Dry method rolling granulation production process

A production process and granulation technology, applied in the direction of die extrusion granulation, etc., can solve the problems of no unqualified material screening steps, the quality of finished products cannot be guaranteed, and the development of chemical fertilizer industry is restricted, so as to improve product transportation capacity, maintenance and repair. Convenience, Conducive to the effect of connection and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

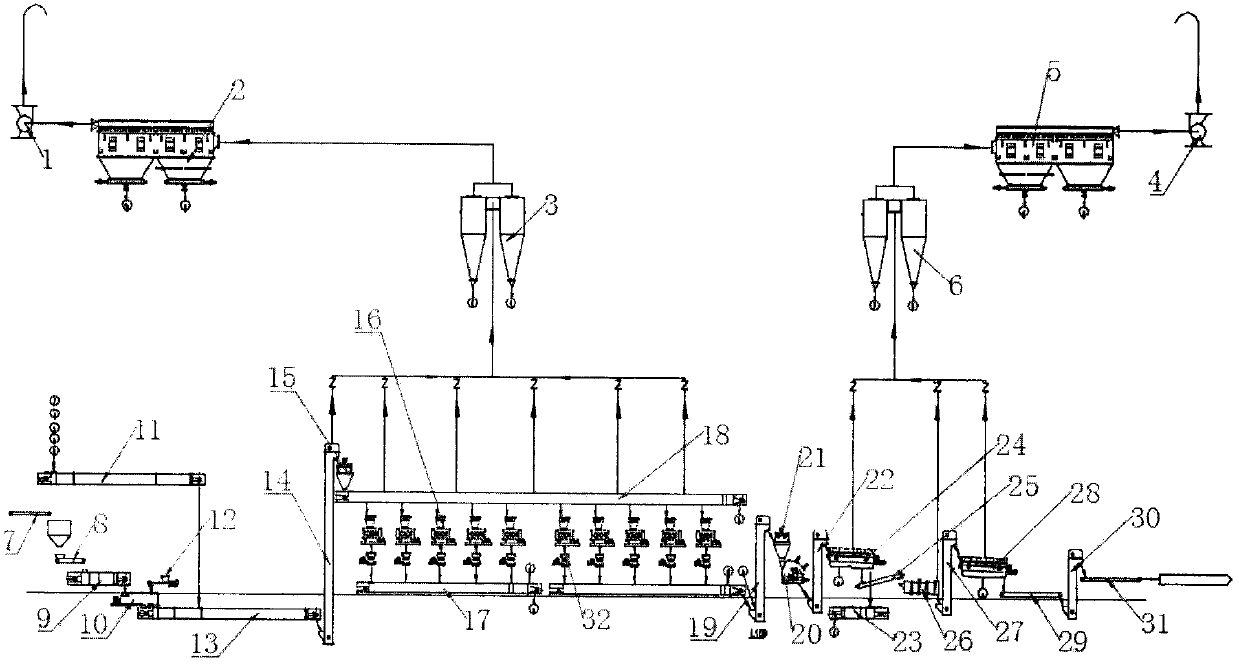

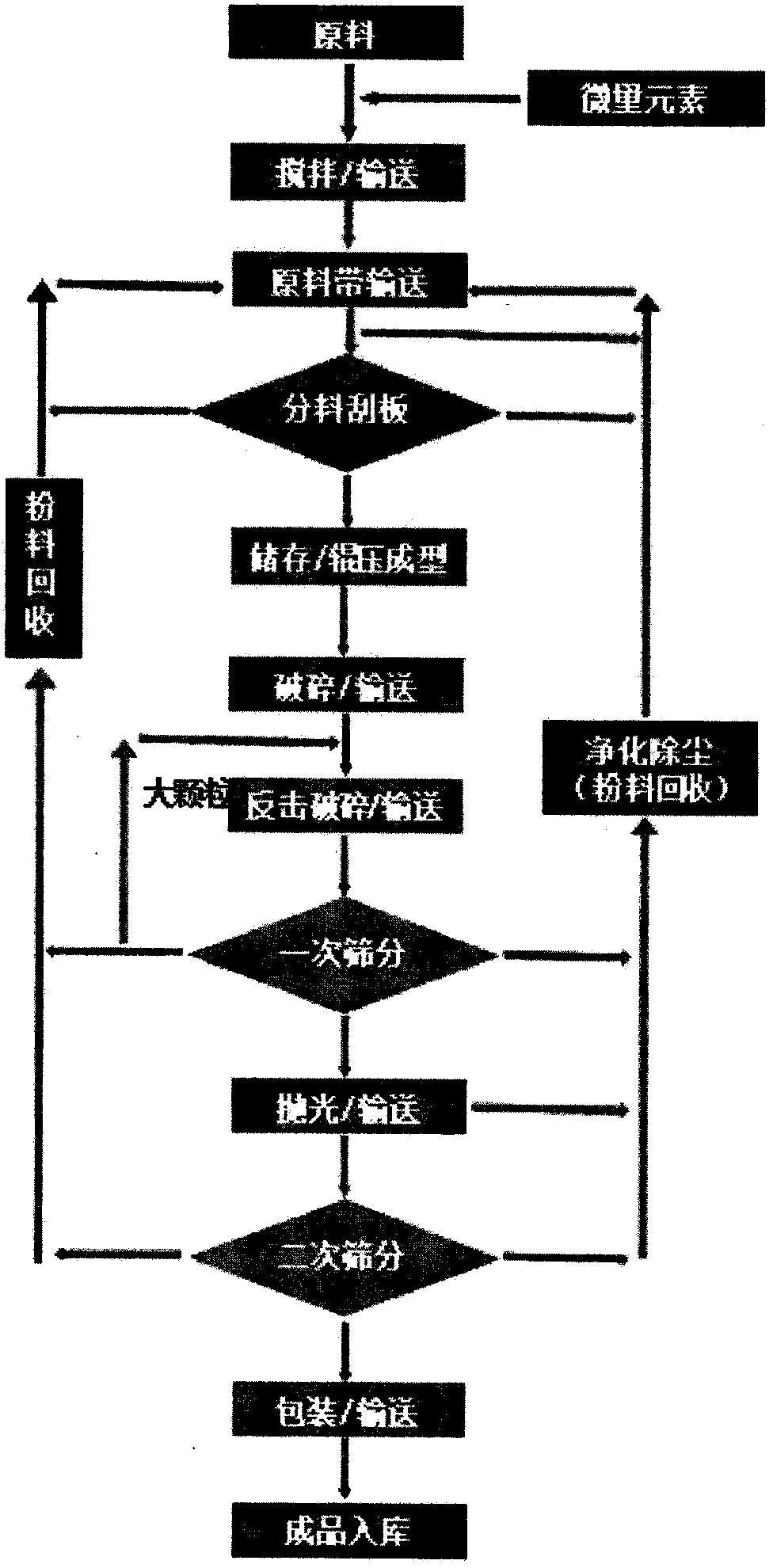

[0021] see Figure 1-2 , a production process of dry rolling granulation, the specific steps are as follows:

[0022] Step 1, the raw material with a water content not greater than 5% is transported from the raw material belt 7 to the storage bin, the outlet of the storage bin is connected with the metering belt 8, the raw material flows from the storage bin to the metering belt 8, and the metering belt 8 sends the raw material to On the first raw material scraper 9, the first raw material scraper 9 sends the raw materials to the twin-shaft mixer 10, the weight loss scale 12 sends the trace elements to the twin-shaft mixer 10, and the twin-shaft mixer 10 stirs and mixes the raw materials and trace elements, The mixed material is sent to the comprehensive raw material hoist 14 through the second raw material scraper 13, and the comprehensive raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com