Sealing device between flue gas recirculation cover and trolley of sintering machine

A technology of flue gas circulation and sealing device, which is applied to furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of destroying the continuity of sintering production, short service life of rubber sheets, affecting the production efficiency of sintering machines, etc., to ensure long-term protection. The effect of continuous and stable operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

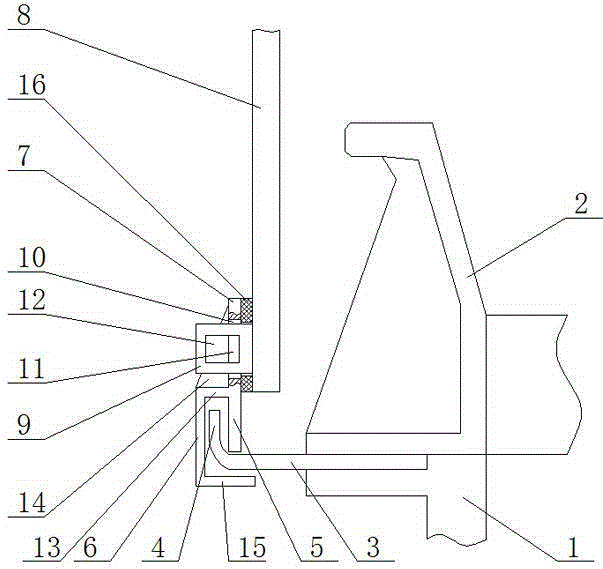

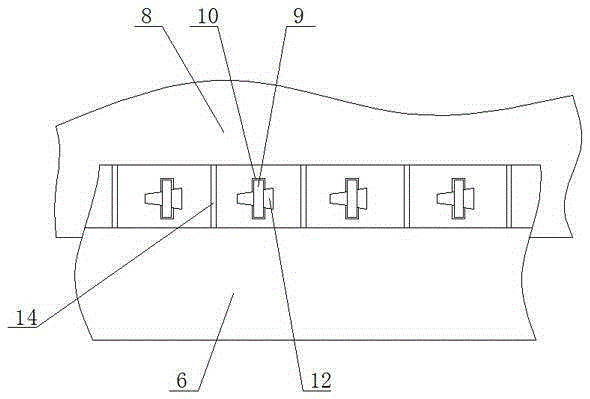

[0008] A sealing device between a sintering machine flue gas circulation hood and a trolley according to the present invention includes a trolley 1, a fence 2 is arranged on both sides of the trolley 1, a lower sealing support plate 3 is installed on the outer side of the fence 2, and a lower sealing support Flange 4 is arranged on the outside of board 3, and flange 4 is perpendicular to the horizontal plane, and the length direction of flange 4 is parallel to the length direction of fence 2, and the side of flange 4 close to fence 2 is provided with inner baffle 5, and flange 4 is away from One side of the fence 2 is provided with an outer baffle 6, and the tops of the inner baffle 5 and the outer baffle 6 are connected with the connecting plate 7, and the connecting plate 7 is connected with the circulating smoke hood 8 of the sintering machine through a connecting piece. The present invention forms a labyrinth seal structure through the inner baffle plate 5, the outer baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com