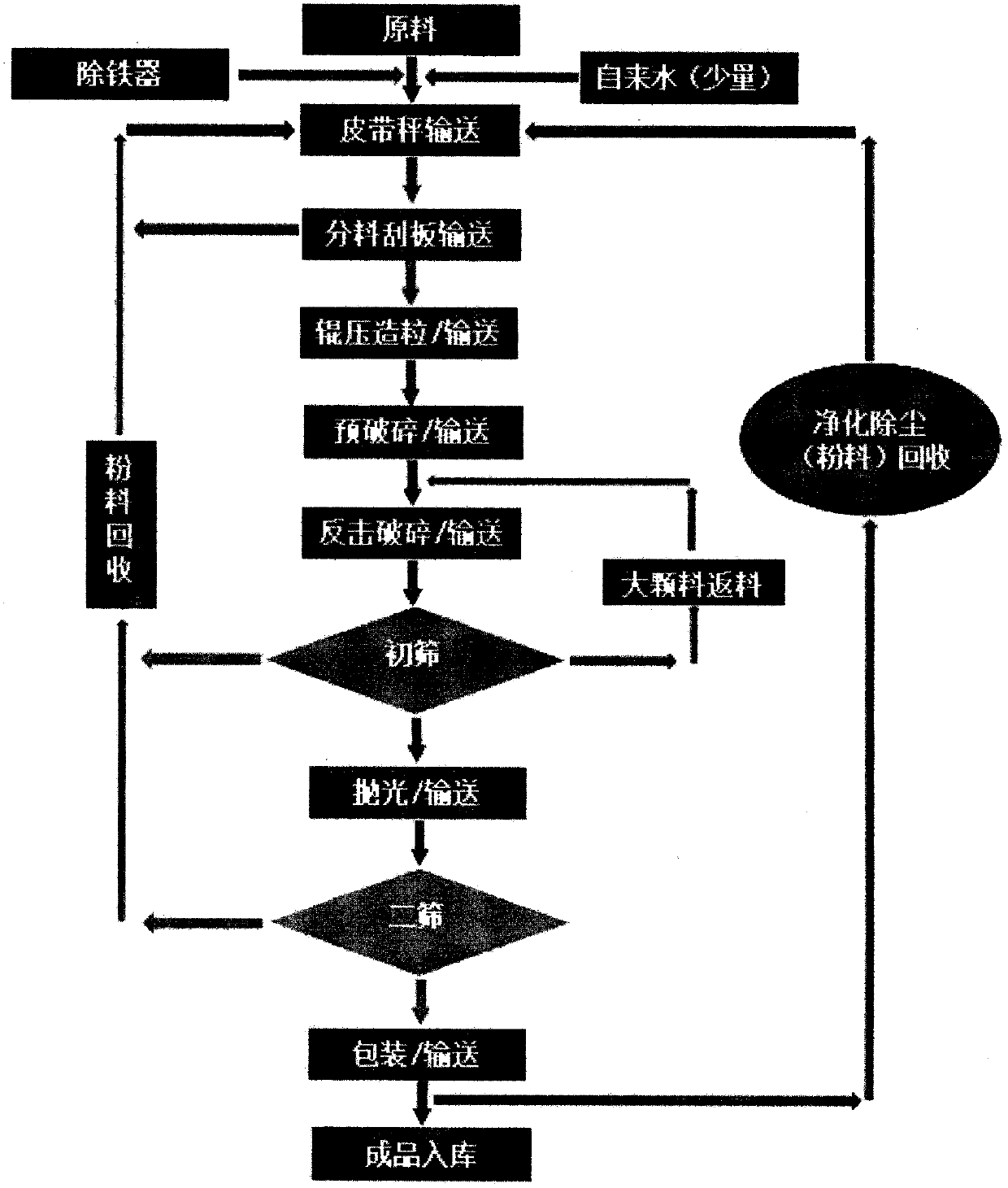

Dry method rolling granulation production process

InactiveCN107670585AImprove efficiencyHigh degree of automationGranulation by pressingCompression moldingFailure rate

The invention discloses a dry method rolling granulation production process. The whole production process is a cyclic operation, and the strength of a finished product is controlled by adjusting the pressure of a roller. A material is directly compressed by mechanical pressure and formed without any additives. The product purity is guaranteed. According to the process, dry powder is adopted for direct granulation without a subsequent drying process, and the process is more favorable for connection and convergence and transformation of an existing production process. A production system is compact in structure, convenient to maintain, simple to operate, low in energy consumption, high in efficiency and low in failure rate. In the production process, a dedusting system is arranged and can control environmental pollution, reduce powder waste and packaging costs, and improve product transport capacity; a metering belt is adopted to convey raw materials for feeding of the process, the raw material conveying amount can be known at any time, and the rate of finished products in the whole process can be obtained by simple calculation; in the manufacturing process of the process, unqualified materials are collected and are rolled and formed again, and the raw material utilization rate and the rate of finished products are improved.

Owner:江苏福亿自动化设备有限公司

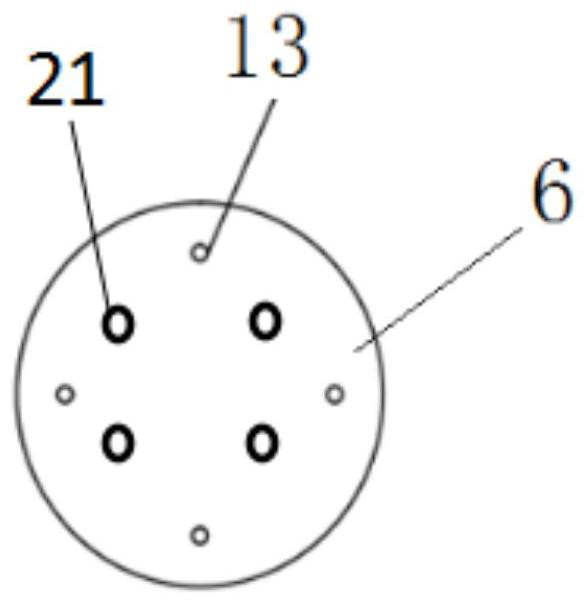

Method and equipment for nylon 66 short-flow continuous polymerization

The invention relates to a method and equipment for nylon 66 short-flow continuous polymerization. The method comprises the steps of carrying out heating, evaporation, concentration and polycondensation of 30-70% of a nylon 66 salt solution in a normal pressure pre-polypolycondensation tower by adopting a reaction distillation method to obtain a prepolymer with a polymerization degree of 5-50 (preferably 20-40) and equimolar terminal carboxy group and terminal amine group, and allowing the prepolyer to directly produce a polymer with a polymerization degree meeting technical indicators without flash distillation. A falling film devolatilization method is adopted in the polycondensation kettle to accelerate distillation out of condensation water, reduce reaction temperature, shorten reaction time and reduce gel; and the falling liquid film is used to seal and cover the kettle wall to avoid scarring of the kettle wall. Compared with the traditional nylon 66 continuous polymerization device, the method and the equipment provided by the invention has the advantages of short process, large single line scale, less investment, low operating cost, good product quality, long continuous operation cycle, and environmental friendliness.

Owner:XCEED CHEMTECH

VOCs adsorption treatment device

InactiveCN106621703AReduce resistanceEnhanced mixing processGas treatmentDispersed particle separationSorbentDesorption

The invention provides a VOCs adsorption treatment device which comprises a bubbling fluidized bed, a gas-solid separation device and a desorption device. A low-concentration VOCs mixed gas inlet, an adsorbent inlet and a mixture outlet are arranged on the bubbling fluidized bed, the gas-solid separation device is provided with a mixture inlet, a purified gas outlet and a solid-phase material outlet, and the mixture inlet is communicated with the mixture outlet; a to-be-desorbed material inlet, a fluidized gas inlet and an enrichment gas outlet are arranged on the desorption device, and the to-be-desorbed material inlet is communicated with the solid-phase material outlet. The bubbling fluidized bed is utilized as an adsorption device, so that running gas speed is low, bed layer resistance is low, and running energy consumption of a system can be lowered remarkably. In addition, mixing and wearing of a VOCs adsorbent can be enhanced, more sufficient contact between low-concentration VOCs mixed gas and the adsorbent can be realized, adsorption capacity of the adsorbent is improved, and adsorption efficiency of the VOCs adsorbent is further improved. Moreover, the VOCs adsorption treatment device can continuous and stably run for a long time and can meet industrial production needs.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

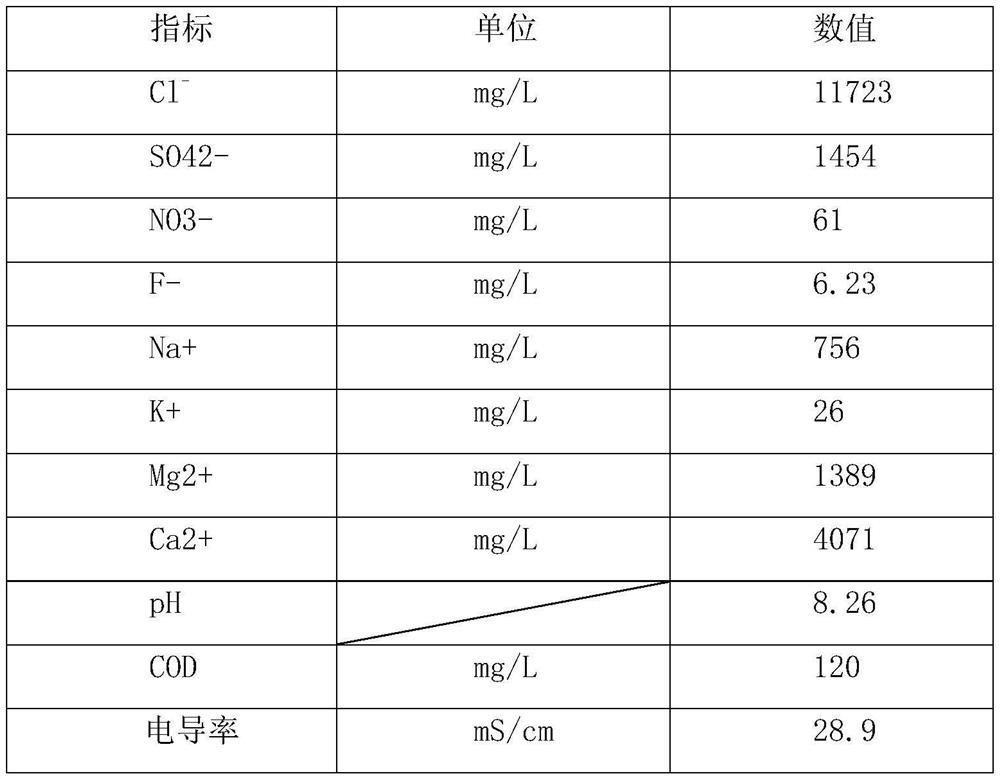

Seawater treatment method

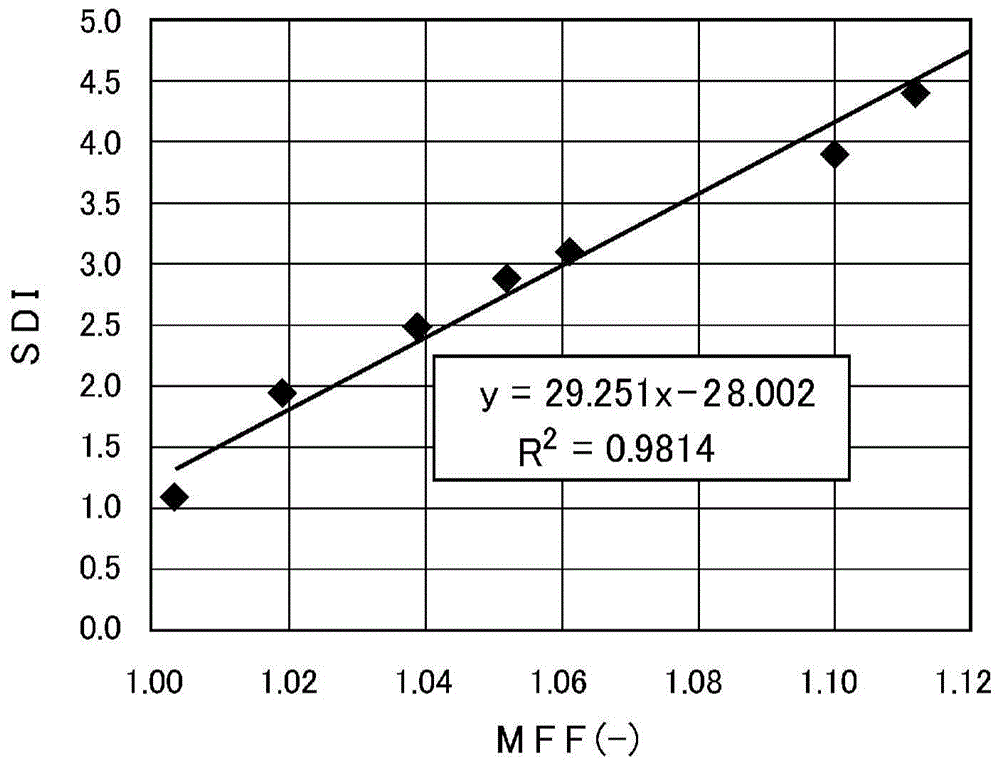

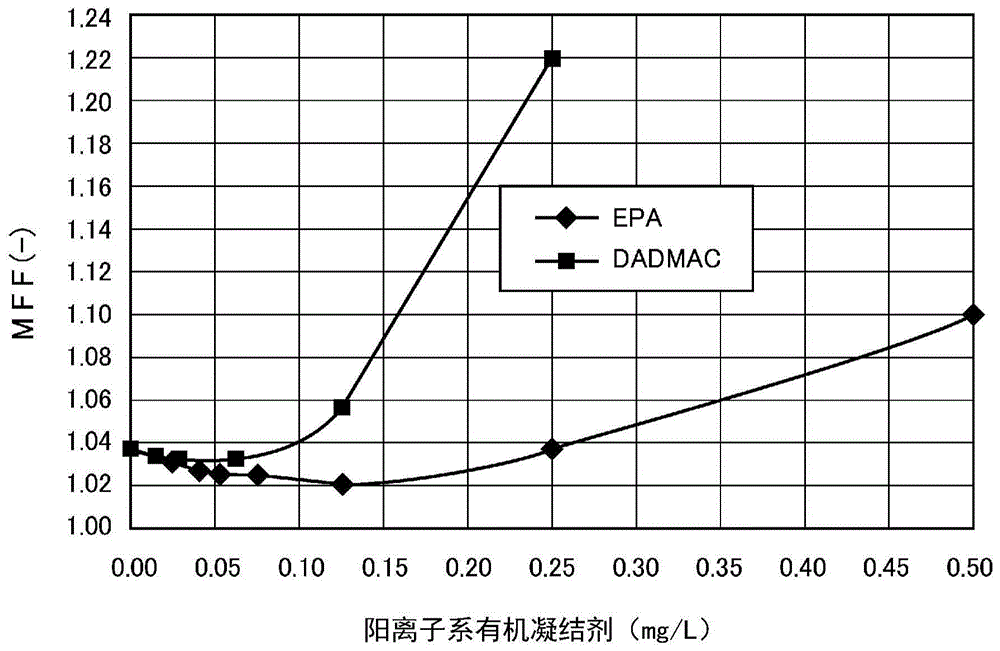

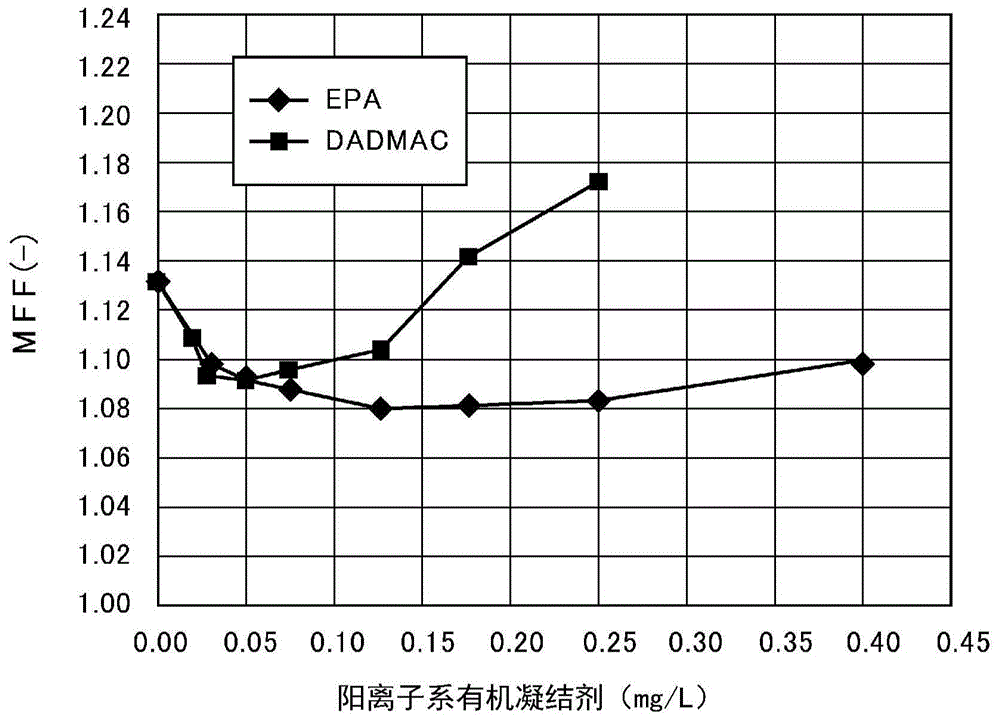

InactiveCN104023808AGood SDI valueAgglutinationMembranesGeneral water supply conservationSoil scienceSalinity

In a seawater treatment method which comprises subjecting seawater to coagulation with a coagulant and solid-liquid separation and then conducting RO treatment of the resulting seawater, the present invention makes it possible to provide high-quality feed water for the RO treatment, even when the amount of the coagulant added is reduced. The use of this high-quality feed water enables the RO treatment to be stably conducted over a long period. This seawater treatment method is a method for pre-treating seawater prior to membrane separation, said method being characterized by adding a cationic organic flocculant and / or an inorganic coagulant to seawater to conduct reaction, thereafter adding an alkaline solution of a high-molecular compound which has a phenolic hydroxyl group and which is insolubilized under a high salt concentration to the resulting seawater to conduct agglomeration, and then subjecting the thus treated seawater to solid-liquid separation. The treated seawater obtained by the method is thereafter desalinated by membrane separation.

Owner:KURITA WATER INDUSTRIES LTD

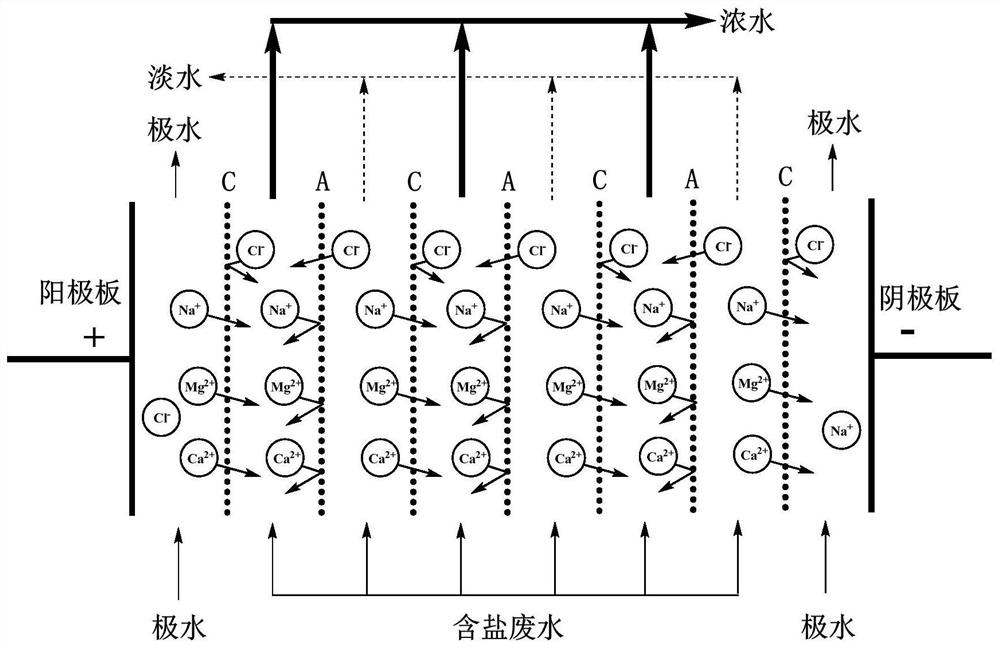

Anti-scaling electrodialysis system based on pH control and treatment process

PendingCN112408558AAchieve fouling-free operationImprove processing efficiencyWater/sewage treatment by electrochemical methodsDispersed particle separationPh controlAcid uptake

The invention relates to an anti-scaling electrodialysis system based on pH control. The anti-scaling electrodialysis system comprises an electrodialysis reactor, a fresh water tank, a concentrated water tank, a pH control system and an acid absorption system, wherein the electrodialysis reactor is formed by assembling an anode plate, a membrane stack and a cathode plate in sequence; the membranestack is composed of cation selective exchange membranes and anion selective exchange membranes which are arranged at intervals to form fresh water channels and concentrated water channels which are arranged at intervals, and polar water channels are arranged on the two sides close to the polar plates respectively; the pH control system is mainly composed of an acid storage tank, an acid adding pump, a pipeline mixer and an online pH meter, a polar water outlet of the polar water tank is connected to an inlet of the pipeline mixer, and the online pH meter is installed at the inlet end of the pipeline mixer. The anti-scaling electrodialysis system based on pH control has the beneficial effects that polar plate scaling in the system operation process can be avoided, scaling-free operation ofthe electrodialysis system is achieved, the operation working condition is optimized, and the water treatment efficiency is improved.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Processing method for electro-adsorption demineralized water

ActiveCN102603040BPromote regenerationNo foulingDispersed particle separationElectricitySaline water

The invention discloses a processing method for electro-adsorption demineralized water, which belongs to the water processing with an electrochemical separation method. The processing method for the electro-adsorption demineralized water comprises the following technical processes of energizing working, discharging for standing, carrying out short circuit and regenerating, and has the characteristics that industrial hydrochloric acid is injected into an electro-adsorption module (1) under the condition of continuously feeding water and energizing before the technical process of discharging for standing; water injected with the hydrochloric acid is controlled to just fill in the electro-adsorption module without being discharged out of the system; in addition, the pH (Potential Of Hydrogen) value range of the electro-adsorption module is controlled to 2.0-6.0; while the hydrochloric acid is injected, yielding water normally enters a water production tank (6) and is switched to a middle water discharging tank B (12); and after the electro-adsorption module is full of the hydrochloric acid, water is stop to feed, and the power supply is cut off to enter the technical processes of discharging for standing and regenerating. The invention provides the processing method for the electro-adsorption demineralized water, which has the advantages of simple step and excellent electrode regeneration effect, the electro-adsorption module does not scale, and an electro-adsorption demineralizer is guaranteed to continuously and stably operate for a long term.

Owner:CHINA PETROLEUM & CHEM CORP

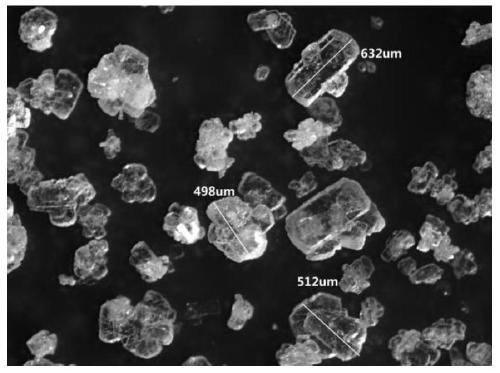

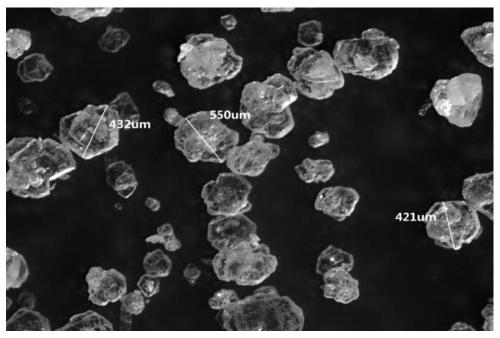

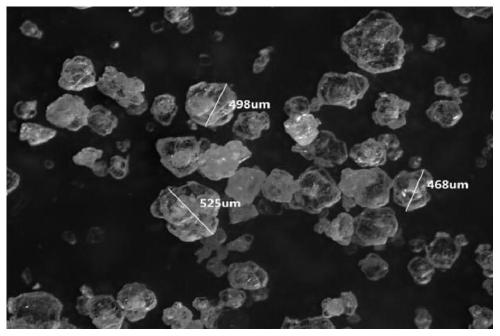

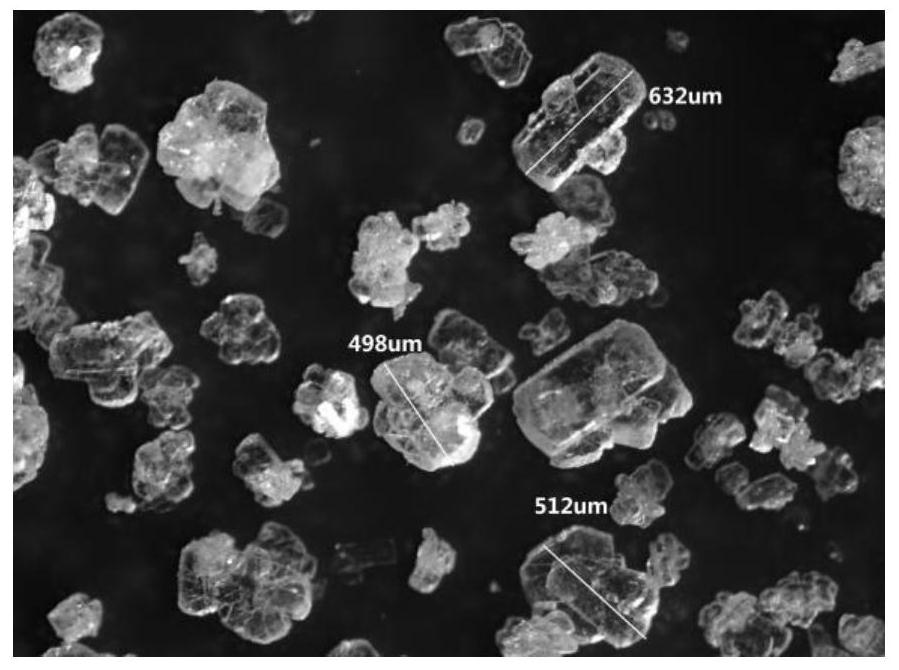

Additive used in methionine preparation process and preparation method of methionine

ActiveCN111100051AEasy to useImprove stabilityOrganic compound preparationFood processingMethionine biosynthesisStructural formula

The invention relates to an additive used in a methionine preparation process and a preparation method of methionine. The additive provided by the invention is a mixture containing a component A, a component B and a component C, wherein the component A has a structural formula represented by the following general formula (1), the component B has a structural formula represented by the following general formula (2), the component C is silicone oil, the general formula (1) is RCON(CH3)CH2CH2SO3Na (1), and the general formula (2) is shown in the specification. The preparation method of methionineprovided by the invention comprises the step of carrying out crystallization and / or recrystallization of methionine in the presence of the additive provided by the invention. The additive provided bythe invention is uniform in emulsification, good in stability, capable of being stably used for a long time and suitable for a continuous crystallization process. The prepared methionine is good in crystallization crystal form, high in bulk density and good in flowability. Besides, according to the preparation method of methionine, a crystallization system can continuously and stably operate fora long time, no obvious foaming phenomenon exists, and the crystallization process of the methionine product is stably carried out.

Owner:SHANDONG XINHECHENG AMINO ACID +2

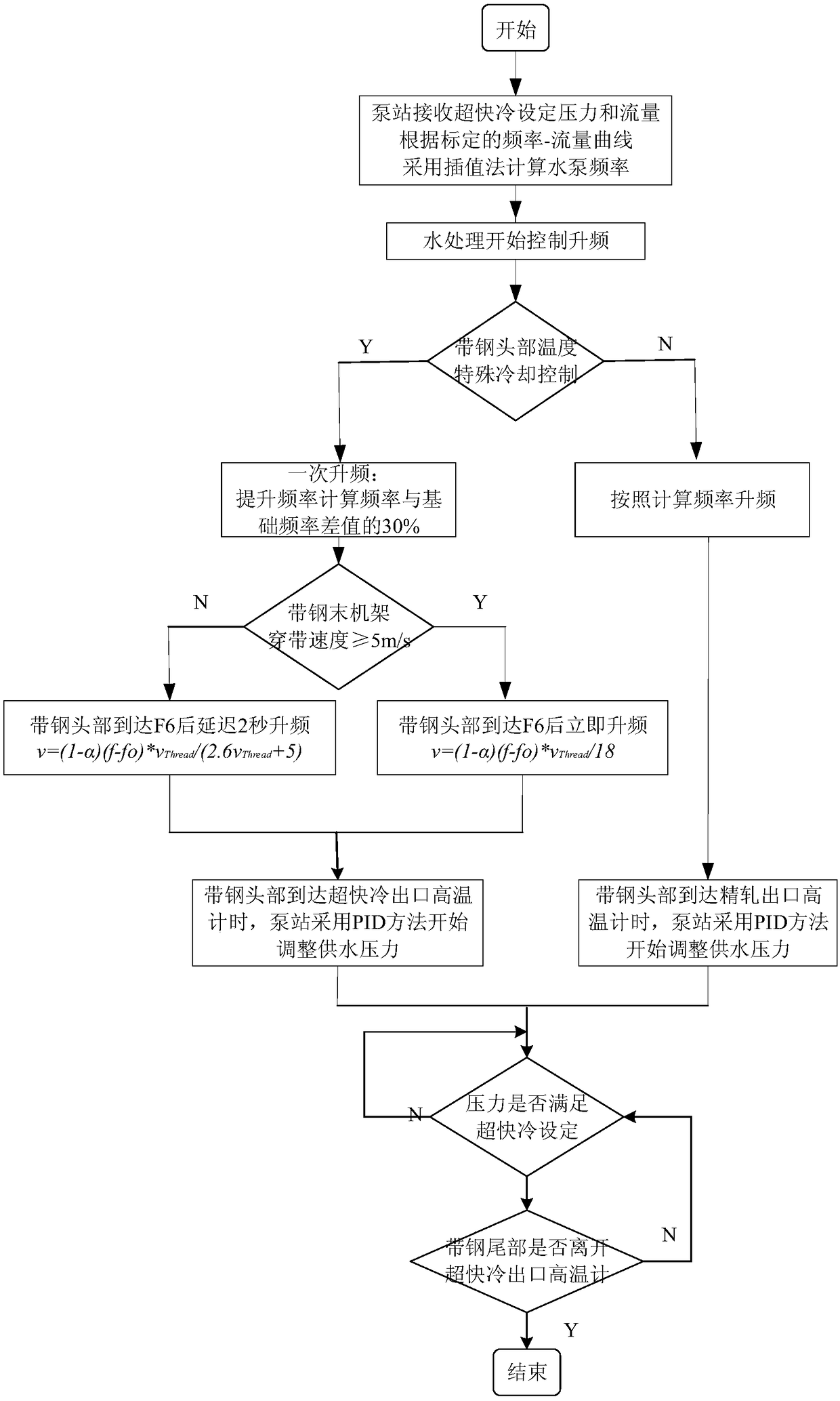

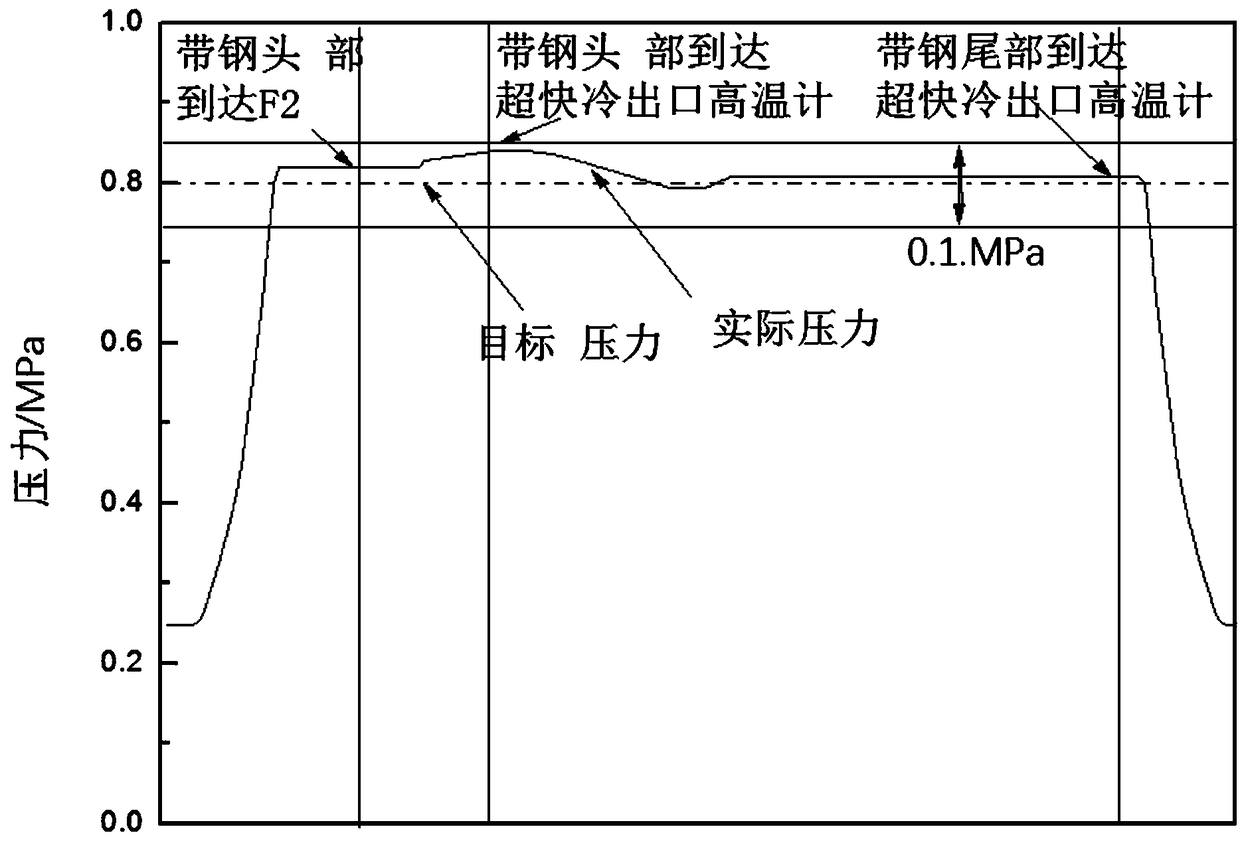

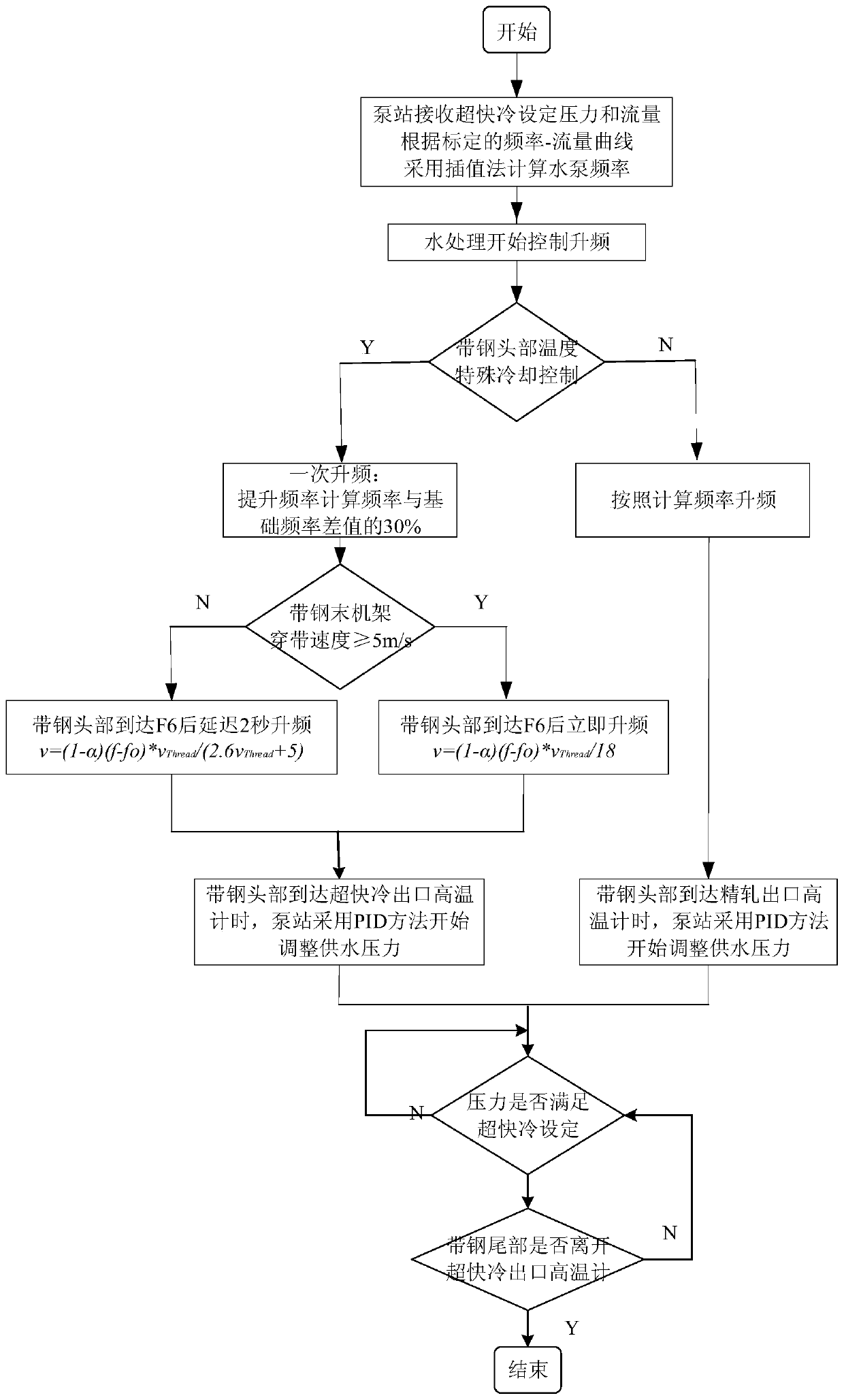

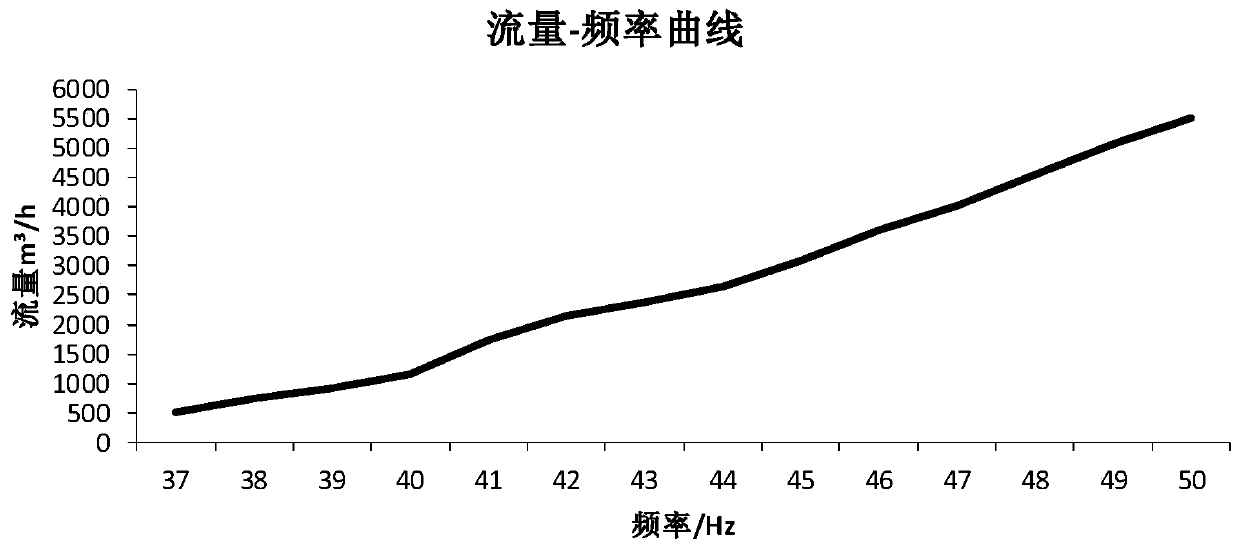

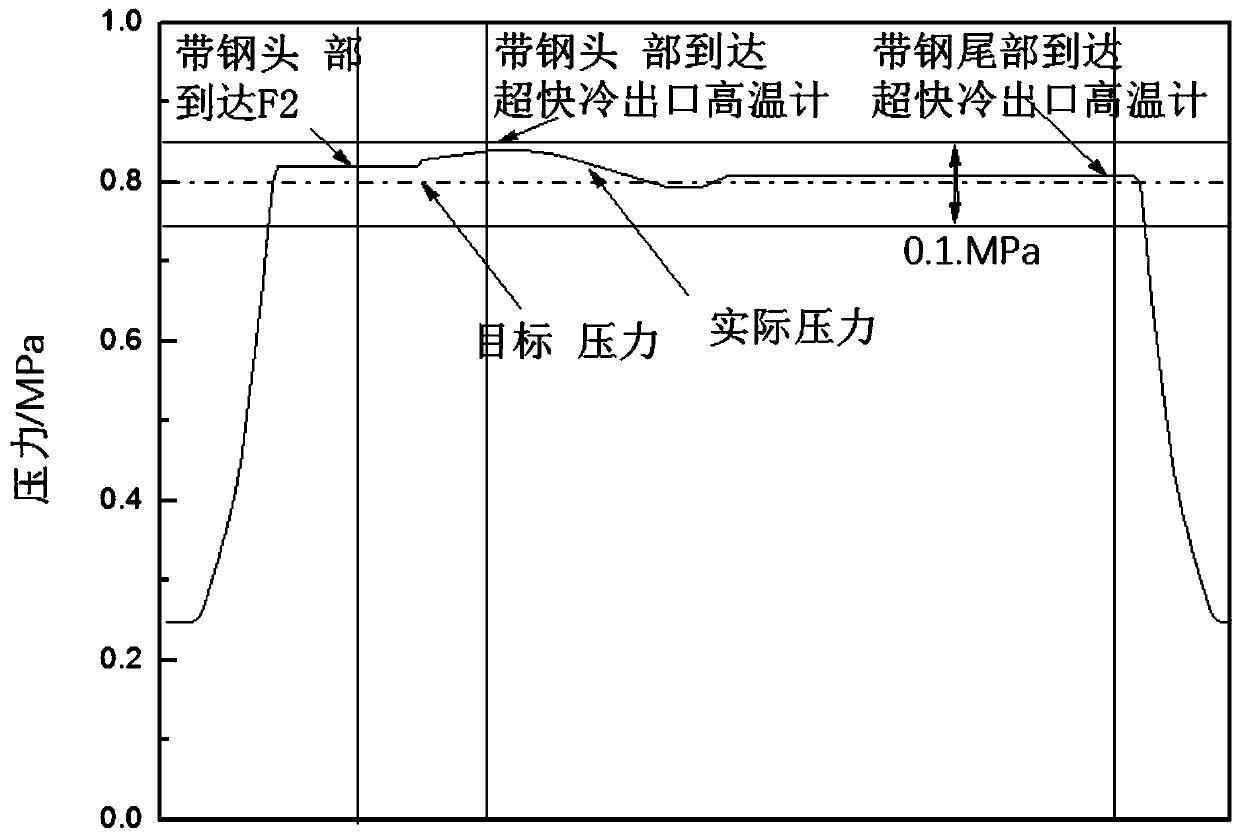

Frequency-changing water supply method for hot continuous line rolling and ultra-fast cooling system

ActiveCN109174974AReduce shockReduce vibrationTemperature control deviceWork treatment devicesUltra fastStrip steel

The invention discloses a frequency-changing water supply method for a hot continuous line rolling and ultra-fast cooling system, and belongs to the field of hot continuous rolling and ultra-fast cooling. The frequency-changing water supply method comprises the steps that at an accelerating point of a water pump, the frequency of the water pump is calculated according to the ultra-fast cooling setpressure and water quantity; when the strip steel head does not need special cooling control, a pump station is directly accelerated to the calculated frequency, and then when the strip steel head reaches a pyrometer of a finishing rolling outlet, the water supply pressure of the water pump is dynamically adjusted to reach the ultra-fast cooling pressure set value; when the strip steel head needsspecial cooling control, two times of accelerating are required; then when the strip steel head reaches the pyrometer of the finishing rolling outlet, the water supply pressure of the water pump is dynamically adjusted to reach the ultra-fast cooling pressure set value; and when the strip steel tail leaves an ultra-fast cooling area, the pump station is decelerated to the base frequency state. According to the frequency-changing water supply method, the problem of high-pressure and large-flow stable water supply is solved, especially when special cooling control is conducted on the strip steel head, ultra-fast cooling of the water pressure can be quickly and stably conducted, energy consumption is lowered, pipeline impact is reduced, pipeline vibration is lowered, and thus equipment is protected.

Owner:NORTHEASTERN UNIV LIAONING

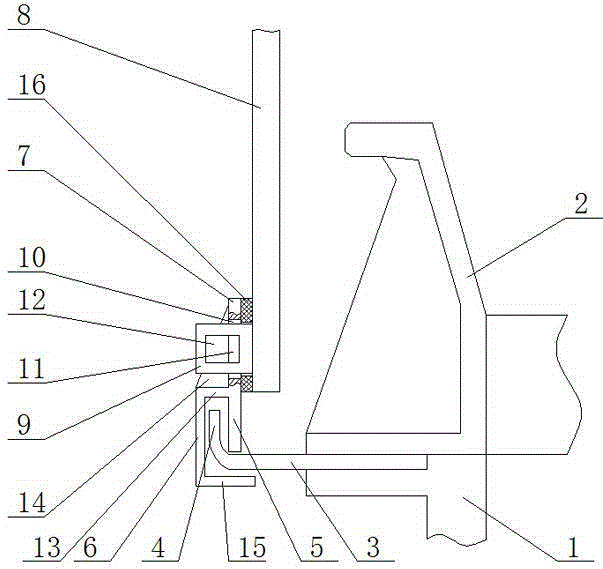

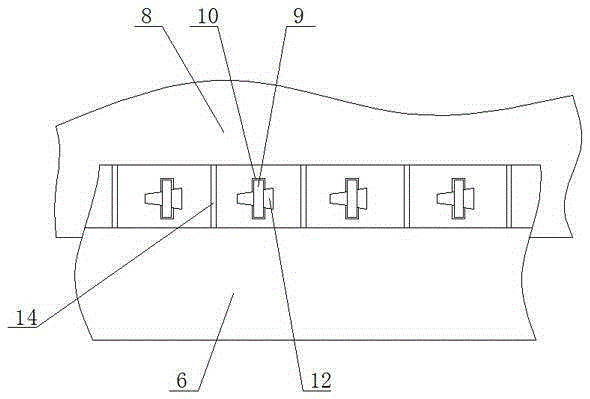

Sealing device between flue gas recirculation cover and trolley of sintering machine

ActiveCN105403049AExtended service lifeGuarantee long-term continuous and stable operationFurnace typesLeakage rateFlue gas

The invention discloses a sealing device between a flue gas recirculation cover and a trolley of a sintering machine. The sealing device comprises the trolley, and breast boards are arranged on the two sides of the trolley. The sealing device is characterized in that lower sealing supporting boards are arranged on the outer sides of the breast boards; folding edges are arranged on the outer sides of the lower sealing supporting boards and are perpendicular to the horizontal plane; the length direction of the folding edges is parallel to that of the breast boards; inner baffles are arranged on the sides, close to the breast boards, of the folding edges, and outer baffles are arranged on the sides, far away from the breast boards, of the folding edges; the tops of the inner baffles and the tops of the outer baffles are connected with a connecting plate; and the connecting plate is connected with the flue gas recirculation cover of the sintering machine through a connecting piece. The service life is long, the sealing structure can be replaced without shutdown, the air leakage rate of the part between the trolley and the flue gas recirculation cover can be lowered to be below 10%, and the energy saving and emission reducing effect of the sintering process is guaranteed; and along with sintering production, the sealing effect is gradually enhanced on the original basis, and long-term continuous and stable running of the sintering process can be guaranteed.

Owner:JIGANG INT ENG & TECH CO LTD

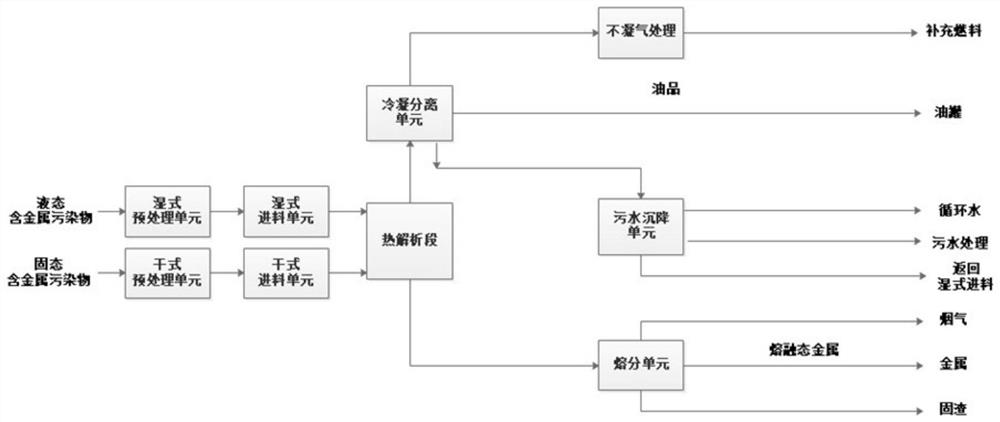

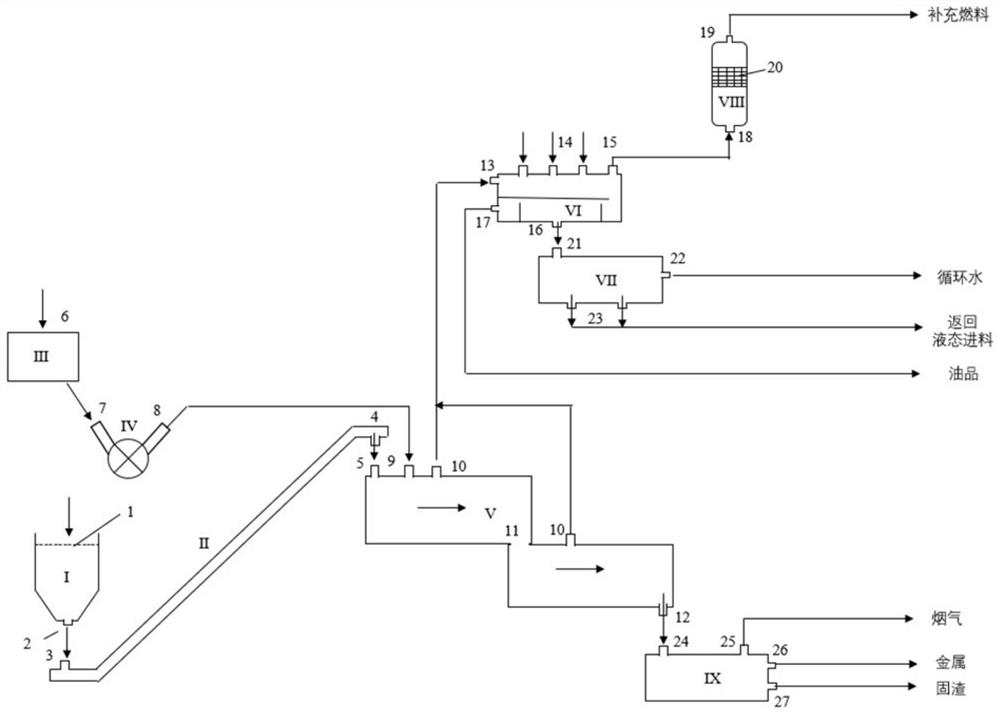

Harmless treatment and resource utilization method for metal-containing pollutants

The invention discloses a harmless treatment and resource utilization method for metal-containing pollutants. The method includes the following steps that the metal-containing pollutants are fed into a pretreatment unit, pretreating is conducted, the metal-containing pollutants are fed into a thermal desorption unit through a feeding unit, pyrolyzing is conducted in the thermal desorption unit, and pyrolyzed high-temperature oil gas is fed into a condensation separation unit; solid slag obtained after pyrolysis enters into a melt separation unit, a melt separation furnace is adopted in the melt separation unit to continue to heat the solid slag to 1200-1800 DEG C, produced metal elementary substances are melted into liquid and float on an upper layer, the liquid metal elementary substances are discharged out of the melt separation furnace through a molten metal outlet, and metal is obtained after cooling; and the solid slag at a lower part is discharged out of the melt separation furnace through a slag outlet, and is used as a building raw material after being cooled and crushed. According to the harmless treatment and resource utilization method for the metal-containing pollutants, two-step pyrolysis, melt separation and the like are combined, so that the metal-containing pollutants with different characteristics can be fully treated, high-added-value products such as metal resources and oil resources can be obtained, and harmless treatment and resource comprehensive utilization are achieved.

Owner:北京鑫源寰宇环保科技有限公司

Spray drying method for goat milk

InactiveCN111802456ASatisfy processingClean in placeMilk preparationOther dairy technologyProcess engineeringSpray dried

The invention relates to the technical field of processing of goat milk, in particular to a spray drying method for goat milk. The spray drying method for the goat milk comprises the following steps:(1) pumping raw milk out of a milk tank car into a double filter through a first milk pump for filtering to obtain raw milk subjected to primary filtering; (2) pumping the raw milk subjected to primary filtering into a vacuum de-muttony tank through a second milk pump for de-muttony treatment to obtain milk without muttony odour; and (3) pumping the milk without muttony odour out of the vacuum de-muttony tank into a plate-type heat exchanger through a third milk pump for cooling, and then storing obtained goat milk in a vertical milk storage tank. Compared with an existing spray drying methodfor goat milk, the spray drying method for the goat milk has the advantages that the requirements of efficient processing and de-muttony of multiple kinds of goat milk are met, the whole system and technology can automatically run through control of a PLC at the same time, long-term continuous stable running is guaranteed, the acceptance level of people of the goat milk is greatly raised, good color, fragrance, looseness, liquidity and dispersity of goat milk powder are maintained, and the goat milk powder can be fast dissolved during brewing, so that a novel breakthrough of the spray drying technology for the goat milk is achieved.

Owner:金诚

Additive used in the preparation process of methionine and the preparation method of methionine

ActiveCN111100051BEasy to useImprove stabilityOrganic compound preparationFood processingPolymer scienceMethionine biosynthesis

The invention relates to an additive used in the preparation process of methionine and a preparation method of methionine. The additive provided by the present invention is the mixture that comprises A, B and C component, and A component has the structural formula represented by following general formula (1); B component has the structural formula represented by following general formula (2): C component is Silicone oil; RCON(CH 3 )CH 2 CH 2 SO 3 Na(1) The preparation method of methionine provided by the present invention comprises crystallization and / or recrystallization of methionine in the presence of the additive provided by the present invention. The additive provided by the invention has uniform emulsification, good stability, can be used stably for a long time, and is suitable for continuous crystallization process. The prepared methionine has good crystal form, high bulk density and good fluidity. In addition, according to the preparation method of methionine of the present invention, the crystallization system can run continuously and stably for a long time without obvious foaming phenomenon, and the crystallization process of the methionine product proceeds smoothly.

Owner:SHANDONG XINHECHENG AMINO ACID +2

A method of frequency conversion water supply for ultra-fast cooling system of hot tandem rolling line

ActiveCN109174974BReduce shockReduce vibrationTemperature control deviceWork treatment devicesThermodynamicsFrequency conversion

The invention relates to a frequency conversion water supply method for an ultra-fast cooling system of a hot continuous rolling line, which belongs to the field of ultra-fast cooling of hot continuous rolling. The method includes: at the speed-up point of the water pump, calculate the pump frequency according to the ultra-fast cooling set pressure and water volume; The high temperature gauge at the exit of the finish rolling is used to dynamically adjust the water supply pressure of the water pump to make it reach the set value of ultra-fast cold pressure; when the strip head needs special cooling control, it needs to increase the speed twice; then when the strip head When the pyrometer at the exit of finishing rolling is reached, the water supply pressure of the water pump is dynamically adjusted to make it reach the ultra-fast cooling pressure setting value; when the tail of the strip leaves the ultra-fast cooling area, the pump station decelerates to the basic frequency state. This method solves the problem of stable water supply with high pressure and large flow rate, especially for the special cooling control of the strip head, which can achieve fast and stable ultra-fast cold water pressure, reduce energy consumption, reduce pipeline impact, reduce pipeline vibration, and protect equipment effect.

Owner:NORTHEASTERN UNIV LIAONING

Gas floatation separation device

InactiveCN101417184BBetter even distributionEfficient separationFlotationLiquid separationExternal energyMicrobubbles

The invention discloses an air flotation separation device, comprising an external cylinder (2), a rotational flow mixed cylinder (8), a first slag-retaining cylinder (7), a first scum drainage pipe (4) and a scum collecting guide plate (10); wherein, the bottom end of the first slag-retaining cylinder (7) and the bottom of the external cylinder (2) have spacing so as to form a water passage; thebottom of the side wall of the rotational flow mixed cylinder (8) is connected with a water inlet pipe (16) which enters in tangent direction; the periphery of the top of the external cylinder (2) isprovided with a clean water collecting trench (14); and the scum collecting guide plate (10) is a strip-typed plate in an involute shape, with the involute direction right opposite to the water rotational flow direction in the rotational flow mixed area (A). Compared with the prior art, the air flotation separation device does not need to add external energy cleaning systems, achieves the object of long-term continuously and stably running, and ensures that the requirement that the micro air bubbles adhere to the dispersed oil, emulsified oil and dissolved oil of small particle size as much as possible is met, thus achieving the object of high-efficiency separation of oil from water. The air flotation separation device is especially suitable for low-consistency water containing oil.

Owner:宁波威瑞泰默赛多相流仪器设备有限公司

Horizontal rotary reaction device

PendingCN113680307ANot easy to scaleImprove utilization efficiencyPressure vessels for chemical processChemical/physical/physico-chemical moving reactorsSlurryMechanical engineering

A horizontal rotary reaction device comprises a reactor cylinder, a liquid inlet pipe, a liquid outlet pipe, a gas inlet pipe, a driving device and a supporting device; the two ends of the reactor cylinder are connected with rotary joints, a baffle, a first partition plate and a second partition plate which are vertically arranged are sequentially arranged in the reactor cylinder, and the first partition plate is connected with the second partition plate through a low-temperature liquid inlet pipe; one end of the liquid inlet pipe extends into the cylinder from the front end of the reactor cylinder, the liquid outlet pipe is located in the reactor cylinder, the liquid inlet end of the liquid outlet pipe is connected with the first partition plate, and the liquid outlet end of the liquid outlet pipe extends out of the cylinder from the front end of the reactor cylinder; the gas outlet end of the gas inlet pipe extends into the cylinder from a rotary joint at the tail end of the reactor cylinder; and the driving device is used for driving the reactor cylinder to rotate, and the supporting device is arranged below the reactor cylinder. Slurry mixing, reaction and heat exchange can be carried out synchronously, the driving device drives the reactor to rotate, stirring is uniform, the surface of the cylinder is not prone to scaling, the heat energy utilization efficiency is high, and cost is low.

Owner:JINCHUAN GROUP LIMITED

Novel dry process rolling granulation production process

The invention discloses a novel dry process rolling granulation production process. In the process, an iron remover is installed on a raw material scraping plate; when raw materials pass across the raw material scraping plate, the iron remover removes ferromagnetic impurities in the raw materials, the abrasion to the surface of a roller caused by the impurities in the raw materials is reduced, andthe service life of a machine is prolonged; the process can undergo cyclic operation, continuous production is achieved, and the quality of finished products is high. In the process, dry powder is adopted for direct granulation, and a follow-up drying process is not required, which is favorable for the convergence and transformation of existing production processes. A dust removal system is arranged for the production process of the process, environmental pollution can be controlled, powder waste and packaging cost are reduced, and the product transportation capability is improved. Granular powder materials collected by a bag filter and a dual cyclone dust collector are returned to a fine powder return scraping plate in the process, and are subjected to roll forming and further treatmentto improve the utilization of raw materials.

Owner:江苏福亿自动化设备有限公司

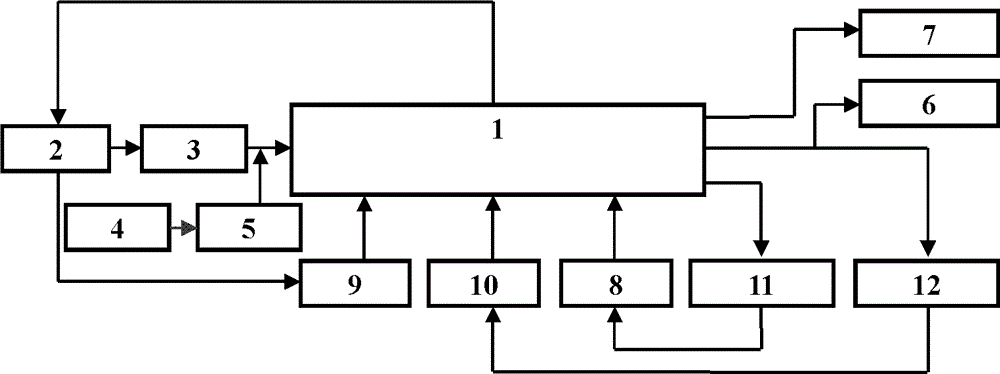

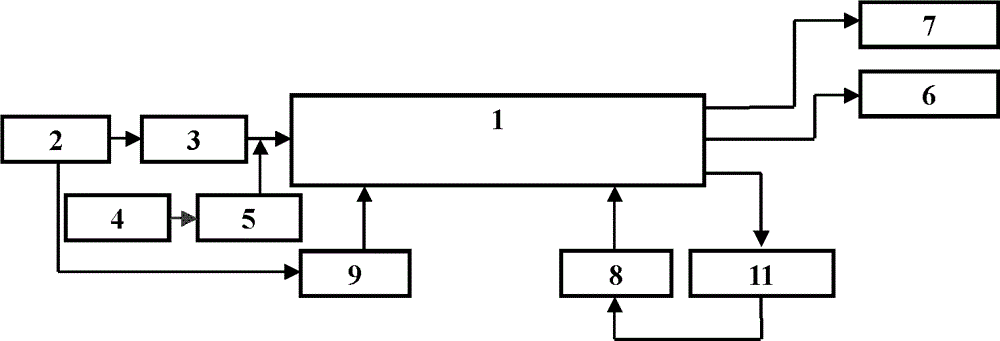

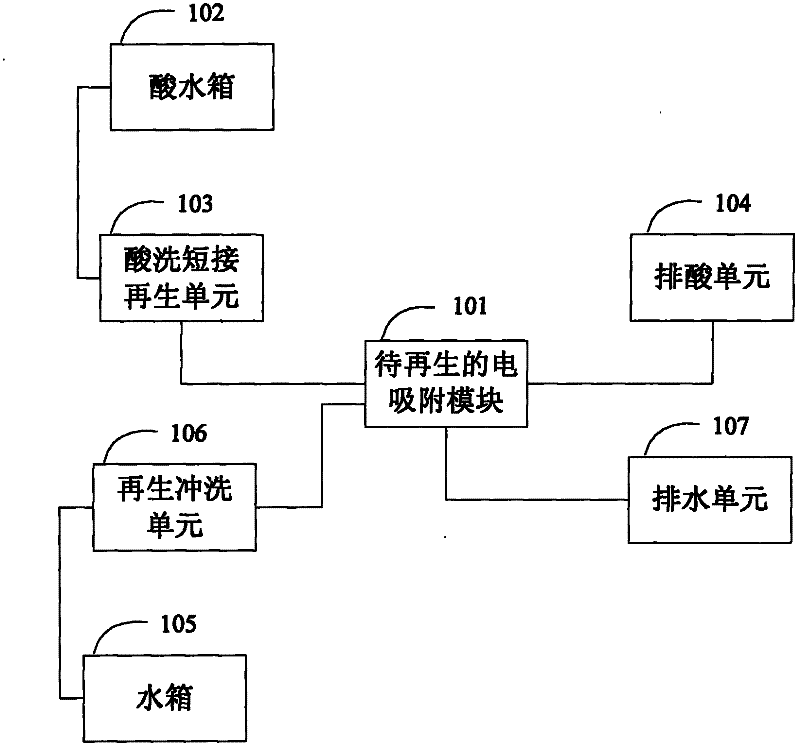

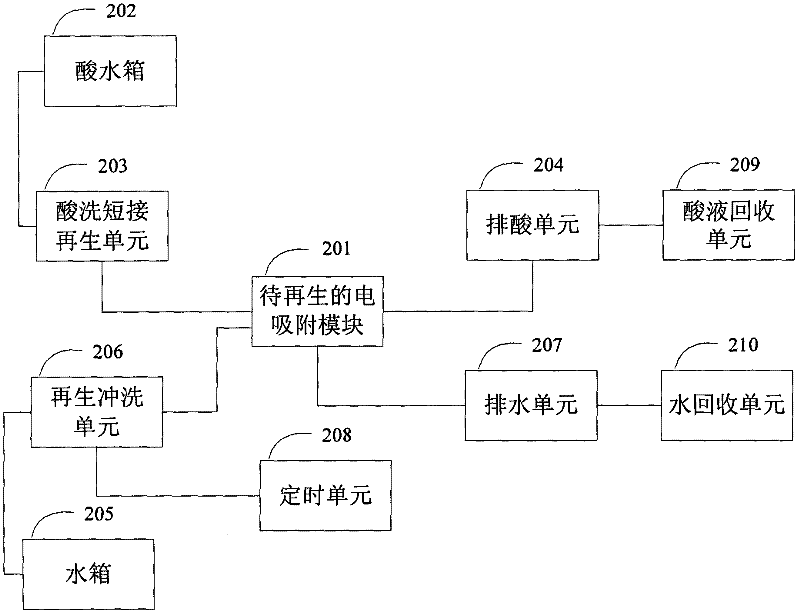

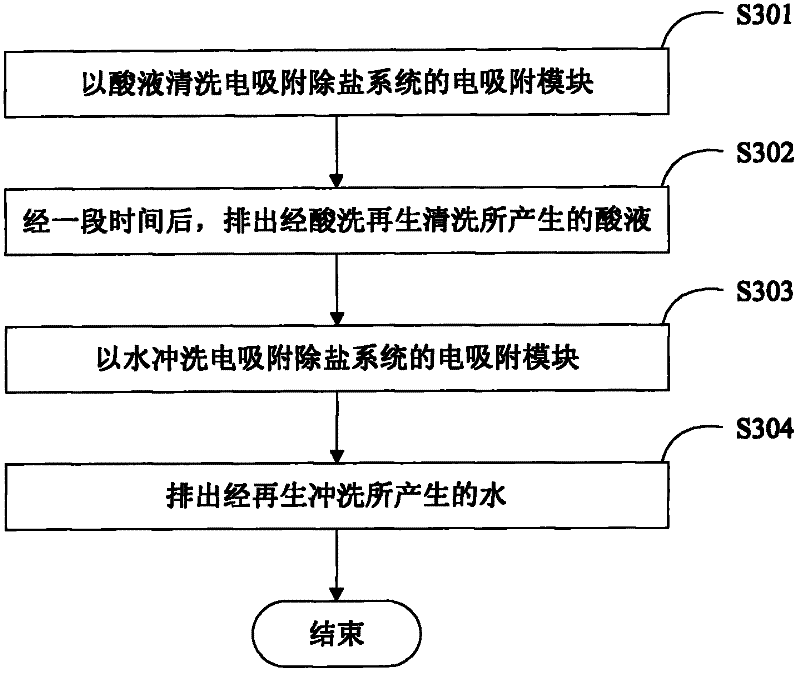

Electroabsorption desalting regeneration system and regeneration method

ActiveCN102126772BLong-term continuous and stable operationDispersed particle separationAcid waterWater rinsing

The invention discloses an electroadsorption desalting regeneration system and an electroadsorption desalting regeneration method, which relate to the field of sewage treatment and are used for solving the problem of a relative poor regeneration effect of an electroadsorption module in the prior art. The system comprises an electroadsorption module to be regenerated, an acid water tank for storing acid liquor, an acid-washing short connected regeneration unit for washing the electroadsorption module by using the acid liquor in the acid water tank, an acid discharging unit for discharging the acid liquor generated after the washing of the acid-washing short connected regeneration unit, a water tank for storing water, a regeneration washing unit for washing the electroadsorption module by using the water stored in the water tank, and a drainage unit for draining the water generated after the washing of the regeneration washing unit. The method comprises the following steps of: performing acid-washing regeneration; discharging the acid liquor; performing regeneration washing; and draining the water. In the invention, an acid-washing regeneration process is added, so that positive ions on a group of the electroadsorption module can be completely displaced to fulfill the aim of complete regeneration.

Owner:EST WATER & TECH

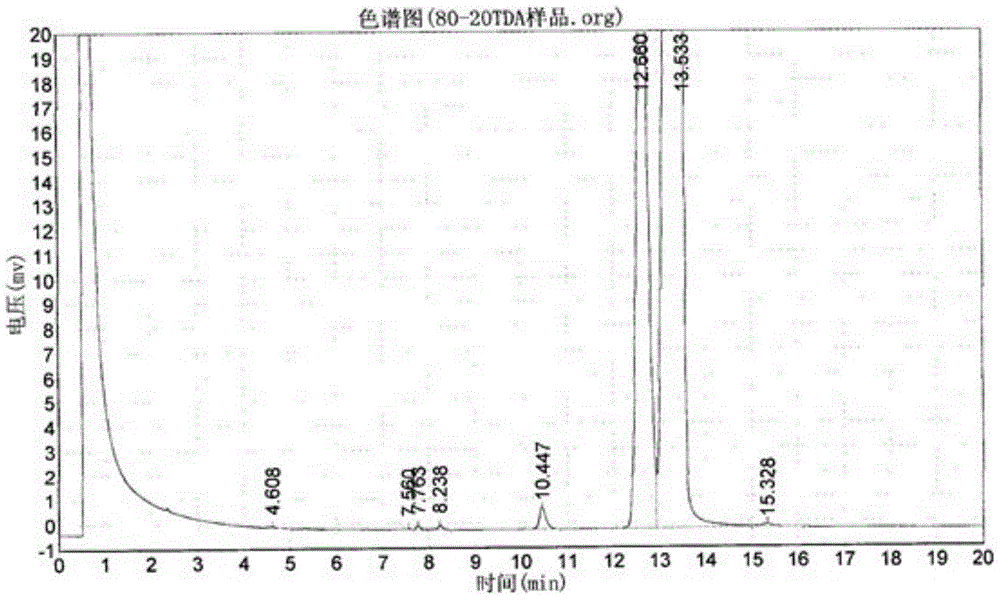

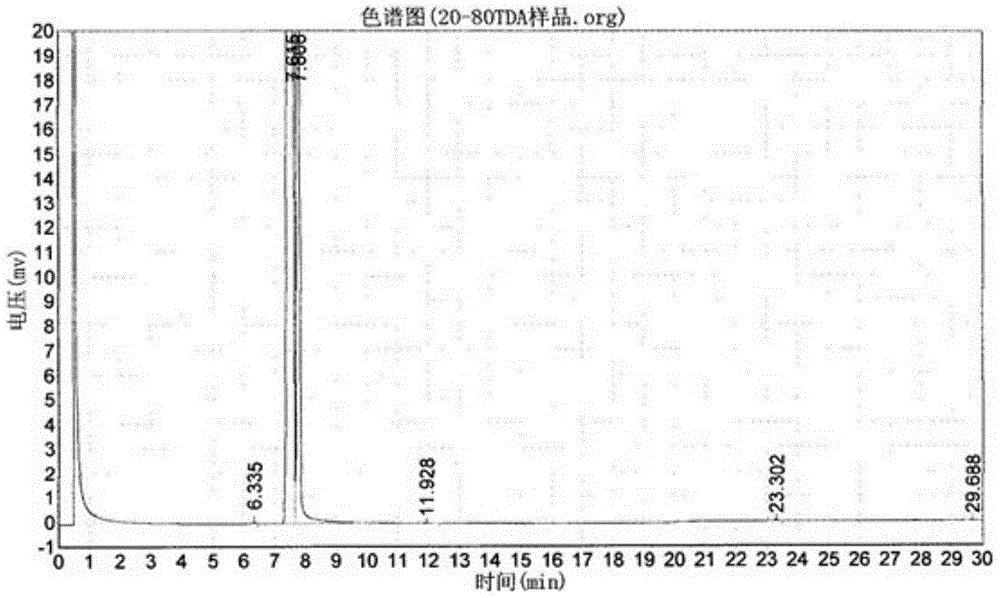

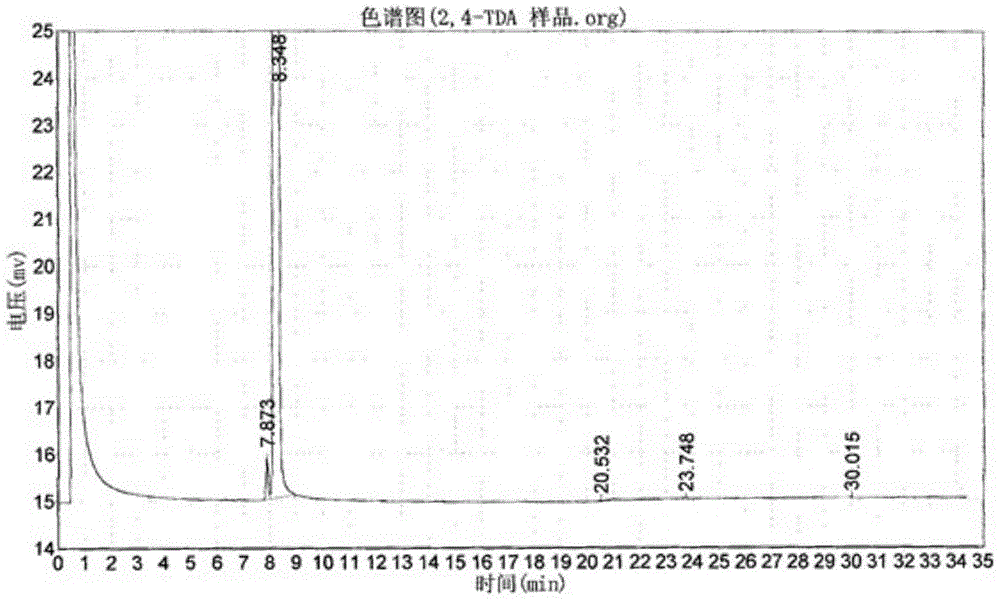

Detection method of diaminotoluene isomers

InactiveCN104062378BEfficient separationLong-term continuous and stable operationComponent separationGas phasePolyethylene glycol

The invention discloses a detection method of a diaminotoluene (TDA) isomer. The diaminotoluene isomer is determined by adopting a gas chromatographic method. The detection method comprises the following operation steps: (1), obtaining a to-be-detected diaminotoluene isomer test product; and (2), injecting the test product in a gas chromatograph, wherein chromatographic conditions are as follows: a chromatographic column is a polyethylene glycol (PEG) gas-phase capillary-column chromatographic column, a carrier gas is N2, and the starting column pressure is 0.1MPa, column temperature conditions are as follows: the initial temperature is 130 DEG C, and is kept for 5min, the temperature rise rate is 10 DEG C / min, the final temperature is 200 DEG C and is kept for 20min, the temperature of a vaporizing chamber is 250-280 DEG C, an adopted detector is a flame ionization detector (FID), and the detection temperature is 250-280 DEG C. The detection method disclosed by the invention relates to purities of six isomer monomers of TDA and content analysis of all components of a mixture of the six isomer monomers of the TDA, and the minimum detectable quantity reaches 0.001 percent; meanwhile, six isomers of the TDA can be effectively separated and detected, and thus a TDA production device can continuously and stably run for a long time.

Owner:四川北方红光特种化工有限公司

Method and system for desalting and backwashing through electric absorption

ActiveCN102010039BReduce dosageGood regeneration performanceDispersed particle separationElectricityReclaimed water

The invention discloses a method and a system for desalting and backwashing through electric absorption, belonging to the field of water treatment. The invention aims at solving the problem that the prior art can not ensure both the regeneration effect of an electric absorbing module and higher water yield. The method comprises the following steps of: backwashing the electric absorbing module by water recycled in the previous period, re-backwashing the electric absorbing module by raw water, and recycling water obtained by backwashing through the raw water for backwashing in the next period. The system comprises an electric absorbing module to be regenerated, a recycled water tank, a recycled water backwashing unit, a raw water tank, a raw water backwashing unit and a recycling water unit. By increasing the steps and units on the basis of the prior art, the invention realizes both the regeneration effect of the electric absorbing module and the higher water yield.

Owner:EST WATER & TECH

Polymethyl methacrylate (PMMA) continuous production process for long-time operation without accumulation

The invention relates to a preparation method of a polymer, particularly relates to a polymethyl methacrylate (PMMA) continuous production process for long-time operation without accumulation, and belongs to the technical field of polymer preparation. A polymeric kettle and a stirring warming kettle which enter from the bottom and leave from the top are used, and use a ribbon-type stirrer and chromeplated or polished inner walls; a small amount of an inert solvent is added in the reaction mixture to increase the fluidity of a mixture system; an extruder screw and the inner walls are chromeplated; and by such means as adding a circulation loop and adding a polymerization inhibitor between a distillation column reboiler and a waste liquid tank, the polymer is prevented from being accumulated in a container or a pipeline when the PMMA continuous body is polymerized, and long-time continuous and stable operation is ensured.

Owner:SUZHOU DOUBLE ELEPHANT OPTICAL MATERIALS CO LTD

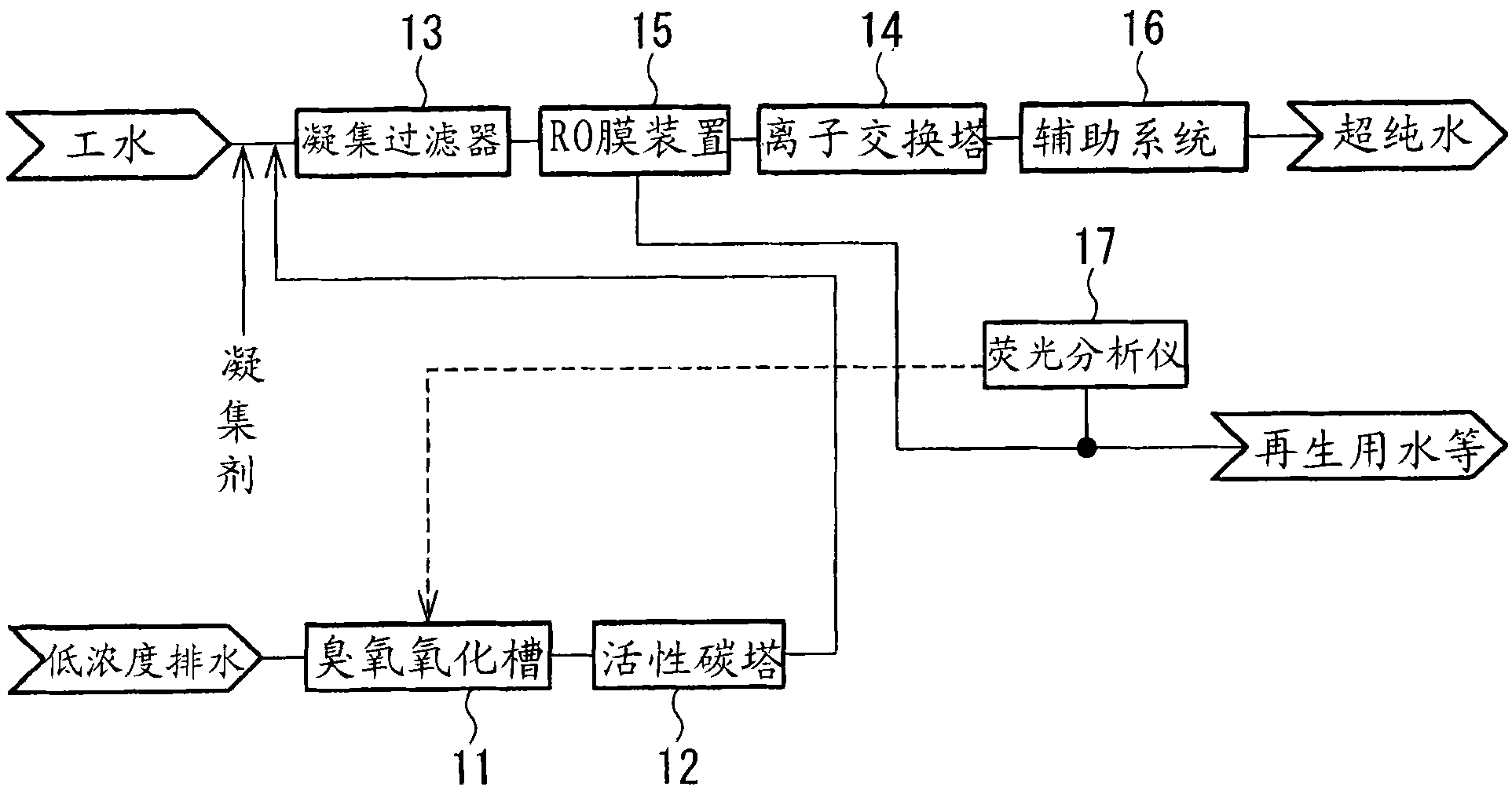

Method for evaluating feed water of reverse osmosis membrane apparatus, and method and apparatus for treating water

ActiveCN101042347BLong-term continuous and stable operationIncrease through flowWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentWater qualityReverse osmosis

The present invention provides a method for evaluating reverse osmosis membrane supply water, a method for water treatment and a water treatment device. The invention can evaluate the quality of reverse osmosis membrane supply water in a short time simply and accurately, thereby operating the water treatment device with the reverse osmosis membrane device stably in a long term. The reverse osmosis membrane supply water evaluation method for evaluating the quality of water supplied to the reverse osmosis membrane device is characterized in that the method detects fluorescence intensity of the reverse osmosis membrane supply water and evaluates the water quality based on the fluorescence intensity detection result. The water treatment device with the reverse osmosis membrane device is operated and managed based on the evaluation result.

Owner:KURITA WATER INDUSTRIES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com