Processing method for electro-adsorption demineralized water

A treatment method and electro-adsorption technology, applied in separation methods, dispersed particle separation, etc., can solve the problems of blockage of electro-adsorption module channels, prolonged electrode usage time, and unsatisfactory electrode regeneration effect, so as to avoid system pressure rise and avoid Effect of fouling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

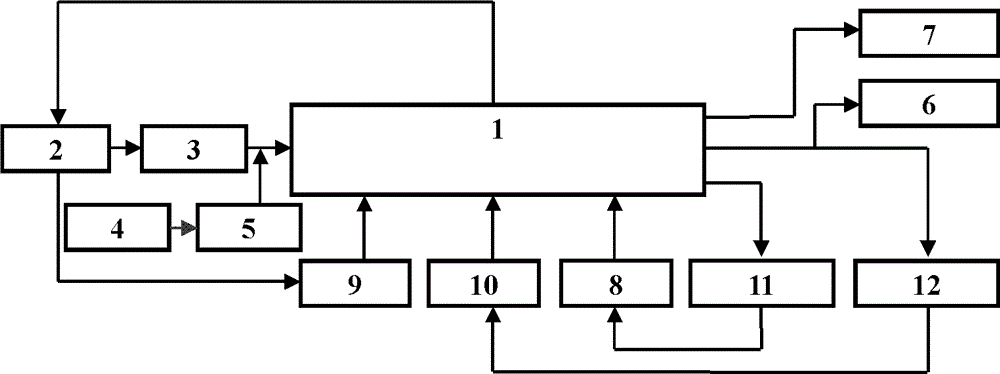

[0052] A treatment method for electro-adsorption desalinated water of the present invention, see figure 1 .

[0053] Including the following steps:

[0054] a power-on working process

[0055] ① Pre-arrangement steps

[0056] The working pump (3) draws the water to be treated from the water inlet tank 2 to be absorbed and desalinated by the electro-adsorption module 1, and the initial water production that has not yet reached the technical index enters the intermediate water tank B12;

[0057] ② Adsorption desalination step

[0058] The working pump (3) draws the water to be treated from the water inlet tank 2 to be absorbed and desalinated by the electro-adsorption module 1, and the produced water that reaches the technical index enters the produced water tank 6;

[0059] ③Back steps

[0060] When the output water quality of the adsorption desalination step ② cannot meet the technical indicators, inject industrial hydrochloric acid into the electro-adsorption module 1 wh...

Embodiment 2

[0073] According to the method and steps of embodiment 1, the difference is:

[0074] 1. The pre-discharging step ① in the power-on working process a is omitted, and the working pump (3) draws the water to be treated from the water inlet tank (2) to be adsorbed and desalinated by the electro-adsorption module 1, and the output water reaches the technical level. indicators, directly into the product water tank6.

[0075] 2. In the last step ③ of the power-on work process a, when the technical index of the produced water in the adsorption desalination step ② is close to a certain set value exceeding the standard, the industrial hydrochloric acid is injected into the The electro-adsorption module controls the water after injecting hydrochloric acid until it is just full of the electro-adsorption module system and is not discharged from the system; and the pH value range of the electro-adsorption module system is controlled between 3.0 and 5.0; at the same time as hydrochloric aci...

Embodiment 3

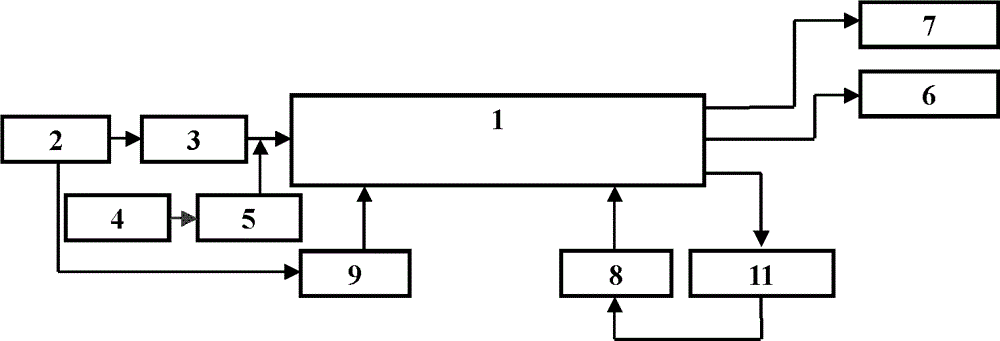

[0078] According to the method and steps of embodiment 1, see figure 2 .

[0079] The difference is:

[0080] 1. In the back step ③ of the power-on work process a

[0081] When the output water quality of the adsorption desalination step ② cannot meet the technical indicators, inject industrial hydrochloric acid into the electro-adsorption module 1 while continuing to supply water and electricity, and control the water injected with hydrochloric acid, just to fully charge the adsorption module system, instead of until it is discharged from the system; and the pH range of the electro-adsorption module system is controlled between 4.5 and 6.0; at the same time as hydrochloric acid is injected, the produced water is switched from normally entering the produced water tank 6 to being discharged into the intermediate water tank B 12; After the adsorption module system is fully charged, stop the water supply, cut off the power supply, and enter the process of discharging and resti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com