A long-life deep cycle positive electrode grid alloy and its preparation method

A positive plate and long-life technology, applied in the field of long-life deep-cycle lead-acid battery positive grid alloy and its preparation, can solve the problems of early capacity decay of lead-acid batteries, decreased corrosion resistance of alloys, poor corrosion resistance of alloys, etc. problems, to achieve the effect of avoiding a large amount of burning loss, improving corrosion resistance, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

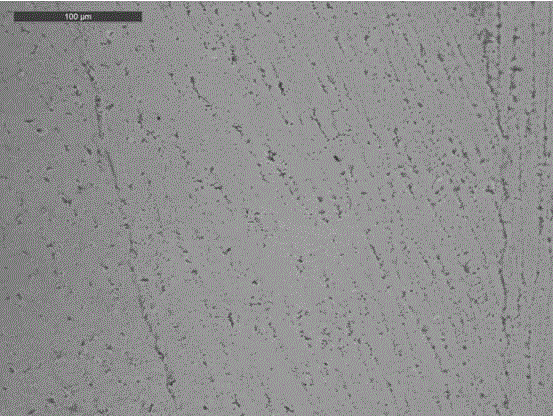

Image

Examples

Embodiment 1

[0025] A method for preparing deep-cycle positive grid alloy for low temperature, which is characterized by comprising the following steps:

[0026] (1) Preparation of raw materials: lead, calcium, tin and aluminum, and the mass percentages of each raw material in the total raw materials are: calcium: 0.09%, tin: 0.2%, aluminum: 0.05%, zinc: 0.02%, silver: 0.01%, Lead is the balance;

[0027] (2) Put 85% of the total mass of lead raw materials into the graphite melting pot of the intermediate frequency furnace and heat the lead particles to 670~680℃ to fully melt the lead particles. Use 0.5% of the total mass of lead raw materials to wrap and mix evenly. Calcium scraps and broken aluminum flakes, and press them into the molten lead together, and then stir for 2~3min to make the calcium and aluminum elements in the lead liquid evenly mixed. During this process, keep the melt temperature at 670~680 Between ℃;

[0028] (3) Stop stirring and heating, add the remaining lead pellets, and...

Embodiment 2

[0032] A method for preparing deep-cycle positive grid alloy for low temperature, which is characterized by comprising the following steps:

[0033] (1) Preparation of raw materials: lead, calcium, tin and aluminum, and the mass percentages of each raw material in the total raw materials are: calcium: 0.09%, tin: 0.18%, aluminum: 0.05%, zinc: 0.08%, silver: 0.05%, Lead is the balance;

[0034] (2) Put 85% of the total mass of lead raw materials into the intermediate frequency furnace and heat to 670~680℃ to fully melt the lead particles. Use 0.5% of the total mass of lead raw materials to wrap the mixed calcium chips and Crush the aluminum flakes and press them into the molten lead solution together, and then stir for 2~3min to mix the calcium and aluminum elements in the lead solution evenly. During this process, keep the melt temperature between 670~680℃;

[0035] (3) Stop stirring and heating, add the remaining lead pellets, and stir the melt. When the temperature drops to 520~54...

Embodiment 3

[0039] A method for preparing deep-cycle positive grid alloy for low temperature, which is characterized by comprising the following steps:

[0040] (1) Preparation of raw materials: lead, calcium, tin and aluminum, and the mass percentages of each raw material in the total raw materials are: calcium: 0.09%, tin: 0.2%, aluminum: 0.05%, zinc: 0.15%, silver: 0.15%, Lead is the balance;

[0041] (2) Add 80~85% of the total mass of lead raw materials to lead pellets in an intermediate frequency furnace and heat to 670~680°C to fully melt the lead pellets, wrap the mixed calcium and aluminum flakes with lead skins, and combine them It is pressed into the molten lead liquid, and then stirred for 2~3min to mix the calcium and aluminum elements in the lead liquid evenly. During this process, keep the temperature of the melt between 670~680℃;

[0042] (3) Stop stirring and heating, add the remaining lead pellets, and stir the melt. When the temperature drops to 520~540℃, add tin, zinc and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com