VOC (Volatile Organic Compounds) enrichment device

An enrichment and adsorbent technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of continuous operation and high cost, and achieve the effect of meeting industrial production needs, improving adsorption rate and efficiency, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

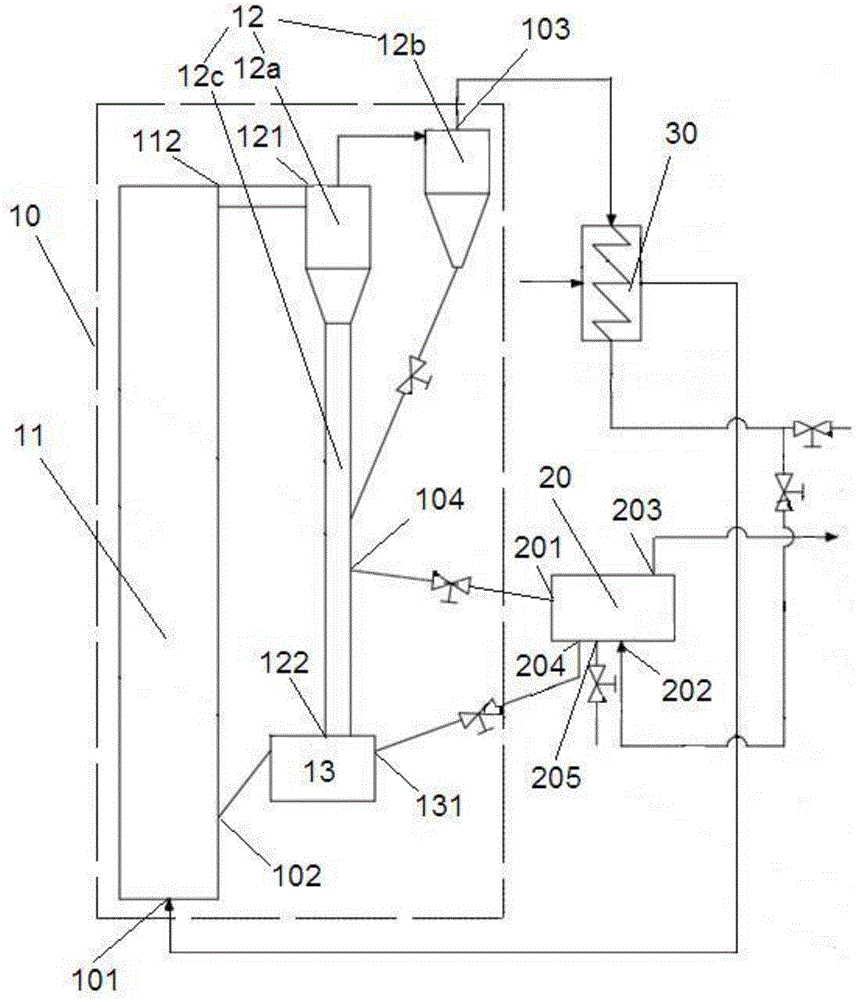

[0041] Such as figure 1 As shown, the circulating material in the circulating fluidized bed device 10 is a VOCs adsorbent, the adsorbent is solid particles, and the particle size of the adsorbent is 0.1-2mm. The fluidizing gas of the circulating fluidized bed device 10 is a low-temperature mixed gas containing low-concentration VOCs produced by the high-temperature mixed gas containing low-concentration VOCs after heat exchange by the heat exchanger 30. The temperature of the high-temperature mixed gas is greater than 200°C, and the temperature of the low-temperature mixed gas is less than 200°C. The purified gas discharged from the circulating fluidized bed device 10 is heated up through the heat exchanger 30, part of it is removed from the device, and the other part is returned to the desorption device 20 as fluidization gas, and the flow rate of the purified gas removed is much larger than that of the purified gas used as fluidization gas capacity. Part of the adsorbent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com