Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

476results about How to "Improve suction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

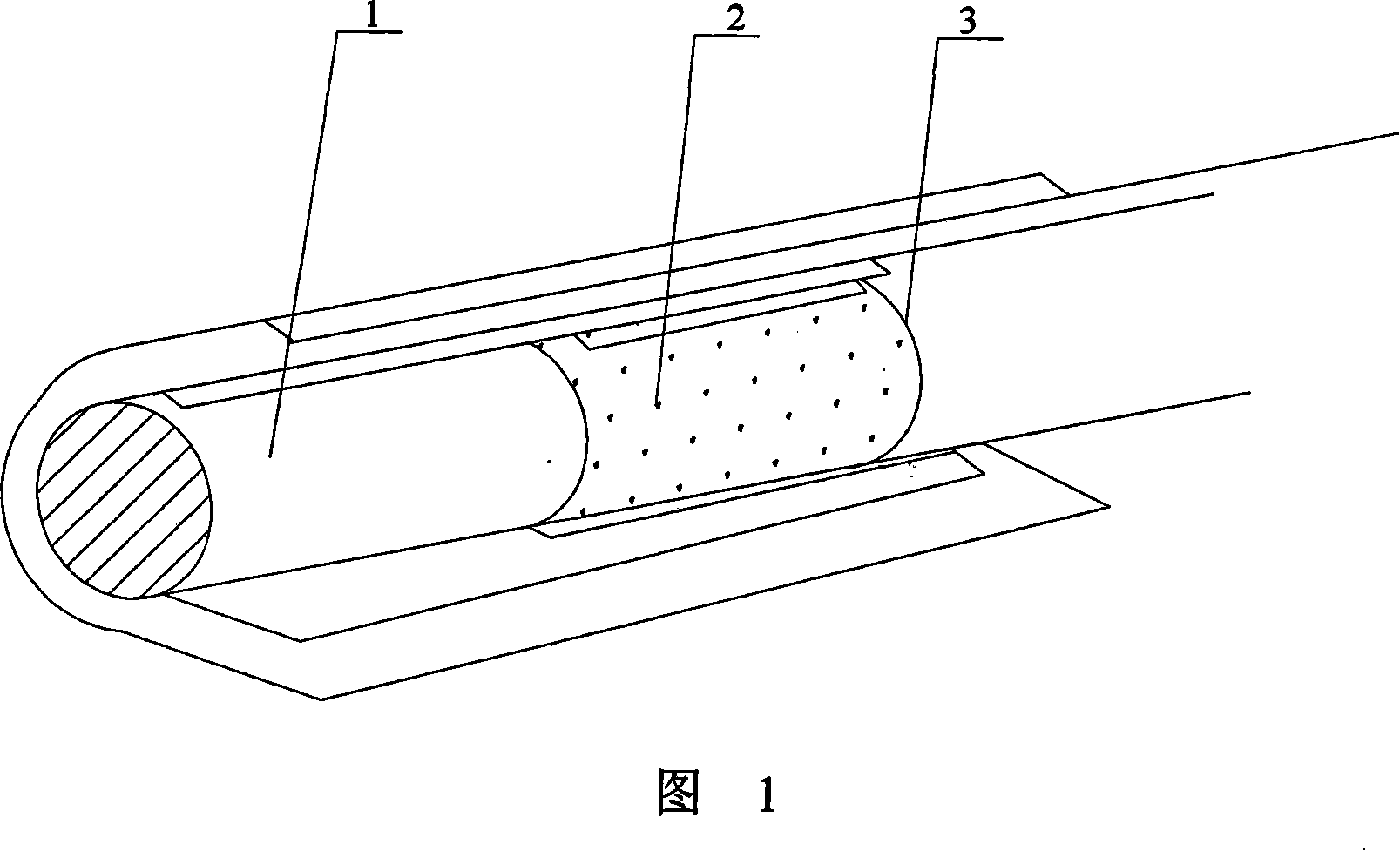

Filtering material for cigarette filter tip and its preparation method

ActiveCN101103845AEasy to shapeConducive to the manufacture of cigarettesTobacco preparationTobacco treatmentEconomic benefitsTar

The invention discloses a filter material for cigarette filter and the preparation method. Based on the expanded cabo particles from <The Preparation Method of an Expanded Cabo Particles and Relevant Equipment> (Application No.: 200710065892.3), the expanded cabo particles are extracted, shaped and selected as so to become the required filter material. The filter material utilizes the waste in the cigarette production, which not only has significant economic benefits, but also is not necessary to be recycled, and will not cause the abrasion of equipment and affect the sensory quality of cigarette. The filter material is uniformly arranged on the filter tows so as to make a composite filter; as the composite is applicable to the cigarette, the smell of the cigarette will be more clear and soft, and the tar and nicotine content in the smoke gas can be reduced effectively. The invention has the advantages that: the operation is simple; the effect is remarkable, therefore the invention has a good applicable prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

Method for preparing slices reconstituted from tea, and application in tobacco product

ActiveCN1957777AImprove suction qualityImprove adaptabilityTobacco preparationTobacco treatmentTarTobacco product

A reformed tea leaf sheet used to replace part or all of tobacco leaf for decreasing tar, nicotine and CO is prepared from tea leaves or the mixture of tea leaves and tobacco leaves through extracting in water, catalytic degradating, mixing, preparing pulp, making sheet, coating the concentrated liquid extract of tea leaves onto the sheet, rolling, cutting and baking.

Owner:XIAMEN TOBACCO IND

Cigarette filter stick with function of reducing main stream smoke temperature of cigarette

ActiveCN106690415AThe processing technology is simple and effectiveReduce flue gas temperatureTobacco smoke filtersAlcoholPolyethylene glycol

The invention relates to a cigarette filter stick with a function of reducing the main stream smoke temperature of a cigarette. The filter stick is added with heat-absorption gel, wherein the heat-absorption gel is prepared from the following components in parts by weight: 30-70 parts of propylene glycol, 30-60 parts of polyethylene glycol and 5-15 parts of hexadecyl alcohol. Compared with the prior art, the cigarette filter stick has the advantages that the cigarette or tobacco product which is not burnt by heating uses the cigarette filter stick, the smoke temperature can be reduced by 1.0-8.0 DEG C, the smoking comfortable feeling of the cigarette and tobacco product which is not burnt by heating can be improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

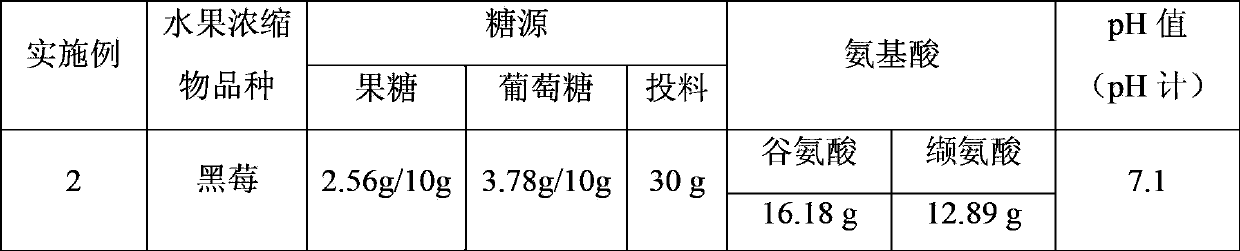

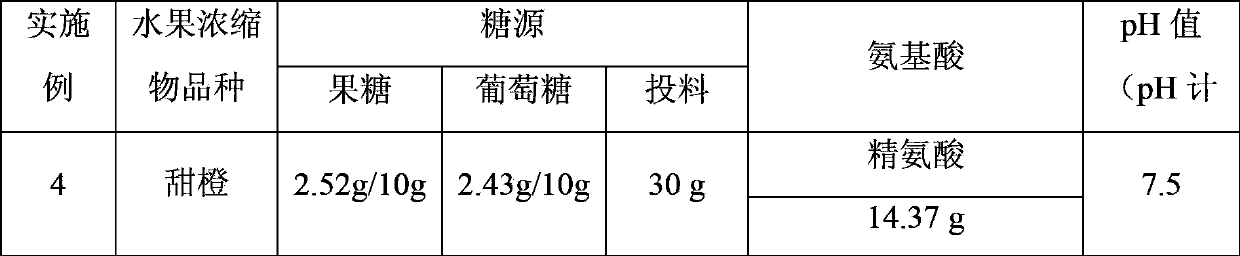

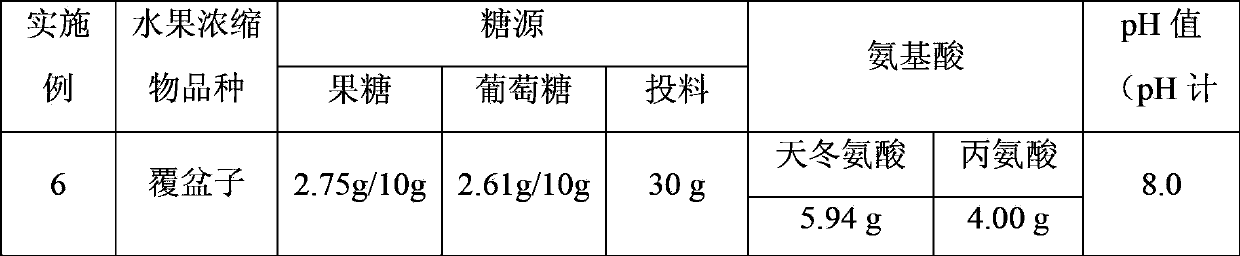

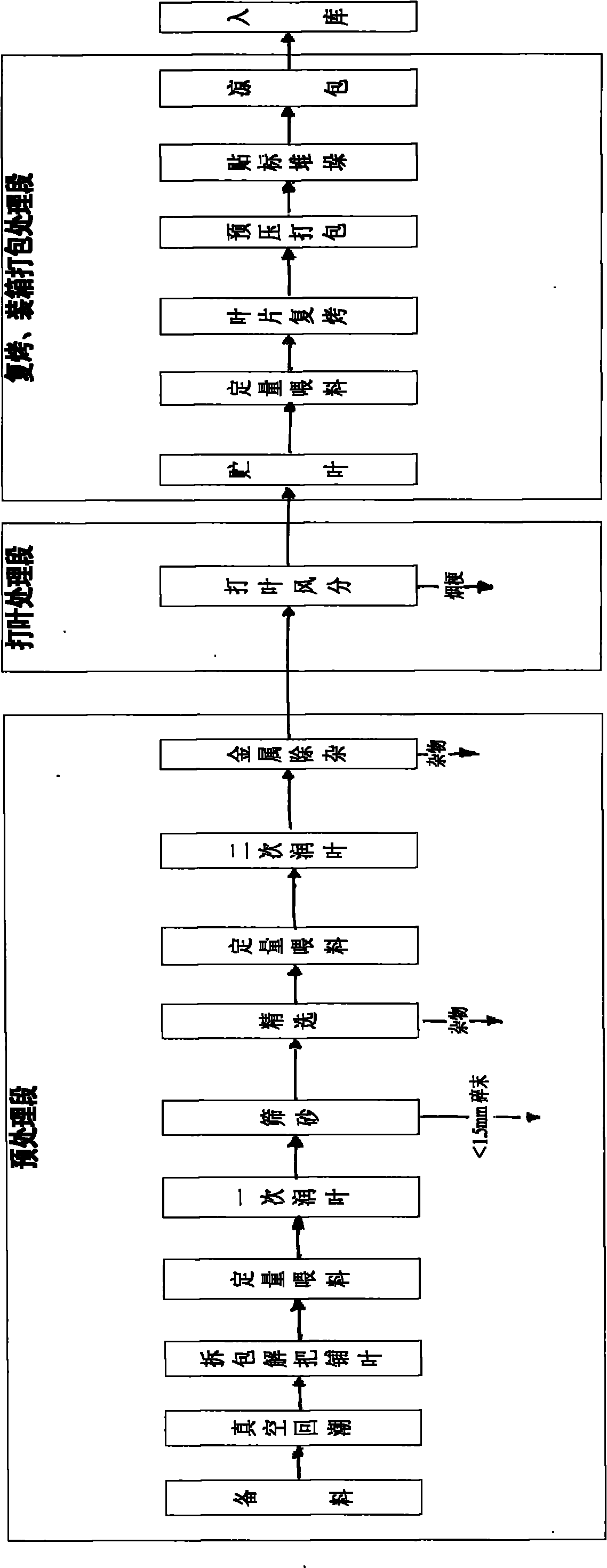

Preparation method of fruit concentrate Maillard reaction product, and application of product in tobacco perfuming

ActiveCN103865645AHigh fullnessMild reaction conditionsTobacco preparationEssential-oils/perfumesMaillard reactionFlavor

The invention relates to a preparation method of a fruit concentrate Maillard reaction product, and an application of the product in tobacco perfuming. The preparation method comprises the following steps: mixing a fruit concentrate or the fruit concentrate containing reducing monosaccharide with amino acids and a reaction solvent, using an aqueous solution of sodium hydroxide to adjust the pH value of a reaction system to 6-9, heating to 80-100DEG C within 20-90min, continuously reacting for 0.5-1.5h, and cooling to obtain the corresponding reaction product. The Maillard reaction product generated after reacting the fruit concentrate with the amino acids is rich in the natural perfume of fruits, can be naturally coordinates with the original perfume of tobacco, and is safe and reliable. The above reactive perfume prepared in the invention is used to process cut tobacco under certain conditions, and is added to tobacco according to different proportions, so the smoking quality of the the prepared cut tobacco is substantially improved. The fruit concentrate Maillard reaction product can improve the fullness and the softness of the smoke of cigarette, improves the smoking smell comfortableness, and highlights the delicate perfume style of the cigarette.

Owner:APPLE FLAVOR & FRAGRANCE GRP +1

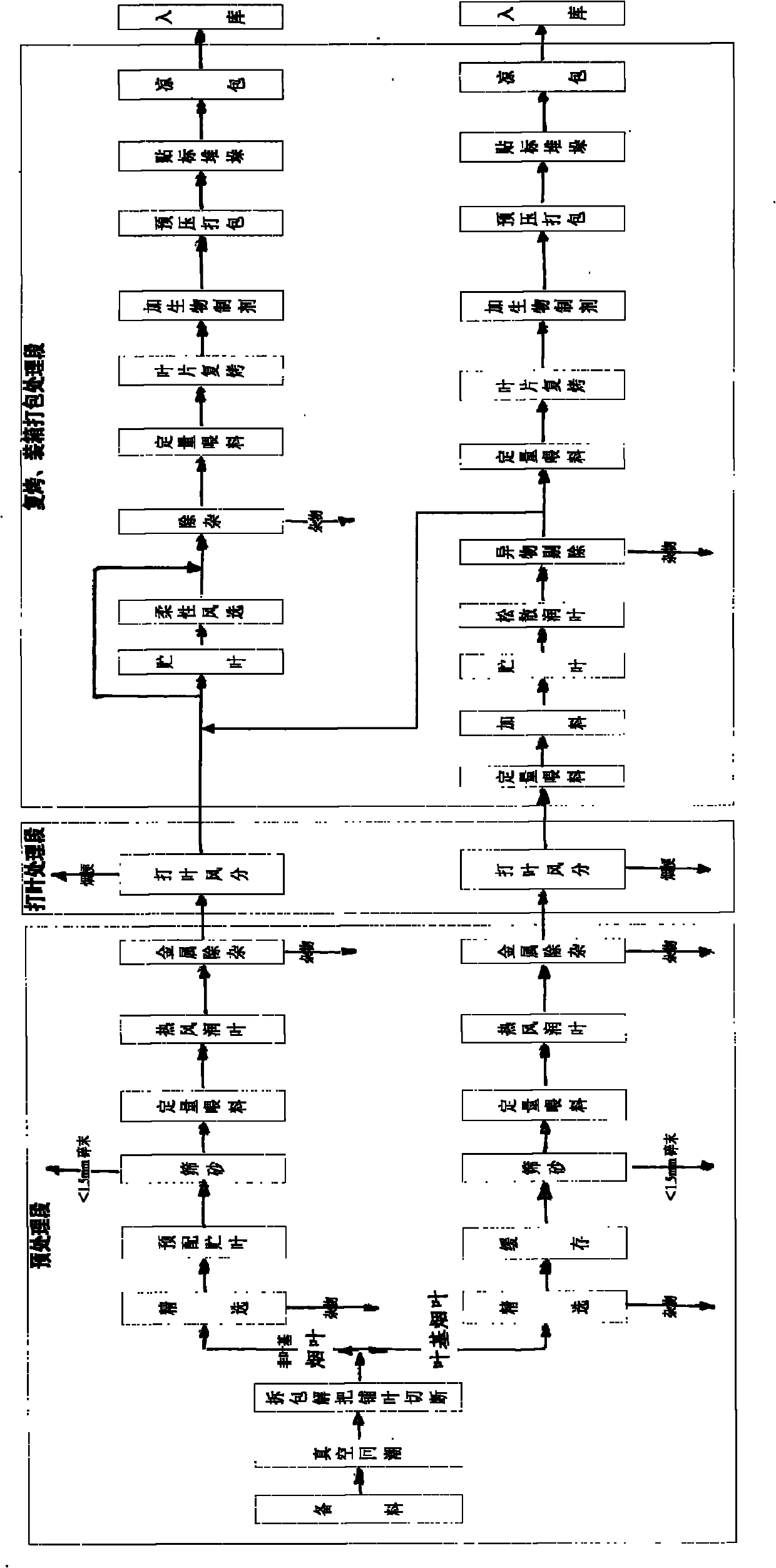

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

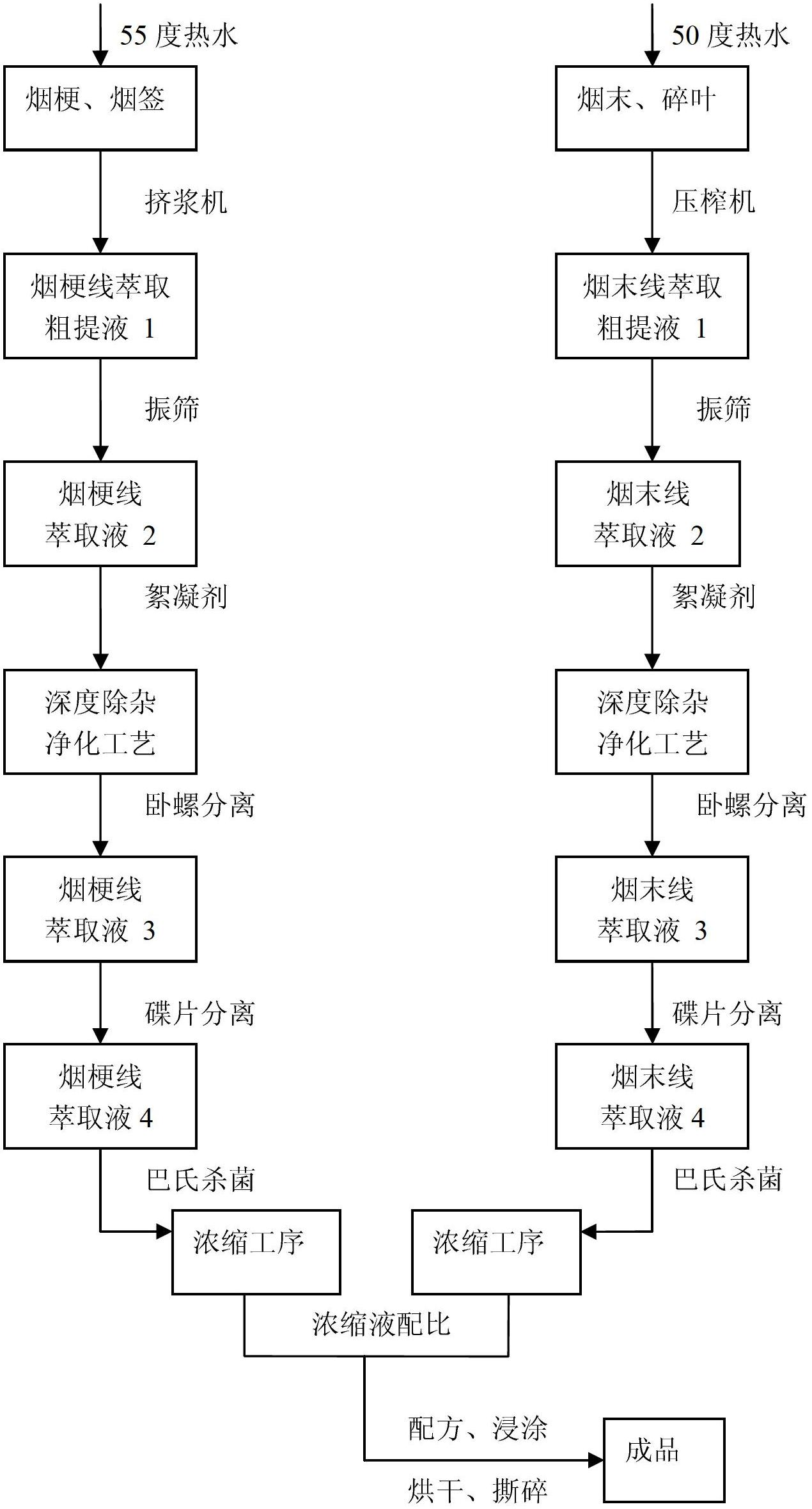

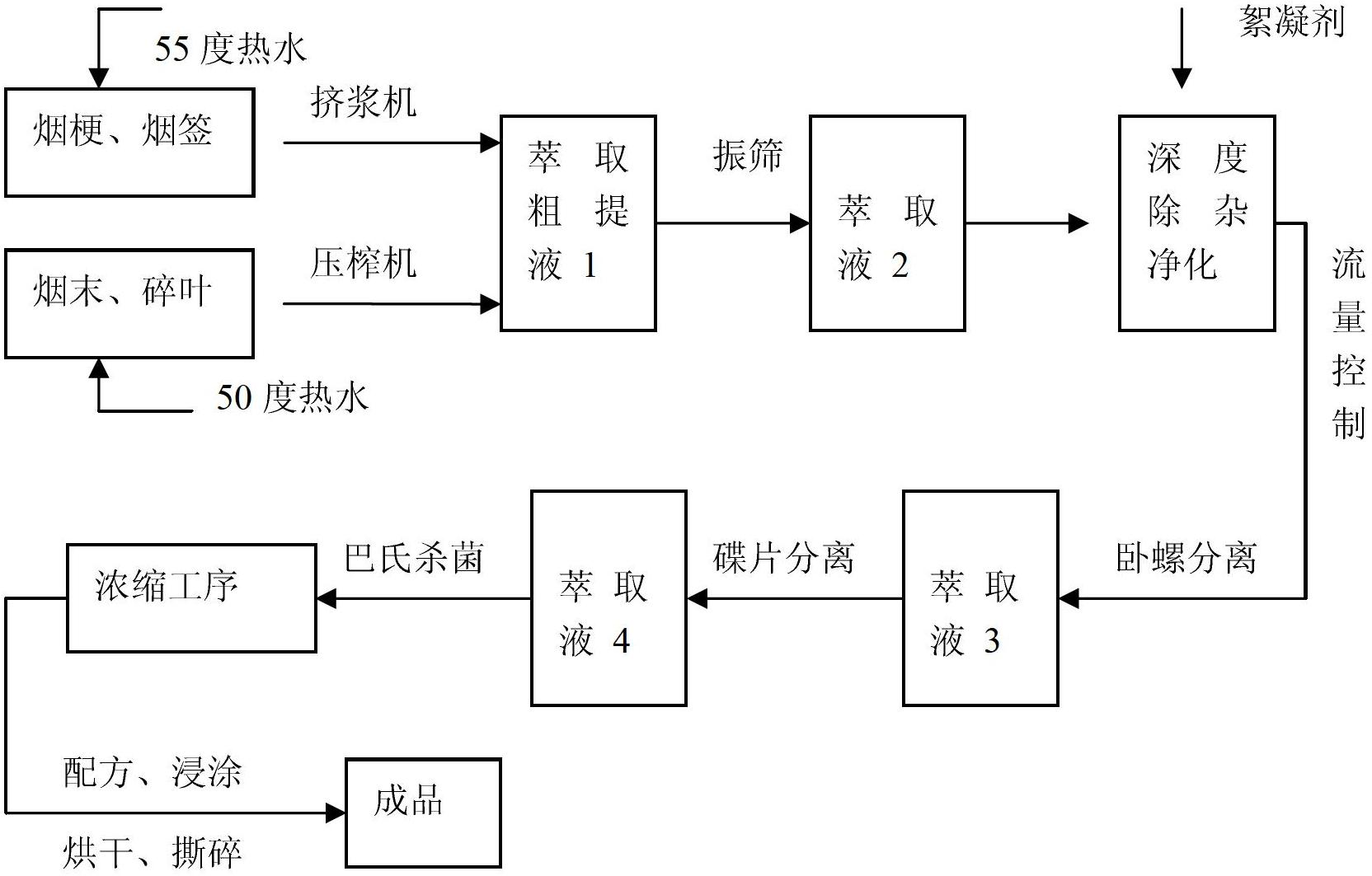

Extract deep purification and edulcoration process in manufacturing technology of papermaking tobacco sheets

ActiveCN102688613APrecise and efficient directional macromolecular separationOvercome the heavy airTobacco preparationCentrifugal force sediment separationScrapProcess module

The invention relates to an extract deep purification and edulcoration process in the manufacturing technology of papermaking tobacco sheets. The process comprises the following steps: a, tobacco waste including tobacco stems, tobacco sticks and tobacco powder is fully soaked in hot water and then extracted; b, the mixture of tobacco waste and water is fed into a squeezer and then squeezed for solid-liquid separation, and the liquid part is extracted crudely and is screened through a linear vibrating screen for solid-liquid separation; c, the liquid separated through the linear vibrating screen enters a filter aid process module to be processed through deep macromolecule flocculation, wherein an edible flocculating agent is adopted, the addition proportion is 0.1 to 0.8%, and the flocculation time is 5 to 50 minutes; liquid processed through deep macromolecule flocculation enters a primary horizontal spiral discharge settling centrifuge to be separated; and e, the liquid separated by the centrifuge in step d is pasteurized at the temperature of 60 to 70 DEG C for edulcoration, and then enters a concentration system to be concentrated. The process can effectively remove macromolecule particles, improves the concentration efficiency and ensures the quality of concentrate.

Owner:杭州利群环保纸业有限公司

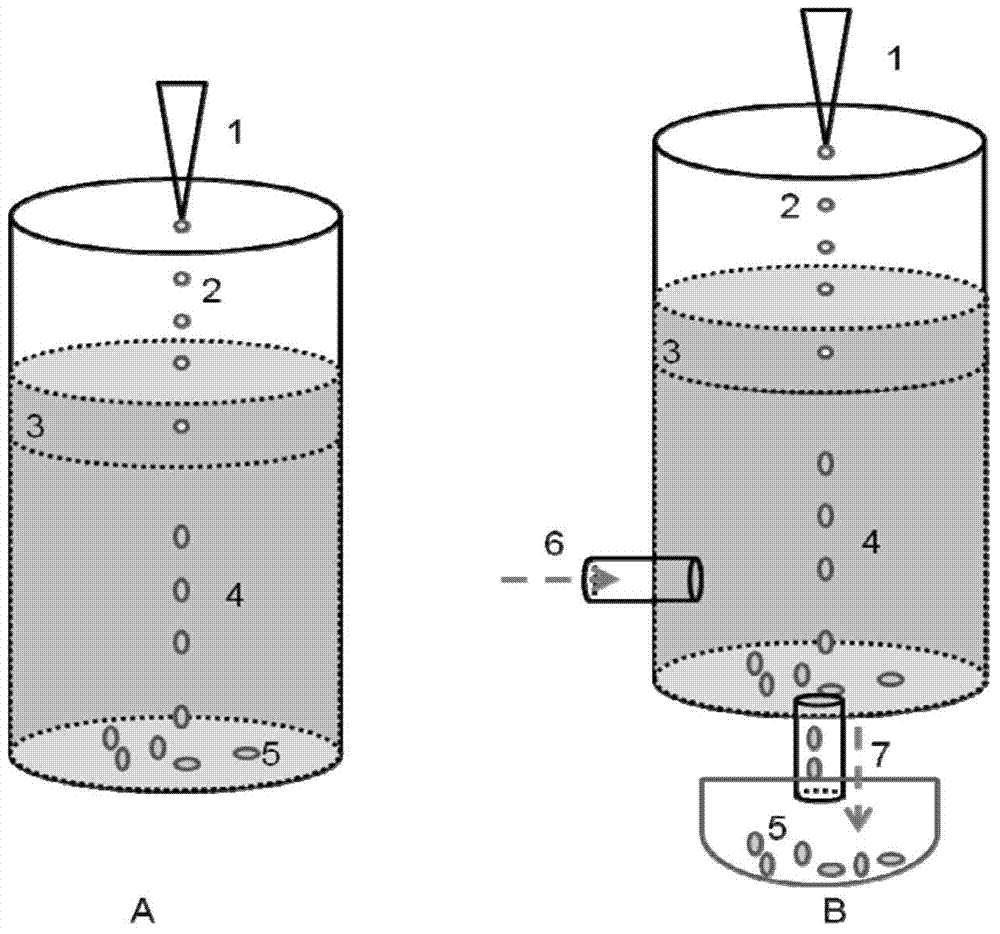

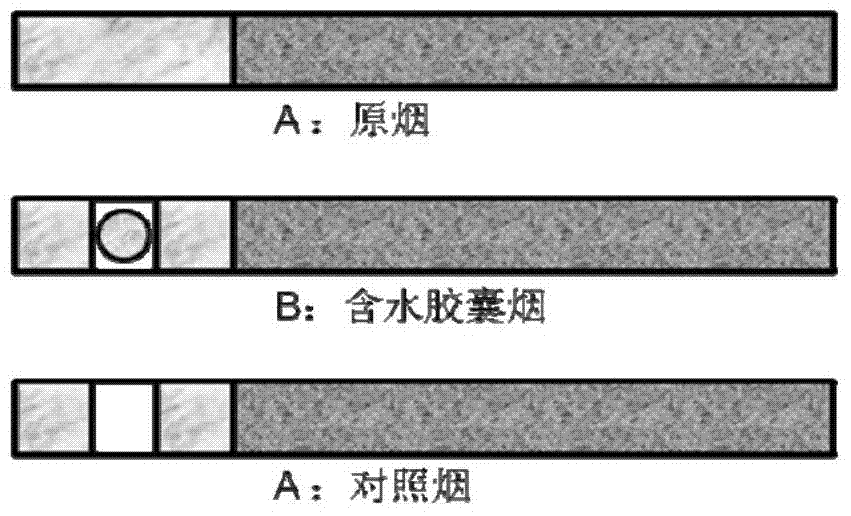

Water-bearing capsule and preparation method thereof

ActiveCN104726199AModerate intensityImprove suction qualityTobacco smoke filtersEssential-oils/perfumesWaxWater based

The invention relates to a water-bearing capsule and a preparation method thereof. The water-bearing capsule consists of a water-based capsule core and a solid capsule shell wrapping the water-based capsule core, wherein the solid capsule shell consists of a hydrophobic membrane layer, a powder wrapping layer and a modified wax layer from outside in sequentially, and the strength of the solid capsule shell reaches 0.5-2.2kg. The water-bearing capsule can significantly reduce multiple harmful ingredients in smoke, reduces harms of a cigarette, and has the efficacy of improving a cigarette smoking moist feeling; the characteristic odor type can be endowed to the cigarette; in addition, the solid capsule shell of the water-bearing capsule is great in strength and difficult to break, so that stable water holding and quality guaranteeing effects of the cigarette are ensured; and the above benefits have very positive significance in improving the cigarette quality.

Owner:江西省华宝芯荟科技有限公司

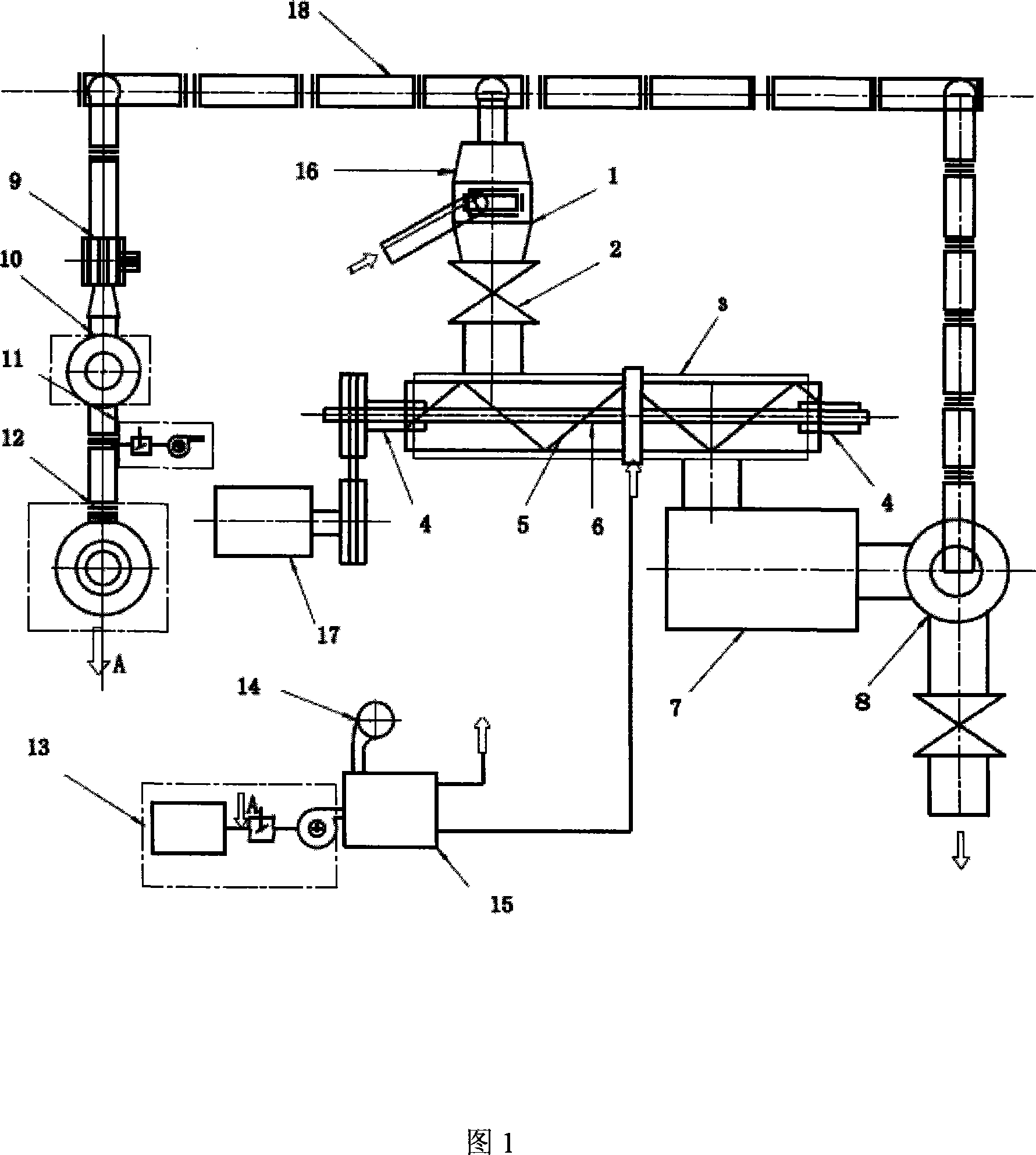

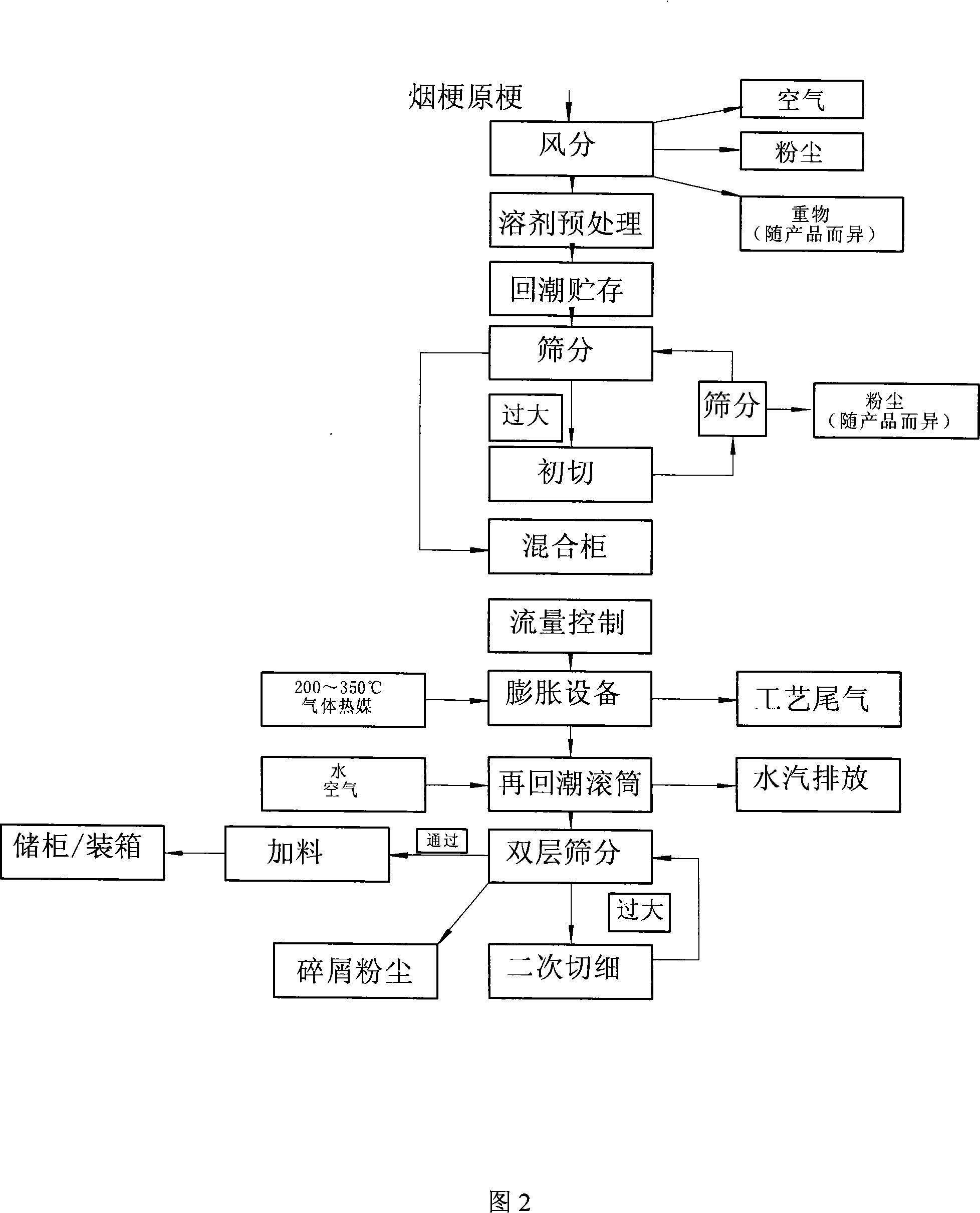

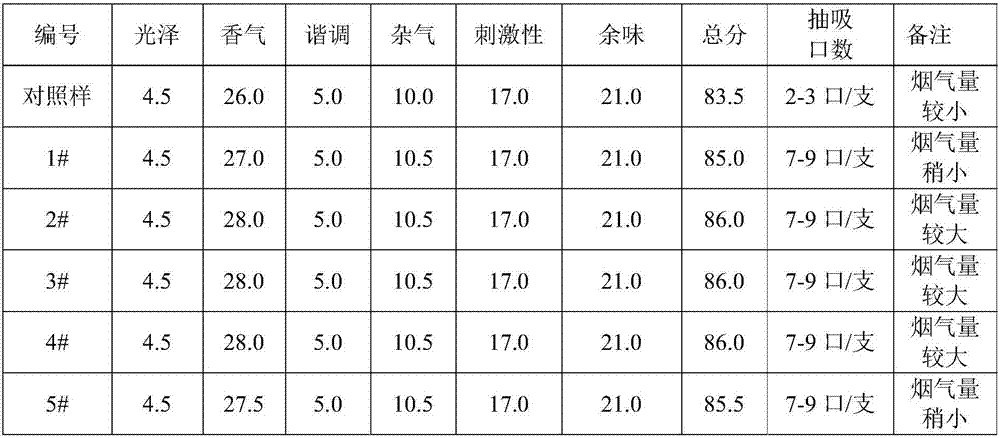

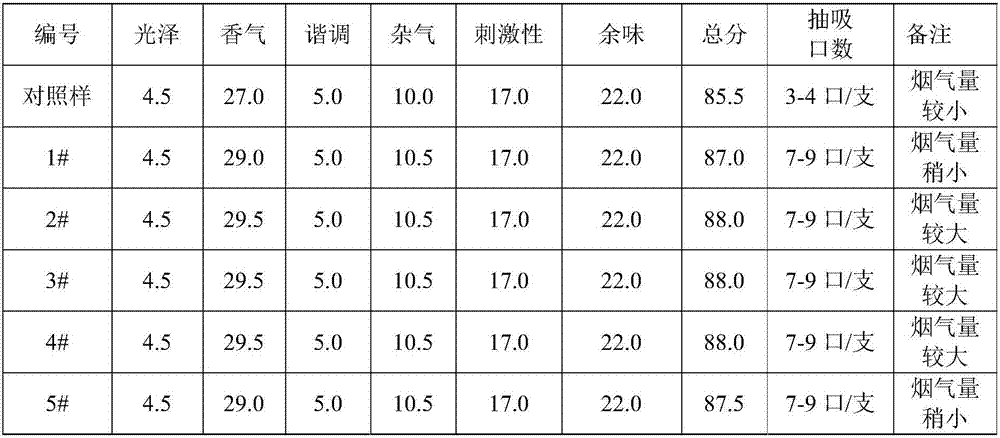

Method and equipment for pretreatment cabo

ActiveCN101214086AImprove uniformityHigh expansion rateTobacco preparationTobacco treatmentGas solidPretreatment method

The invention relates to a pretreatment method of tobacco stem which is preheated through gas heat medium and is treated with microwaves in the gas heat medium environment and equipment which adopts the method. The tobacco stem which is required to be processed is treated: preheating the raw materials to be 100-170 DEG C; heating the gas heat medium to be 150-350 DEG C; mixing the tobacco stem and the gas heat medium and implementing the gas-solid separation after the microwave field action to obtain solid expanded tobacco stem which is treated completely. Then,granular expanded tobacco stem is obtained after the moisture regaining, the screening, the fine shearing, etc. The equipment includes a gas heat medium preheating mechanism, a microwave complex expansion treatment mechanism, etc. With the process and the equipment of the invention, the breakage during the expansion process is small; the pressure used by the process is close to the normal pressure; the pressure resistance requirement for the equipment is not high; the production process is simple and easy; the most fundament lies in that through the gas heat medium with low oxygen content used for preheating the tobacco stem, the evenness and the expansion ration of the tobacco stem and the aspiration quality of the tobacco stem materials are obviously improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Processing method for heating non-combusted cigarette

ActiveCN107048469AImprove ventilationImprove consistencyTobacco treatmentCigar manufacturePorosityEngineering

The invention discloses a processing method for heating a non-combusted cigarette. The processing method comprises the steps that flaky reconstituted tobaccos are cut into multiple elongated tobacco shreds in one direction; the multiple elongated tobacco shreds are extruded to be close together in the width direction of the elongated tobacco shreds and then are wrapped by formed paper to form cylindrical cigarettes, and multiple elongated tobacco shreds in each cigarette are regular and are orderly arranged. Orderly arranged gaps are also formed among the tobacco shreds by orderly arranging the tobacco shreds, the porosity is greatly improved compared with out-of-order tobacco shred arrangement, good air permeability and airflow consistency inside the cigarettes are ensured, approximate linear airflow channels are provided for smoke circulation through the orderly arranged tobacco shreds and the formed orderly arranged gaps, the smoking resistance and the smoke adsorption property of the tobacco shreds are reduced, and the smoke passing efficiency is improved.

Owner:GUANGDONG GOLDEN LEAF TECH DEV +1

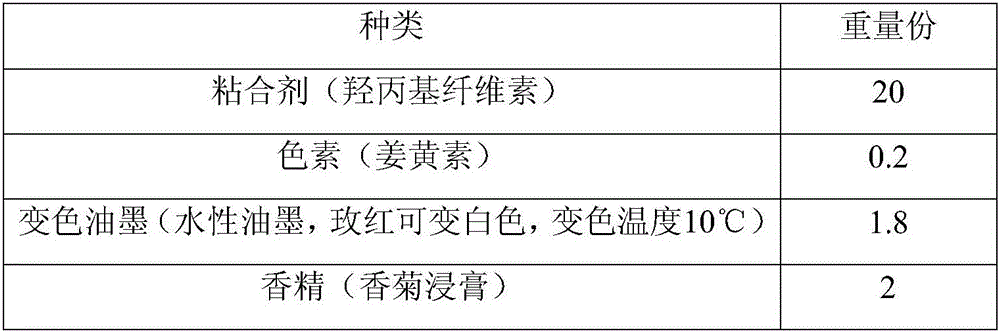

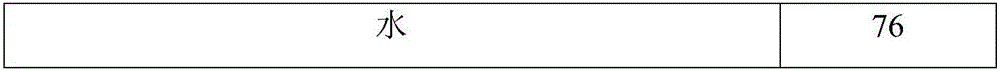

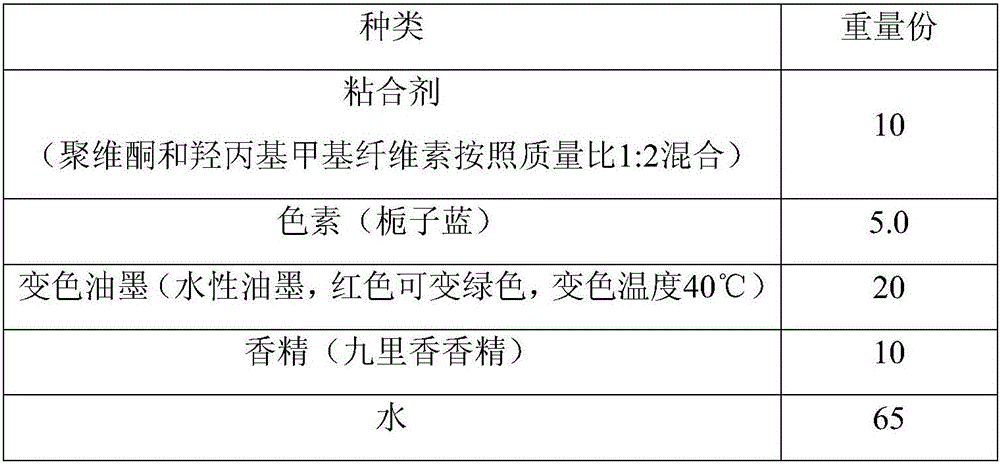

Variable color fragrance bead for tobacco and preparation method of the fragrance bead

The invention provides a variable color fragrance bead for tobacco and a preparation method of the fragrance bead. The fragrance bead is prepared by the following steps: firstly solid mixed powder material is placed in a centrifugal coating granulator, and an adhesive solution is sprinkled as a slurry material, the powder material is rotated in the centrifuge and forms mother cores, then the mother cores are still placed in the centrifugal coating granulator, a variable color fragrance adhesive solution is sprinkled as a slurry material, the solid mixed powder material is added during the process of sprinkling, enlargement and preparation of granules is continued and the granule size increases, and the granules form variable color fragrance beads for tobacco. The solid powder material is formed by evenly mixing natural plant powder, starch, chitosan and microcrystalline cellulose. The variable color fragrance adhesive solution is formed by mixing adhesives, pigments, essence, variable color printing ink and water. The method can provide tobacco with fragrance which can improve the smoking quality, and a customer can see color change of the beads directly during smoking, so that the customer can have both vision and taste experience.

Owner:HUBEI CHINA TOBACCO IND

Preparation method of high-nicotine tobacco extract

ActiveCN106509981AHigh extraction rateAvoid destructionTobacco treatmentMaillard reactionDistillation

The invention discloses a preparation method of a high-nicotine tobacco extract. The preparation method of the high-nicotine tobacco extract belongs to the field of tobacco additives, and mainly comprises three steps of raw material pretreatment, subcritical extraction and molecular distillation. A baking process is adopted for pretreating tobacco leaves, so that reducing sugar of tobacco and a nitrogen-containing compound are promoted to generate maillard reaction, substances such as pyrone and furanone are produced, the baking aroma is improved, the reducing sugar content is reduced, the suction offensive odor is reduced, meanwhile, combined-state nicotine in the tobacco leaves is converted into a free state, and the content of the free-state nicotine is improved. A weak polar solvent is adopted for subcritical extraction, so that the extraction rate of tobacco feature aroma substances and the free-state nicotine can be improved; and low-temperature molecular distillation is combined, so that low-boiling-point aroma substances and the nicotine can be effectively enriched, the damage on thermosensitive substances due to high temperature is avoided, and meanwhile, the content of macromolecular substances such as pectin and protein in an extract is reduced. The method is simple in preparation process, simple and convenient to operate, and suitable for industrial production and application.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

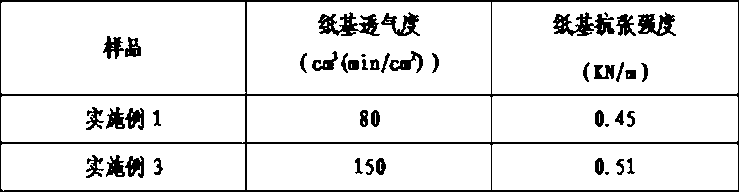

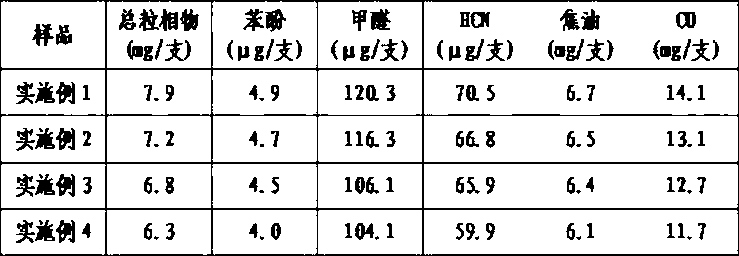

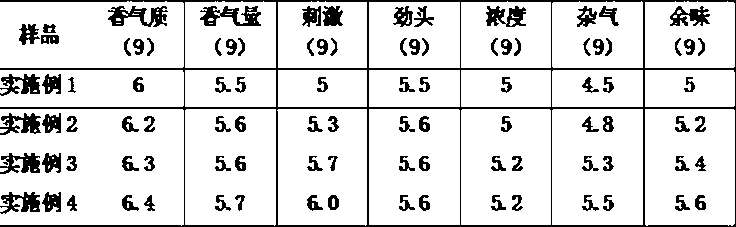

Preparation method of natural tobacco texture cigarette paper

InactiveCN103469691AIncrease the fragranceReduce mistSpecial paperPaper coatingCombustionSolid matter

The invention discloses a preparation method of natural tobacco texture cigarette paper. The method comprises the following steps: firstly weighing 5-60% of tobacco raw material and 40-95% of wood pulp by weight percentage; extracting the tobacco raw material, and separating to get a tobacco solid matter and an extraction solution; mixing the tobacco solid matter and the wood pulp to obtain mixed pulp; and preparing a cigarette paper base from the mixed pulp; concentrating the extraction solution to prepare a tobacco extract; adding 1-4% of a combustion-supporting agent, 0-4% of a natural pigment extract and 0-3% of a moisture retention agent relative to the weight of the tobacco extract into the tobacco extract to prepare a coating solution, coating the cigarette paper base with the coating solution, and directly performing embossing treatment by utilizing an embossing roller carved with tobacco textures after coating and drying to prepare the cigarette paper with the tobacco vein textures. According to the preparation method disclosed by the invention, the natural tobacco fragrance of the cigarette paper is increased, and the cigarette paper is also endowed with the tobacco characteristic appearance; the cigarette grade is upgraded; the cigarette paper miscellaneous gas during combustion is reduced, and the smoking quality is upgraded; the natural tobacco texture cigarette paper can further serve as wrappers of hand-rolled cigars.

Owner:HUBEI CHINA TOBACCO IND +1

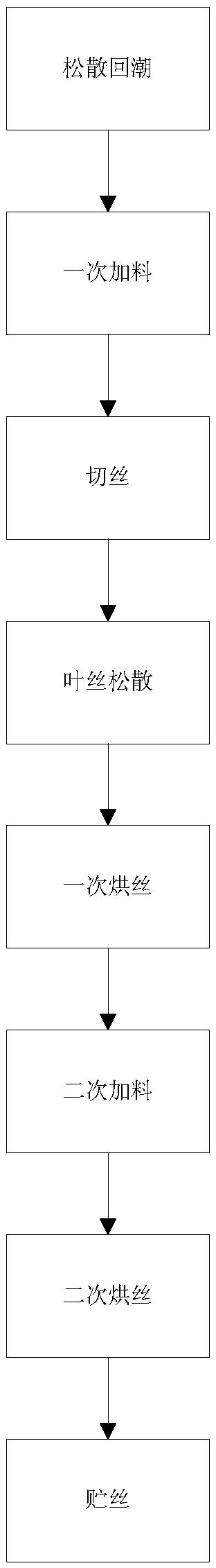

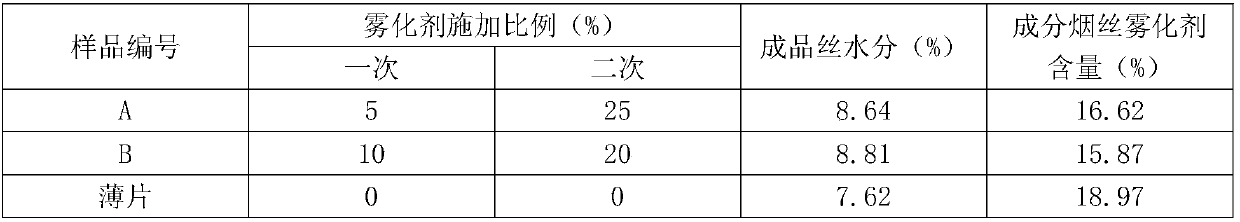

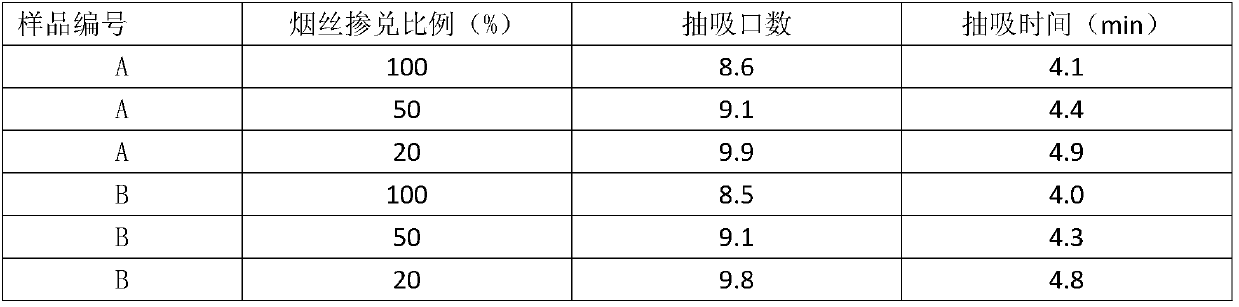

Novel tobacco shred processing technology

ActiveCN109602061AThick breathImprove suction qualityTobacco preparationTobacco treatmentAbsorption capacityEngineering

The invention provides a novel tobacco shred processing technology. The novel tobacco shred processing technology sequentially comprises the following processing processes: loosening and regaining moisture, primarily charging, shredding, drying leaf shreds, secondarily charging, secondarily drying the shreds and storing the shreds. After processing, the moisture of the tobacco shreds is 8-10% andthe proportion of an atomizing agent reaches 15-20%; the processed tobacco shreds, as tobacco shreds which are nonflammable after being heated, can be added into slice shreds and are used as heated tobacco shreds of cigarettes which are nonflammable after being heated, so that the technical bottleneck problem that the conventional tobacco shreds cannot be directly applied to novel cigarettes due to insufficient atomizing agent applying amount caused by insufficient absorption capacity is solved, and a solution is provided for expanding the application range of raw materials of the novel cigarettes and improving the sensory quality of the novel cigarettes.

Owner:HUBEI CHINA TOBACCO IND

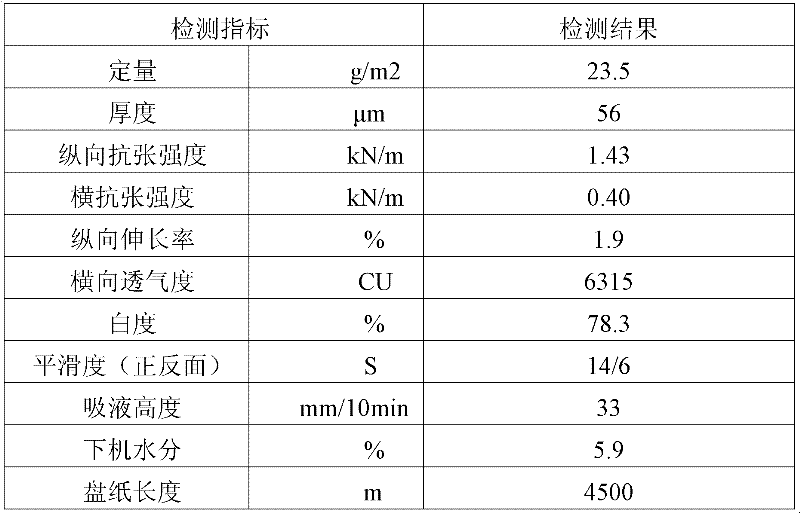

Filter stick shaping paper capable of improving cigarette smoking quality and preparation method thereof

The invention discloses a filter stick shaping paper capable of improving cigarette smoking quality and a preparation method thereof. The filter stick shaping paper is obtained in a way that natural plant extract is added in common or high-transparency shaping paper. The natural plant extract is prepared by the steps of extracting Momordica grosvenori, chrysanthemum, honeysuckle, lophatherum gracile, scaphium scaphigerum and lemon with pure water; then, removing flavour and color with edible alcohol; and extracting, decentralizing, carrying out ultrafiltration and finally condensing. The obtained filter stick shaping paper does not has the peculiar smell of the existing shaping paper cellulose, the internal representation form of the filter stick shaping paper is diversified, so that the sucking quality and the style characteristic of the product are improved as compared with those of the existing product, and the filter stick shaping paper has good application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Cigarette paper employing natural baccy fiber

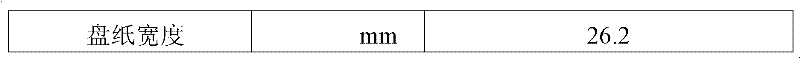

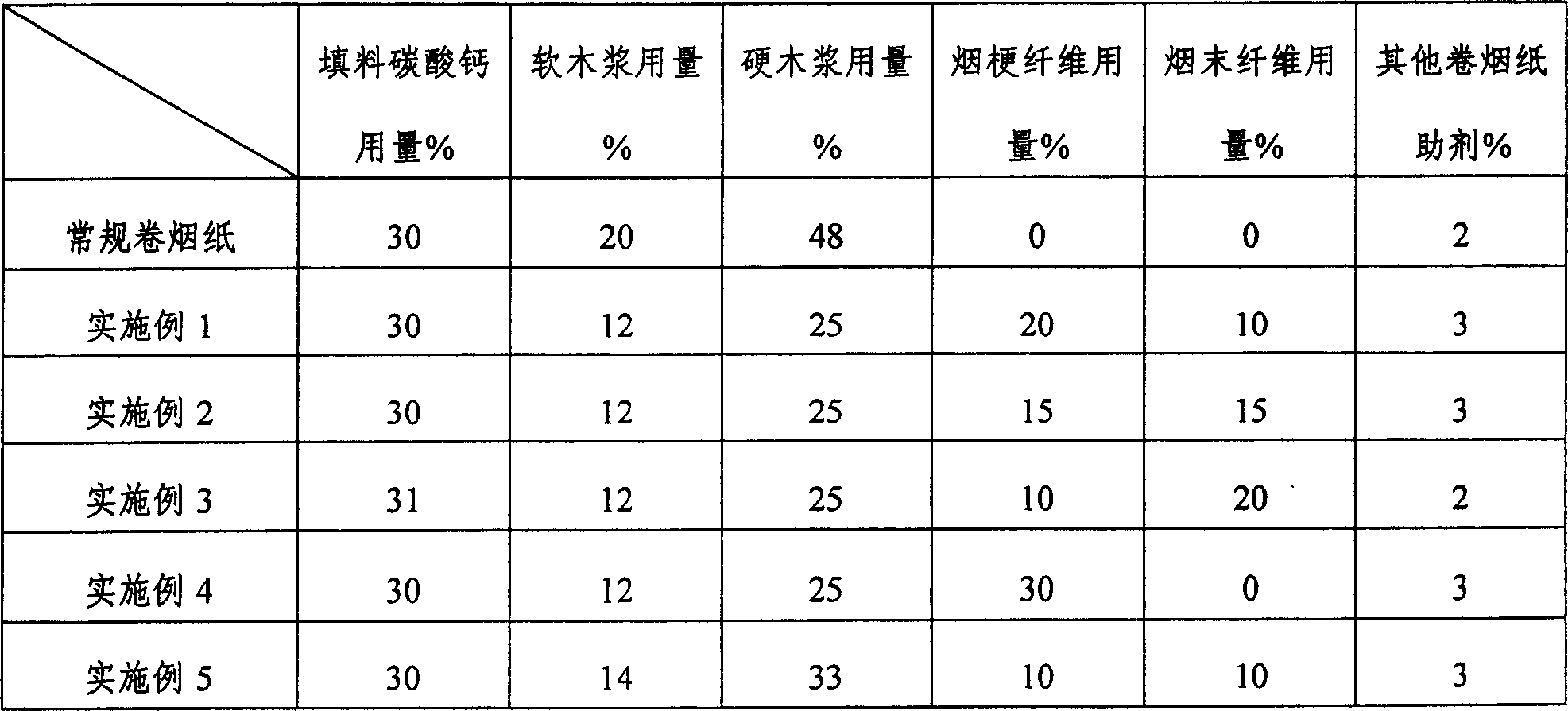

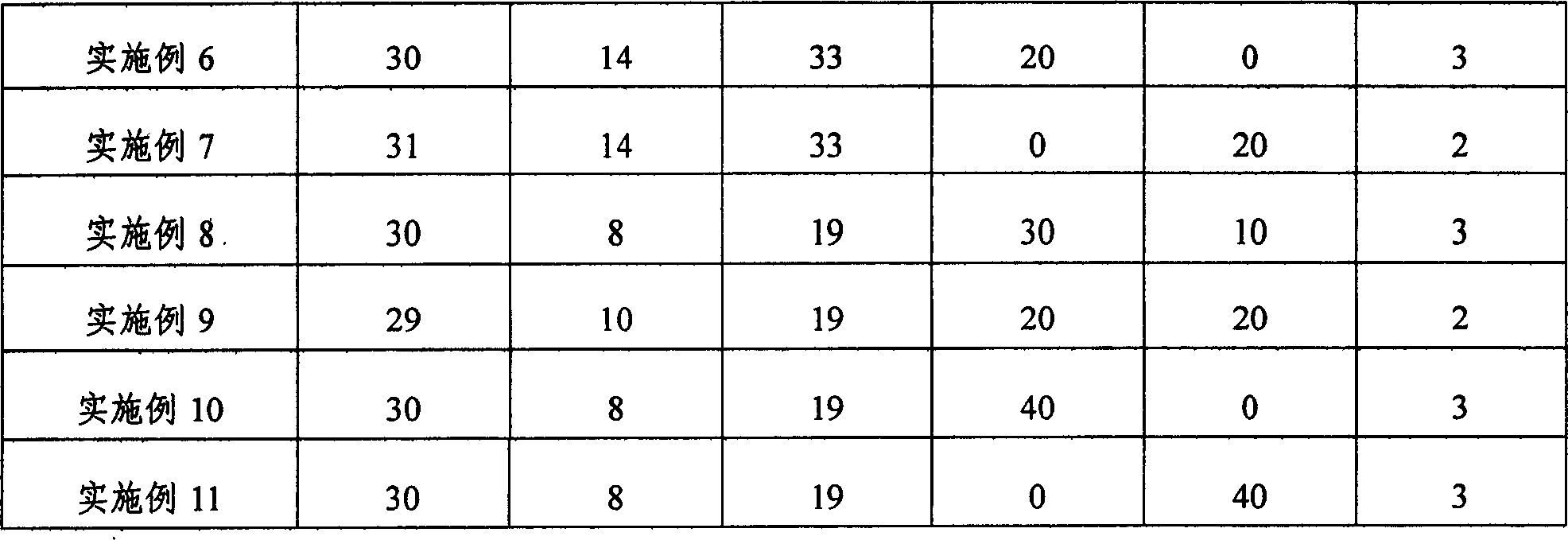

ActiveCN101016707ASimple processReduce pollutionNatural cellulose pulp/paperInorganic compound additionNatural fiberNicotiana langsdorffii

The invention discloses a cigarette paper which uses natural tobacco fiber as main material, wherein the natural tobacco fiber is one of stem fiber or tobacco end fiber, or their mixture. The material comprises 0-40% stem fiber, 0-40% tobacco end fiber, 20-30% stuff calcium carbonate, 5-20% soft wood pulp, 20-50% hard wood pulp, and 1-5% cigarette agents. Tests have proved that the inventive cigarette has higher quality.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

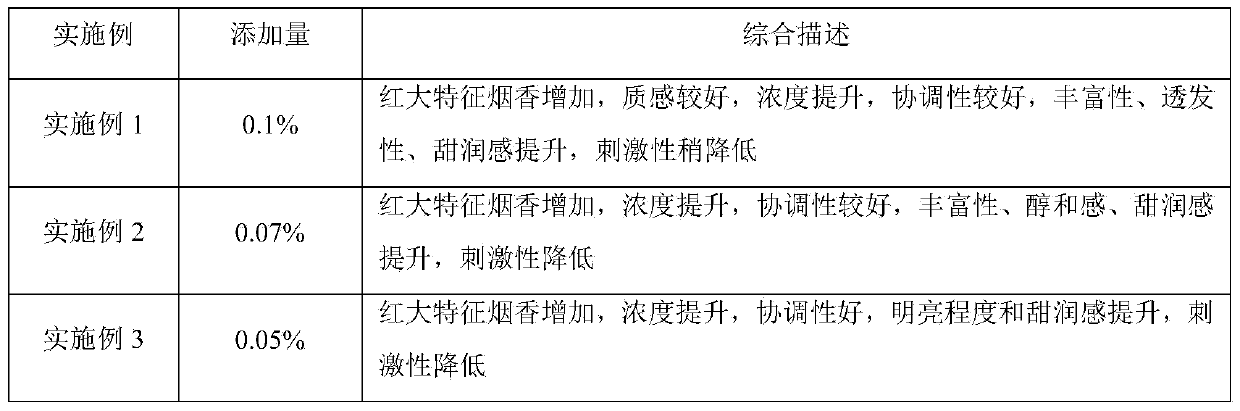

Preparation method of tobacco extract and application of tobacco extract in cigarettes

InactiveCN103720031ATake advantage ofImprove suction qualityTobacco treatmentReflux extractionNicotiana tabacum

The invention relates to a preparation method of tobacco extract and application of the tobacco extract in cigarettes. The preparation method includes: weighing tobacco material, adding 70-95% ethanol according to the material-liquid mass ratio of 1:5-1:10, adding phosphoric acid or sulfuric acid accounting for 0.5-3% of the tobacco material by weight, performing heat reflux extraction for 1-3 hours at the temperature of 60-90 DEG C, filtering the product, allowing for cooling and clarifying, and subjecting supernate to reduced pressure compression to obtain extract, namely herbal extract; adding the tobacco extract, accounting for 0.05-0.1% of a tobacco leaf set by weight, to the tobacco leaf set. The tobacco extract made by the method is natural and safe, has the significant effect of making tobacco products more fragrant and less irritating, and has high application value. The preparation method is simple and easy, and the technical process is highly repeatable.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Preparation and application of crop waste cigarette filter additive carrier materials

InactiveCN103355743AImprove reuseReuse reducesTobacco smoke filtersCelluloseAgricultural engineering

Disclosed is preparation and application of crop waste cigarette filter additive carrier materials. The carrier materials use crop waste such as crop straw, or corncob, or peanut shells or cane trash as raw materials, the processes of washing, offensive odor removing, drying, smashing and sieving are conducted in sequence, and finally the crop waste cigarette filter additive carrier materials are prepared. After the carrier materials are loaded with cigarette harm reduction agents or flavoring agents directly or chemical modification is conducted, the carrier materials are added into a cigarette filtering rod so that a binary or multielement composite filtering bar can be achieved, and the crop waste cigarette filter additive carrier materials are applied to cigarette filters and have the advantages of reducing harmful ingredients of cigarette smoke, adding fragrance, improving smoking quality and the like. The crop waste cigarette filter additive carrier materials further have the advantages that crop waste materials are provided with porous structures, and the crop waste cigarette filter additive carrier materials are rich in cellulose, hemicellulose, lignin and the like, wide in source, simple in production technology, low in cost, environmentally friendly, capable of facilitating recycling of the waste and the like, thereby being excellent cigarette filter additive carrier materials.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

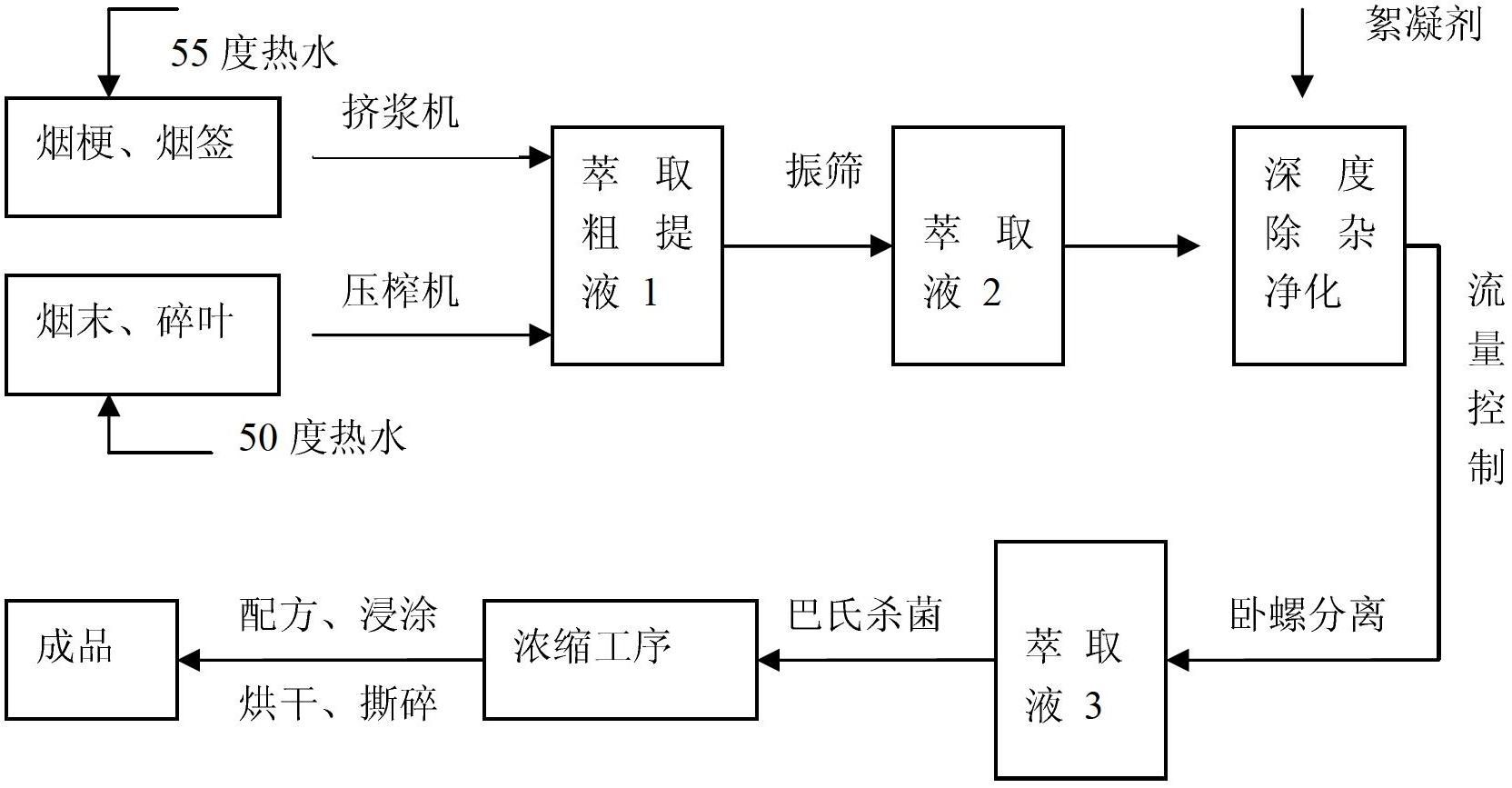

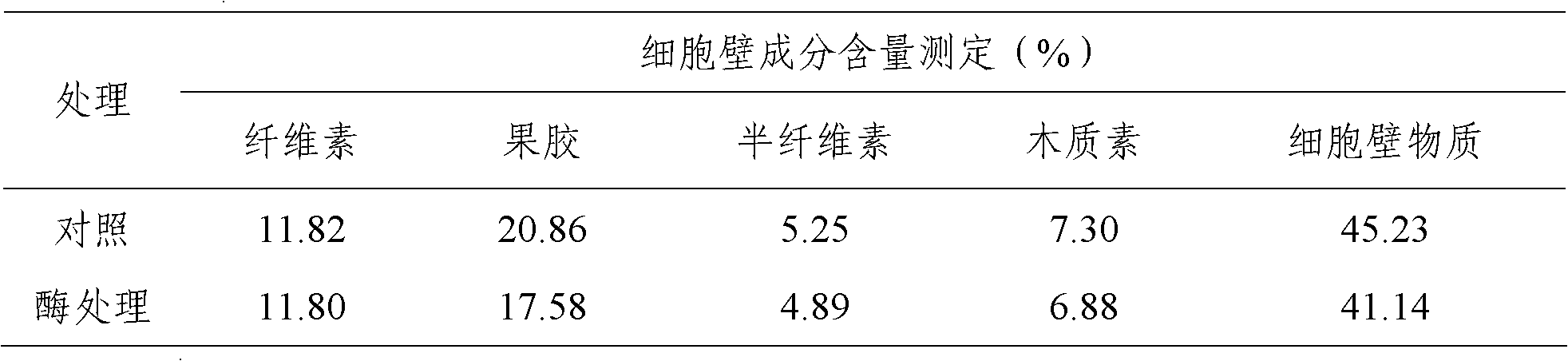

Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

Improved preparation method for electronic cigarette smoke solution

InactiveCN104983063ASolve the shortcomings of easy to produce burnt smellGood fragrance permeabilityTobacco treatmentEssential-oils/perfumesBiotechnologyChemical synthesis

Provided is an improved preparation method for electronic cigarette smoke solution. The method comprises charging and perfuming procedures. A charging procedure is aimed at high boiling point edible and tobacco flavor or edible and tobacco flavor containing waxiness, the edible and tobacco flavor is mixed with propylene glycol or propylene glycol / glycerin, and then molecular distillation is performed to obtain an electronic smoke solution base stock. The perfuming procedure is aimed at essential oil kind and low boiling point chemical synthesis perfumes and edible and tobacco flavors blended by the two kinds of perfumes. Through adding perfumes and natural nicotine in the base stock, an electronic cigarette smoke solution product is obtained. In the method, charging and perfuming are processed respectively, high boiling point and waxy components in the perfumes are removed, and defects that high boiling point perfumes easily generate charring smell, and electronic cigarette smoke solution is clear and bright and fragrance transmission property is better. Perfuming is performed in a final step, preventing loss of low boiling point essences, and kinds and contents of essences can be adjusted according to characteristics of the electronic cigarette base stock. The method gives rich note on the electronic cigarette smoke solution.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

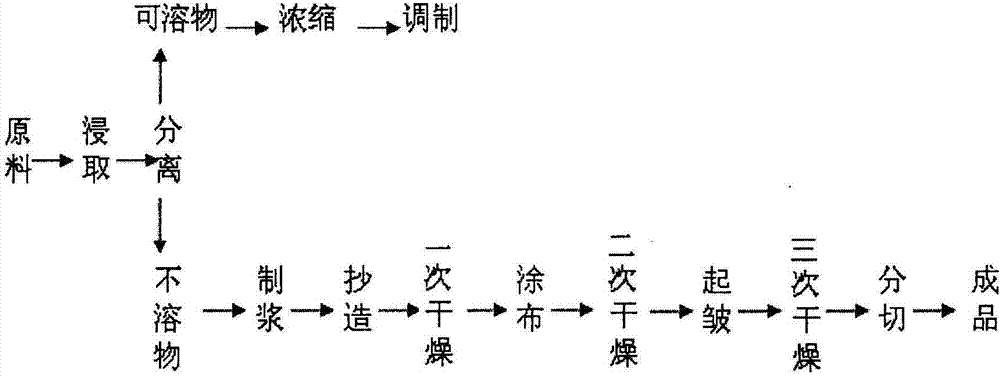

Manufacturing technique of tobacco remaking with fold paper-making method

InactiveCN103082396AEasy to fillGood size controllabilityTobacco preparationCombustionInsoluble fiber

The invention provides a manufacturing technique of tobacco remaking with a fold paper-making method. The manufacturing technique of tobacco remaking with the fold paper-making method comprises the following steps: raw materials of tobacco are soaked and extracted through extraction agent, insolubility fiber materials are separated from soluble substances, film base is made of insoluble substances through pulping, coating liquid is made of the soluble substances by concentration in a modulation mode, and the coating liquid is dip-coated or spray-coated on a slice film base, and enters a drying machine to dry. The manufacturing technique of tobacco remaking with the fold paper-making method is characterized in that slice film base after being dried is made to be diamond-shaped through a pair of corrugated rollers reversely rotating, and is made into a fold tobacco slice after being dried and cut. The manufacturing technique of tobacco remaking with the fold paper-making method is not limited by drying modes, is simple in manufacturing technique, and capable of being widely applied to the production of tobacco remaking with the fold paper-making method, and facilitates improving padding performance of remade tobacco, and reducing consumption of raw materials and production cost. According to measurement and calculation, compared with the prior ordinary tobacco remaking, the manufacturing technique of tobacco remaking with the fold paper-making method can save the consumption of the raw materials by 1.0% or so, improve combustion performance of cigarettes, reduce suction resistance and improve suction quality of the cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

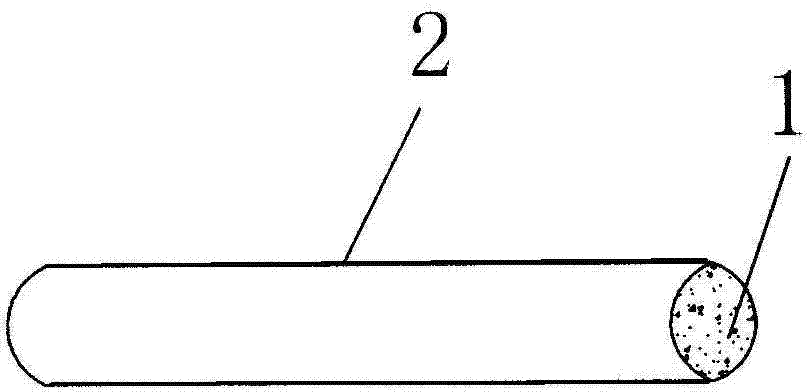

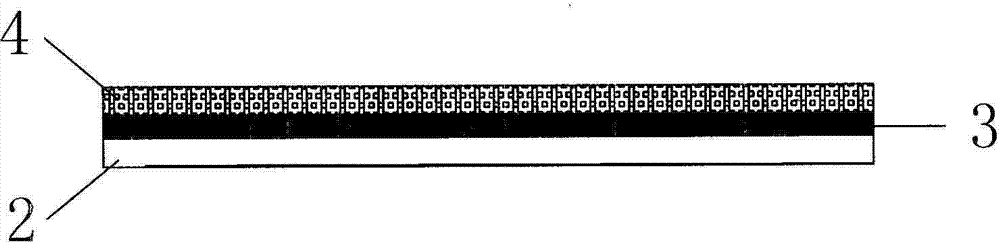

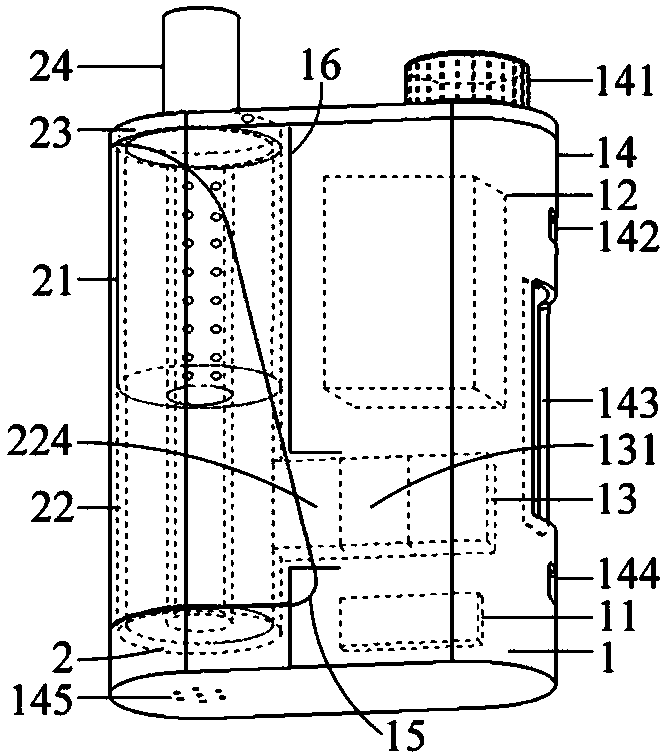

Filtering rod capable of reducing smoke temperature and preparation method of filtering rod

The invention discloses a filtering rod capable of reducing smoke temperature and a preparation method of the filtering rod. Smokers feel obvious hot burning feeling and spicy stimulating feeling when smoking the cigarettes. In order to solve the problem, the invention adopts the following technical scheme: the filtering rod comprises a bundle core rod (1) and externally wrapped molding paper (2). The right side of the molding paper (2) is coated with a microporous aluminum layer (4) through a glue layer (3). The microporous aluminum molding paper is formed by adhering the microporous aluminum onto the the molding paper in a vacuum aluminizing way. Then the molding paper coated with the microporous aluminum is used for coiling to form the filtering rod. The filtering rod containing the microporous aluminum is used, and when high-temperature smoke of smoked cigarettes enters the filtering rod from the tail end of the cigarette, the temperature of smoke entering the mouth can be reduced to 28-32 DEG C because of condensation of the microporous aluminum, thereby enabling harmful substances of the smoke to be easily adhered to the filtering rod and obviously reducing harmful substances of the smoke, so that the hot burning feeling and spicy stimulating feeling of the mouth can be obviously lightened after people smoke.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

Paper tube with functions of reducing smoke temperatures and releasing aroma and application of paper tube

PendingCN107960680AThe processing technology is simple and effectiveImprove suction qualityTobacco pipesTobacco devicesFluid phaseAdhesive glue

The invention relates to a paper tube with functions of reducing mainstream smoke temperatures of cigarettes and releasing aroma. 2-20 pieces of food-grade paper are adhered and rolled by food-grade glue in a spiral manner according to the quantification of 25-200 g / m<2> to obtain the paper tube. The paper tube has the advantages that the paper tube can be used in filter tips of cigarettes or heated incombustible tobacco products, solid-liquid phase transformation can be carried out on thermal induction sustained-release gel by smoke generated when the tobacco products are smoked, the smoke temperatures can be reduced along with generation of latent heat energy and can be reduced by 1.0-7.0 Celsius degrees, requirements on the aroma can be met, burning heat sensation of oral cavities can be relieved, and the smoking comfort of the cigarettes and heated incombustible cigarettes can be improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Acetate plasticizer for improving smoking property of cigarette and method for preparing same

InactiveCN1994164AQuality improvementHigh fullnessTobacco smoke filtersVegetal fibresFlavorPlasticizer

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

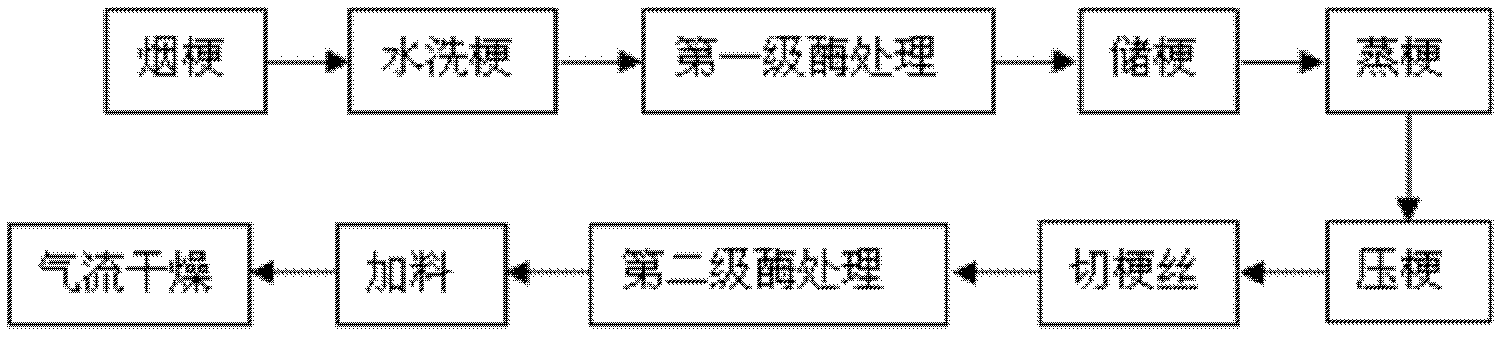

Two-stage enzyme treatment method for improving stalk shred smoking quality

The invention discloses a two-stage enzyme treatment method for improving stalk shred smoking quality. First-stage enzyme treatment aims at the tobacco stalk, and second-stage enzyme treatment aims at the stalk shred. The method comprises the following steps of: soaking the washed tobacco stalk in a first-stage enzyme preparation for 10-20 seconds, taking out and storing at the temperature of 20-50 DEG C for 2 hours, and shredding after the stalk is evaporated; and according to the dosage that 50ml of enzyme liquid is sprayed onto 1kg of the stalk shred, evenly spraying the second-stage enzyme treatment preparation onto the stalk shred, and carrying out pneumatic drying on the stalk shred at the temperature of 180 DEG C after storing for 2 hours. The treated stalk shred has the advantages that the oral comfort can be increased, and the impure gas and the stimulus can be reduced, so that the smoke is softer. The method is high in practical applicability, the use ratio of the stalk shred can be improved, and the tobacco leaf resource can be saved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Plant compound particles for cigarette filter and preparation method thereof

ActiveCN105595421AEnhance natural sweetnessIncrease moist feelingTobacco smoke filtersFreeze-dryingVatica mangachapoi

The invention discloses plant compound particles for a cigarette filter and a preparation method thereof. The method comprises the following steps: preparing rhizoma dioscoreae, radix puerariae, fructus crataegi, lonicera japonica, fructus phyllanthi, siraitia grosvenorii, gynostemma pentaphylla and vatica mangachapoi serving as major raw materials, and performing wall-breaking treatment on the raw materials; adding a small amount of yeast into the raw material powder, adding water into the powdery materials, and mixing uniformly; performing the procedures of extruding-pelletizing, material fermentation, microwave sizing, vacuum freeze drying, particle shaping and sieving in sequence to prepare a particular smell sucking material suitable for the cigarette filter finally. The plant compound particles for the cigarette filter are low in fragrance loss and high in fragrance releasing degree; by adding the plant compound particles into cigarette filter tows, the sweetness and salivation promotion of cigarette smoke can be improved, the smoke stimulation of cigarettes is lowered, the cigarette fragrance is enriched, and the smoking quality of the cigarettes is improved remarkably.

Owner:CHINA TOBACCO YUNNAN IND

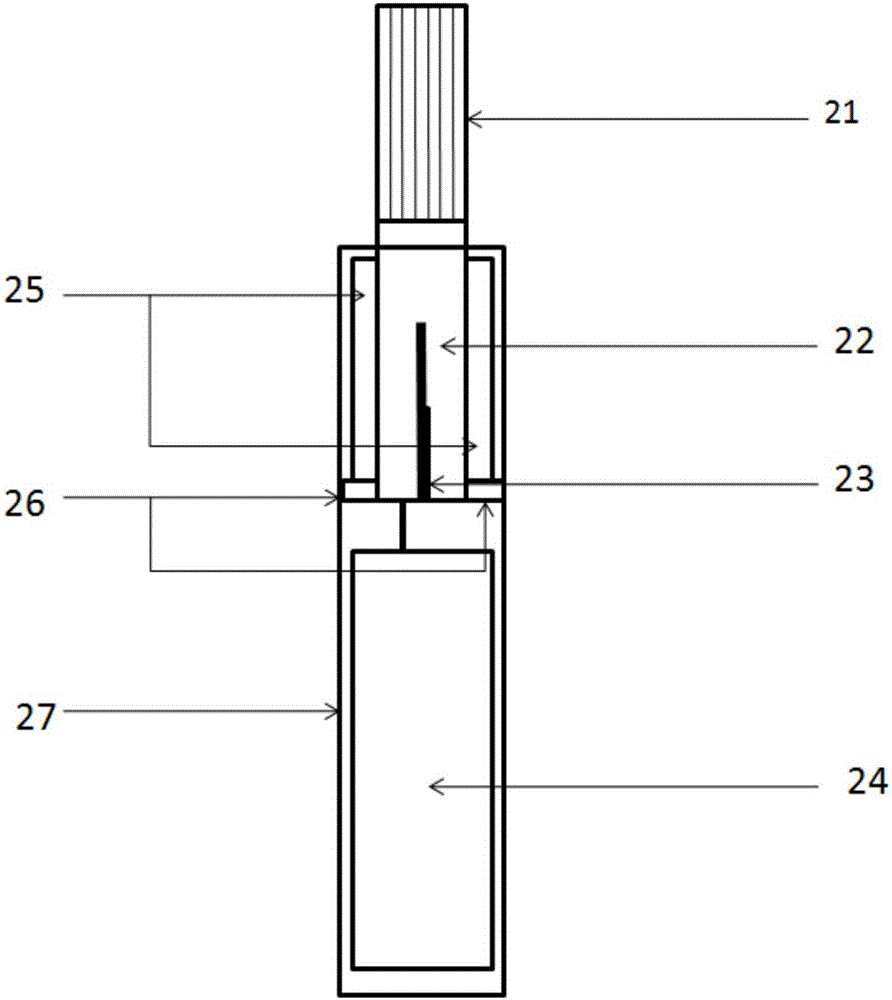

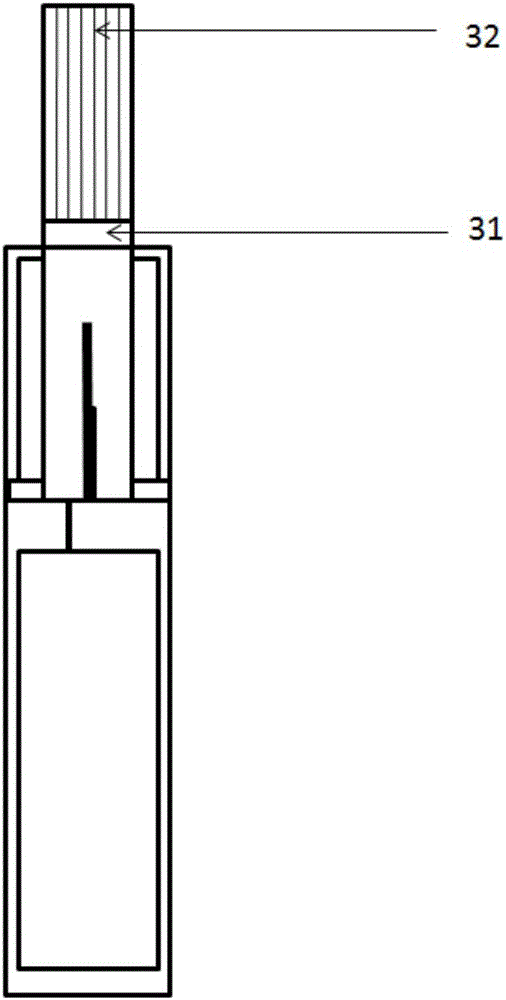

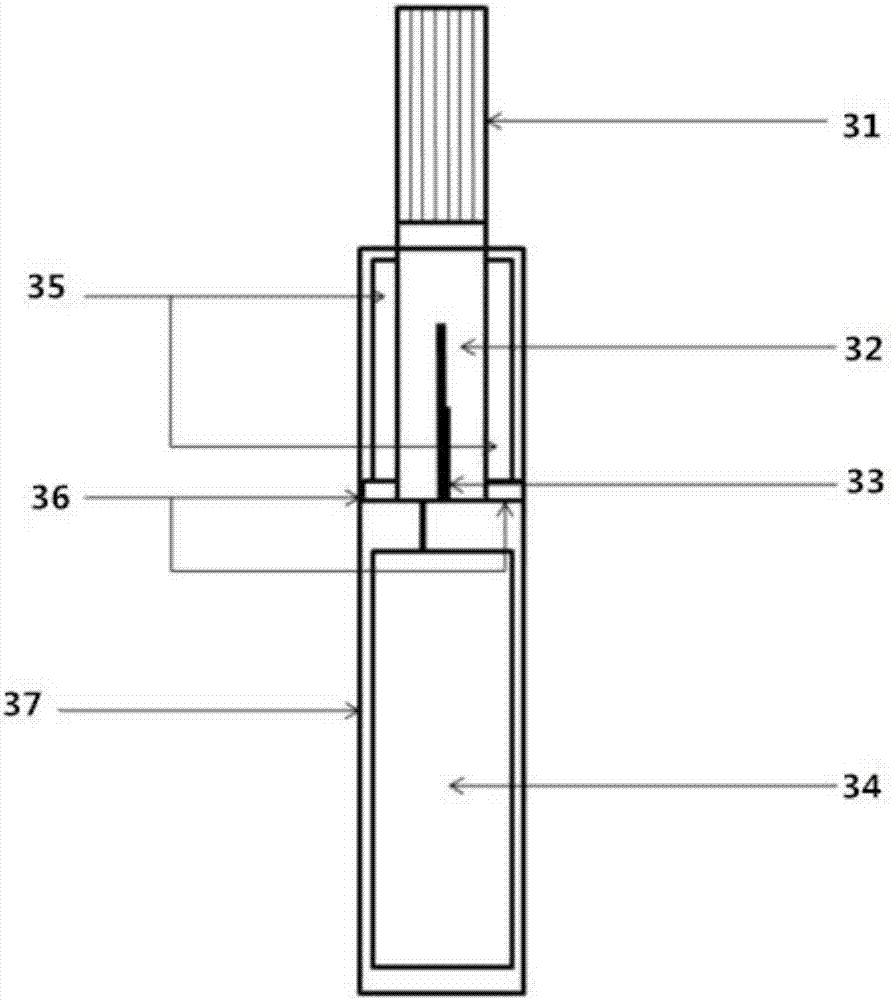

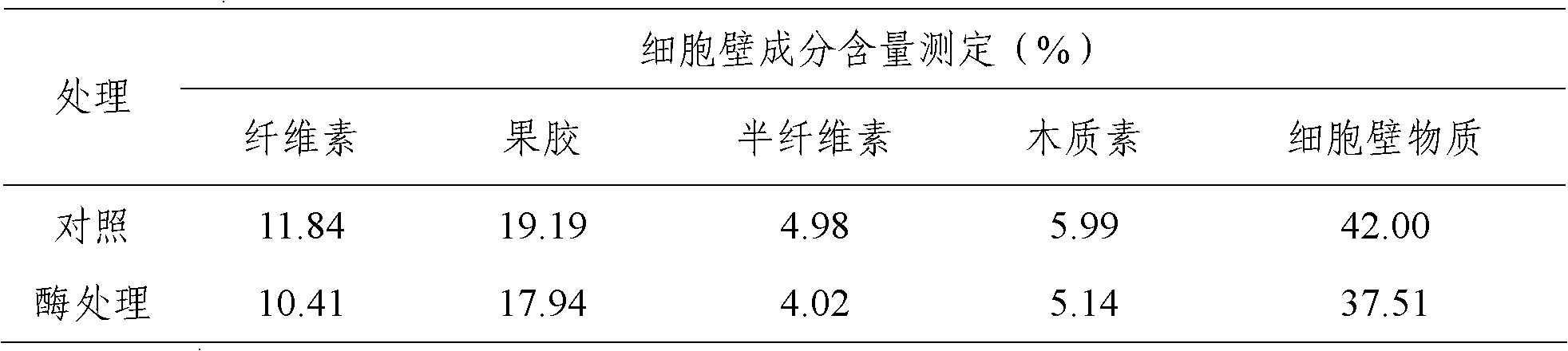

Microwave resonant atomizer for electronic cigarette

InactiveCN108552614AAvoiding patent infringementIncrease energy densityTobacco devicesTarInterior space

The invention discloses a microwave resonant atomizer (2) for an electronic cigarette. The microwave resonant atomizer comprises an oil storage unit (21), an atomizing unit (22), an upper cover plate(23) and a suction nozzle (24), wherein a microwave resonant cavity (221) is formed in the internal space of the atomizing unit (22); and a coupling hole (225) is formed in the side wall of the microwave resonant cavity (221), and the outer side wall of the microwave resonant cavity (221) with the coupling hole (225) can be covered with an energy coupling (224). When being applied to the electronic cigarette, the microwave resonant atomizer has the advantages that instant heating is realized, the efficiency is high, heat uniformity is good, non-contact atomization is realized, the low temperature sterilization of tobacco tar can be realized, and the like.

Owner:CHINA TOBACCO YUNNAN IND

Working system for uniformly heating tobacco materials by induction heating mode

PendingCN109567275AHeating evenlyUniform and controllable heatingTobacco devicesTemperature controlControl system

The invention relates to a working system for uniformly heating tobacco materials by an induction heating mode. The working system comprises an energy generation body, an energy receiving body and a heating temperature control system, wherein the energy generation body is a small electromagnetic heating device; the energy receiving body is added with a micro-particle material capable of sensing electromagnetic energy; and in combination with a temperature control system, cigarettes can be uniformly heated controllably, and the smoking quality and safety of tobacco products using the technicalsystem are further improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Porous moringa oleifera particles, preparation method of porous moringa oleifera particles as well as cigarette filter stick containing porous particles

ActiveCN104687246AFully contactedSimple processTobacco smoke filtersMORINGA OLEIFERA LEAFMoringa pterygosperma

The invention discloses porous moringa oleifera particles. The particles comprise porous particles made from moringa oleifera leaves and / or porous particles made from moringa oleifera seeds, wherein porous particles made from the moringa oleifera leaves comprise porous moringa oleifera leaf super-micro-powder particles, porous composite moringa oleifera leaf particles or porous moringa oleifera leaf extract powder particles; the porous particles made from the moringa oleifera seeds comprise porous moringa oleifera seed super-micro-powder particles, porous composite moringa oleifera seed particles or porous moringa oleifera seed extract powder particles, the porous composite moringa oleifera leaf or seed particles are particles prepared from moringa oleifera leaf or moringa oleifera seed super-micro-powder and other plant powder after mixing. The invention further discloses a preparation method of the porous moringa oleifera particles as well as a cigarette filter stick containing the porous particles. With the adoption of the cigarette filter stick, cigarette smoke is fine, smooth and mild, the irritation of the smoke is reduced, the cigarette fragrance is clear and mild, the smoking quality of cigarettes is improved, and the cigarette filter stick has obvious functions of reducing the irritation, increasing the fragrance and improving the quality.

Owner:CHINA TOBACCO YUNNAN IND

Method for preparing maillard reaction type tobacco flavor by utilizing high hydrostatic pressure

ActiveCN103343050AImprove suction qualityAroma and thornTobacco preparationEssential-oils/perfumesFlavorMaillard reaction

The invention relates to a preparation method of tobacco flavor and in particular relates to a method for preparing maillard reaction type tobacco flavor by utilizing high hydrostatic pressure. The method comprises the following steps of: (1), sufficiently dissolving amino acid and glucose in an aqueous solution according to certain proportion, adjusting a pH value of the mixed solution to 8-12 by using alkali liquor, and carrying out vacuum packaging; and (2), placing the mixed solution which is vacuum-packaged in the step 1 into a high hydrostatic pressure treatment kettle, controlling the applied pressure to 100MPa-400MPa, and treating for 20-50 minutes at 50 DEG C-70 DEG C to obtain the tobacco flavor. According to the method disclosed by the invention, the high hydrostatic pressure technology is introduced into the preparation of a maillard reactant at low temperature, and the optimized technological parameter range is determined; and the prepared tobacco flavor has the functions of enhancing aroma, reducing pungent smell as well as fining and softening smoke and is more mellow and coordinated in aroma, and the smoking quality of cigarettes can be remarkably improved.

Owner:HUBEI CHINA TOBACCO IND +1

Application of stevia rebaudiana in aspect of preparing reconstituted tobacco and reconstituted tobacco

ActiveCN103783650ARaw materials are easy to getLess irritatingTobacco preparationTobacco treatmentNicotiana tabacumTar

The invention discloses the application of stevia rebaudiana in the aspect of preparing reconstituted tobacco and the reconstituted tobacco. The stevia rebaudiana is extracted through alcohol to obtain stevia rebaudiana extractum and / or stevia rebaudiana fibers, one or both the stevia rebaudiana extractum and the stevia rebaudiana fibers can be used for preparing the reconstituted tobacco, the reconstituted tobacco can be endowed with special fragrance, the irritation can be reduced, and the smoking taste can be improved. The effective ingredients of the stevia rebaudiana are fully utilized, the smoking quality of the cigarette is improved, meanwhile, the releasing amount of CO, tar and other ingredients in the cigarette is reduced, and a powerful technological foundation is provided for adding new tobacco products and reducing the tobacco harm. The raw materials are easy to obtain, the reconstituted tobacco is safe and healthy, and popularization and application are facilitated.

Owner:CHINA TOBACCO GUANGDONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com