Porous moringa oleifera particles, preparation method of porous moringa oleifera particles as well as cigarette filter stick containing porous particles

A technology of porous particles and Moringa, which is applied in e-liquid filter elements, tobacco, applications, etc., to achieve the effects of reducing irritation, increasing sweetness, and improving smoking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

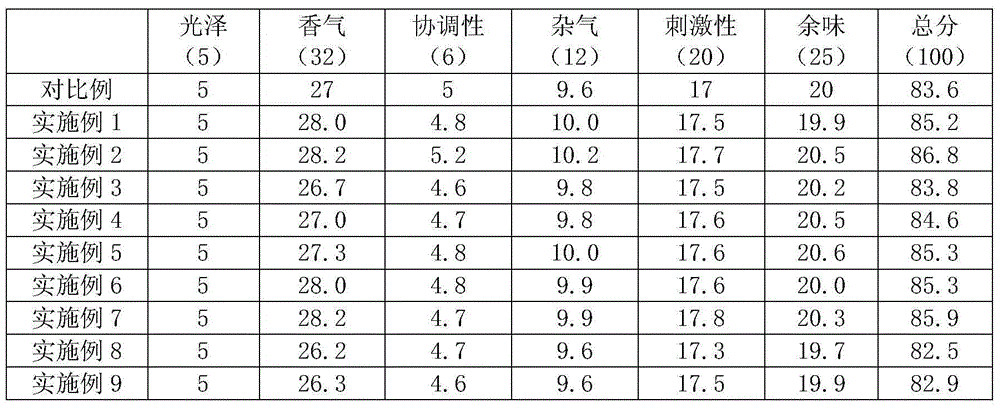

Examples

Embodiment 1

[0034] Clean the fresh leaves of Moringa oleifera, dry them naturally, place them in an oven and dry them at 40°C for 5 hours, then carry out microwave sterilization treatment, and then process them into superfine powder of Moringa leaves with a particle size of less than 60 μm through an ultrafine pulverization process; The superfine powder of Moringa leaves and the hydrophilic macromolecular binder are prepared into porous particles of superfine powder of Moringa leaves through a fluidized bed spray granulation process.

[0035] In the preparation of the superfine powder porous particles of Moringa leaf, the superfine powder of Moringa leaf and the hydrophilic binder are prepared according to the following mass percentages: 98% of superfine powder of Moringa leaf, 1.5% of dextrin, 0.5% of gum arabic, each The sum of the components is 100%; the hydrophilic binder mixture is first dissolved in distilled water to make a binder solution with a concentration of 5w / v%, which is ato...

Embodiment 2

[0038]Clean the fresh leaves of Moringa oleifera, dry them naturally, place them in an oven and dry them at 40°C for 5 hours, then carry out microwave sterilization treatment, and then process them into superfine powder of Moringa leaves with a particle size of less than 60 μm through an ultrafine pulverization process; Moringa leaf superfine powder is uniformly mixed with other plant powders and then mixed with a hydrophilic polymer binder through a fluidized bed spray granulation process to prepare Moringa leaf composite porous particles.

[0039] In the preparation of the composite porous particles of Moringa leaves, wherein the plant powder is Ophiopogon japonicus powder, Pueraria root powder, Puer tea extract powder and licorice powder, and the mass ratio is superfine powder of Moringa oleifera leaves: Ophiopogon japonicus powder: Pueraria radicis Powder: Pu'er tea extract powder: licorice powder = 3:2:2:2:1 to obtain a composite powder. The composite powder and the hydro...

Embodiment 3

[0042] The Moringa oleifera seeds were cleaned and coarsely crushed, dried naturally, and then dried in an oven at 50°C for 5 hours, then microwave sterilized, and superfinely pulverized to obtain Moringa oleifera seed superfine powder with a particle size of less than 60 μm. The superfine powder of Moringa seed and the hydrophilic polymer binder are used to make porous particles of superfine powder of Moringa seed through a fluidized bed spray granulation process.

[0043] In the preparation of the superfine powder porous particles of Moringa seeds, the superfine powder of Moringa seeds and the hydrophilic binder are prepared according to the following mass percentages: 98% of superfine powders of Moringa seeds, 2% of edible gelatin, and the sum of each component is 100%; Dissolve the prepared edible gelatin in distilled water first to make a binder solution with a concentration of 3w / v%, atomize and spray onto the superfine powder of Moringa oleifera seeds for bonding into gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com