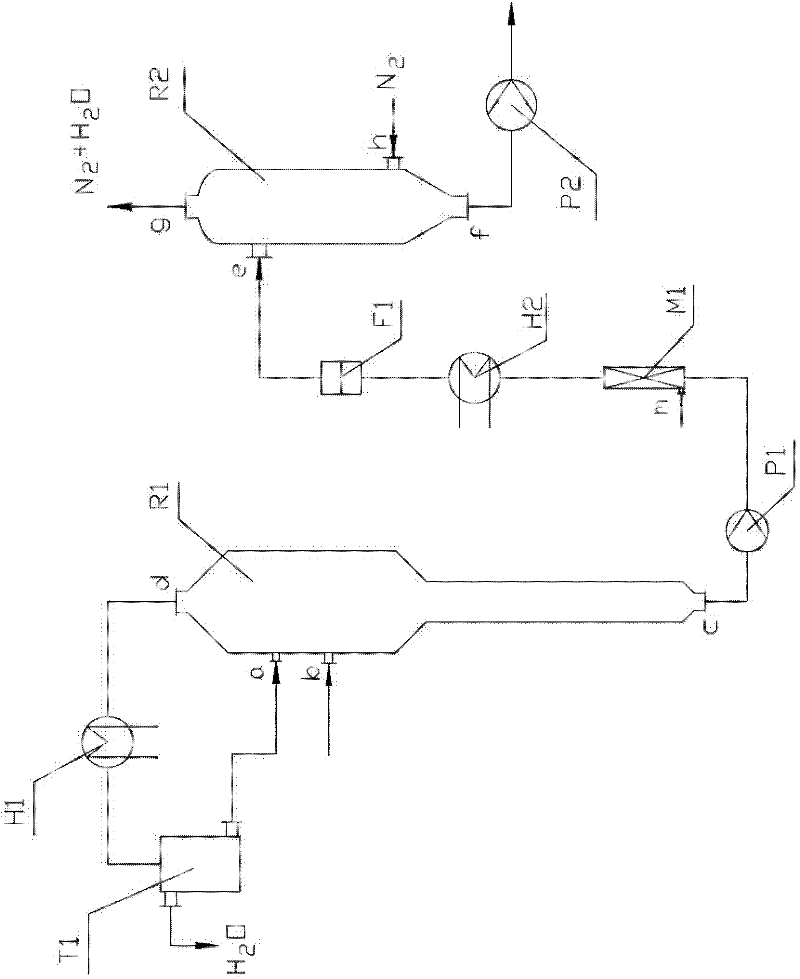

Method and equipment for nylon 66 short-flow continuous polymerization

A short-process, nylon-based technology, applied in the field of short-process continuous polymerization of nylon 66, can solve the problems of condensation water not being easily evaporated, affecting polymer quality, and scarring of the reactor wall, etc., achieving short process and reaction time, and less gel , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Using ASPEN simulation calculation results are as follows:

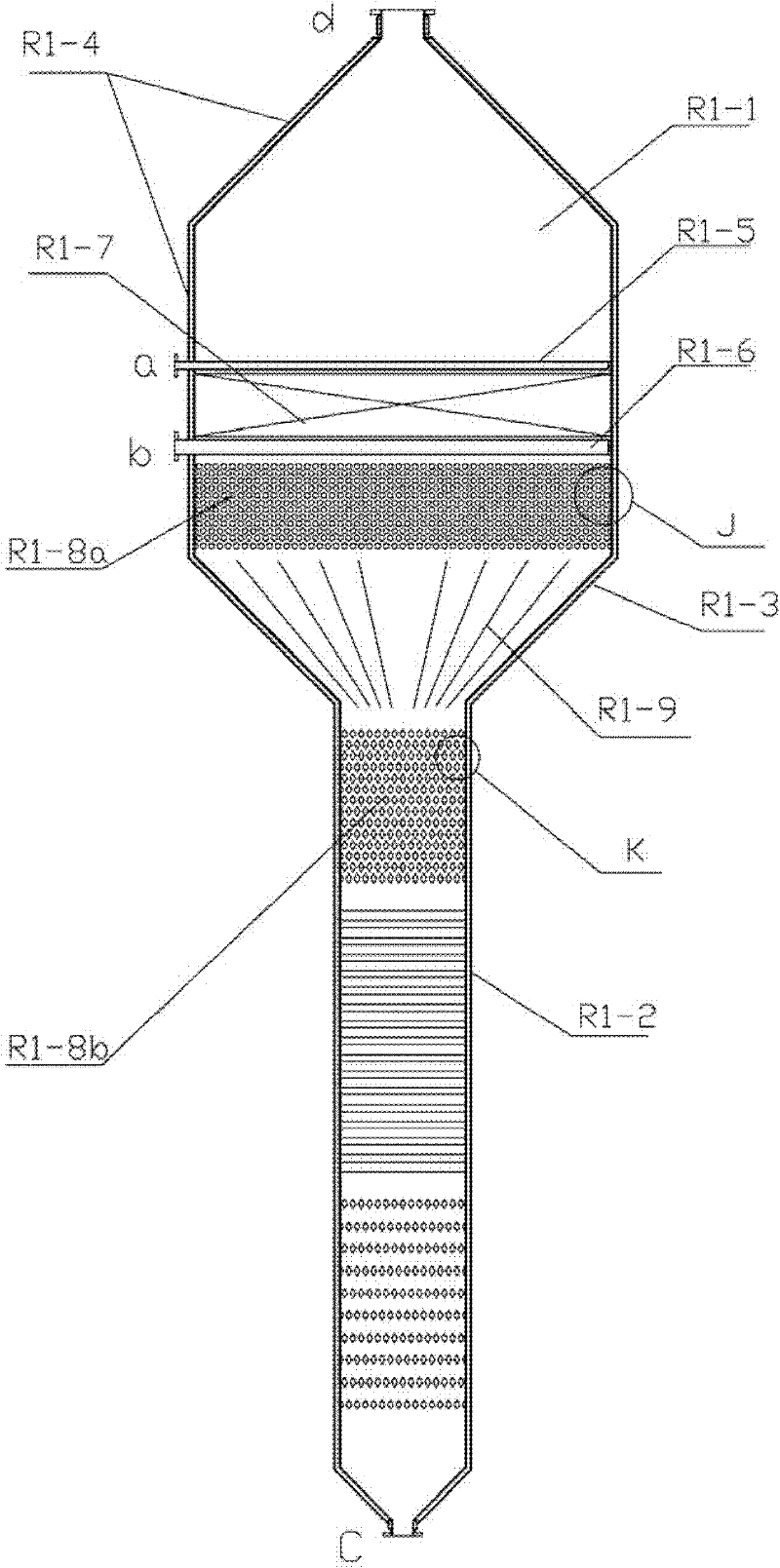

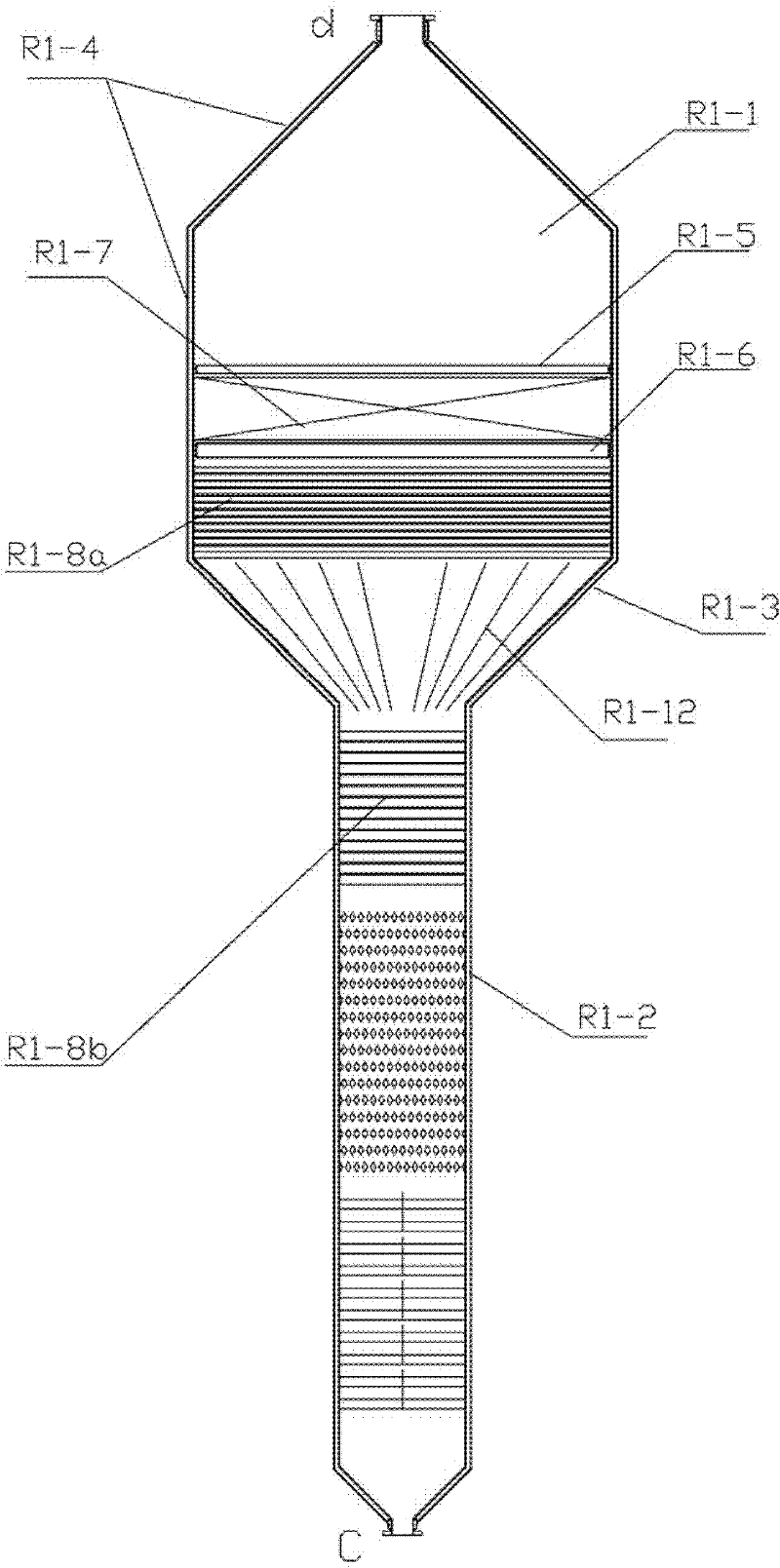

[0054] 1. Nylon 66 brine solution with a concentration of 50% is fed into the precondensation tower at a flow rate of 14,500kg / hr, operated under normal pressure. The upper part of the precondensation tower is 3,200mm wide and the lower part is 900mm wide. The temperature of the heating pipe layer in the upper part of the tower gradually rises from 90°C to 200°C, and the temperature of the heating pipe layer in the lower part of the tower gradually rises from 200°C to 258°C. The total residence time of the materials in the heating pipe layer at the lower part of the tower is 12 minutes, and the degree of polymerization of the prepolymer is 24. The flow rate of the reflux water in the filler is 750kg / hr, and the content of hexamethylenediamine in the overhead steam is less than 20ppm. The prepolymer is heated to 278°C and fed into the polycondensation tank. The polycondensation tank has a diameter of 1,500m and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com