Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improves deep cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste lead storage battery repair and activation method

InactiveCN105870530AImprove repair effectReduce recycling costsLead-acid accumulatorsWaste accumulators reclaimingElectrolytic agentElectrical battery

The invention relates to the field of recycling and reusing of waste lead storage batteries, in particular to a waste lead storage battery repair and activation method. Aimed at solving the problems existing in the prior art, appearance inspection, instrument testing, primary charging and discharging detection, and original capacity inspection are performed at first; then a repair and activation agent is added, an activation instrument adopts specific high-frequency impulse current to perform repair and activation as well as excitation, a discharging instrument is used to discharge the activated battery for capacity inspection, and discharging further simultaneously promotes the penetration of effective ingredients of the repair and activation agent into the battery; finally, self-discharging detection, battery enclosing, charging and discharging simulation and the like are performed, irreversible sulfate crystals on a pole plate of the storage battery are better cleaned away and avoided, the contact area of an active substance of the pole plate with an electrolyte is greatly enlarged, the function degeneration phenomenon of the waste storage battery is recovered to be higher than 86% of original functions, and the service life of the storage battery is prolonged by more than one time.

Owner:山西嘉禾兴节能技术有限公司

Non-cadmium lead stibium slab lattice alloy for traction type accumulator

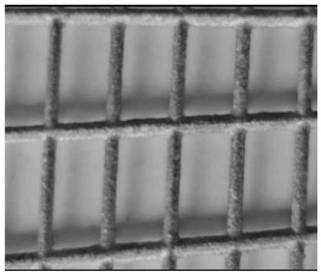

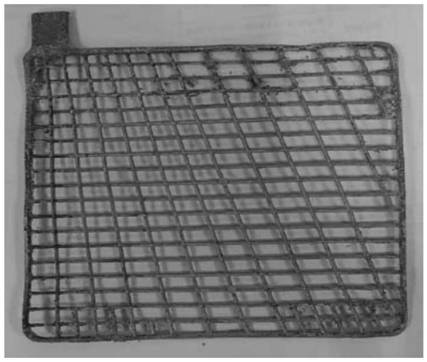

InactiveCN101295789ASolve the problem of thermal crackingSmall and uniform crystal grainsElectrode carriers/collectorsRare-earth elementAlloy

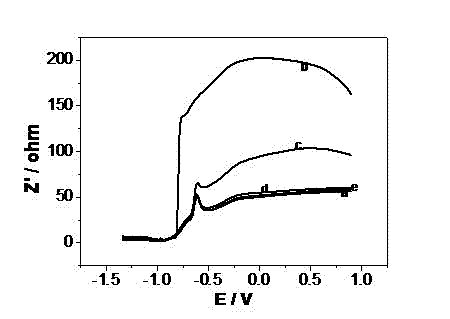

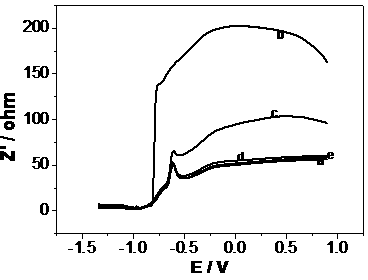

The invention discloses a cadmium free lead-antimony grid alloy for traction batteries. The lead-antimony alloy contains antimony, mischmetal and lead and the weight percentage of the antimony in the lead-antimony alloy is 0.5 to 4.5 percent, that of the mischmetal is 0.05 to 2 percent and the rest is the lead. The grid alloy adds rare earth elements into the lead-antimony alloy and causes the grains of the alloy to become small and even, thereby solving the problem of the hot cracking of the lead-antimony alloy and obviously improving and increasing the toughness, aging strength and corrosion resistance of the alloy. Meanwhile, the adding of the rare earth obviously inhibits the growth of the Pb(II) oxide film and reduces the impedance thereof, thus improving the charging and discharging performance and the deep circulation of the battery. Batteries for electric vehicles combined by lead-acid battery grids produced by the alloy have the advantages of corrosion resistance, deep circulation, high-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

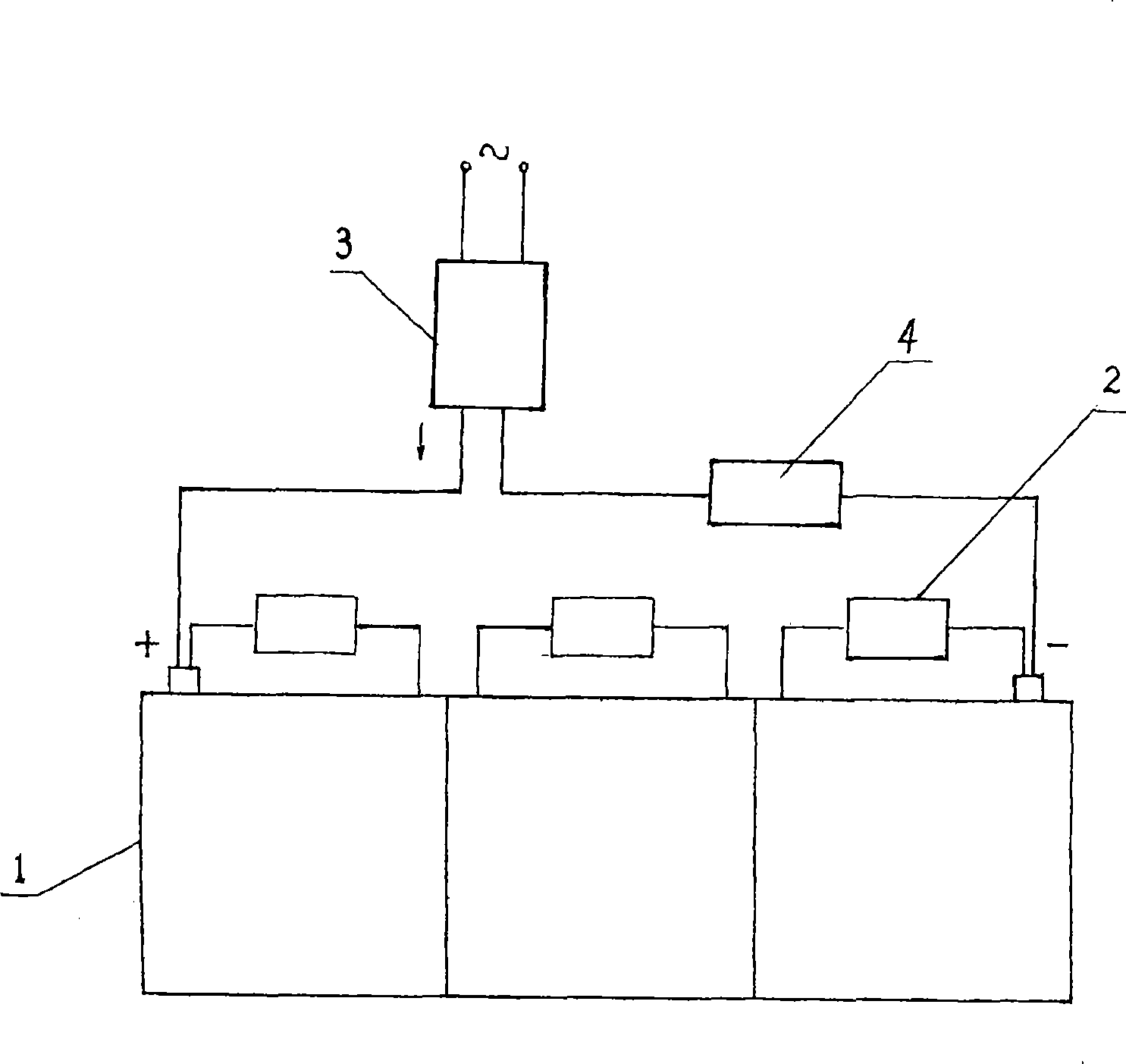

Lead acid accumulator renovation system and method thereof

InactiveCN101431170ASmall self-dischargeReduce pollutionCharge equalisation circuitLead-acid accumulatorsSocial benefitsElectrical battery

The invention relates to a lead-acid battery repair system which is designed against the difficult problem of irreversible vulcanization of a lead-acid battery and formed by combining a battery balancer and a devulcanized charger; and a developed repair agent is used for repair. Or a repair instrument is matched with the repair agent for direct repair. The repair technology can repair and use a waste vulcanized battery. The invention realizes the purpose of rapid elimination of the vulcanization by the self-repair and the principle of combing the physics and the chemistry to eliminate the vulcanization. The invention can prolong the service life of various lead-acid batteries to more than two times, lengthen the driving distance of various vehicles and repair various waste lead-acid batteries. The technology has simple operation, low cost, easy promotion, wide range of application and remarkable economic and social benefits.

Owner:邢纪国

Plumbum calcium alloy for starting type accumulators

InactiveCN101294248ASmall and uniform crystal grainsImprove and increase strengthElectrode carriers/collectorsMisch metalElectric-vehicle battery

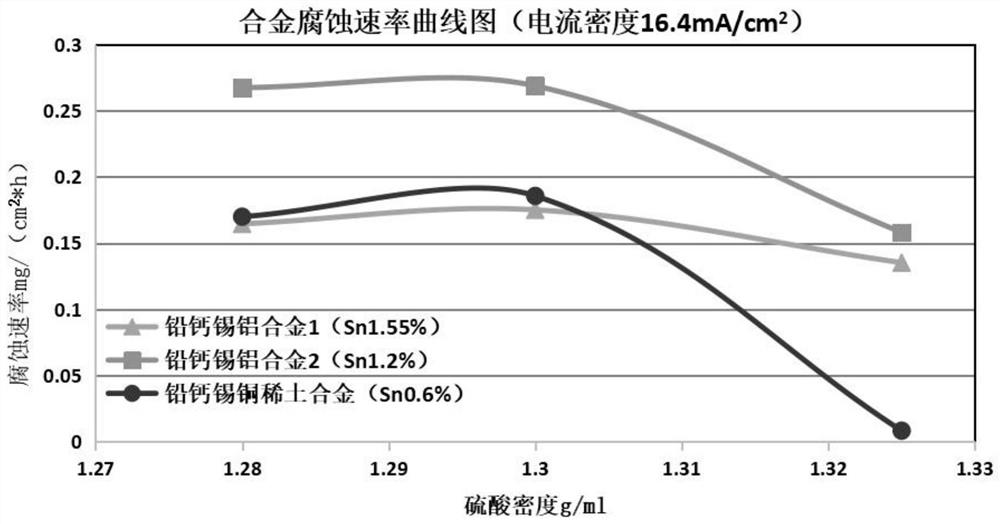

The invention relates to a lead-calcium alloy used on a starting type storage battery, which is composed of a lead-calcium-tin alloy. The lead-calcium-tin alloy comprises calcium, tin, aluminum, misch metal and lead; the weight percentage of the calcium in the lead-calcium-tin alloy is 0.02 to 0.06 percent; the weight percentage of the tin in the lead-calcium-tin alloy is 0.10 to 1.0 percent; the weight percentage of the aluminum in the lead-calcium-tin alloy is 0.01 to 0.03 percent; the weight percentage of the misch metal in the lead-calcium-tin alloy is 0.01 to 1.00 percent; the other weight percentage is composed of the lead. Compared with prior art, an electric vehicle battery which is assembled by a lead-acid accumulator grid produced by using the lead-calcium alloy has the advantages of corrosion resistance, deep cycle, large-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

Lead acid batteries restoring system and method

InactiveCN101252211ACapacity balanceLarge capacityCharge equalisation circuitLead-acid accumulatorsSocial benefitsEngineering

The invention relates to a repairing system for lead-acid storage cells, which is formed by the combination of a cell equalizer and a desulfuration charger, aiming at the problem of the irreversible sulfuration of lead-acid storage cells, wherein the invention uses repair agent to repair, (or a series of repairing apparatuses to be matched with the repair agent for direct repair); the invention can refresh wasted vulcanized cells; the technology which is based on a principle of the self repairing or physical-chemical combination desulfuration realizes an aim of quickly eliminating the sulfuration. The invention has the advantages of more than doubling service lives of all lead-acid storage cells, prolonging driving distance of all vehicles and repairing all wasted lead-acid storage cells; moreover, the technology of the invention also has the advantages of simple operation, low cost, easy popularization, wide application range and obvious economic and social benefits.

Owner:邢纪国

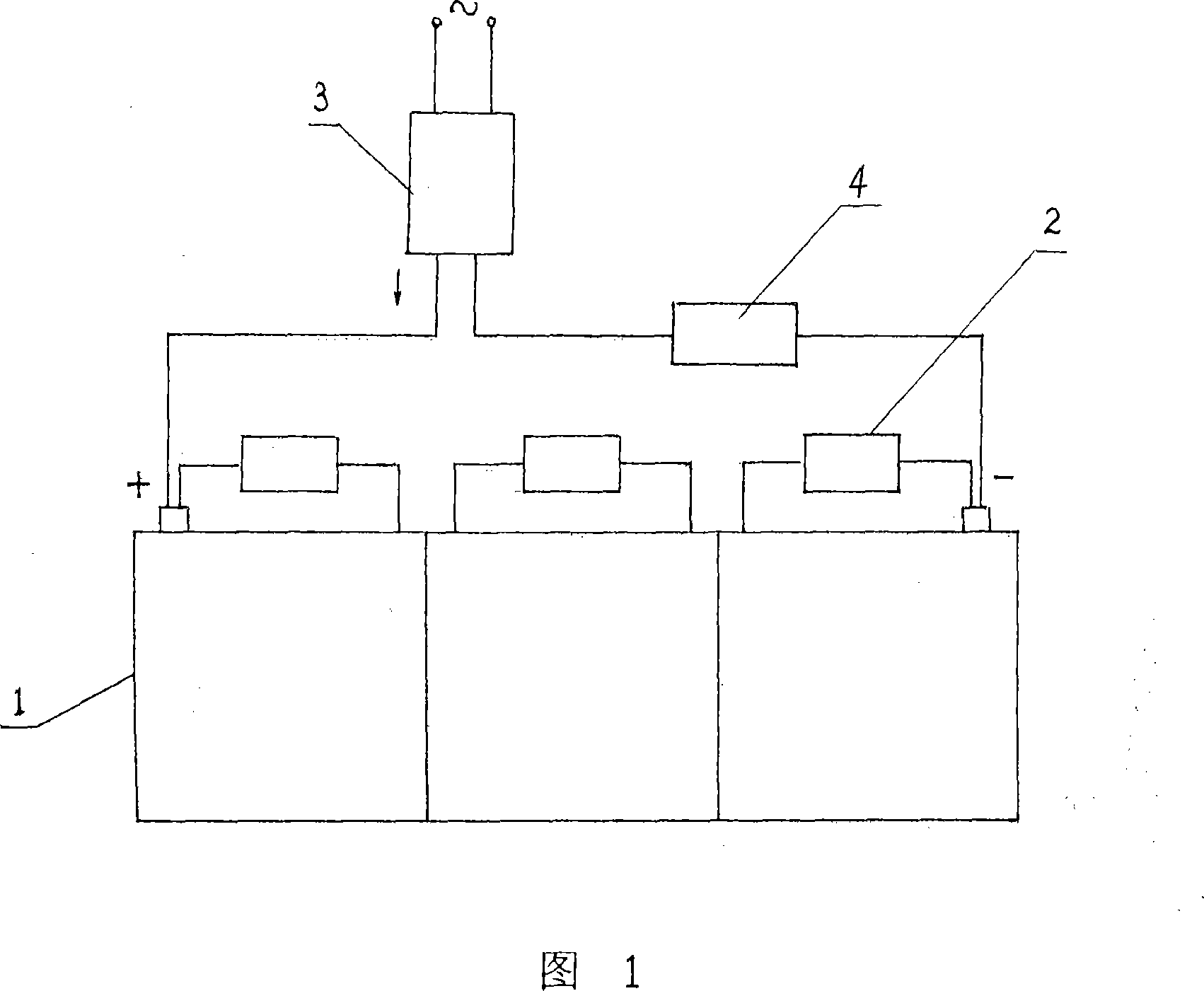

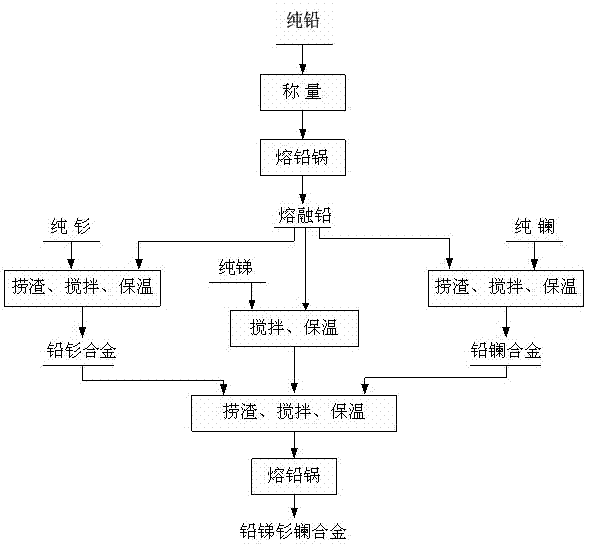

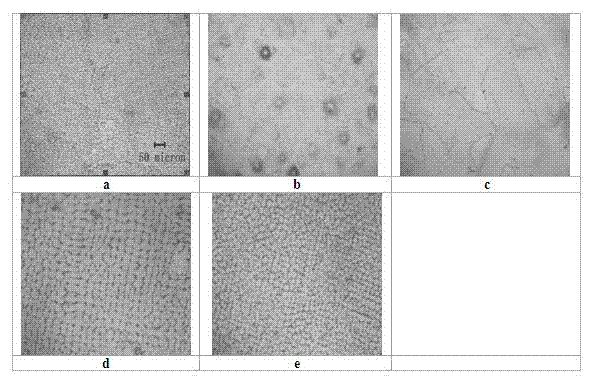

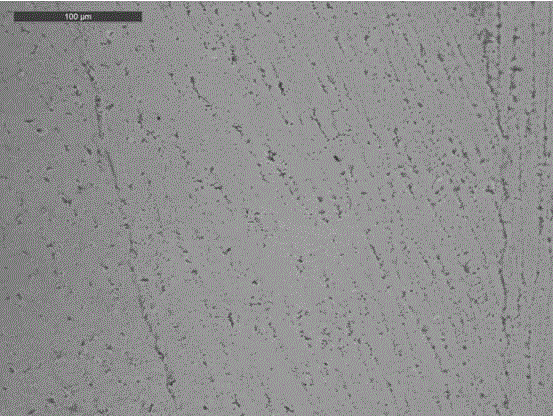

Lead-antimony rare-earth positive grid alloy and preparation method thereof

ActiveCN102329982AFine and uniform grainsImprove mechanical propertiesElectrode carriers/collectorsLanthanoid Series ElementsLanthanum

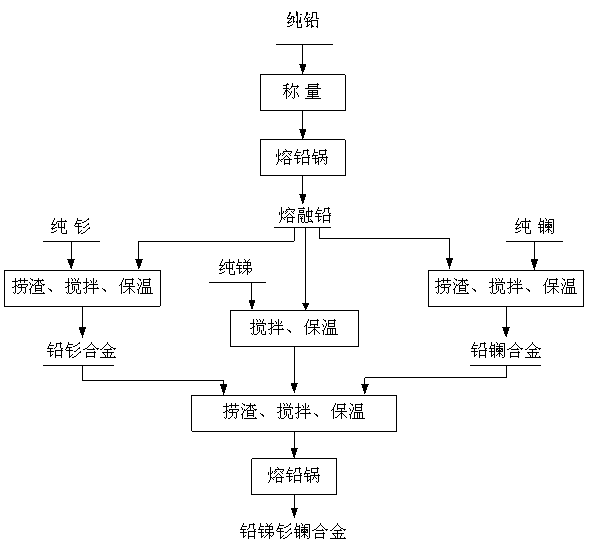

The invention belongs to the field of metallurgy, and relates to a lead-antimony rare-earth positive grid alloy and a preparation method thereof. The alloy comprises the following metal elements in percentage by mass: 0.5 to 1 percent of antimony, 0.005 to 0.1 percent of lanthanum, 0.005 to 0.1 percent of samarium, and the balance of lead. The preparation method comprises the following steps: preparing lead-lanthanum and lead-samarium alloy as master alloys; adding pure antimony into molten lead, stirring until the pure antimony is completely molten; and adding the lead-lanthanum and lead-samarium master alloys to perform mixed melting to prepare the lead-antimony rare-earth positive grid alloy. Grains of the prepared alloy become fine, uniform and regular, so that the comprehensive mechanical performance of the alloy can be improved, the impedance of an oxide film can be reduced, and the charge and discharge acceptance and deep cycle performance of a storage battery can be improved. Meanwhile, rare-earth element serves as an additive to prepare the lead-antimony grid alloy, arsenic, cadmium and other elements harming the environment and workers on the forefront of production severely are not contained. Therefore, lead alloy pollution can be reduced furthest.

Owner:TIANNENG BATTERY GROUP +1

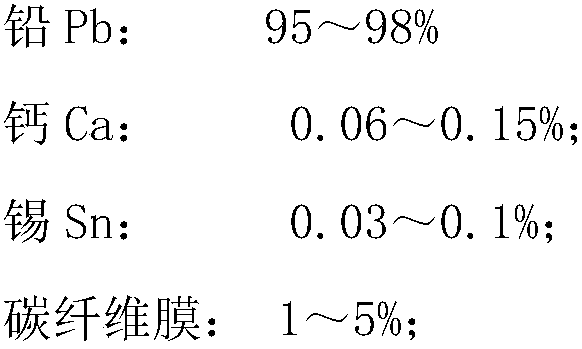

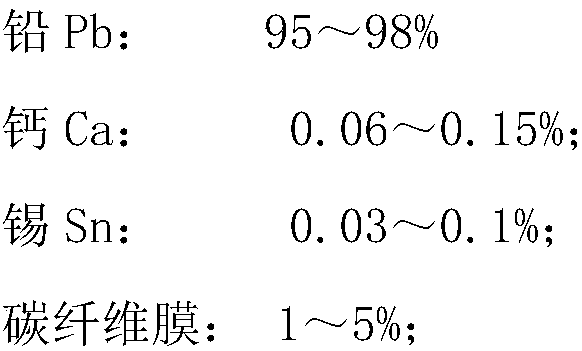

Corrosive-proof grid material with excellent deep-circulating performance

InactiveCN1614053AReduce lossReduce burning rateElectrode carriers/collectorsLead-acid accumulator electrodesHigh energyAlloy

Owner:上海飞轮有色冶炼厂

Lead plaster composition of positive electrode of internally formalized storage battery

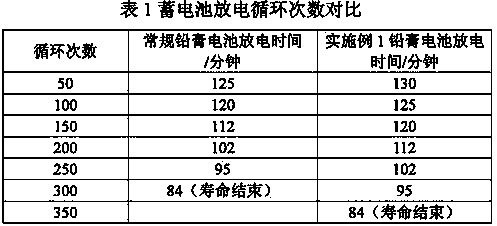

ActiveCN103633320AAvoid generatingImproves deep cycle performanceCell electrodesO-Phosphoric AcidElectrical battery

The invention belongs to the technical field of storage batteries, and specifically relates to a lead plaster composition of a positive electrode of an internally formalized storage battery. The lead plaster composition of the positive electrode of the internally formalized storage battery is prepared from the following raw materials in parts by weight: 990-1010 parts of lead powder, 0.5-1.5 parts of fibers, 0.5-1.0 part of phosphoric acid, 1-2 parts of antimonous oxide, 0.7-1.2 parts of zinc oxide, 0.5-1.5 parts of aluminum oxide, 0.5-0.8 part of ammonium hydrogen carbonate, 0.3-0.5 part of cerium hydroxide, 0.7-1.5 parts of tin monoxide, 110-130 parts of water and 80-90 parts of dilute sulphuric acid. The lead plaster composition of the positive electrode is improved, so that capacity attenuation of the internally formalized battery in the early stage is inhibited, and the service life of deep circular discharge of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

Positive grid lead-calcium alloy for lead-acid storage battery

The invention relates to a novel positive grid lead-calcium alloy for a lead-acid storage battery. The alloy is prepared from components in percentage by weight as follows: 0.05%-0.12% of calcium, 0.5%-1.5% of tin, 0.06%-0.11% of bismuth, 0.07%-0.15% of rare earth elements and the balance of lead, wherein the rare earth elements are one or more of ytterbium, gadolinium and lanthanum. The ingredients of the grid alloy are improved by adding tin, bismuth, the rare earth elements and other additives, and a novel deep-cycle and maintenance-free grid alloy material for the lead-acid storage batterywhich is corrosion-resistant, good in charging property and mechanical property and long in cycle life is obtained.

Owner:WUHAN YIWEIDENG TECH DEV

Pb-Sb grid material for storage battery

InactiveCN101604754ASolve the problem of thermal crackingSmall and uniform crystal grainsElectrode carriers/collectorsRare-earth elementAlloy

The invention provides a Pb-Sb grid material for a storage battery, which comprises the following components in percentage by weight: 0.5-3.5 percent of Sb, 0.01-2 percent of La as a rare earth element and the balance of Pb. The rare earth element is added into Pb-Sb alloy, thereby leading a crystal grain of the alloy to become small and even, solving the problem of the thermal cracking of the Pb-Sb alloy and obviously improving the toughness, the aging strength and the erosion resistance of the alloy. The added rare earth element obviously restrains the growth of a Pb (II) oxide film and reduces the resistance of the Pb (II) oxide film, thereby improving the charge-discharge performance and the deep-cycle performance of the storage battery. A Pb-acid battery grid assembled electrocar battery produced by the alloy has the advantages of erosion resistance, deep cycle, large current discharge and long service life.

Owner:上海飞轮有色冶炼厂

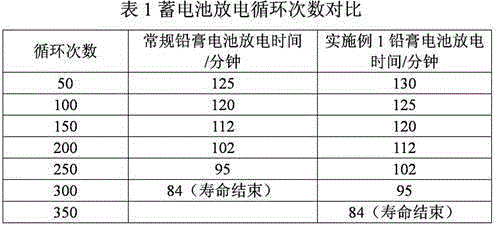

Deep-cycle long-life lead-acid storage battery lead paste for parking, battery thereof and manufacturing process method of battery

ActiveCN113675397AImprove production efficiencyImproves deep cycle performanceFinal product manufactureLead-acid accumulator electrodesPolyesterFiber

The invention belongs to the technical field of manufacturing of lead-acid storage batteries for starting, and particularly relates to a deep-cycle long-life lead-acid storage battery lead paste for parking, a battery thereof and a manufacturing process method of battery. The deep-cycle long-life lead-acid storage battery lead paste for parking comprises positive lead paste and negative lead paste, wherein the positive lead paste is prepared from 71-80% of lead powder, 5.8-7.2% of sulfuric acid solution, 10-12% of water, 4-10% of red lead, 0.06-0.25% of antimony trioxide and phosphoric acid in total and 0.07-0.08% of polyester fiber; and the negative lead paste is prepared from 79.5-82% of lead powder, 6.5-6.8% of a sulfuric acid solution, 10-12% of water, 0.8-1.0% of superfine barium sulfate, 0.15-0.25% of Norway A type lignin, 0.3-0.4% of humic acid, 0.2-0.3% of acetylene black and 0.05%-0.06 of polyester fibers. The deep cycle performance of the battery is effectively improved and the cycle service life of the battery is obviously prolonged by optimizing the positive and negative lead paste formulas, performing age hardening and grid surface corrosion film generation treatment on the grid in stages, curing the unformed plate in stages and optimizing the charging formation process parameters.

Owner:浙江巨江电源制造有限公司

High temperature resisting deep-circulation lead acid battery

InactiveCN103700812AImprove corrosion resistanceImprove uniformityLead-acid accumulatorsLead-acid accumulator electrodesRare earthAlloy

The invention provides a high temperature resisting deep-circulation lead acid battery, whose positive grid alloy employs silver-bearing alloy with high temperature and corrosion resistance and dehydration prevention, and rare earth oxide yttria is added into the anode lead paste formula, and a mixed expanding agent with high temperature resistance and oxidation prevention is added into the cathode lead paste formula. A battery housing and a top cover are made of PC / ABS alloy plastic with high temperature resistance. In order to satisfy the tight assembling requirement of the battery, the pole group is banded and packed into the housing, thereby guarantying the pole group assembling pressure does not change obviously during the usage period of the battery. The battery has effectively improved high temperature resisting deep circulation performance and service life, and is suitable for application in environment above 45 DEG C.

Owner:SHUANGDENG GRP +1

Deep-cycle valve-control lead-acid storage battery

InactiveCN102903927AHigh activityImprove over-discharge resistanceCell electrodesFinal product manufactureSulfatePhosphoric acid

The invention discloses a deep-cycle valve-control lead-acid storage battery. 1-2% of super electric conducting carbon black and 2-3% of colloidal graphite material are added into a positive electrode active material, and 0.5-1.5% of sulfate and 1%-2% of phosphoric acid are added into electrolyte, and the plate group assembled compression ratio is 60%-70%. According to the invention, excessive charging and discharging withstanding capabilities of the battery are improved, and high-temperature and normal-temperature cycle service lives of the battery are prolonged; the problems that the conventional lead-acid storage battery is easy to dehydrate at high temperature and the cycle service life is short are solved; and the valve-control lead-acid storage battery which is suitable for energy storage in deep cycle occasions is provided.

Owner:SHUANGDENG GRP

Rare earth grid alloy for lead-acid storage battery

PendingCN111063894AGrowth inhibitionPromote growthElectrode carriers/collectorsMetallurgyBattery cell

The invention discloses rare earth grid alloy for a lead-acid storage battery. The rare earth grid alloy comprises the raw materials of, by weight, 0.10% to 0.14% of calcium, 0.8% to 1.5% of tin, 0.02% to 0.05% of aluminum, 0.2% to 0.4% of bismuth, 0.05% to 0.15% of RE and the balance of Pb. When rare earth elements are added into the lead-based alloy for the lead-acid storage battery, the rare earth alloy has the advantages of a Pb-Sb system and a Pb-Ca system. The problems existing in preparation of a grid in the prior art are effectively solved. The performance of the grid is obviously improved, meanwhile, the performance of the battery is improved, and the service life of the battery is prolonged. The problem of poor charging acceptance in winter is solved. The rare earth grid alloy has a good application prospect in the field of lead-acid storage batteries.

Owner:HENAN CHAOWEI POWER SUPPLY

Super recovery technique for lead acid battery

InactiveCN1697244AHigh recovery rateEliminate self-dischargeBatteries circuit arrangementsSecondary cells charging/dischargingSulfuric acidEngineering

The invention applies technique of activation and recovery to lead acid battery by using activator and activating instrument. Having high frequency impulse power supply, the activating instrument can send out high frequency impulse in frequency identical to natural frequency of molecule of compound sulfuric acid. The invention solves technical difficulties of low degree of recovery if the activator and activating instrument is applied solely in prior art. The invention is mainly applied to activation and recovery for each sort of lead acid battery (set).

Owner:QINGDA LUJING TECH DEV DEZHOU

Low-temperature deep-cycle positive grid alloy and preparation method thereof

ActiveCN104073683AImprove low temperature performanceImprove conductivityElectrical batteryAluminium

The invention discloses a low-temperature deep-cycle positive grid alloy which consists of the following materials in percentage by weight: 0.05-0.12% of calcium, 0.2-2.0% of tin, 0.01%-0.1% of aluminum, 0.01-0.2 of zinc and the balance of lead. The alloy disclosed by the invention has good low temperature performance, and reduces impedance for forming an anode corrosion membrane at a low temperature. The zinc element can improve deep-cycle performances of the battery very obviously even under a low temperature condition due to good conductivity of PbZnO oxides.

Owner:TIANNENG GRP JIANGSU TECH

Lead-antimony rare-earth positive grid alloy and preparation method thereof

ActiveCN102329982BFine and uniform grainsImprove mechanical propertiesElectrode carriers/collectorsLanthanoid Series ElementsLanthanum

The invention belongs to the field of metallurgy, and relates to a lead-antimony rare-earth positive grid alloy and a preparation method thereof. The alloy comprises the following metal elements in percentage by mass: 0.5 to 1 percent of antimony, 0.005 to 0.1 percent of lanthanum, 0.005 to 0.1 percent of samarium, and the balance of lead. The preparation method comprises the following steps: preparing lead-lanthanum and lead-samarium alloy as master alloys; adding pure antimony into molten lead, stirring until the pure antimony is completely molten; and adding the lead-lanthanum and lead-samarium master alloys to perform mixed melting to prepare the lead-antimony rare-earth positive grid alloy. Grains of the prepared alloy become fine, uniform and regular, so that the comprehensive mechanical performance of the alloy can be improved, the impedance of an oxide film can be reduced, and the charge and discharge acceptance and deep cycle performance of a storage battery can be improved. Meanwhile, rare-earth element serves as an additive to prepare the lead-antimony grid alloy, arsenic, cadmium and other elements harming the environment and workers on the forefront of production severely are not contained. Therefore, lead alloy pollution can be reduced furthest.

Owner:TIANNENG BATTERY GROUP +1

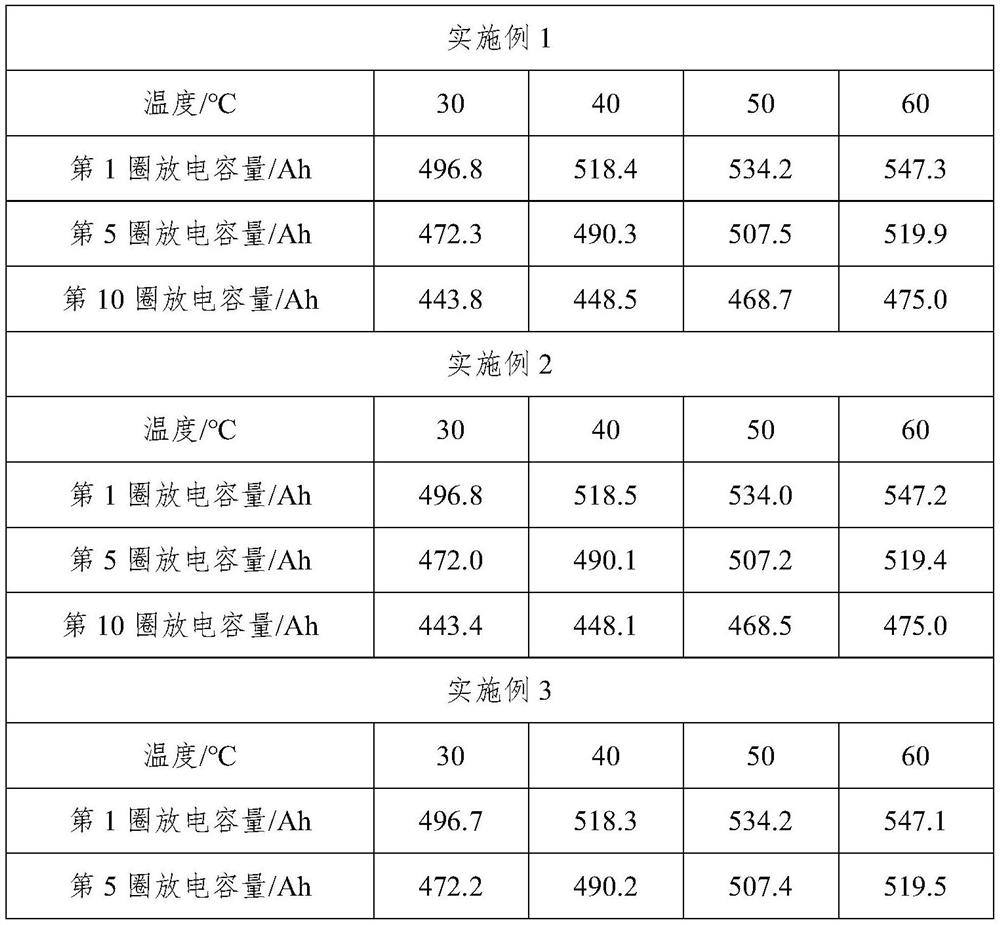

High-temperature valve-regulated lead-acid battery and preparation method thereof

ActiveCN107146890BImprove performanceImprove corrosion resistanceFinal product manufactureElectrode carriers/collectorsAlloyAmmonium sulfate

The invention belongs to the technical field of lead storage batteries, and in particular relates to a high-temperature valve-regulated lead-acid storage battery and a preparation method thereof. In the high-temperature valve-regulated lead-acid battery, the positive electrode grid alloy adopts a high-tin alloy and adds La, Ce and Ag metal elements; the positive electrode active material adds 4BS, Bi 2 o 3 、Lu 2 o 3 and Na 2 SO 4 Add 2 Naphthalene Sulfonate Sodium, Cabot Carbon Black and β Naphthol in the negative electrode active material; Add stannous sulfate and ammonium sulfate in the electrolyte. The high-temperature valve-regulated lead-acid battery of the present invention enhances the corrosion resistance of the positive electrode grid under high temperature environment, shortens the aging hardening speed of the grid, enhances the strength of the active material of the positive electrode, reduces the shrinkage of the negative electrode, improves the conductivity of the active material, and enhances charging. High efficiency, so that the service life of the battery in the environment of 50°C to 70°C is about 1.5 times longer than that of the existing battery; the preparation method is scientific, reasonable, simple and easy to implement.

Owner:ZIBO TORCH ENERGY

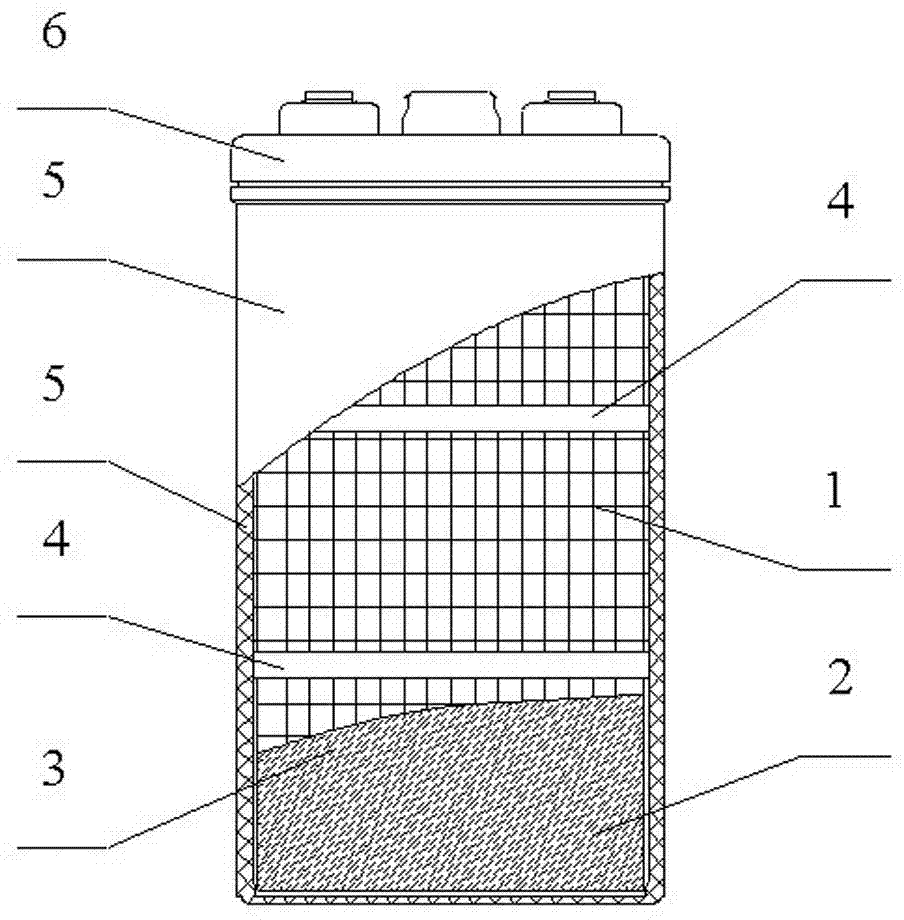

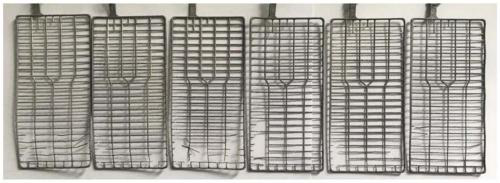

High-specific-energy valve-regulated lead-acid storage battery and preparation method thereof

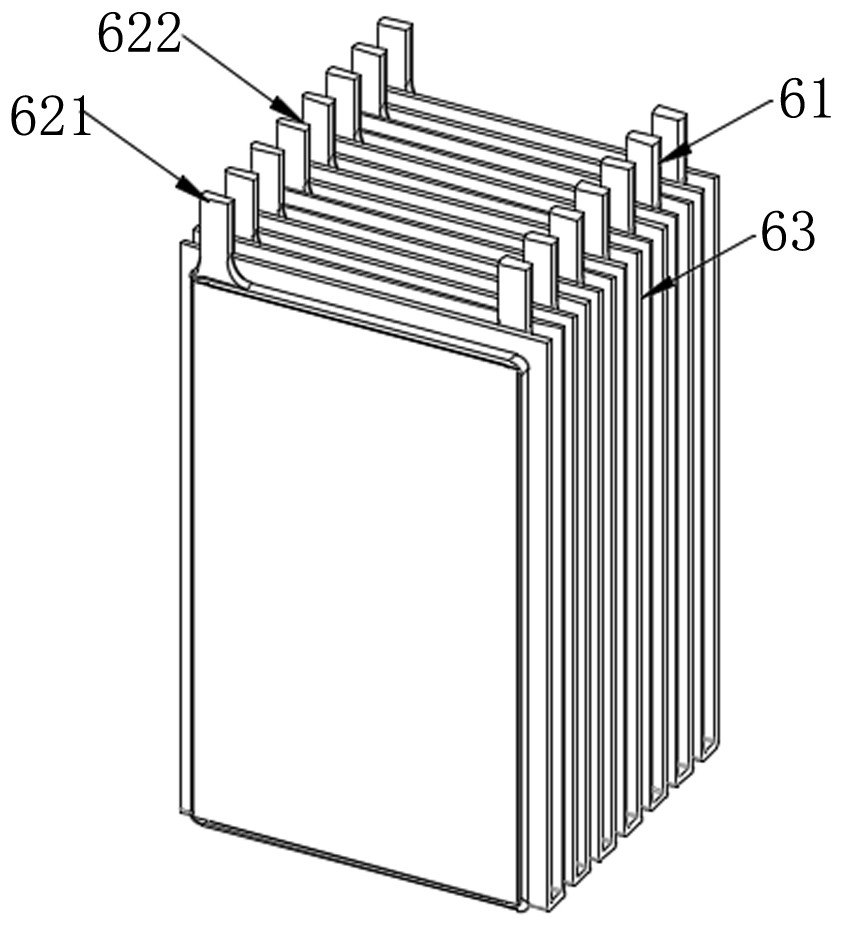

PendingCN113488704AReduce weightReduce utilizationFinal product manufactureElectrode carriers/collectorsElectrical batteryBusbar

The invention discloses a high-specific-energy valve-regulated lead-acid storage battery. The battery comprises an upper cover, a cover plate, a safety valve, a wiring terminal, a busbar, a bottom groove and pole groups, the pole groups are connected in series through the busbar in a direct connection manner, each pole group comprises seven positive plates and eight negative plates which are alternately arranged, each positive plate is wrapped by partition paper from the bottom in a U-shaped mode, each positive plate is located between the negative plates, and the thickness of the negative plates on the outermost sides of the two ends is smaller than that of the other negative plates. The boundary dimension of the storage battery is consistent with that of a 6-DZF-12 battery commonly used in the market at present, and the storage battery can be universally used with a corresponding electric moped; meanwhile, the 2 hr gravimetric specific energy of the storage battery prepared by the preparation method disclosed by the invention can reach 45 Wh / kg, the volumetric specific energy reaches 120 kWh / m<3>, the 100% DOD cycle service life can reach 500 times or more, and the storage battery has relatively high specific energy cycle use performance.

Owner:江苏海宝新能源有限公司

Rare earth/lead/calcium alloy plumbic acid battery panel grate material and preparation method thereof

InactiveCN109136640AHigh porosityImproves deep cycle performanceElectrode carriers/collectorsPorosityRare earth

The invention discloses a rare earth / lead / calcium alloy plumbic acid battery panel grid material. The rare earth / lead / calcium alloy comprises 0.1-5 wt% of rare earth, 90-99 wt% of metal lead and 0.1-5wt% of metal calcium. The invention further comprises a preparation method of the rare earth / lead / calcium alloy plumbic acid battery panel grid material. The method comprises the steps that rare earth, metal lead and metal zinc are melted in a metal pot, rapid solidifying cooling is conducted before pouring is conducted, and the rare earth / lead / calcium alloy plumbic acid battery panel grid material is obtained. The method has the advantages of being simple and efficient, the resistance of a divalent lead compound on the surface of the plumbic acid battery panel grid material is lower, the porosity is higher, the conductivity is improved, and deep circulation performance of a plumbic acid battery is improved fundamentally.

Owner:周霞

Alloy capable of improving creep resistance

InactiveCN108977718AChange plasticityChange stress resistanceElectrode carriers/collectorsRare-earth elementManganese

The invention discloses alloy capable of improving the creep resistance. The alloy capable of improving the creep resistance comprises the following raw materials in percentage by weight: 2 to 2.5 percent of Si, 0.01 to 0.03 percent of S, 25 to 33 percent of Cr, 25 to 33 percent of Fe, 6 to 8 percent of Co, 22 to 29 percent of Ni, 2.2 to 5.3 percent of Cu, 4.3 to 5.2 percent of Mo, 5.1 to 6.3 percent of B, 0.1 to 0.25 percent of C, 0.01 to 0.2 percent of rare-earth, 1.3 to 2.6 percent of Mg, 2.8 to 4.1 percent of Mn and 0.01 to 0.05 percent of Se. According to the alloy disclosed by the invention, through the addition of a rare-earth element-La and other elements, a crystal structure forming the alloy is changed, and the properties such as the plasticity and the stress resistance of the alloy are changed, so that the corrosion resistance and the creep resistance of a grid are improved, the maintenance-free performance of a battery is favorably improved, the polarization performance ofan electrode is improved, passivation of active matters is effectively reduced, the efficiency of redox reaction of lead plaster on different zones of the grid during a charging-discharging process ischanged, and the service life is prolonged.

Owner:江苏永达电源股份有限公司

Internalization into battery cathode lead paste composition

ActiveCN103633320BAvoid generatingImproves deep cycle performanceCell electrodesO-Phosphoric AcidElectrical battery

The invention belongs to the technical field of accumulators, and in particular relates to a lead paste composition internalized into a positive electrode of a battery. The internalized battery cathode lead paste composition of the present invention is made of the following raw materials in parts by weight: 990-1010 parts of lead powder, 0.5-1.5 parts of fiber, 0.5-1.0 parts of phosphoric acid, 1-2 parts of antimony trioxide, and 0.7 parts of zinc oxide. ~1.2 parts, 0.5~1.5 parts of aluminum oxide, 0.5~0.8 parts of ammonium bicarbonate, 0.3~0.5 parts of cerium hydroxide, 0.7~1.5 parts of tin oxide, 110~130 parts of water, 80~90 parts of dilute sulfuric acid. The invention improves the anode lead paste composition so as to suppress the early stage capacity decay of the internalized battery and prolong the service life of the deep cycle discharge of the battery.

Owner:HENAN CHAOWEI POWER SUPPLY

Lead-calcium-tin-copper rare earth grid alloy, positive grid and lead-acid storage battery

InactiveCN112281024AImprove corrosion resistanceLower impedanceLead-acid accumulatorsElectrode carriers/collectorsRare-earth elementLead dioxide

The invention relates to a lead-calcium-tin-copper rare earth grid alloy, a positive grid and a lead-acid storage battery. The lead-calcium-tin-copper rare earth grid alloy comprises the following components of, in weight by percentage, 0.04wt%-0.1wt% of calcium, 0.3wt%-1.0wt% of tin, 0.02wt%-0.06wt% of copper, 0.02wt%-0.2wt% of rare earth elements and the balance lead; and the method comprises the following steps of S1, dividing the required amount of electrolytic lead in claim 1 into two components, namely a component 1 and a component 2; S2, preparing copper rare earth master alloy; and S3,preparing the lead-calcium-tin-copper rare earth grid alloy. According to the lead-calcium-tin-copper rare earth grid alloy, the positive grid and the lead-acid storage battery, lanthanum and ceriumrare earth elements and copper elements are simultaneously added on the basis of the lead-calcium alloy which is widely used at present, so that the impedance of an oxide film on the surface of the grid can be effectively reduced, the deep cycle performance is improved, the growth of lead dioxide can be promoted, the corrosion resistance of the alloy is improved, good deep cycle performance and longer floating charge service life are realized, and meanwhile, the production cost is further reduced.

Owner:ANHUI LEOCH POWER SUPPLY

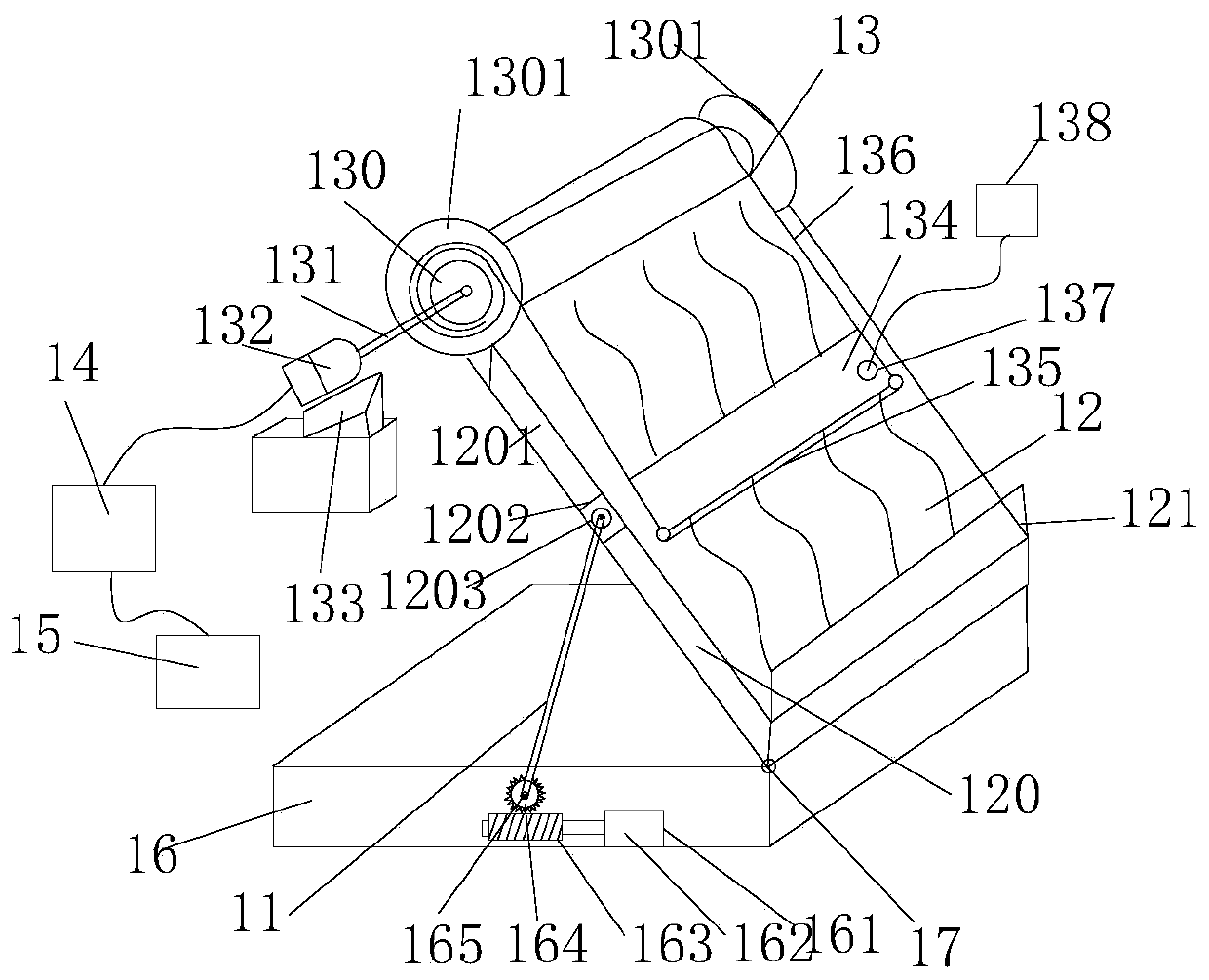

Superlow antimony alloy for plate of accumulator

The alloy with very low Sb content for accumulator plate contains Sb 0.7-1.0 wt%, Cu 0.03-0.06 wt%, S 0.003-0.006 wt%, As 0.15-0.25 wt% and Sn 0.1-0.3 wt% except Pb. The alloy has lower Sb content and thus low cost, and has raised Cu, As and trace elements resulting in raised strength, raised anticorrosive performance, high creepage resistance, and raised comprehensive product performance.

Owner:CHAOWEI POWER CO LTD

A long-life deep cycle positive electrode grid alloy and its preparation method

ActiveCN104073682BImprove corrosion resistanceDoes not affect deep cycle performanceElectrical batteryAlloy

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

Superlow antimony alloy for plate of accumulator

The alloy with very low Sb content for accumulator plate contains Sb 0.7-1.0 wt%, Cu 0.03-0.06 wt%, S 0.003-0.006 wt%, As 0.15-0.25 wt% and Sn 0.1-0.3 wt% except Pb. The alloy has lower Sb content and thus low cost, and has raised Cu, As and trace elements resulting in raised strength, raised anticorrosive performance, high creepage resistance, and raised comprehensive product performance.

Owner:CHAOWEI POWER CO LTD

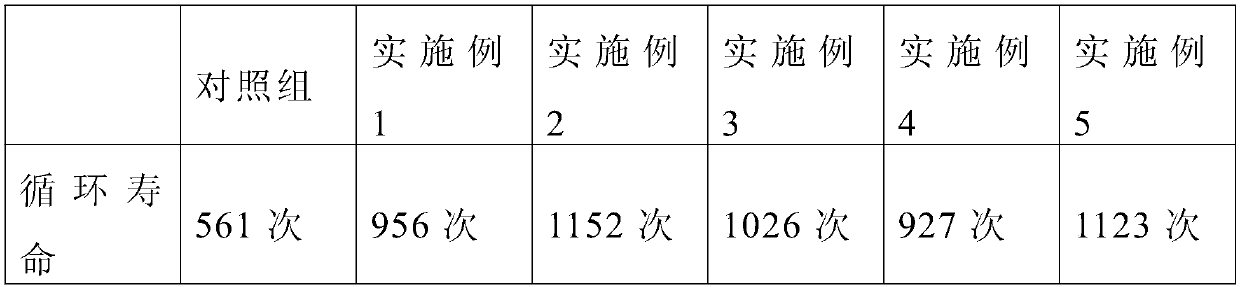

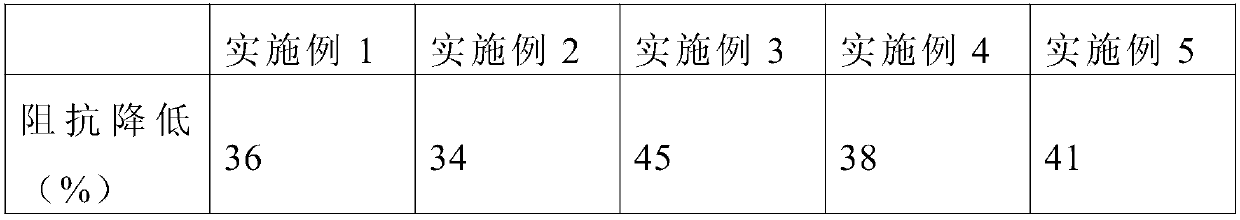

Repair method of decommissioned lead-acid battery, repair electrolyte and preparation method of repair electrolyte

ActiveCN113437372AImproves deep cycle performanceExtended service lifeLead-acid accumulatorsElectrolyte/reactants regenerationElectrical batteryLead sulfate

The invention discloses a repair method of a decommissioned lead-acid battery, a repair electrolyte and a preparation method of the repair electrolyte, and relates to the field of repair of lead-acid batteries. The invention aims to provide a method for preparing a lead-acid battery, which can effectively promote the dissolution of non-conductive coarse-grain lead sulfate, revive the decommissioned battery, enhance the deep cycle performance of the decommissioned lead-acid battery, prolong the service life of the decommissioned lead-acid battery and prolong the service life of the decommissioned lead-acid battery. According to the repair method, the repair electrolyte and the preparation method of the repair electrolyte, the heat resistance is improved so as to adapt to different working conditions in echelon utilization of the decommissioned lead-acid battery. The repair electrolyte for the decommissioned lead-acid battery is prepared from the following components in parts by mass: 0.5 to 1.2 parts of polyvinylpyrrolidone, 2.8 to 3.8 parts of active carbon fiber, 6.5 to 9.5 parts of sodium silicate, 1.5 to 2.5 parts of nano silicon dioxide, 4 to 7 parts of sodium sulfate, 4 to 6.5 parts of zinc sulfate, 3 to 5 parts of copper sulfate and 70 to 86 parts of ultrapure distilled water. According to the repair method of the decommissioned lead-acid battery, the repair electrolyte for the decommissioned lead-acid battery is adopted for repair.

Owner:河南润祥能源科技有限公司

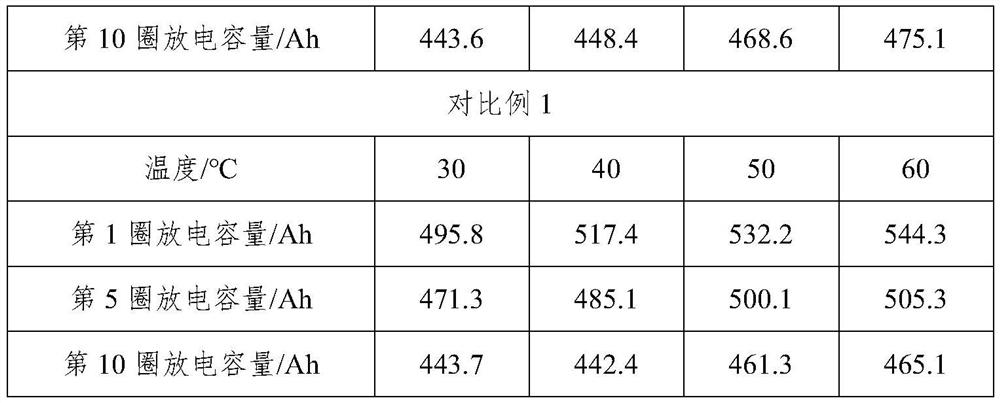

Power Generation Optimization System for Photovoltaic Power Stations

ActiveCN109980681BIncrease profitImprove power generation efficiencyPhotovoltaic supportsSingle network parallel feeding arrangementsElectrical batteryEngineering

The invention relates to the technical field of photovoltaic power generation, in particular to a power generation capacity optimization system of a photovoltaic power station. The system comprises aphotovoltaic module for absorbing sunlight and converting solar radiation energy into electric energy, wherein the photovoltaic module is formed by connecting solar cells in series or in parallel; a storage battery pack for storing the electric energy generated by the photovoltaic module, wherein the photovoltaic module is connected with the storage battery pack through a photovoltaic controller to perform over-charge and over-discharge protection for the storage battery pack; an inverter connected with the storage battery pack to convert a direct current to an alternating current; and a cooling cycle unit connected with the photovoltaic module to perform cooling and temperature reduction of the photovoltaic module. The photovoltaic module is cooled by cooling water circulation to greatlyimprove the utilization of the photovoltaic module, optimize the power generation system of the photovoltaic power station and improve the power generation efficiency.

Owner:内蒙古能源规划设计研究院有限公司

Accumulator plate grid alloy with lead, calcium, strontium and rare earth

InactiveCN100483811CAccelerated corrosionImprove creep resistanceElectrode carriers/collectorsCapacity lossRare earth

The alloy is composed of 0.06í½0.08úÑ by weight Ca, 0.80í½2.50úÑ by weight Sn, 0.02í½0.05úÑ by weight Sr, and lead in amount of margin. Appropriate amount of Sr is added to improve corrosion-resistance and creep- resistance of the alloy, and to last useful life, and to improve age hardening speed, hardness and mechanic properties, and also to improve the early capacity loss and poor deep cycle ability.

Owner:上海飞轮有色冶炼厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com