Seawater treatment method

A treatment method and seawater technology, which are used in the desalination treatment of seawater, the coagulation treatment of seawater and the separation of solids and liquids, which can solve the problems of adding a large amount of inorganic flocculants and increasing the solid content of sludge, preventing pollution and corresponding high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Hereinafter, examples and comparative examples will be described. In the following Experiment I (Examples I-1 to I-10, Comparative Examples I-1 to I-9) and Experiment III (Examples III-1 to III-10, Comparative Examples III-1 to III-13) , used relatively clear seawater (hereinafter referred to as "seawater") as the treated water; Experiment II (Example II-1~II-15, Comparative Example II-1~II-8) and Experiment IV (Example IV -1 to IV-8, Comparative Examples IV-1 to IV-16), artificially polluted seawater (hereinafter referred to as "contaminated seawater") was used as the water to be treated.

[0103] The cationic organic coagulants, inorganic coagulants, and phenolic polymers used in Experiments I to IV, and the test methods are as follows.

[0104] [Cationic organic coagulant]

[0105] Cationic organic coagulant 1: a commercially available liquid product of a condensation system of epichlorohydrin and amine (FL2749 manufactured by SNF Corporation). The colloidal equiv...

Embodiment I-1~I-10

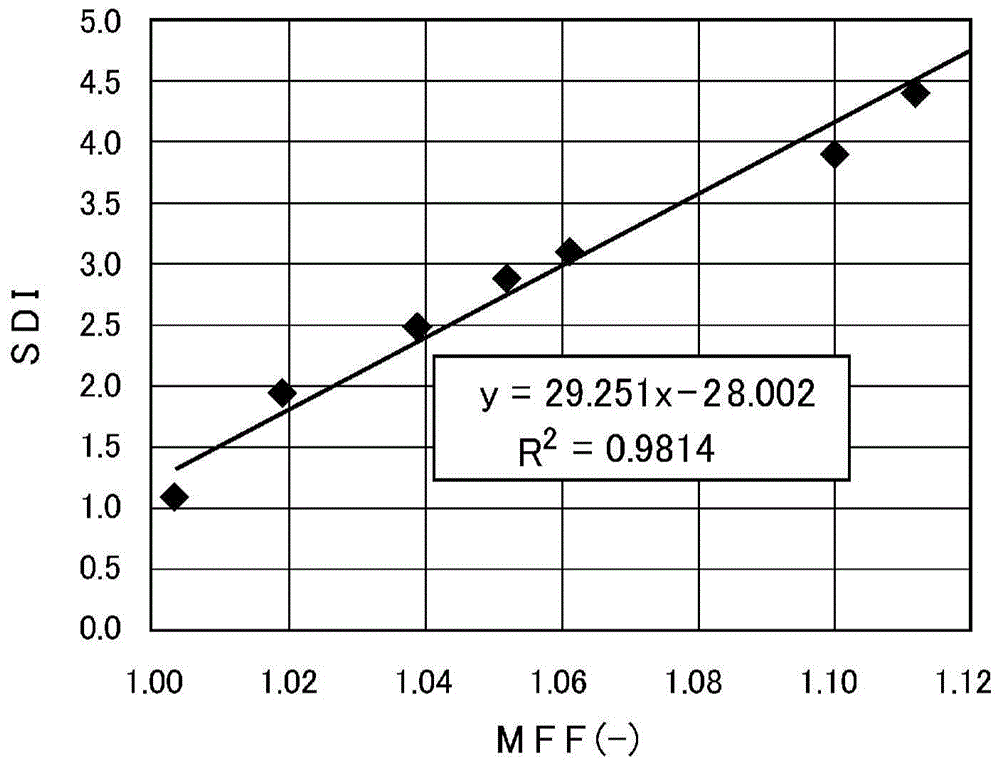

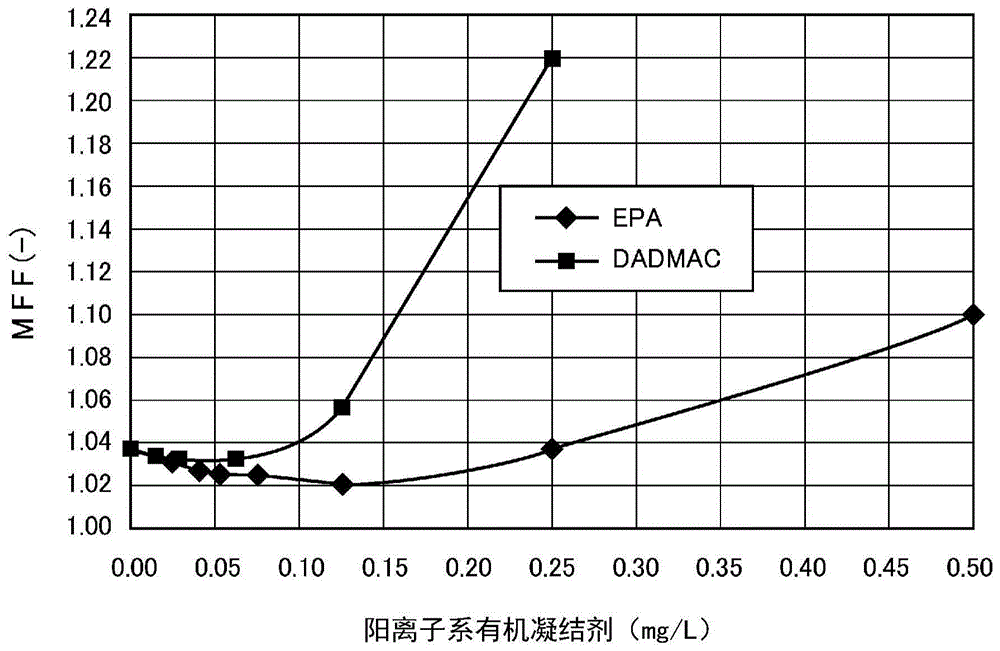

[0129] As seawater, the seawater collected in Chatan Town (place name) in Okinawa Prefecture, Japan was adjusted to 24° C., and the cationic organic coagulant and phenolic polymer shown in Table 1 were used to test according to the above test method. Table 1 shows the addition amount of the cationic organic coagulant and the phenolic polymer, the measured value of MFF, and the amount of solid generation. The estimated values of SDI estimated from MFF are also shown in Table 1.

Embodiment II-1~II-15

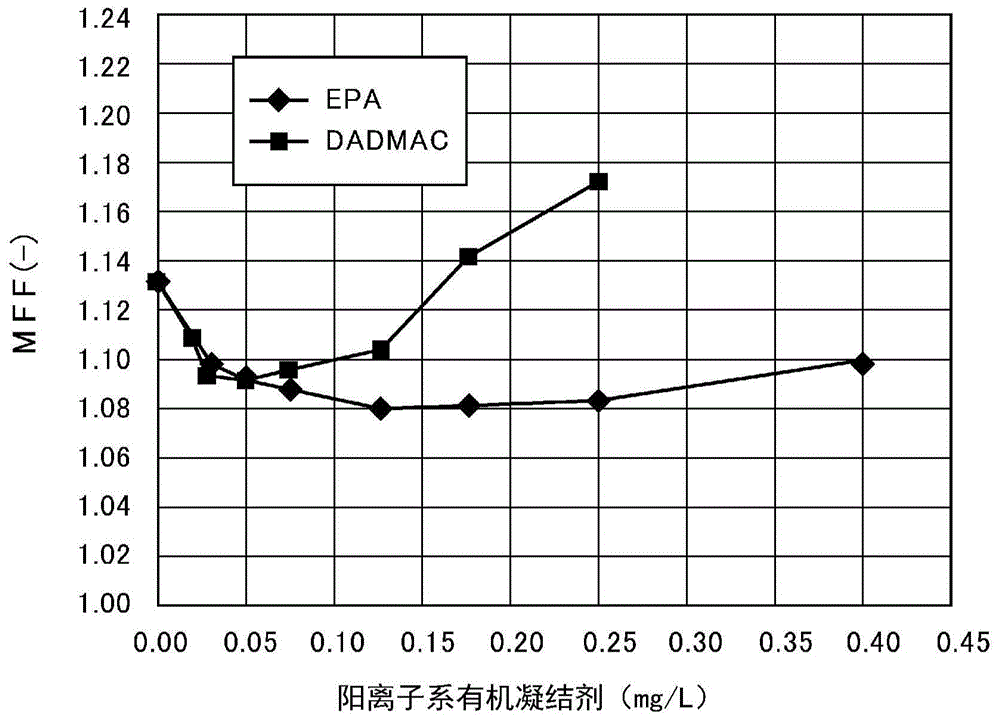

[0154] Add 3 mg / L acetic acid to the seawater of Experiment I and aerate it for 1 hour. After supplying sufficient oxygen, place it at 20-25°C for 5 days to allow the originally existing marine microorganisms to multiply, thereby preparing polluted seawater. Using this polluted seawater as water to be treated, the same test as Experiment I was performed.

[0155] The types and amounts of cationic organic coagulants and phenolic polymers are shown in Table 2. Table 2 shows the amount of solid generation, MFF measured value, and SDI estimated value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com