Rare earth grid alloy for lead-acid storage battery

A lead-acid battery and alloy technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as production restrictions, increased alloy grain size, and intergranular corrosion of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

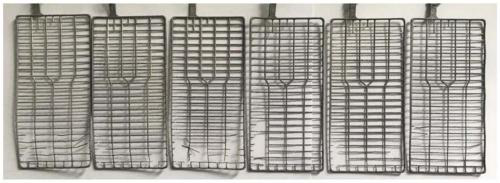

Image

Examples

Embodiment 1

[0030] A kind of rare earth grid alloy for lead-acid battery, the element weight ratio of this rare earth grid alloy is: Ca is 0.125%, Al is 0.022%, Sn is 1.16%, Bi is 0.21%, RE is 0.059%, wherein RE is La, and the balance is Pb (refined lead with a purity of more than 99.95%).

[0031] The preparation method of the grid alloy is as follows:

[0032] (1) Prepare Pb-Ca master alloy, tin, aluminum, bismuth, RE and refined lead Pb according to the required ratio;

[0033] (2) Take the prepared refined lead and heat it to 400-550°C to make lead liquid;

[0034] (3) Take half of the lead liquid in step (2), add Pb-Ca master alloy to it, melt and mix at 500-600°C for 15-30min, and mix evenly to form a Pb-Ca alloy melt;

[0035] (4) Take the remaining lead liquid in step (2), add La therein, melt and mix at 600-720° C. for 15-30 minutes, melt and mix evenly to form a Pb-La alloy melt;

[0036] (5) Mix the Pb-Ca alloy melt in step (3) and the Pb-La alloy melt in step (4), then add ...

Embodiment 2

[0038] A kind of rare earth grid alloy for lead-acid battery, the element weight ratio of this rare earth grid alloy is: Ca is 0.119%, Al is 0.029%, Sn is 1.21%, Bi is 0.23%, RE is 0.121%, wherein RE is Nd, and the balance is Pb (refined lead with a purity of more than 99.95%).

[0039] The preparation method of the grid alloy is as follows:

[0040] (1) Prepare Pb-Ca master alloy, tin, aluminum, bismuth, RE and refined lead Pb according to the required ratio;

[0041] (2) Take the prepared refined lead and heat it to 400-550°C to make lead liquid;

[0042] (3) Take half of the lead liquid in step (2), add Pb-Ca master alloy to it, melt and mix at 500-600°C for 15-30min, and mix evenly to form Pb-Ca alloy;

[0043] (4) Take the remaining lead liquid in step (2), add Nd thereinto, melt and mix at 600-720° C. for 15-30 minutes, and melt and mix evenly to form a Pb-Nd alloy;

[0044] (5) Mix the Pb-Ca alloy melt in step (3) and the Pb-Nd alloy melt in step (4), then add Sn, Al...

Embodiment 3

[0046] A kind of rare earth grid alloy for lead-acid battery, the element weight ratio of this rare earth grid alloy is: Ca is 0.121%, Al is 0.026%, Sn is 1.35%, Bi is 0.32%, RE is 0.089%, wherein RE is Sm, the balance is Pb (refined lead with a purity of more than 99.95%).

[0047] The preparation method of the grid alloy is as follows:

[0048] (1) Prepare Pb-Ca master alloy, tin, aluminum, bismuth, RE and refined lead Pb according to the required ratio;

[0049] (2) Take the prepared refined lead and heat it to 400-550°C to make lead liquid;

[0050] (3) Take half of the lead liquid in step (2), add Pb-Ca master alloy to it, melt and mix at 500-600°C for 15-30min, and mix evenly to form Pb-Ca alloy;

[0051] (4) Take the remaining lead liquid in step (2), add Sm thereinto, melt and mix at 600-720° C. for 15-30 minutes, and melt and mix evenly to form a Pb-Sm alloy;

[0052] (5) Mix the Pb-Ca alloy melt in step (3) and the Pb-Sm alloy melt in step (4), then add Sn, Al and...

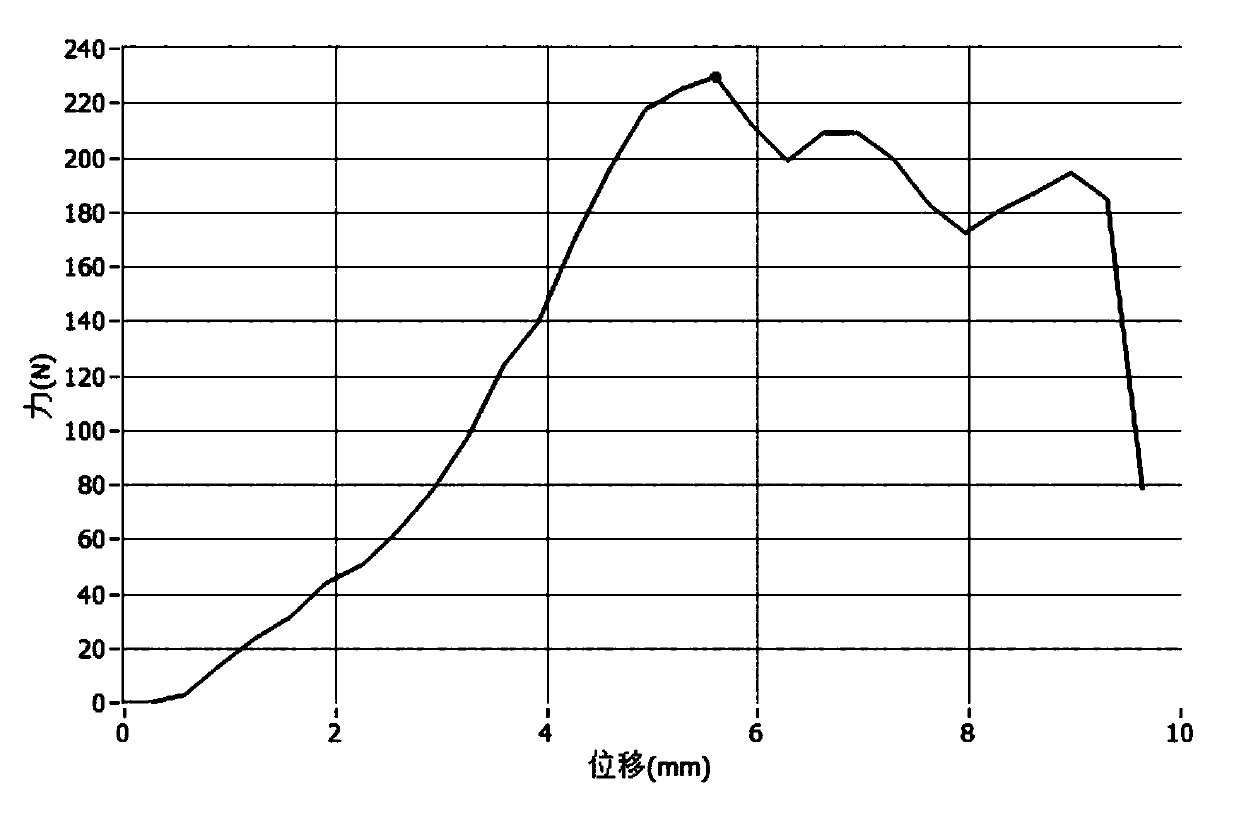

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum pull | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Maximum pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com