Method for continuously polymerizing nylon from bi-component monomer serving as raw material

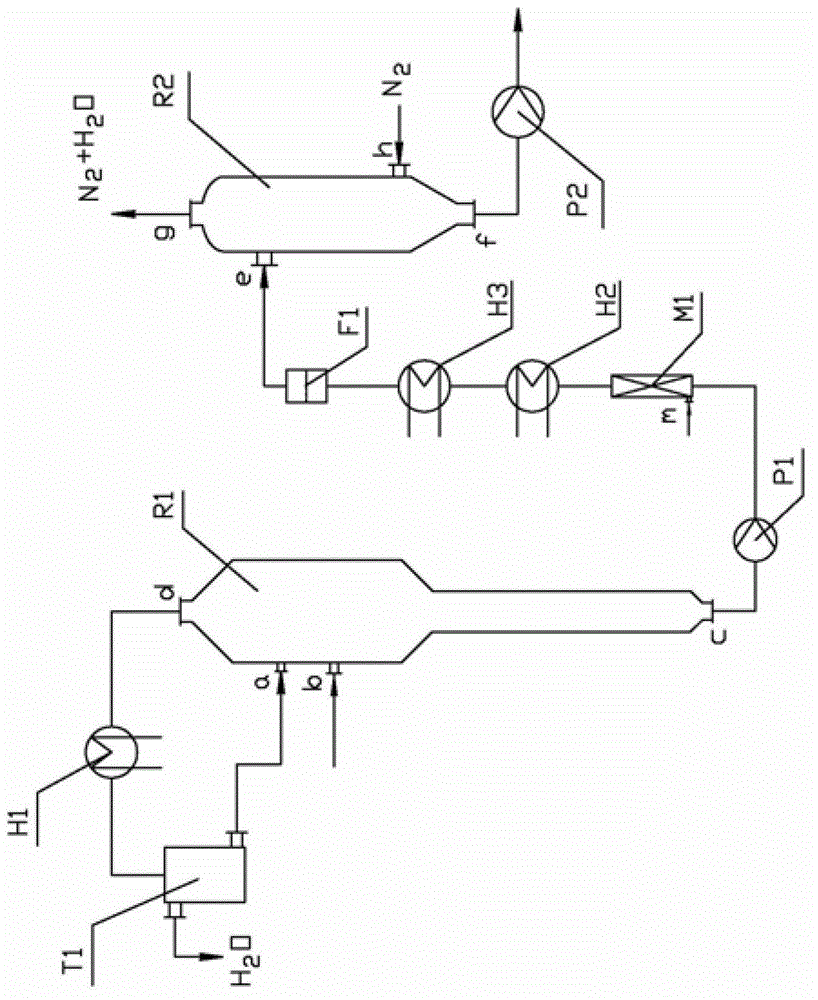

A polymerization method and two-component technology, which is applied in the field of continuous nylon polymerization, can solve the problems of long process, wide molecular weight distribution, high construction investment and operation costs, and achieve low raw material consumption, elimination of diamine emissions, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Adopt ASPEN simulation calculation nylon polymerization method of the present invention, result is as follows:

[0058] Example 1 (polymerization of nylon 66):

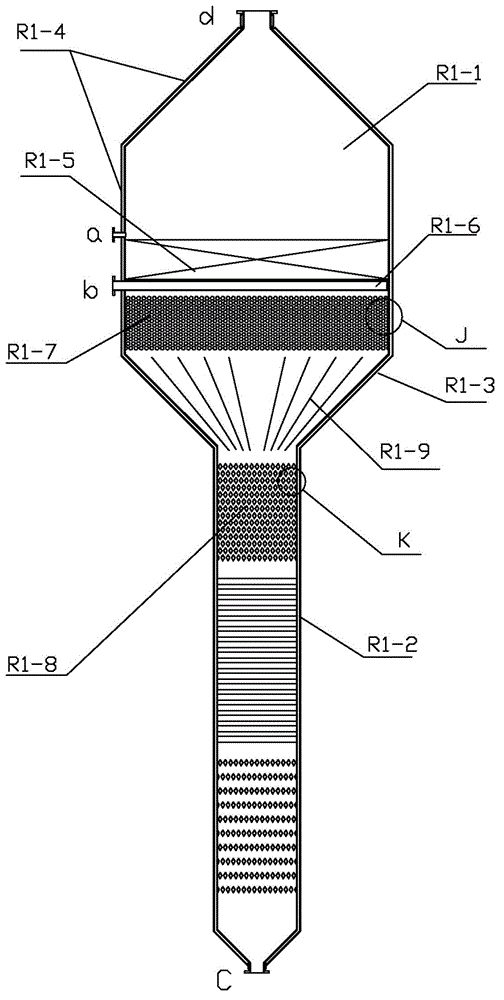

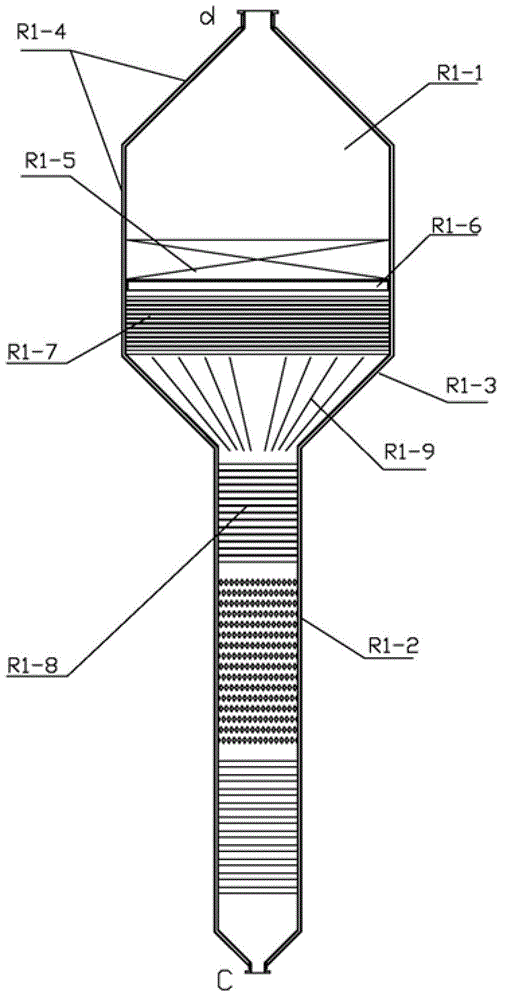

[0059] Feed the nylon 66 salt solution with a temperature of 95°C and a concentration of 50% into the precondensation tower with an operating pressure of 0.6MPa. First, the temperature is gradually raised to 200°C in the upper part of the tower, and the solvent water is evaporated, and then the temperature is gradually raised to 258°C in the lower part of the tower for precondensation. Polycondensation, the pre-condensation reaction time of the lower part of the tower is 18min, and a prepolymer with a degree of polymerization of 23 is generated, the reflux ratio of the condensed water at the top of the tower is 0.15, and the content of hexamethylenediamine in the condensed water is less than 20ppm; the prepolymer is preheated to 278°C and fed into the polycondensation tank , normal pressure operation, the prepo...

Embodiment 2

[0060] Example 2 (nylon 66 polymerization):

[0061] The raw materials and process parameters of the precondensation link are the same as those in Example 1. The generated prepolymer is preheated to 277°C and enters the polycondensation kettle. There is no falling film tube in the polycondensation kettle, and all the prepolymers fall film along the kettle wall. N2 was added, the temperature at the bottom of the tank was 275°C, and the polycondensation reaction time was 25 minutes to obtain a nylon 66 melt with a degree of polymerization of 76.

Embodiment 3

[0062] Example 3 (polymerization of nylon 56):

[0063]Feed the nylon 56 salt solution with a temperature of 95°C and a concentration of 50% into the precondensation tower with an operating pressure of 0.45 MPa, first gradually raise the temperature to 185°C at the upper part of the tower, distill off the solvent water, and then continue to gradually raise the temperature to 240 at the lower part of the tower ℃ for pre-condensation, the pre-condensation reaction time at the lower part of the tower is 22 minutes, and the prepolymer with a degree of polymerization of 23 is obtained, the reflux ratio of the condensed water at the top of the tower is 0.15, and the content of pentamethylenediamine in the condensed water is less than 20 ppm. Preheat the prepolymer to 270°C and feed it into the polycondensation kettle, operate under normal pressure, part of the prepolymer falls into a film along the wall of the kettle, and the rest of the prepolymer falls freely in strips, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com