Horizontal rotary reaction device

A reaction device, horizontal technology, applied in the field of horizontal rotary reaction device, can solve the problems of high spare parts cost and operation cost, serious system heat energy loss, low production efficiency, etc., achieve low equipment maintenance and operation cost, and heat energy utilization efficiency High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

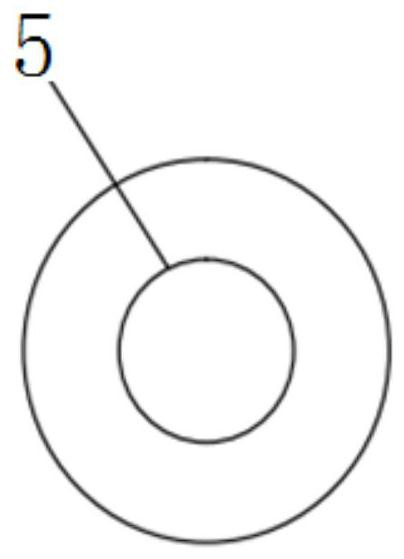

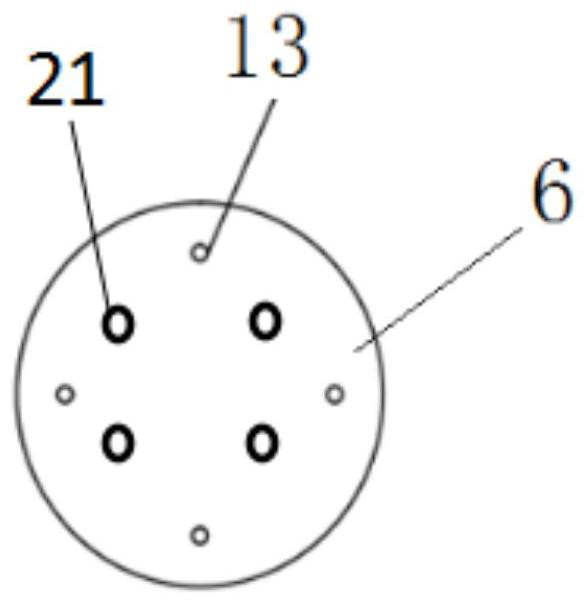

[0038]The low-temperature slurry enters the heat exchange zone 22 through the liquid inlet pipe 2 at a temperature of 30°C and a pressure of 1 MPa. After passing through the through holes in the middle of several baffles 5, the liquid inlet speed is effectively controlled. The temperature of the slurry absorbs heat and rises, and the slurry passes through the first separator. The first low-temperature liquid inlet 13 on 6, the low-temperature liquid inlet pipe 9 and the second low-temperature liquid inlet 14 on the second partition enter the mixing zone 24, and the temperature of the slurry and the inlet pipe 4 is 250°C, and the pressure is The saturated steam of 4.0 MPa is fully mixed in the mixing zone 24, and the mixed slurry enters the reaction zone 23 through the mixed solution outlet 15 on the second partition 7 under pressure, and the high-temperature and high-pressure slurry is fully reacted in the reaction zone 23 The temperature is 220-230°C and the pressure is 3.0-3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com