Method and device for solar reduction iron making

A solar energy and reduction furnace technology, applied in the direction of improving process efficiency and reducing gas emissions, can solve problems such as the inability to completely eliminate greenhouse gas emissions, save non-renewable energy, avoid greenhouse gas emissions, and be conducive to environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

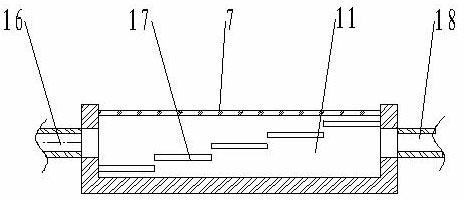

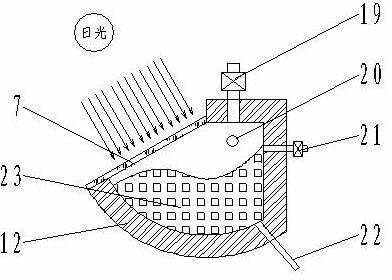

[0025] The solar energy reduction ironmaking device of the present invention is as figure 1 Shown, including solar and wind hydrogen generation equipment, solar hydrogen heating equipment, solar reduction equipment and gas processing equipment. The solar and wind energy hydrogen generation equipment includes a photovoltaic cell 23 , a wind generator 1 , an electrolytic cell 2 , a water tank 3 and a hydrogen storage tank 4 . The photovoltaic cells are connected to the anode and cathode of the electrolytic cell, and the wind generator circuit is connected to the electrolytic cell through a power conversion device. Use solar photovoltaic cells to generate electricity or wind generators to generate hydrogen by electrolyzing water, and also use photovoltaic cells and wind generators to generate electricity to complement each other. In this embodiment, electricity generated by solar photovoltaic cells 23 is used as power. The electrolytic cell is a cylindrical structure made of met...

Embodiment 2

[0028] Another embodiment of the present invention is as Figure 4 As shown, the solar reduction ironmaking device is also provided with a material preheating chamber 25 and a product cooling chamber 13, the material preheating chamber is connected to the hopper 24, and the product cooling chamber is connected to the discharge equipment. The gas outlet 20 of the solar reduction furnace is connected to the inlet of the circulating fan 14 through the material preheating chamber and the gas processing equipment 15 . The circulation fan outlet is connected to the air inlet of the product cooling chamber, and the hydrogen storage tank 4 is also connected to the air inlet of the product cooling chamber, and the connecting pipeline is provided with a valve, which is connected to the hydrogen inlet pipe 16 of the hydrogen heating chamber through the product cooling chamber. In this embodiment, the reduced product is sponge iron, which enters the electric arc furnace for smelting after...

Embodiment 3

[0031] Another embodiment of the present invention is as Figure 5 As shown, the solar reduction ironmaking device is also provided with a material preheating chamber 25 and an electric arc furnace 27, the material preheating chamber is connected with a hopper 24, and the electric arc furnace is provided with an electrode 26 and a molten iron outlet 28. The gas outlet 20 of the solar reduction furnace is connected to the inlet of the circulation fan 14 through the material preheating chamber and the gas treatment equipment 15, the outlet of the circulation fan and the hydrogen storage tank are connected to the hydrogen inlet pipe 16 of the hydrogen heating chamber, and the hydrogen outlet pipe 18 of the hydrogen heating chamber Connect to the gas inlet 21 of the solar reduction furnace. The material preheating chamber is connected to the feed port of the solar reduction furnace 12 through the material delivery pipeline 6, the discharge port of the solar reduction furnace is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com