Novel dry process rolling granulation production process

A production process and granulation technology, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of insufficient service life of the production system, restriction of the development of the chemical fertilizer industry, and low utilization rate of raw materials, so as to improve product transportation capacity and compact structure , The effect of high output of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

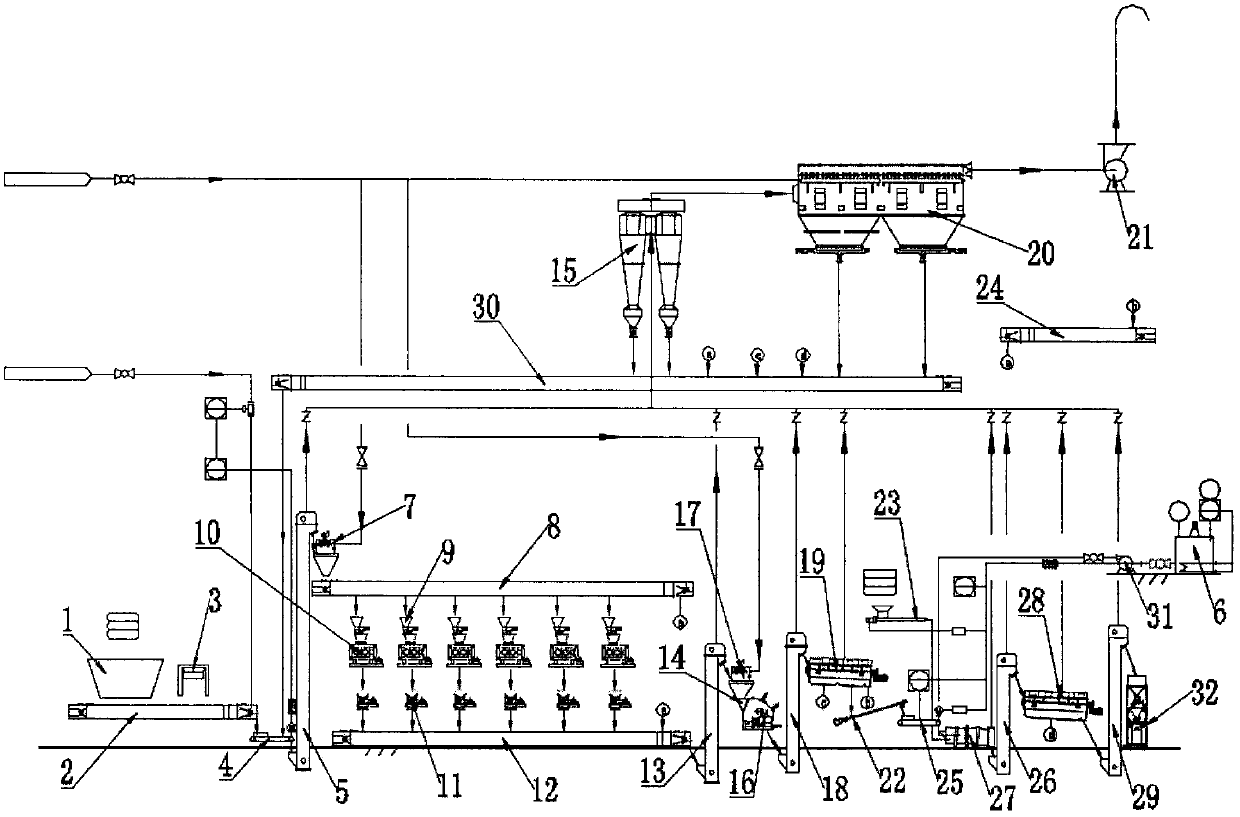

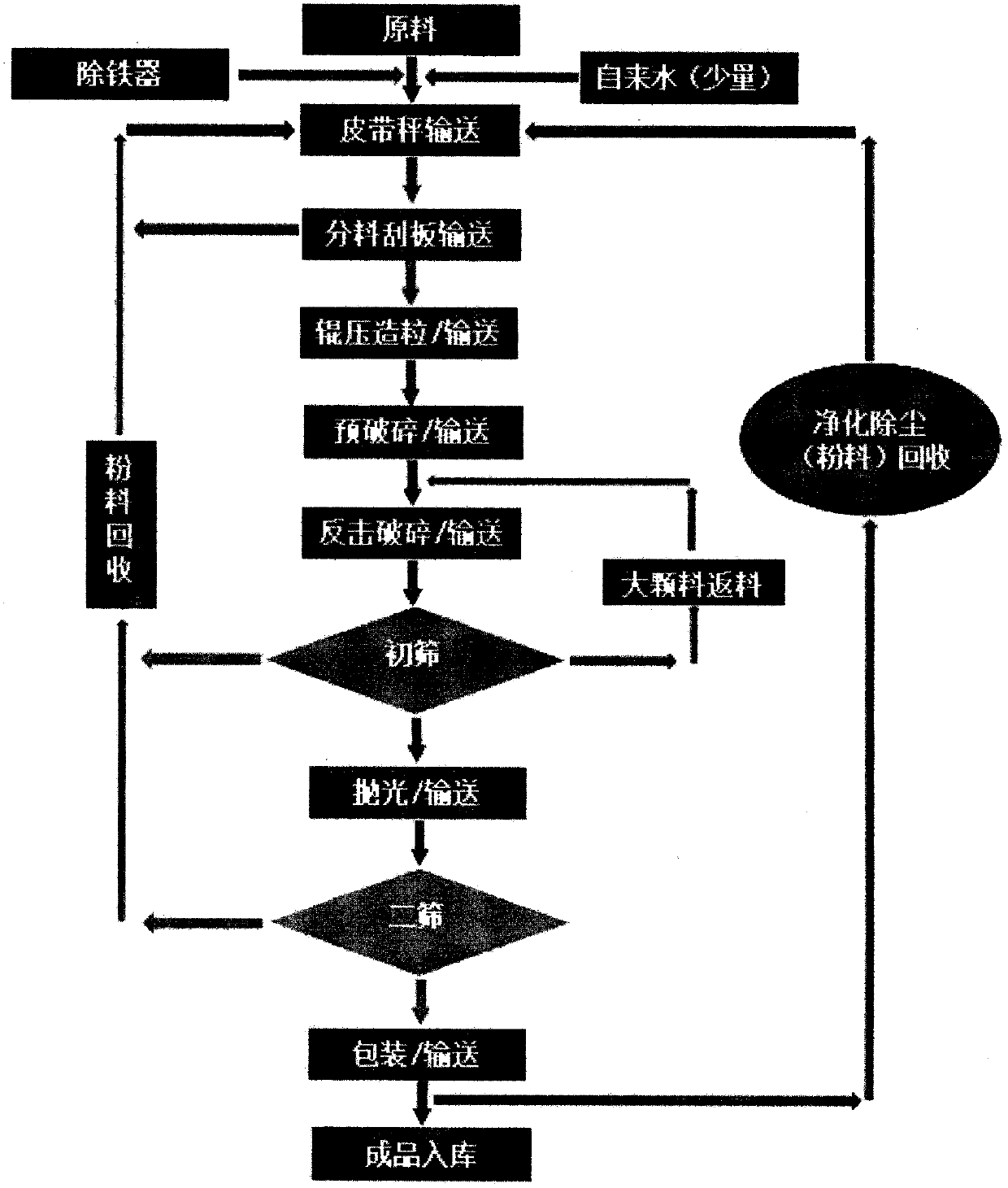

[0020] see Figure 1-2 , a new type of dry roll granulation production process, the specific steps are as follows:

[0021] Step 1, the raw material in the raw material bin 1 is sent to the belt scale 4 through the raw material scraper 2, the iron remover 3 installed above the raw material scraper 2 removes the ferromagnetic impurities in the raw material, and the raw material in the belt scale 4 is transported to the second One hoist 5, the first hoist 5 sends the raw materials to the buffer silo, the first online dust removal system 7 installed above the buffer silo removes the dust during transportation, and the raw materials in the buffer silo are scraped by the material distribution The plate 8 is evenly divided into the upper silos 9 of each extrusion granulator, and then the raw materials in the silos 9 enter the extrusion granulator 10 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com