Accumulator plate grid alloy with lead, calcium, strontium and rare earth

A lead-acid battery, grid technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of reducing the deep charge-discharge cycle life of maintenance-free batteries, poor deep cycle capability, low corrosion resistance, etc. The effect of poor cycle ability, hindering grain growth and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

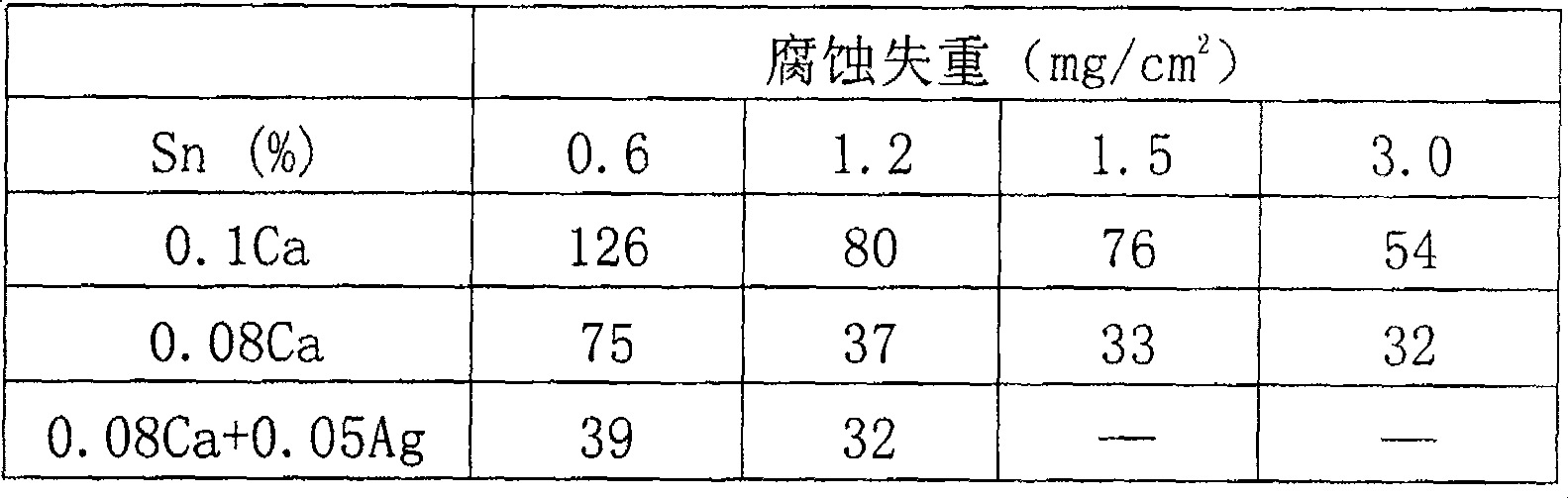

Image

Examples

Embodiment

[0032] Embodiment: The following is weight percentage.

[0033]

serial number

Pb

Calcium (Ca)

Tin (Sn)

Strontium (Sr) rare earth

(Re)

Silver (Ag)

Aluminum (Al) 1 margin 0.08 1.20 0.01 0.03 0.02 2 margin 0.06 1.20 0.02 0.02 0.02 3 margin 0.08 0.80 0.02 0.04 0.02 4 margin 0.06 2.0 0.05 0.01 0.10 0.02 5 margin 0.08 1.5 0.03 0.003

[0034] 6 margin 0.06 2.0 0.03 0.03 7 margin 0.08 1.2 0.04 0.05 0.03 8 margin 0.06 2.5 0.03 0.05 0.05 0.03

[0035] Manufacturing method of lead calcium strontium rare earth battery grid alloy:

[0036] The grid alloy material of the present invention is added into the lead liquid in the form of an intermediate alloy. Specifically: in the alloy pot, heat the lead to 500-800°C, and then add aluminum, tin, lead-calcium master alloy, lead-strontium master alloy, lead-rare-earth master alloy, etc. a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com