A surface-layer rolled carbon fiber film colloidal battery plate and its production and preparation method

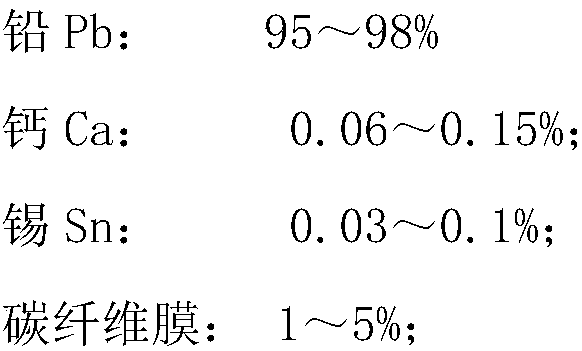

A colloidal battery, carbon fiber membrane technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of uneven negative vulcanization degree, increased battery water loss rate, large grid corrosion rate, etc., and achieve excellent corrosion resistance. performance and high current discharge capability, reducing impedance and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the lead alloy coated with lead paste is used as the substrate. After coating, the surface is pressed into a 0.03mm uneven shape with a precision balance hydraulic press, and a layer of PTFE adhesive is sprayed with a spray gun.

[0020] The specific PTFE binder parameters are as follows: 40g / L tetrafluoroethylene, 12g / L polypropylene, 13g / L potassium sulfate, and 1.8g / L silicon dioxide are completely mixed and dissolved, and then fully stirred , at a distance of 10MM from the plate, spray 3 to 10 microns.

[0021] The remaining components of the carbon fiber membrane are 50g of modified activated carbon, 2g of graphene, and 12g of magnesium oxide, mixed together, ground evenly, coated on a PTFE adhesive plate, rolled by a precision balanced hydraulic machine, and dried at 60 degrees. The surface layer is mainly composed of lead and contains about 12% metallic carbon, 0.8% fiber and trace amounts of organic matter.

Embodiment 2

[0023] In this embodiment, the lead alloy coated with lead paste is used as the matrix. After coating, the surface is pressed into a 0.04mm uneven shape with a precision balance hydraulic press, and a layer of PTFE adhesive is sprayed with a spray gun.

[0024] The specific PTFE binder parameters are as follows: 40g / L tetrafluoroethylene, 12g / L polypropylene, 13g / L potassium sulfate, and 1.8g / L silicon dioxide are completely mixed and dissolved, and then fully stirred , at a distance of 10MM from the plate, spray 3 to 10 microns.

[0025] The remaining components of the carbon fiber membrane are 50g of modified activated carbon, 6g of graphene, and 10g of magnesium oxide, mixed together, ground evenly, coated on a PTFE adhesive plate, rolled by a precision balanced hydraulic press, and dried at 60 degrees. The surface layer is mainly composed of lead and contains about 11% metallic carbon, 0.8% fiber and trace amounts of organic matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com