Paper tube with functions of reducing smoke temperatures and releasing aroma and application of paper tube

A technology of flue gas temperature and paper tube, which is applied in the direction of smoker's products, tobacco, application, etc., and can solve the problems of affecting the product's smoking feeling, poor smoking taste, and reduced smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

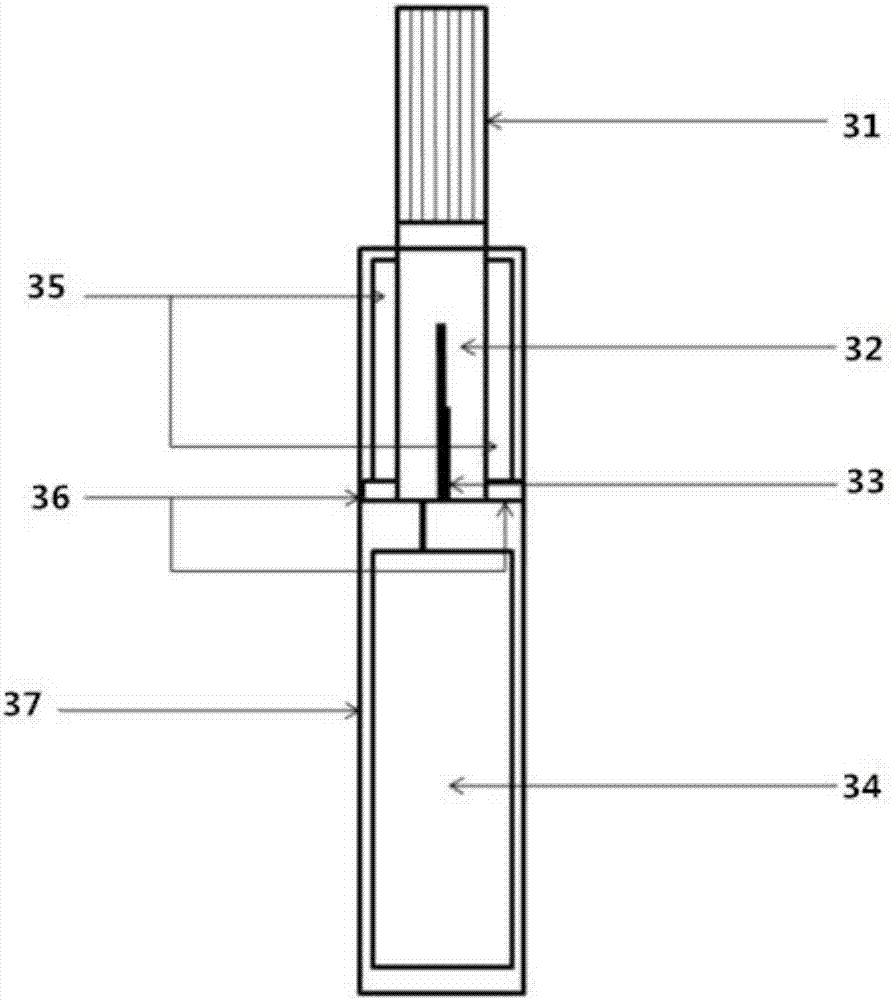

Image

Examples

Embodiment 1

[0056] Embodiment 1: The present invention can reduce the smoke temperature and release the paper tube of fragrance

[0057] The implementation steps of this embodiment are as follows:

[0058] First, 70 parts by weight of the "Peach Milk Mint Essence" tobacco flavor substance sold by Yunnan Balu Biotechnology Co., Ltd., 37 parts by weight of the tobacco flavor substance sold by Guangzhou Fuchun Chemical Co., Ltd. under the trade name "Pharmaceutical Grade Polyethylene Glycol 1000 The polyethylene glycol sold in ", and 10 parts by weight of cetyl alcohol sold by Nanjing Jiaguan Chemical Co., Ltd. under the trade name "Spring Gold Brand Cetyl Alcohol" are evenly mixed to obtain the heat-sensitive slow-release gel.

[0059] Secondly, using the coating equipment sold by Changzhou Jiejiashun Coating Equipment Co., Ltd. under the trade name of roller coater, the above-mentioned thermosensitive slow-release gel was coated at 42 g / m 2 Coated on the surface of ordinary kraft paper us...

Embodiment 2

[0069] Embodiment 2: The present invention can reduce the smoke temperature and release the paper tube of fragrance

[0070] The implementation steps of this embodiment are as follows:

[0071] First, 50 parts by weight of "Peach Milk Mint Essence" tobacco flavor substance sold by Yunnan Bagu Biotechnology Co., Ltd., 44 parts by weight of "Pharmaceutical Grade Polyethylene Glycol 1000" sold by Guangzhou Fuchun Chemical Co., Ltd. The polyethylene glycol sold in ", and 10 parts by weight of cetyl alcohol sold by Nanjing Jiaguan Chemical Co., Ltd. under the trade name "Spring Gold Brand Cetyl Alcohol" are evenly mixed to obtain the heat-sensitive slow-release gel.

[0072] Secondly, using the coating equipment sold by Changzhou Jiejiashun Coating Equipment Co., Ltd. under the trade name of roller coater, the above-mentioned thermosensitive slow-release gel was coated at a rate of 30 g / m 2Coated on the surface of kraft paper used to roll into the innermost layer of paper tube, an...

Embodiment 3

[0084] Embodiment 3: The present invention can reduce the smoke temperature and release the paper tube of fragrance

[0085] The implementation steps of this embodiment are as follows:

[0086] First, 50 parts by weight of "Peach Milk Mint Essence" tobacco flavor substance sold by Yunnan Bagu Biotechnology Co., Ltd., 30 parts by weight of "Pharmaceutical Grade Polyethylene Glycol" sold by Guangzhou Fuchun Chemical Co., Ltd. 1000" and 8 parts by weight of cetyl alcohol sold by Nanjing Jiaguan Chemical Co., Ltd. under the trade name "Spring Gold Brand Cetyl Alcohol" were evenly mixed to obtain the heat-sensitive slow-release gel.

[0087] Secondly, using the coating equipment sold by Changzhou Jiejiashun Coating Equipment Co., Ltd. under the trade name of roller coater, the above-mentioned thermosensitive slow-release gel was coated at 100 g / m 2 Coated on the surface of kraft paper used to roll into the innermost layer of paper tube, and then use the paper tube production equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com