Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168results about How to "Improve the taste of smoking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

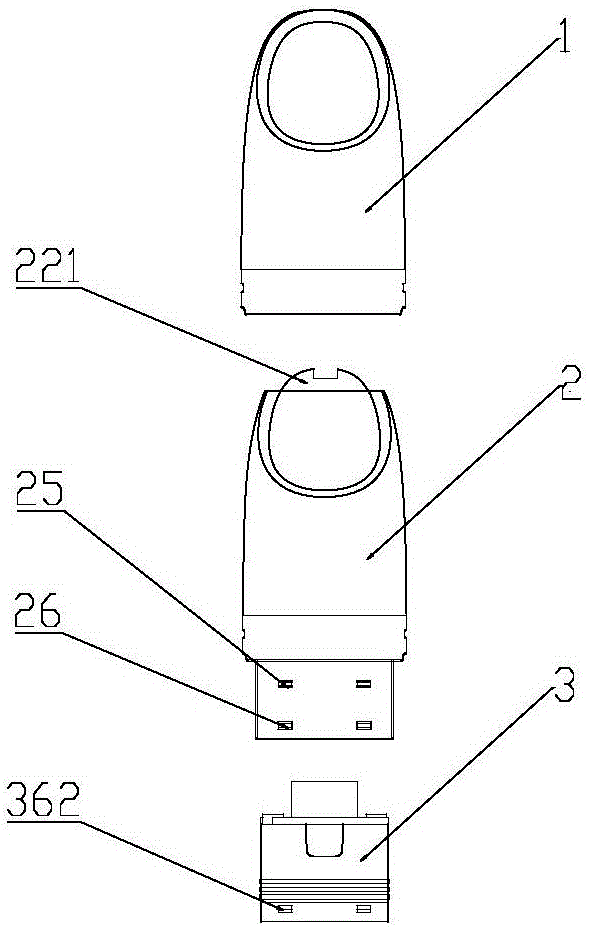

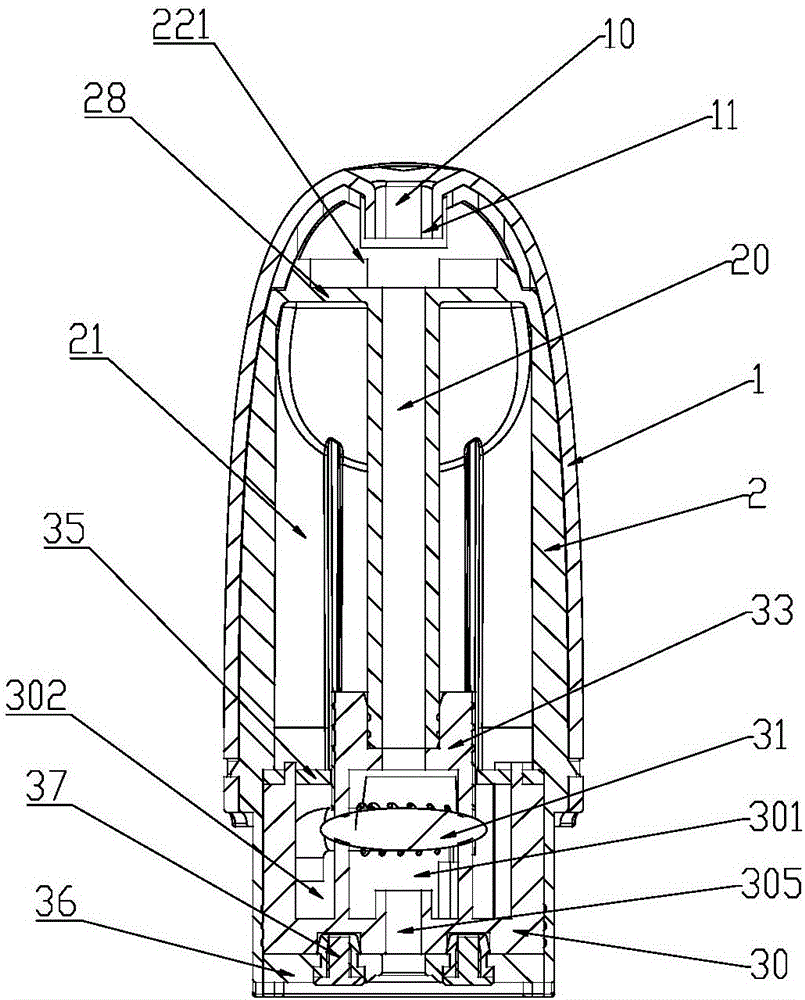

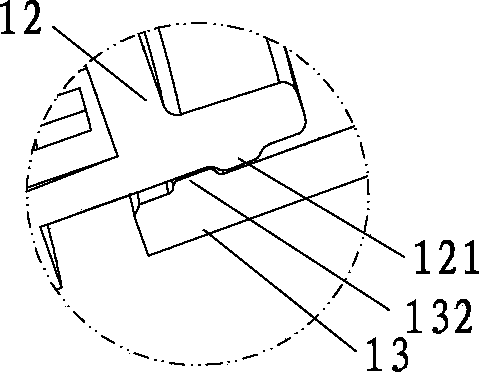

Electronic cigarette smoke atomizer with liquid storage transition cavity

ActiveCN106235419AImprove the taste of smokingPrevent leakageTobacco pipesTobacco devicesElectronic cigaretteEngineering

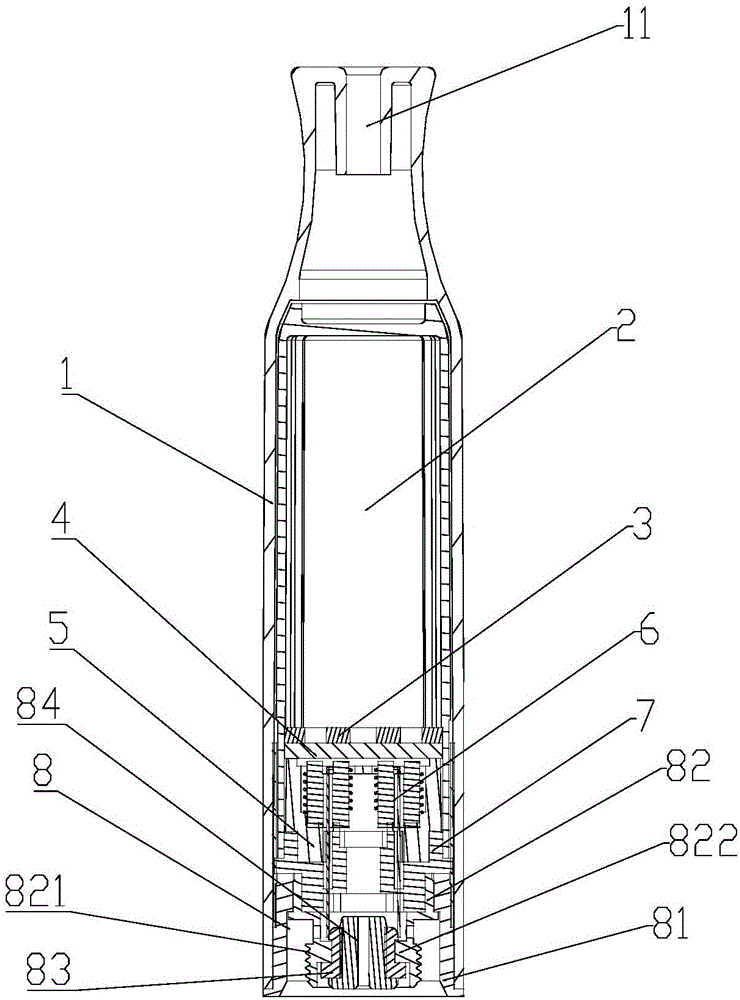

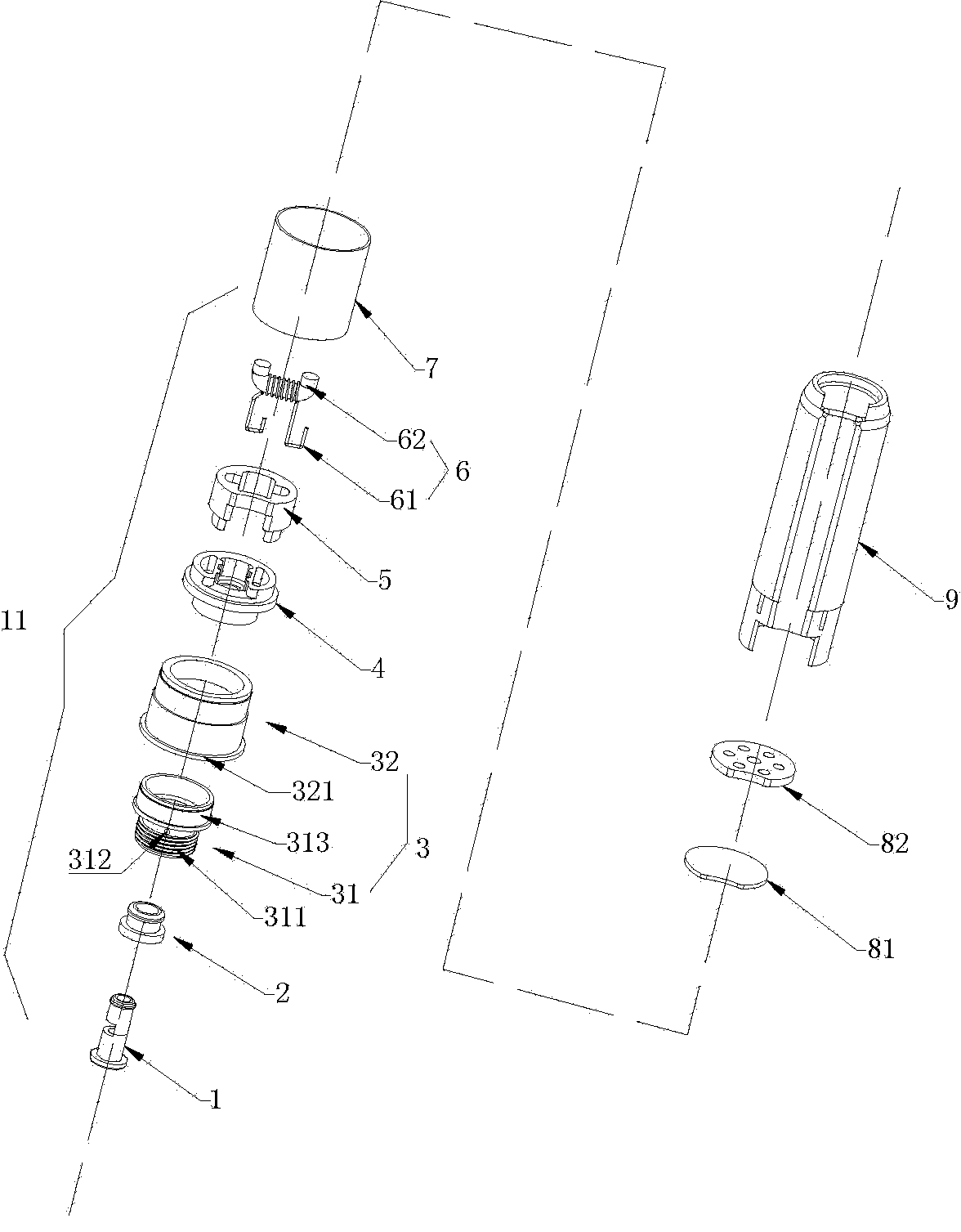

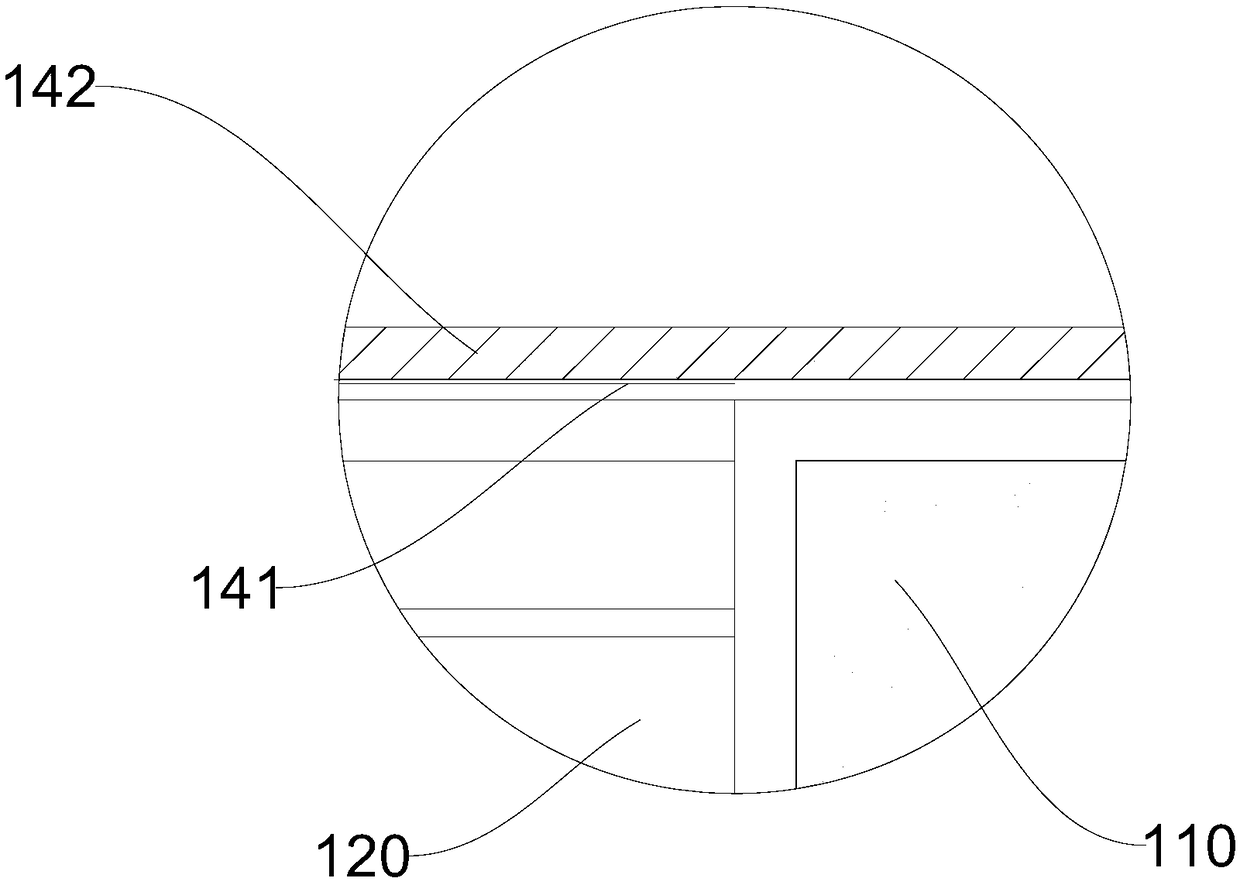

The invention discloses an electronic cigarette smoke atomizer with a liquid storage transition cavity. The electronic cigarette smoke atomizer comprises a suction nozzle, a liquid storage cylinder and an atomizing device, wherein the suction nozzle is a casing of which the top end is provided with a suction nozzle opening, and the inner wall of the casing is tightly attached and sheathed at the outer wall of the upper part of a liquid storage cylinder; the top end of the liquid storage cylinder is provided with an upper wall, and the center of the outer wall is downwards provided with a smoke outlet pipe; in the atomizing device, an atomizing base is sheathed at the inner wall of the lower part of the liquid storage cylinder, and a cavity at the upper surface of the atomizing device and between the inner wall of the liquid storage cylinder and the outer wall of the smoke outlet pipe is a liquid storage cavity; the interior of the atomizing base is provided with an inner cavity and an outer cavity which are mutually sealed, an atomizing unit is arranged in an inner cavity and is used as an atomizing cavity, and the outer cavity is filled with a liquid storage medium to form the liquid storage transition cavity; the atomizing cavity is communicated with the smoke outlet pipe, and the liquid storage transition cavity is communicated with the liquid storage cavity to supply liquid for the atomizing unit. The electronic cigarette smoke atomizer has the beneficial effects that by arranging the liquid storage transition cavity in the atomizing base, the liquid storage medium is contained to avoid leakage; when the cigarette is smoked, the liquid is sufficiently supplied, a large amount of smoke is produced, and the smoking mouth feel of a user is greatly improved.

Owner:SHENZHEN HAPPY VAPING TECH LTD

Oval electronic cigarette and manufacturing technique thereof

ActiveCN103892467AAvoid burnsImprove the taste of smokingSnap-action fastenersTobacco pipesLiquid smokeAerosolize

The invention relates to an oval electronic cigarette and a manufacturing technique thereof. An atomization component inner shell is arranged in an atomization component outer shell of the oval electronic cigarette and sleeves an atomization component, the atomization component comprises an atomizer part and a cigarette liquid cup part, the outer wall of the atomizer part is tightly matched with the inner wall of the atomization component inner shell, a gap is reserved between the outer wall of the cigarette liquid cup part and the inner wall of the atomization component inner shell to form a smoke passage, a smoke outlet is arranged at one end of the atomization component inner shell, the periphery of the smoke outlet is hermetically connected with a horn mouth structure in a compacted manner, and the horn mouth structure is arranged on a cigarette holder and made of a soft material. An air inlet hole formed in the atomization component outer shell is communicated with an air inlet formed in one end, connected with a control component, of the atomization component, a smoke outlet hole formed in the outer wall at the joint of the cigarette liquid cup and the atomizer, the smoke passage formed by the gap between the atomization component inner shell and the outer wall of the cigarette liquid cup, the smoke outlet and an inner passage of the cigarette holder to jointly form a communicated passage for smoking.

Owner:林光榕

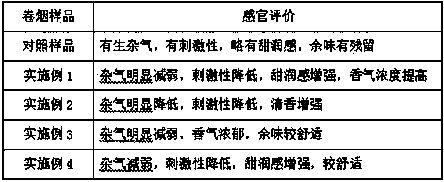

Fruity type flue-cured tobacco essence and applications thereof

ActiveCN101565652ACover up miscellaneous gasImprove the taste of smokingTobacco treatmentEssential-oils/perfumesMethyl acetateTrans-2-hexenal

The invention relates to a fruity type flue-cured tobacco essence and also relates to the applications thereof. The fruity type flue-cured tobacco essence mainly consists of trans-2-hexenal, hexenyl formate, methyl acetate, red date tincture, hawthorn tincture and the like. The fruity type flue-cured tobacco essence can be used for leading the fruit flavor to be coordinated with the flavor of the tobacco to hide the offensive smell of the tobacco and develop the tobacco smoke to be rich and mellow, thereby improving the intake taste with comfortable and mellow, cool and soft smoking feeling and fragrant and elegant aftertaste.

Owner:YINGTAN HUABAO FLAVORS & FRAGRANCES

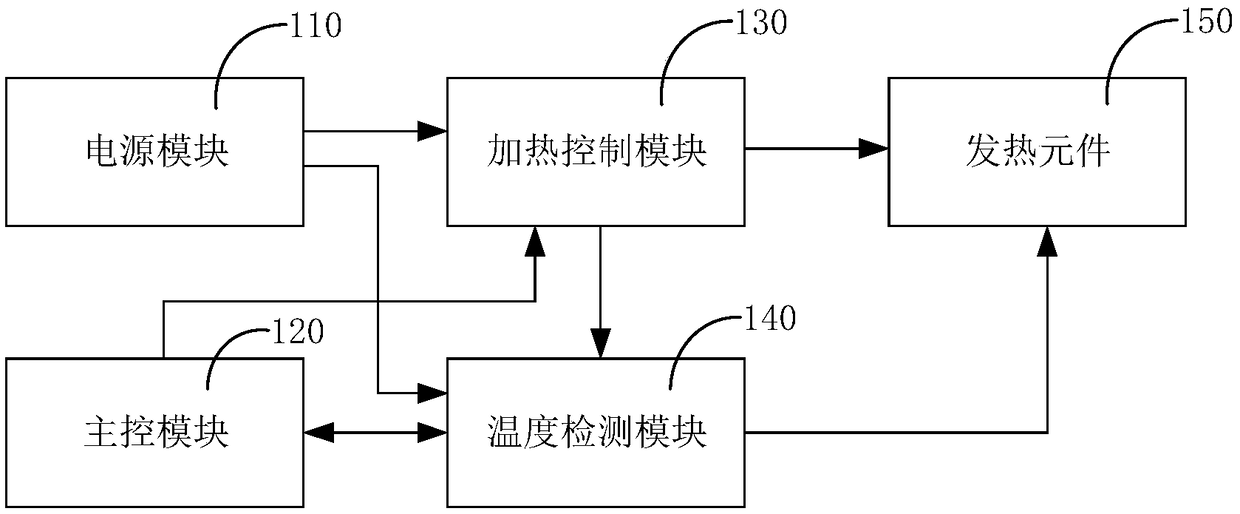

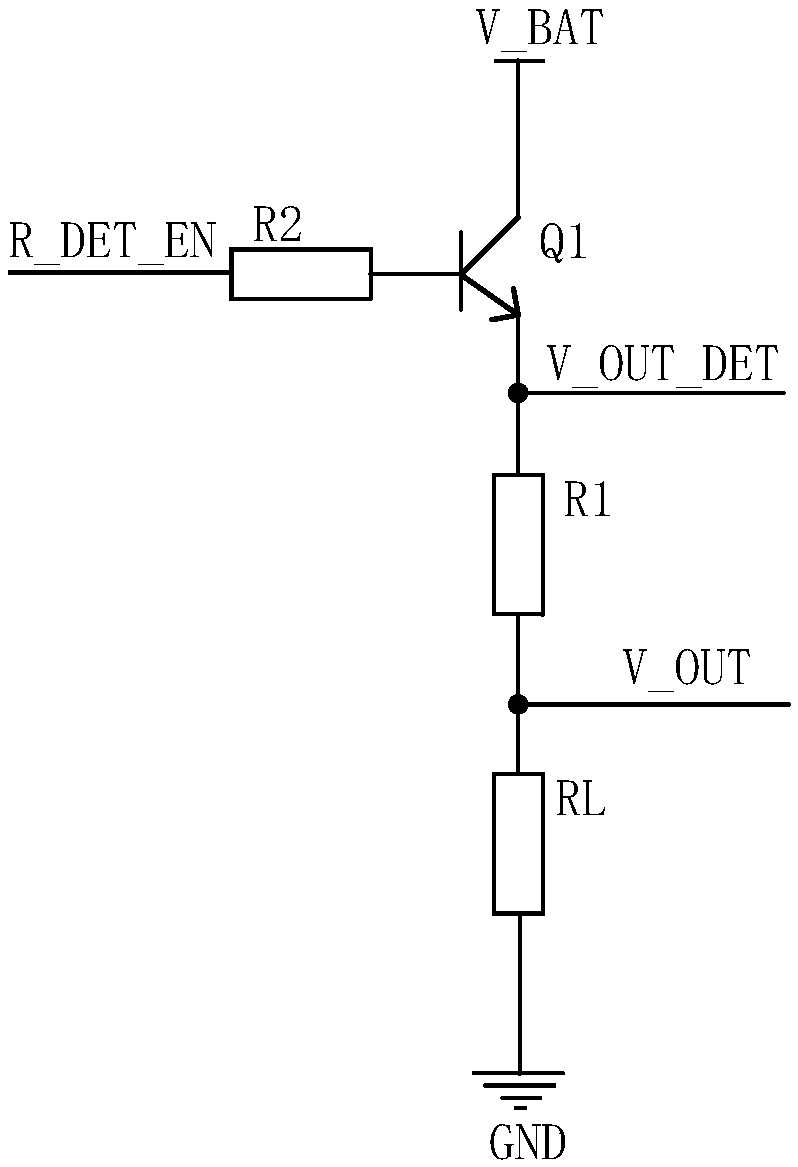

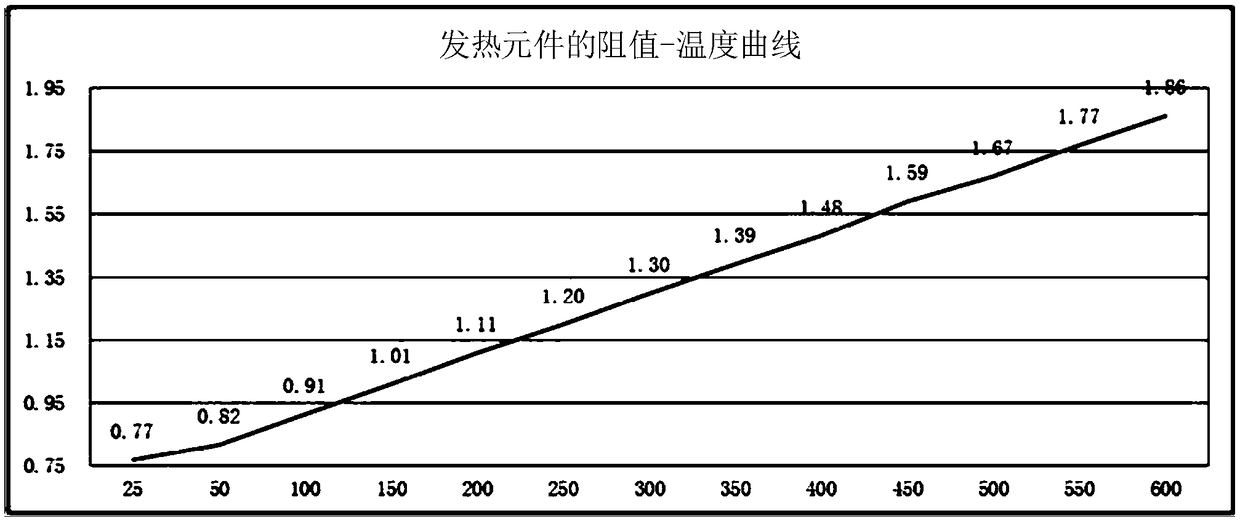

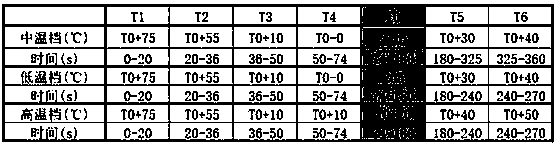

Temperature control system for electronic cigarettes

ActiveCN108873976AControl Temperature StabilityImprove the taste of smokingTemperature control using digital meansElectricityTemperature control

The embodiment of the invention discloses a temperature control system for electronic cigarettes, the system comprising: a power module for supplying power to the system; a heating element for emitting heat to heat a smokable material in an electronic cigarette; a temperature detecting module electrically connected with the power module and the heating element to perform temperature detection on the heating element after receiving the power input from the power module; a heating control module electrically connected to the power module and the heating element for forming a switching circuit between the power module and the heating element, the heating control module being turned on to make the heating element obtain power to emit heat; a main control module electrically connected to the temperature detecting module and the heating control module for sending control signals to the temperature detecting module and the heating control module and controlling the temperature detecting module and the heating control module to alternately operate to control the temperature of the heating element to be the same as the target temperature.

Owner:J&J HERBAL HEATING TECH CO LTD

Tobacco material suitable for heating non-combustion device and preparing method of tobacco material

ActiveCN105433430AImprove heating conditionsIncrease smoke concentrationTobacco treatmentWater contentEngineering

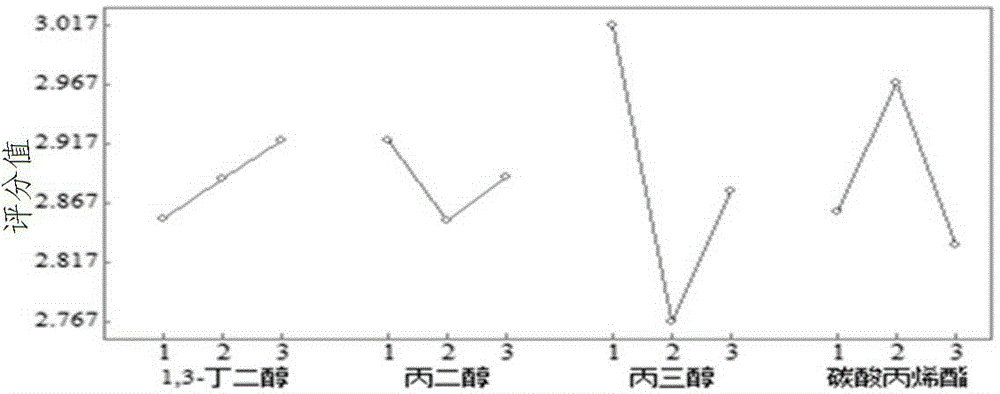

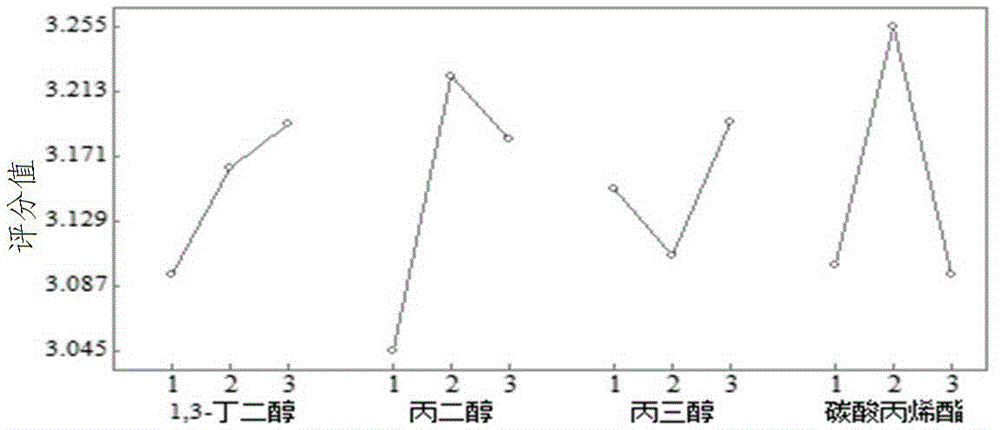

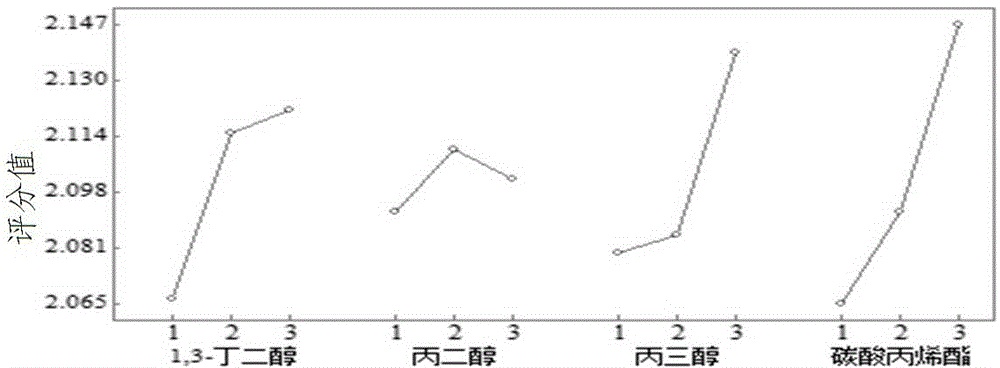

The invention belongs to the technical field of tobaccos, and particularly relates to a tobacco material suitable for heating a non-combustion device and a preparing method of the tobacco material. The tobacco material is prepared from, by mass, 30-80 parts of tobacco powder, 10-30 parts of tobacco extract, 5-30 parts of polyhydric alcohols, 1-5 parts of an expanding auxiliary, 0.1-5 parts of a heat conducting material, 1-5 parts of a dispersing auxiliary and 0.1-5 parts of a natural antibacterial agent, and the water content is 8-15%. Compared with other tobacco materials for heating the non-combustion device in the prior art, the tobacco material has the obvious advantages that the smoke concentration is obviously increased, smoke release uniformity is obviously improved, the quality is more stable, and the application range is wide.

Owner:CHINA TOBACCO HENAN IND +1

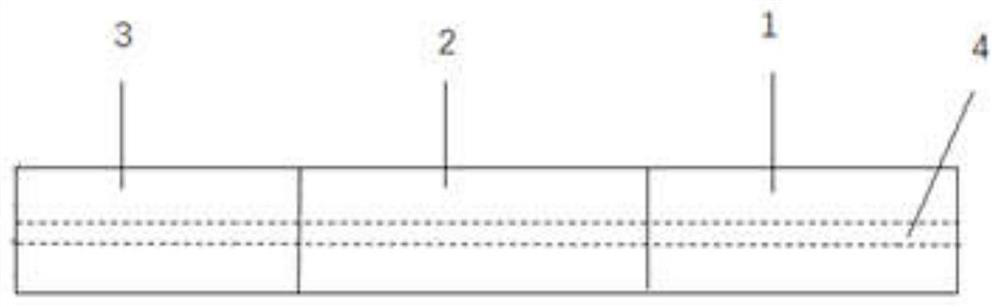

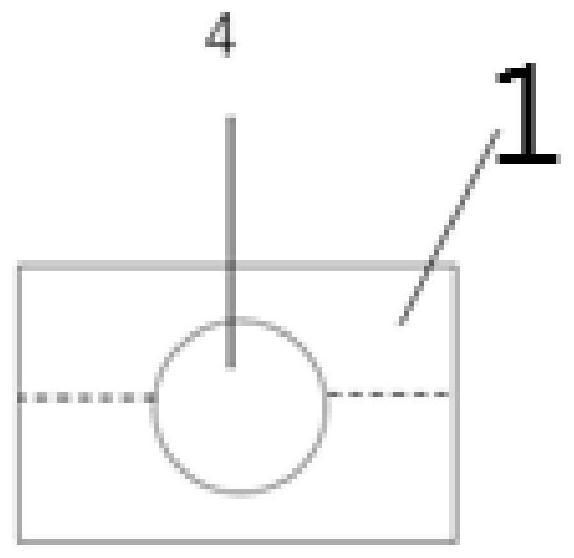

Paper tube with functions of reducing smoke temperatures and releasing aroma and application of paper tube

PendingCN107960680AThe processing technology is simple and effectiveImprove suction qualityTobacco pipesTobacco devicesFluid phaseAdhesive glue

The invention relates to a paper tube with functions of reducing mainstream smoke temperatures of cigarettes and releasing aroma. 2-20 pieces of food-grade paper are adhered and rolled by food-grade glue in a spiral manner according to the quantification of 25-200 g / m<2> to obtain the paper tube. The paper tube has the advantages that the paper tube can be used in filter tips of cigarettes or heated incombustible tobacco products, solid-liquid phase transformation can be carried out on thermal induction sustained-release gel by smoke generated when the tobacco products are smoked, the smoke temperatures can be reduced along with generation of latent heat energy and can be reduced by 1.0-7.0 Celsius degrees, requirements on the aroma can be met, burning heat sensation of oral cavities can be relieved, and the smoking comfort of the cigarettes and heated incombustible cigarettes can be improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

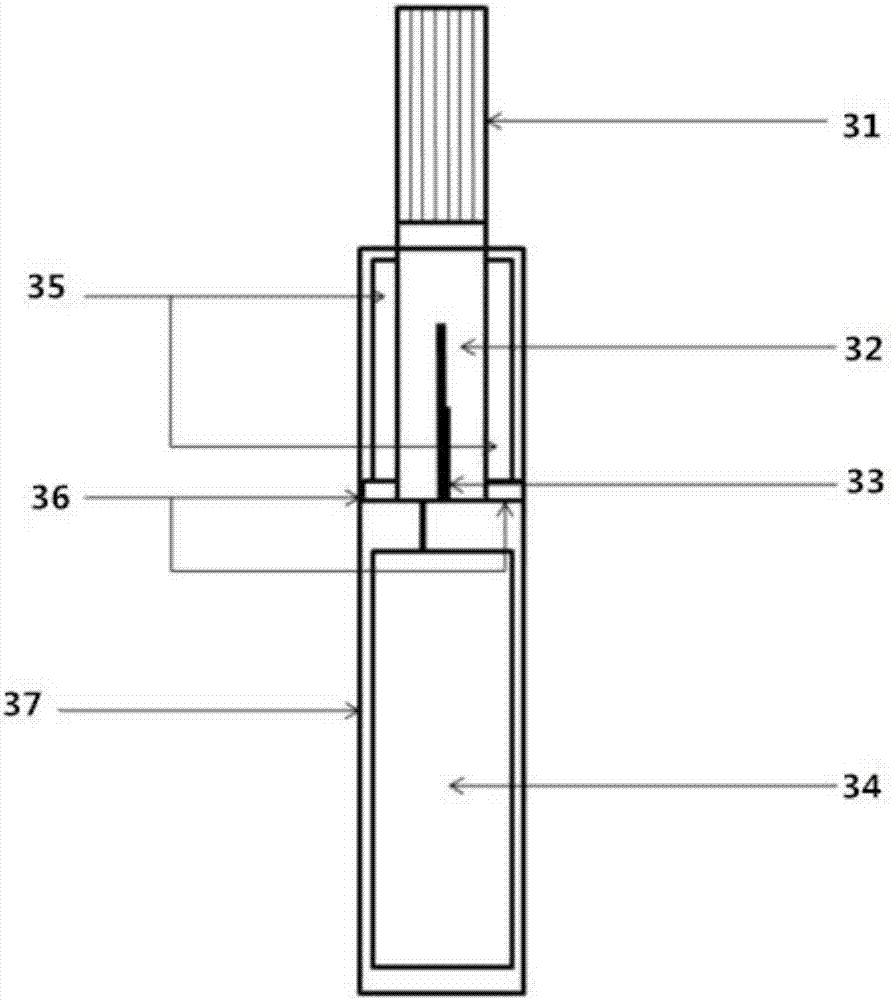

Mint-based wrapper for smoking

InactiveUS20170042217A1Reduce riskImprove the taste of smokingCigar manufactureNon-macromolecular organic additionFiberEngineering

The present invention provides a homogenized organic wrapping sheet made from mint-based fiber pulp for smoking articles. The wrapping sheet imparts distinctive properties to the smoking article, including slow burning, and smooth, cool and pleasant experience to smokers. Furthermore, the invention describes a method to manufacture the homogenized wrapping paper and smoking article.

Owner:FERNANDEZ PAOLA +2

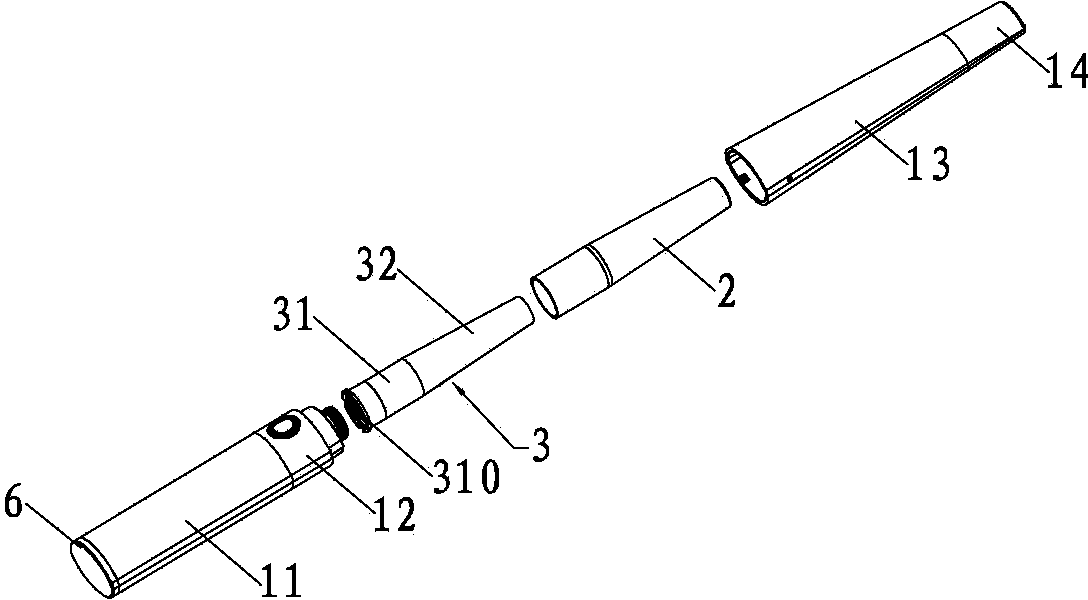

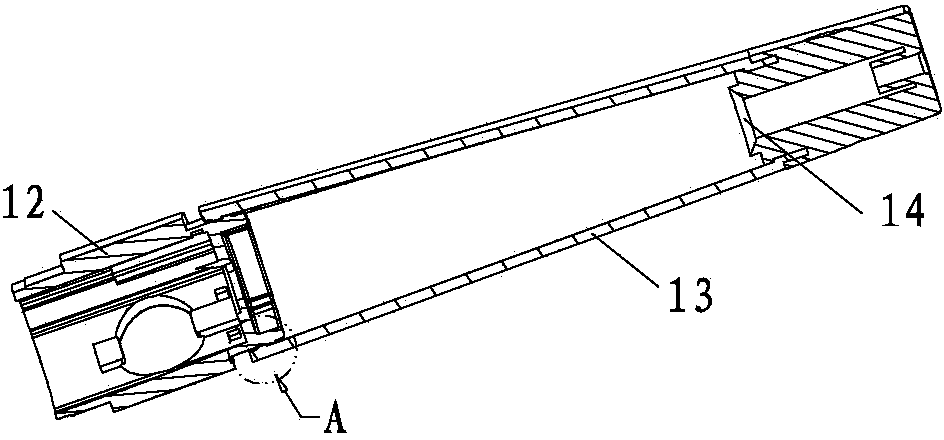

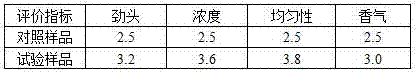

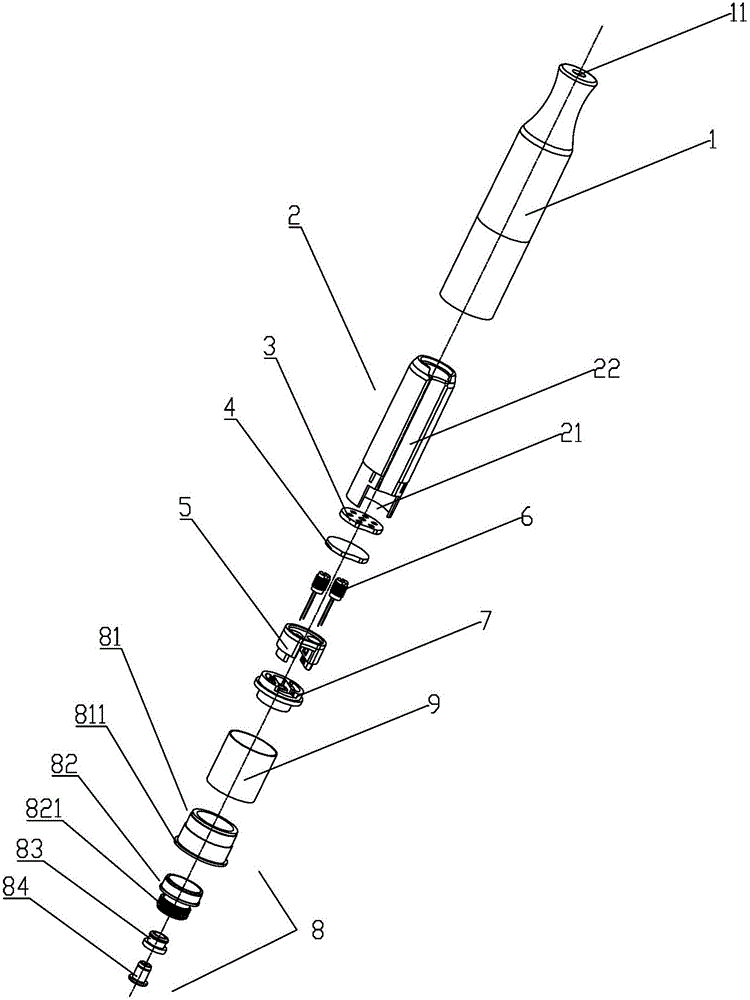

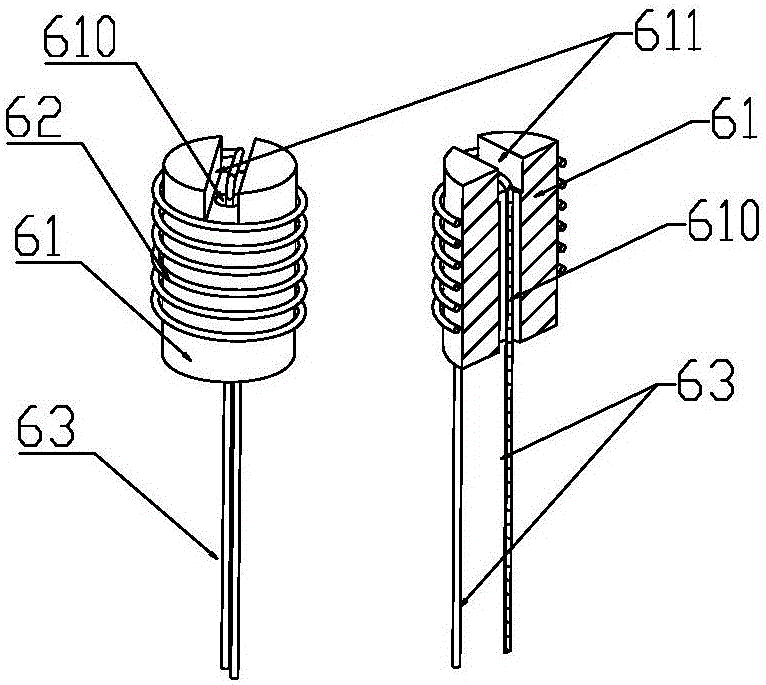

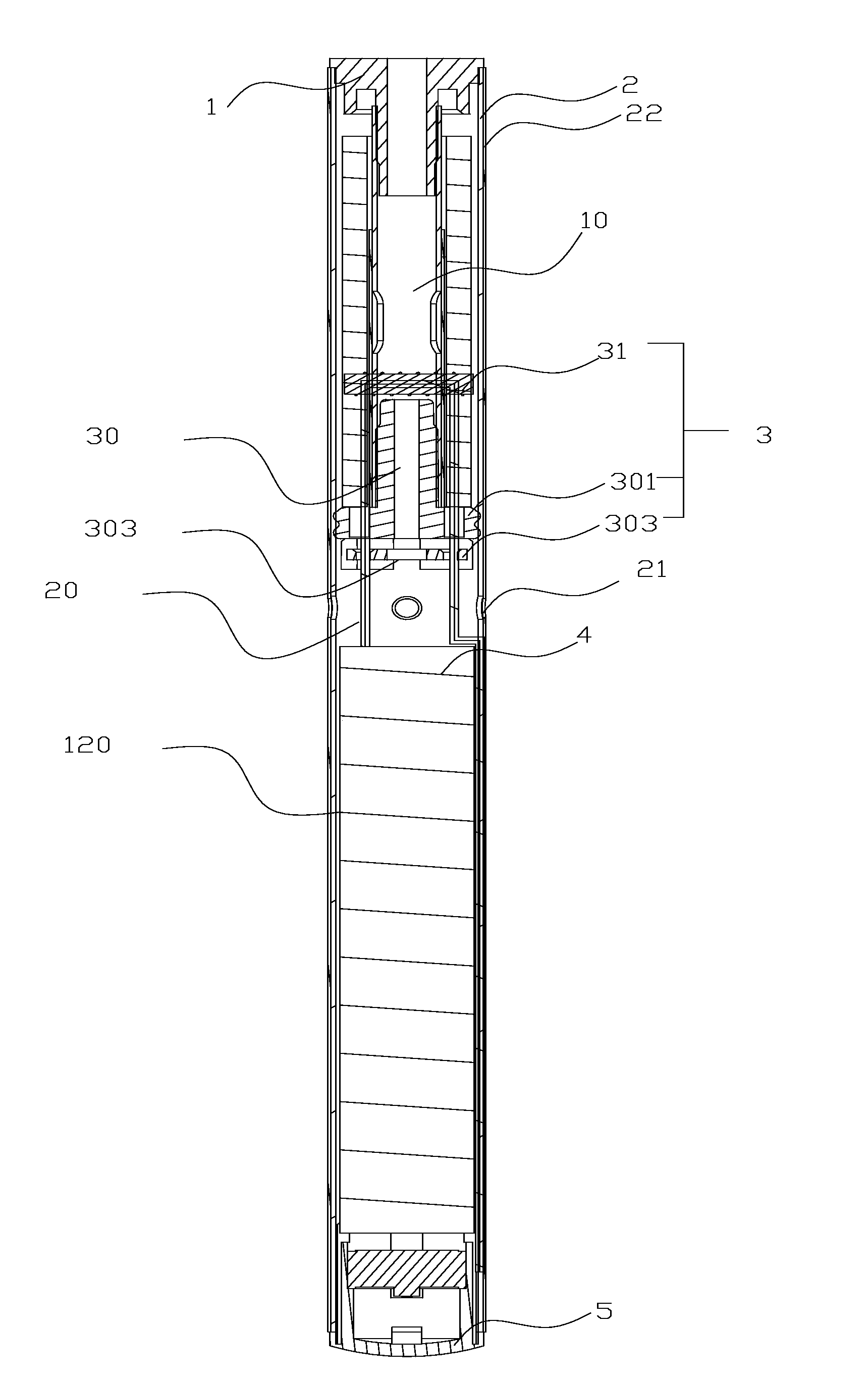

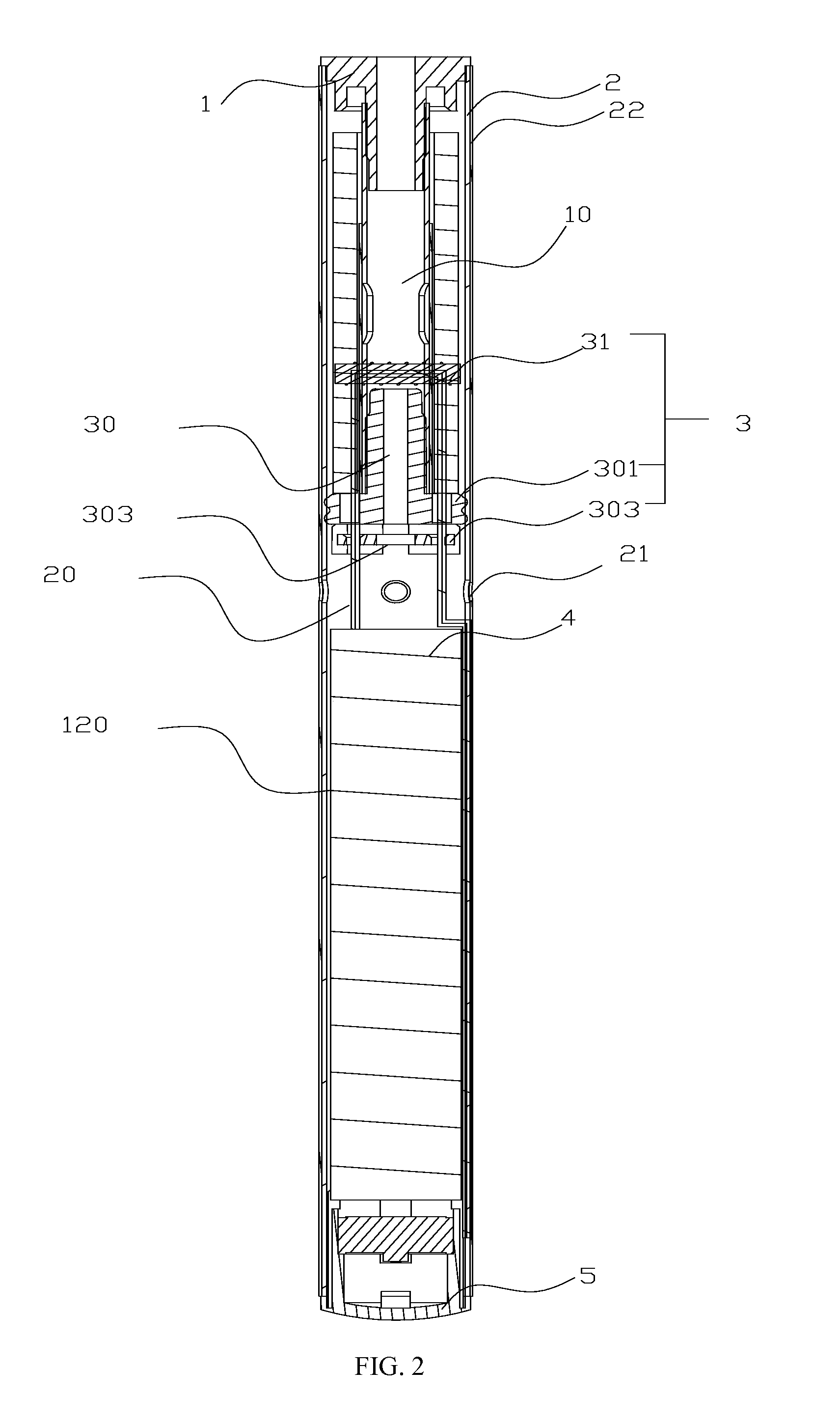

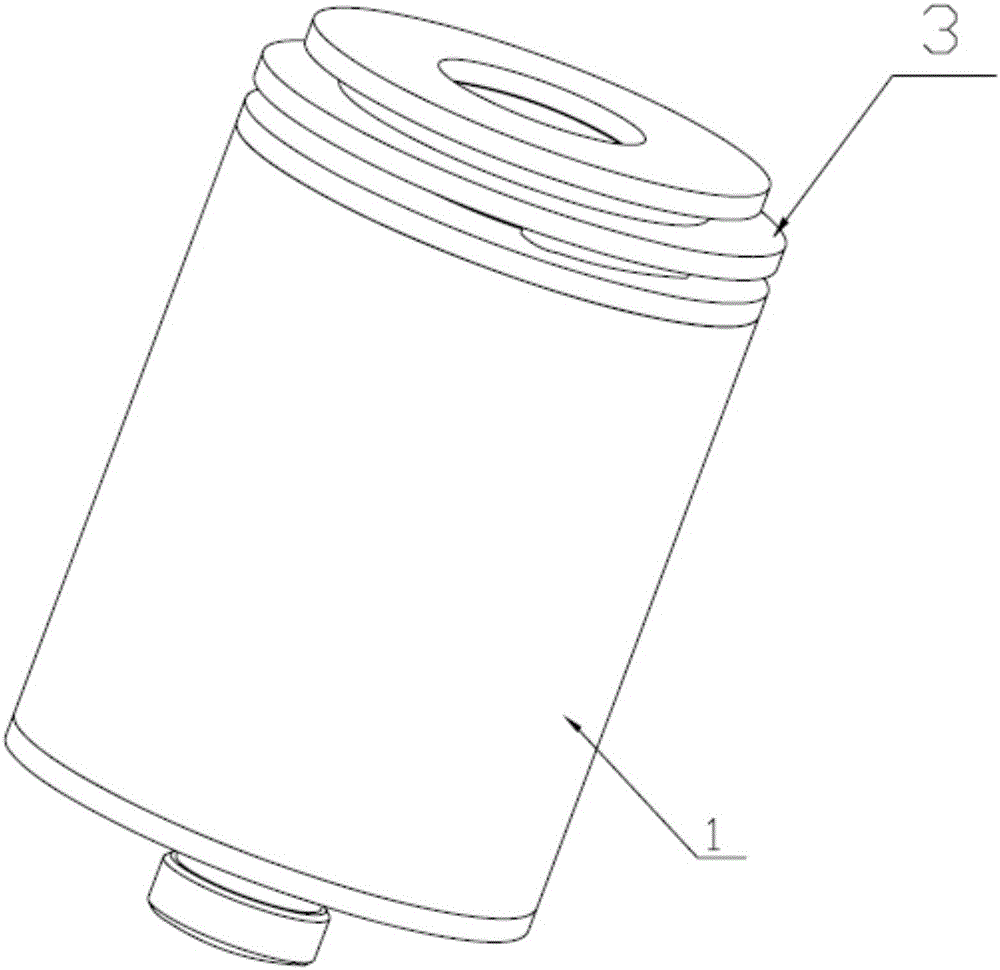

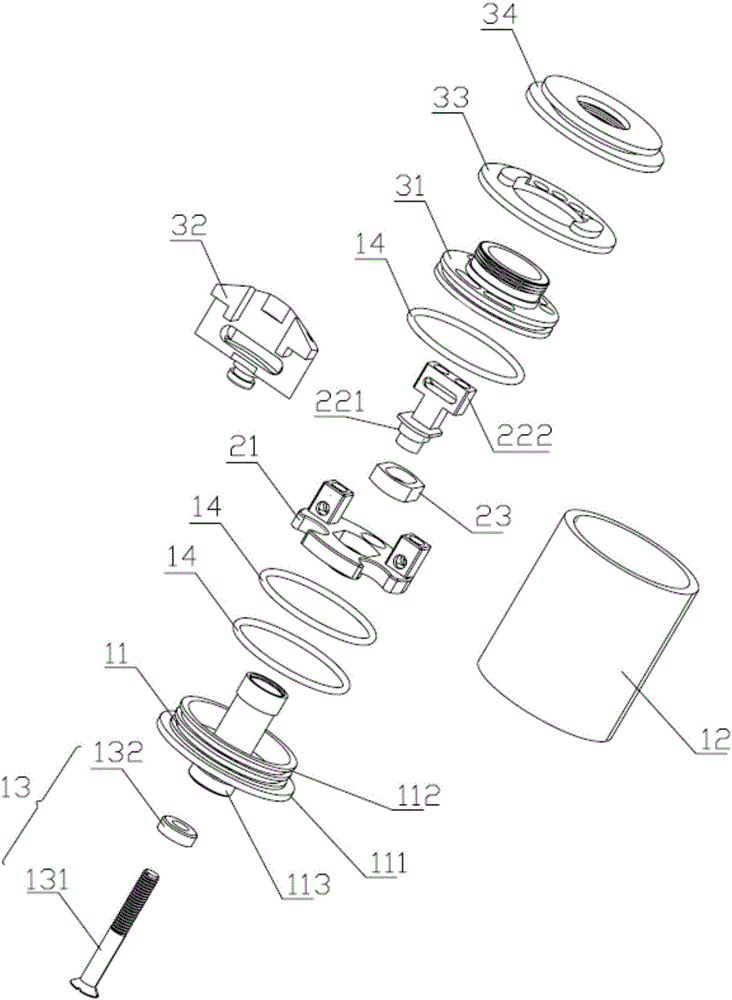

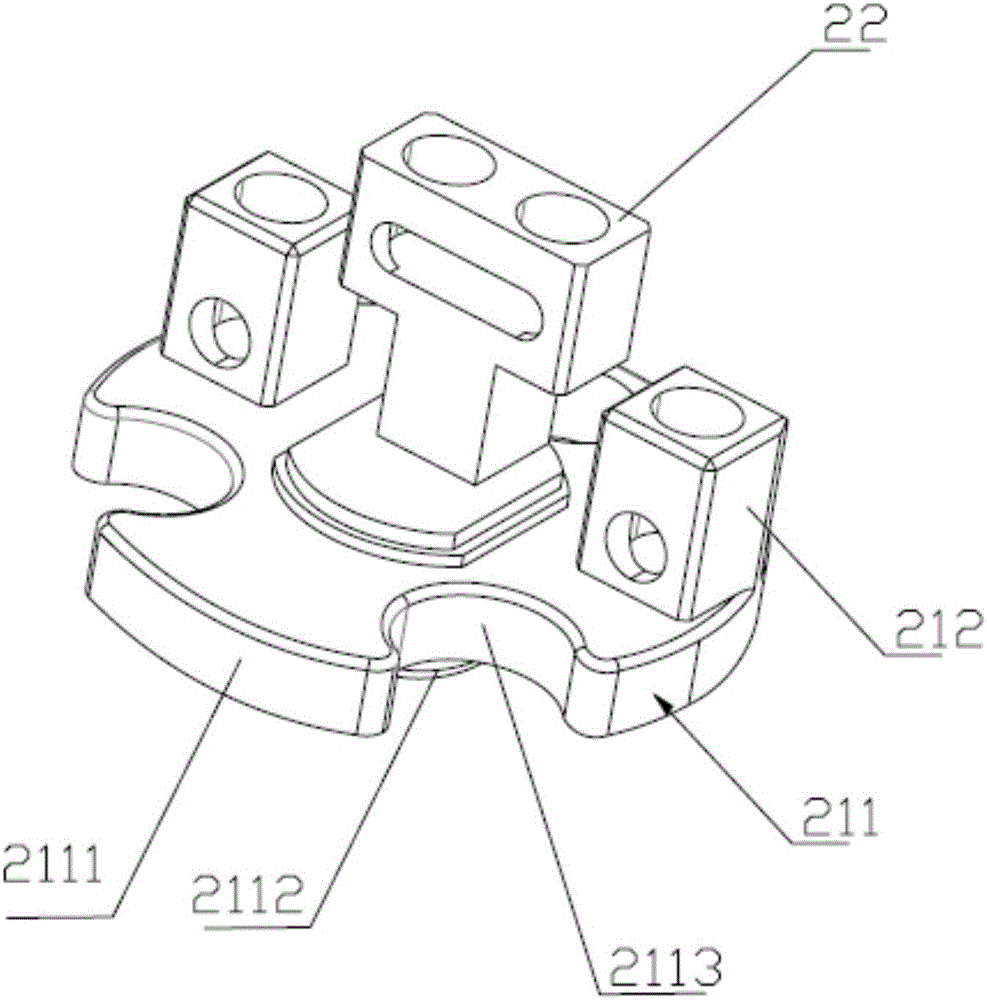

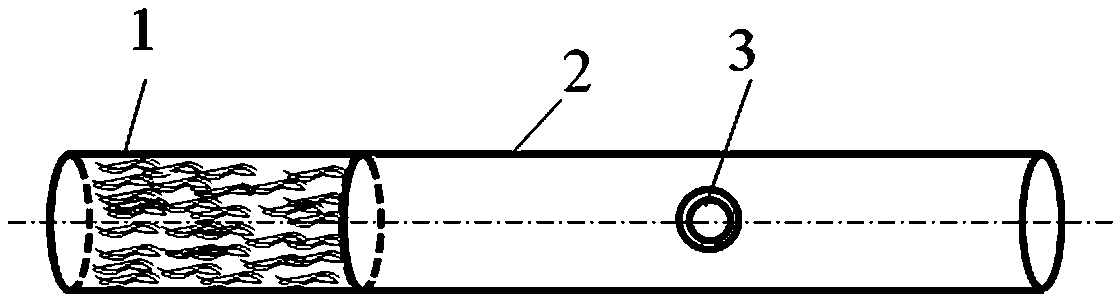

Electronic cigarette atomizer using vertical ceramic atomizing units

ActiveCN105996131AAvoid burnt smellFully contactedTobacco devicesMedical atomisersElectronic cigarette userMaterials science

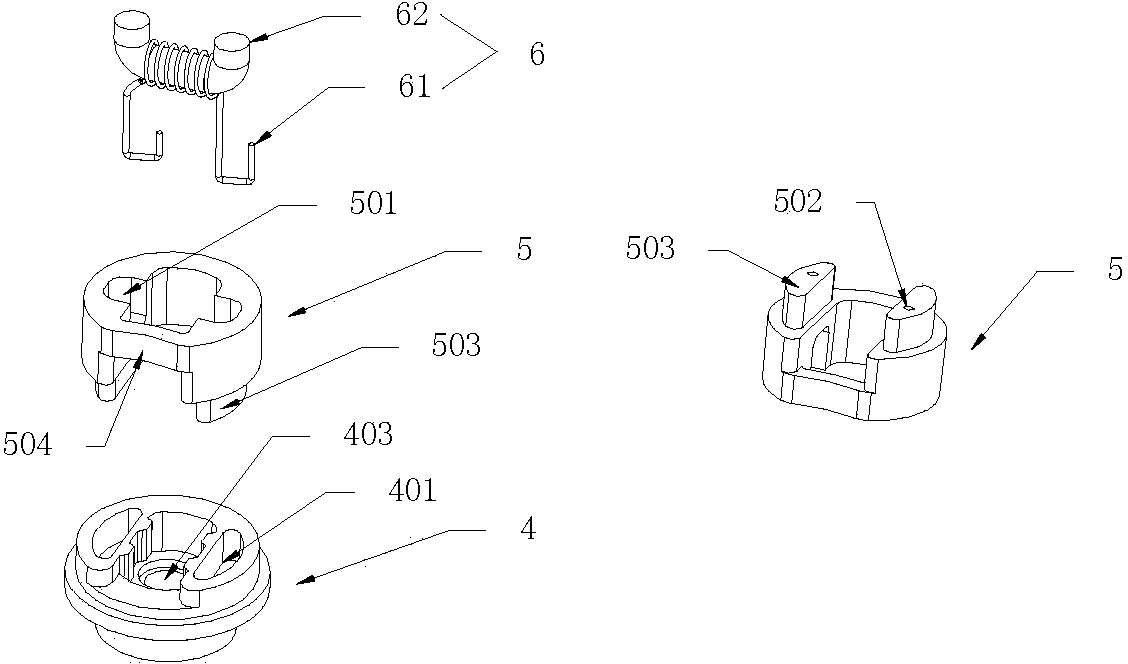

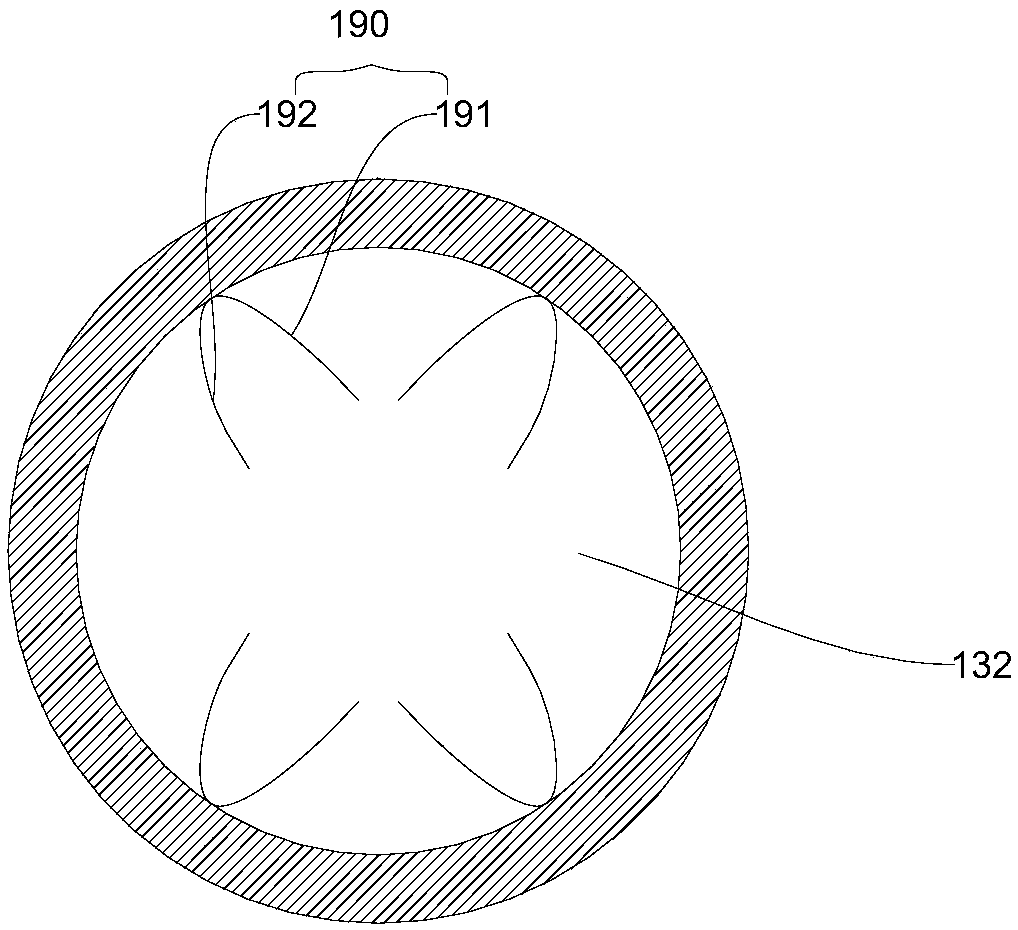

The invention discloses an electronic cigarette atomizer using vertical ceramic atomizing units. The electronic cigarette atomizer comprises an outer pipe, a liquid storage cup, a porous support sheet, a smoke liquid permeating sheet, an atomizing base, atomizing units, a sealing connecting base, and a power source connecting base, wherein each atomizing unit comprises a ceramic atomizing bar, a heating wire and a leading wire; each ceramic atomizing bar is made of a ceramic material; each heating wire is wound on the corresponding ceramic atomizing bar; each leading wire is connected with the two ends of the corresponding heating wire; each ceramic atomizing bar is vertically arranged in the atomizing base, the upper end surface of each ceramic atomizing bar is in contact and connection with the smoke liquid permeating sheet, and each ceramic atomizing bar is used for sucking the electronic cigarette liquid from the smoke liquid permeating sheet and conducting to the winding part of the corresponding heating wire; the sealing connecting base is in sealed connection with the atomizing base and the power source connecting base, and an axial hole is formed in the sealing connecting base along the axial direction; the power source connecting base is sheathed on the inner wall of the lower end of the outer pipe. The electronic cigarette atomizer has the beneficial effects that by adopting a plurality of vertical ceramic atomizing units, the atomizing effect of a large amount of smoke is realized; the burnt flavor caused by high-temperature burning is avoided, and the smoking mouth feel of an electronic cigarette user is greatly improved.

Owner:林光榕

Electronic cigarette atomizer

ActiveCN104223368AAvoid deformation or collapseAvoid burnt smellTobacco devicesElectronic cigarette userFlavor

The invention relates to an electronic cigarette atomizer. The electronic cigarette atomizer comprises an outer casing pipe, and an atomizing component, a filter, a permeating plate and a liquid storage cup, which are sequentially nested in the outer casing pipe; the atomizing component comprises a conductive connecting seat, a tubular electrode, an insulation sleeve, a fixed seat, a supporting seat, an atomizing unit and an insulating casing pipe, one end of the connecting seat is detachably connected with a battery pole, the tubular electrode is arranged in the center of the connecting seat, the insulation sleeve is arranged between the connecting seat and the tubular electrode, the fixed seat is connected with the connecting seat, the supporting seat is connected with the fixed seat and is made of a high-temperature-resisting hard insulation material, the atomizing unit is aerially arranged in the supporting seat and consists of a liquid guide piece and an electric heating wire which is wound on the liquid guide piece, and the insulating casing pipe sleeves the fixed seat and the supporting seat and is connected with the connecting seat in a sleeving manner. After the electronic cigarette atomizer is additionally provided with the fixed seat, the atomizing unit supporting seat is changed to be made of the high-temperature-resisting hard insulation material, so that the high-temperature deformation is prevented, the atomizing effect is effectively guaranteed, scorched flavor produced by the burning of the supporting seat caused by the high temperature of the electric heating wire also can be avoided, and the smoking taste of an electronic cigarette user can be greatly improved.

Owner:林光榕

Tobacco hydrolat as well as preparation method and application thereof

InactiveCN104178344AIncrease concentrationImprove the taste of cigarette smokingTobacco treatmentEssential-oils/perfumesBiochemical engineeringEnvironmental engineering

The invention discloses a tobacco hydrolat as well as a preparation method and an application thereof. The tobacco hydrolat is prepared by use of a method comprising the following steps: drying the collected waste tobacco powder, crushing, sieving by use of a sieve of 60 meshes, weighing and putting the same in a flask, adding a certain amount of deionized water, table salt and zeolite, mixing by shaking and then soaking for 2 hours; connecting a water diffusion steam distillation device, and turning on a heating jacket for heating reflux for 6-8 hours; layering the liquid to separate out the upper layer of oily liquid as a tobacco essential oil and the lower layer as the tobacco hydrolat. Applied to cigarette cut tobacco, the tobacco hydrolat has remarkable effects on improving the smoking taste of cigarettes and improving the interior quality such as favorable aroma of the cigarettes.

Owner:CHINA TOBACCO YUNNAN IND +1

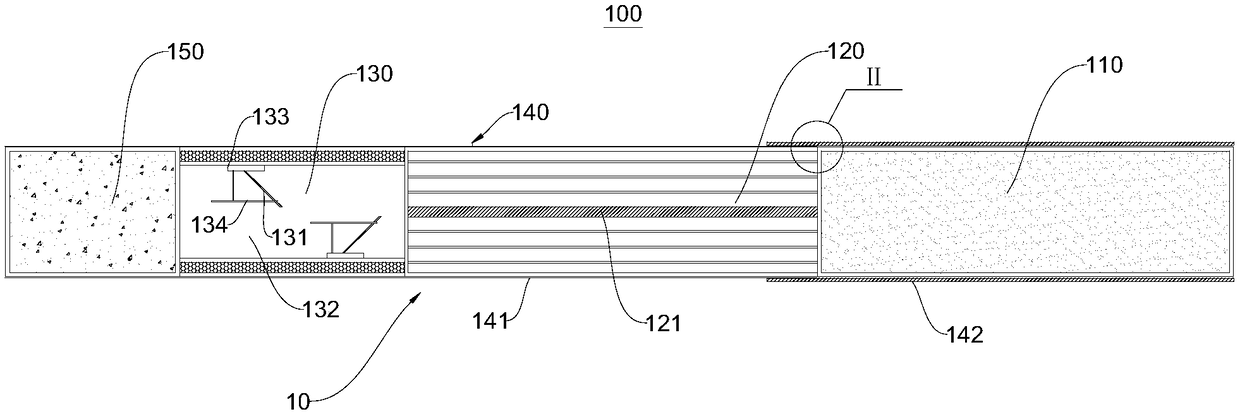

Heating-type smoke generating cigarette and heating-type smoke generating product

PendingCN108813713AAvoid pungent odorsReduce adsorptionTobacco preparationTobacco treatmentFiberPulp and paper industry

The invention provides a heating-type smoke generating cigarette and a heating-type smoke generating product, and relates to the technical field of cigarettes. The heating-type smoke generating cigarette comprises a smoke generating section, a cooling section, an isolating section and an acetate fiber section which are sequentially connected, as well as a piece of forming paper which is used for conducting fixing, wherein the forming paper includes a piece of first forming paper and a piece of second forming paper; the first forming paper covers the cooling section, the isolating section and the acetate fiber section, so that a composite stick is defined; and the second forming paper covers the composite stick and the smoke generation section. By conducting rubbing and connecting in the mode, a stuffed aroma-producing material can be further flattened in a rubbing and connecting process. The heating-type smoke generating product comprises the heating-type smoke generating cigarette; and the heating-type smoke generating cigarette is good in smoking taste and free from irritant smell.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

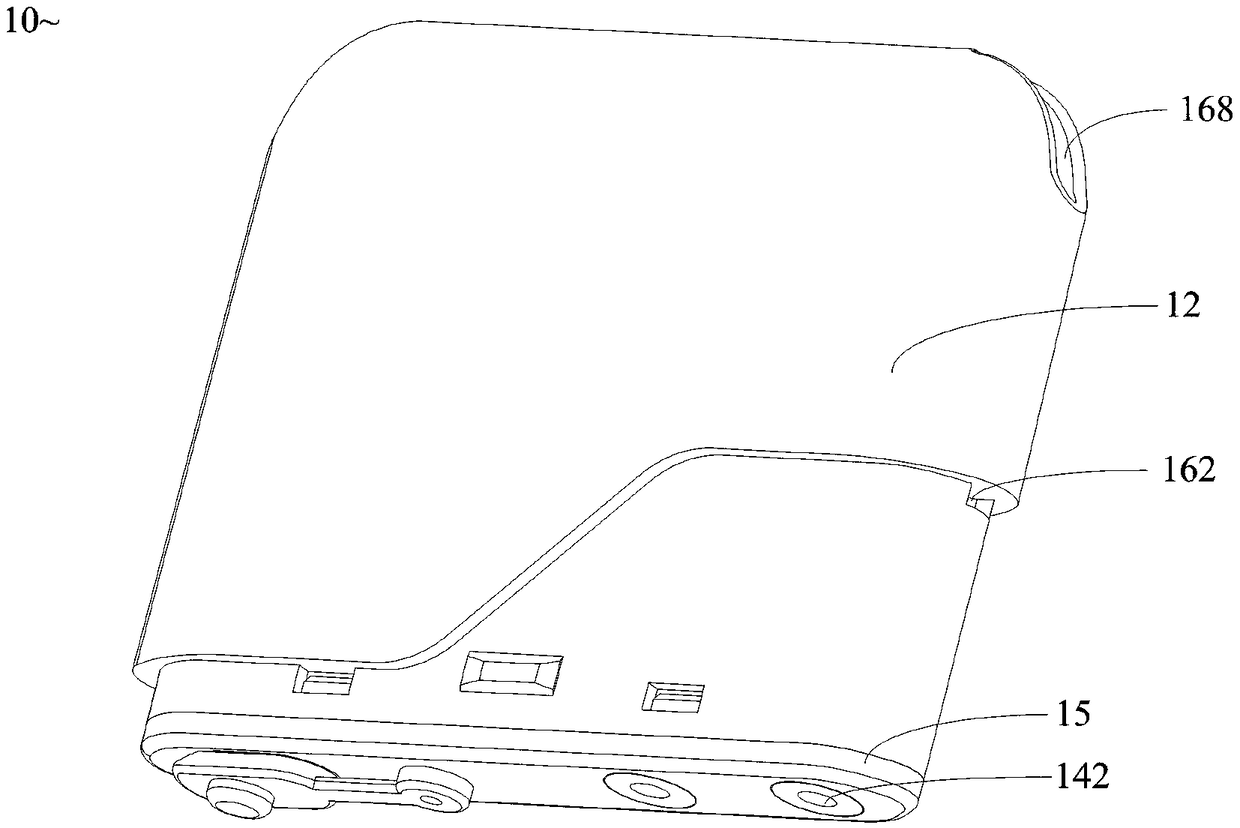

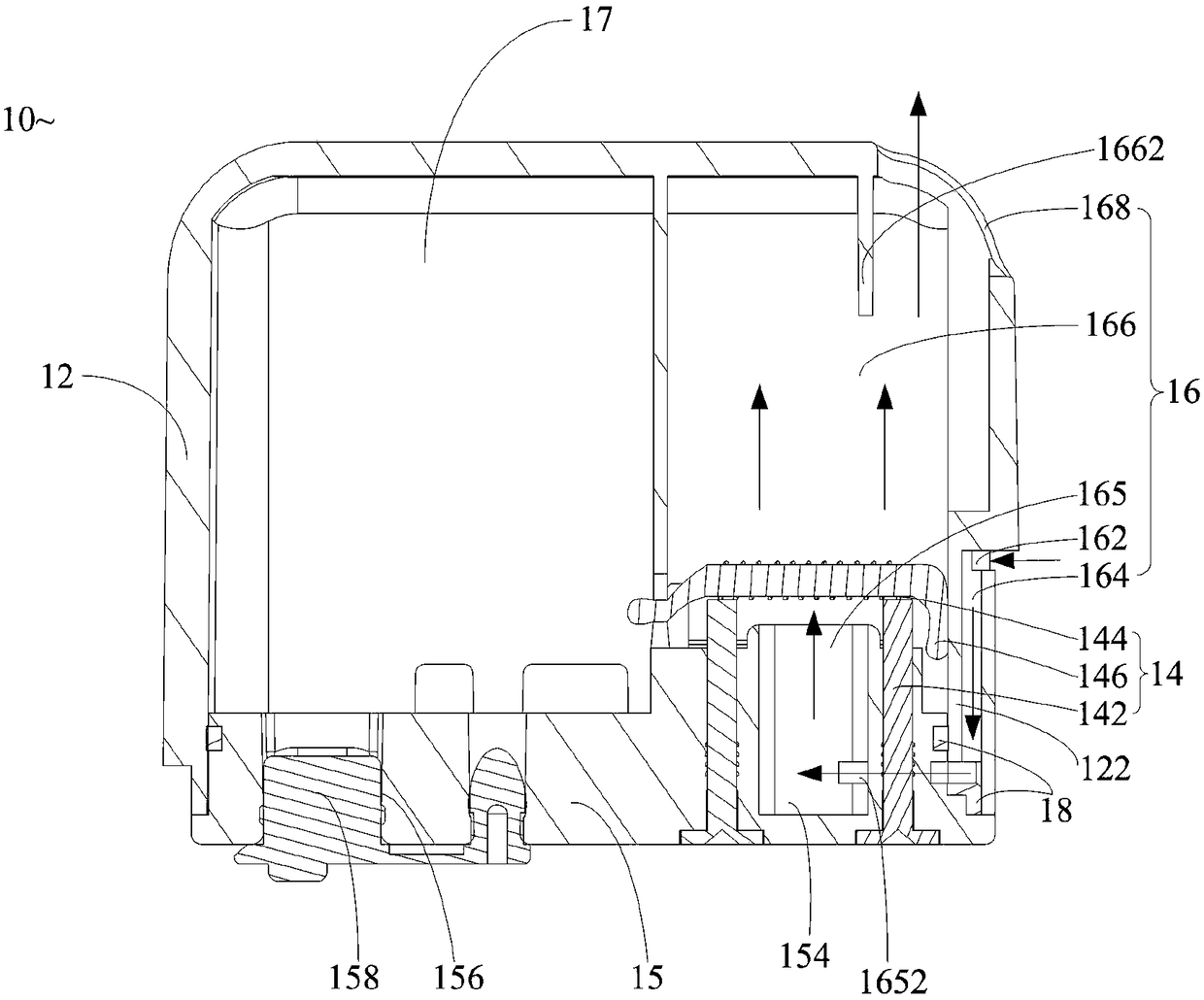

Atomizer and electronic cigarette with same

The invention relates to an atomizer and an electronic cigarette. The atomizer comprises a cover, an atomizing component and a base, the base is in inserted connection with the cover, and the atomizing component is packaged in the cover. The atomizer further comprises a first airflow passage and an oil storage chamber, and the first airflow passage and the oil storage chamber are formed by internal partition of the cover. The atomizing component is arranged in the first airflow passage which comprises an air inlet section and an atomizing section, and the atomizing section and the air inlet section are communicated with a suction nozzle of the atomizer and an air inlet hole of the side wall of the cover. The electronic cigarette with the atomizer comprises a mainframe and the atomizer, themain frame and the atomizer are in inserted connection, the side wall of the cover is provided with an atomizer triggering mainframe pneumatic switch and an air inlet hole of airflow required by cigarette oil atomizing, on and off of the electronic cigarette can be controlled by air suction at the suction nozzle, and circuit board damages caused by flowing out of condensate generated after high-temperature atomization from the base are avoided. Before atomization, airflow convergence is realized through air inlet passages prior to atomization by the atomizing component, so that pure taste ofatomized cigarette oil can be guaranteed, air suction due to mixing of much air is prevented, and great smoking taste and user experience improvement are realized.

Owner:SHENZHEN YOUME NETWORK TECH CO LTD

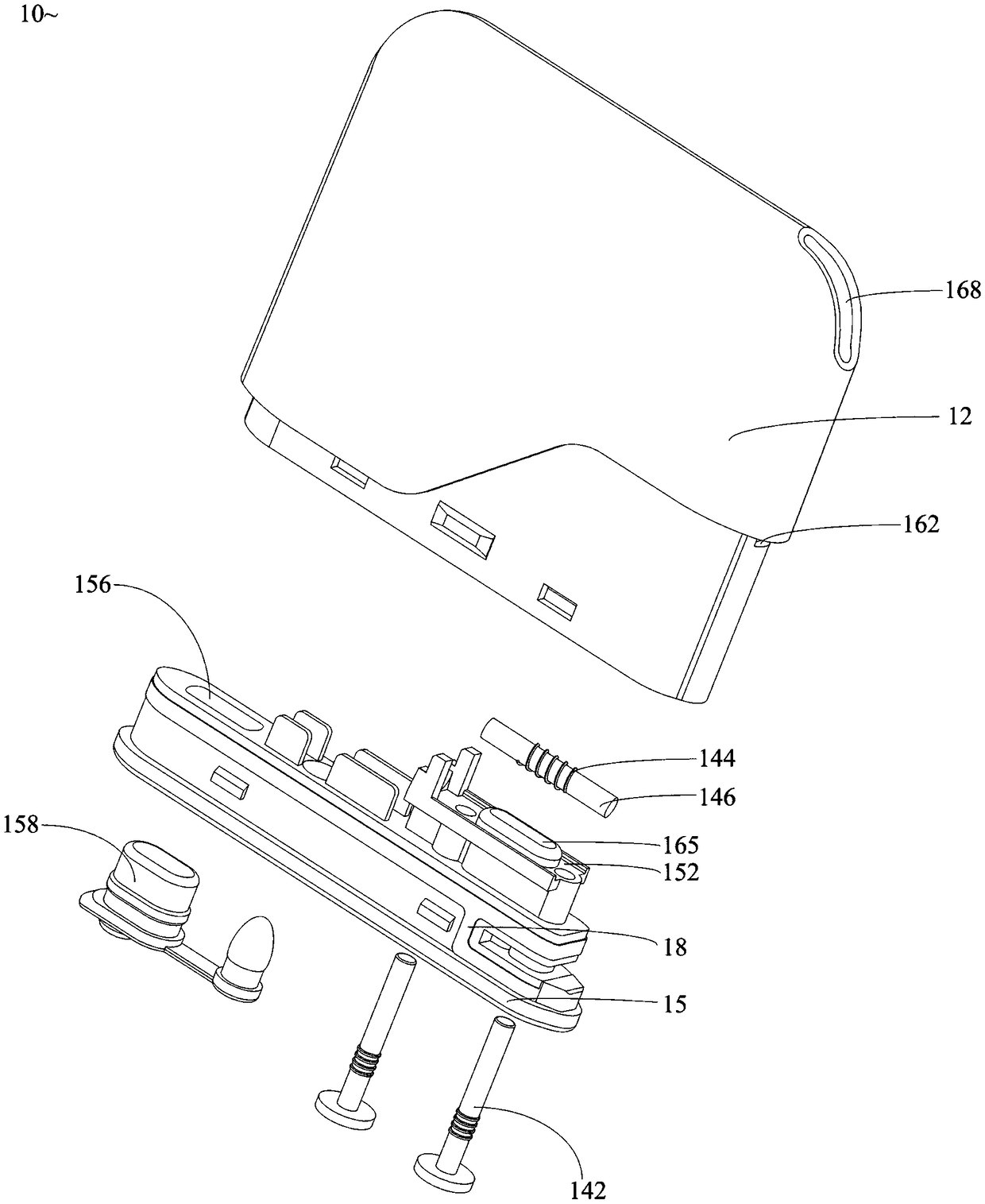

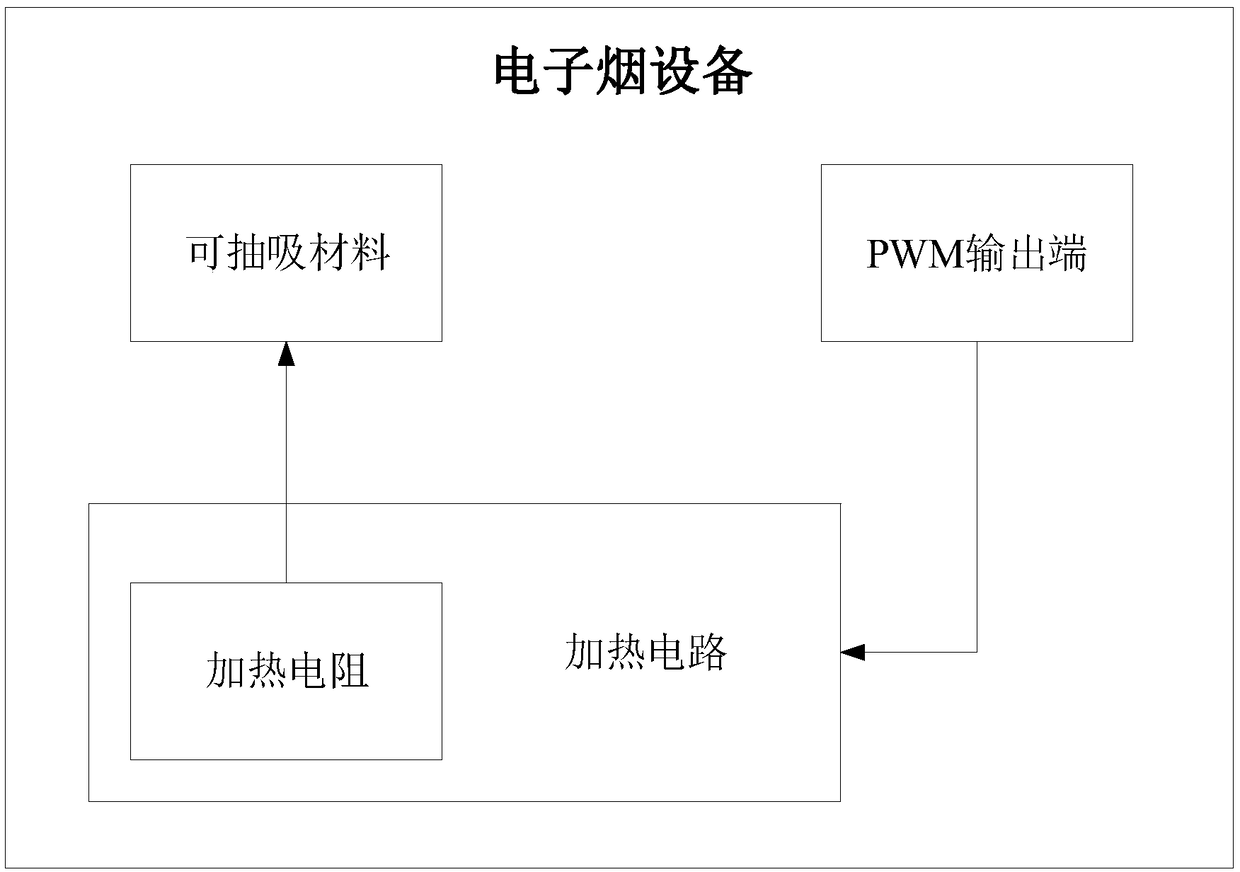

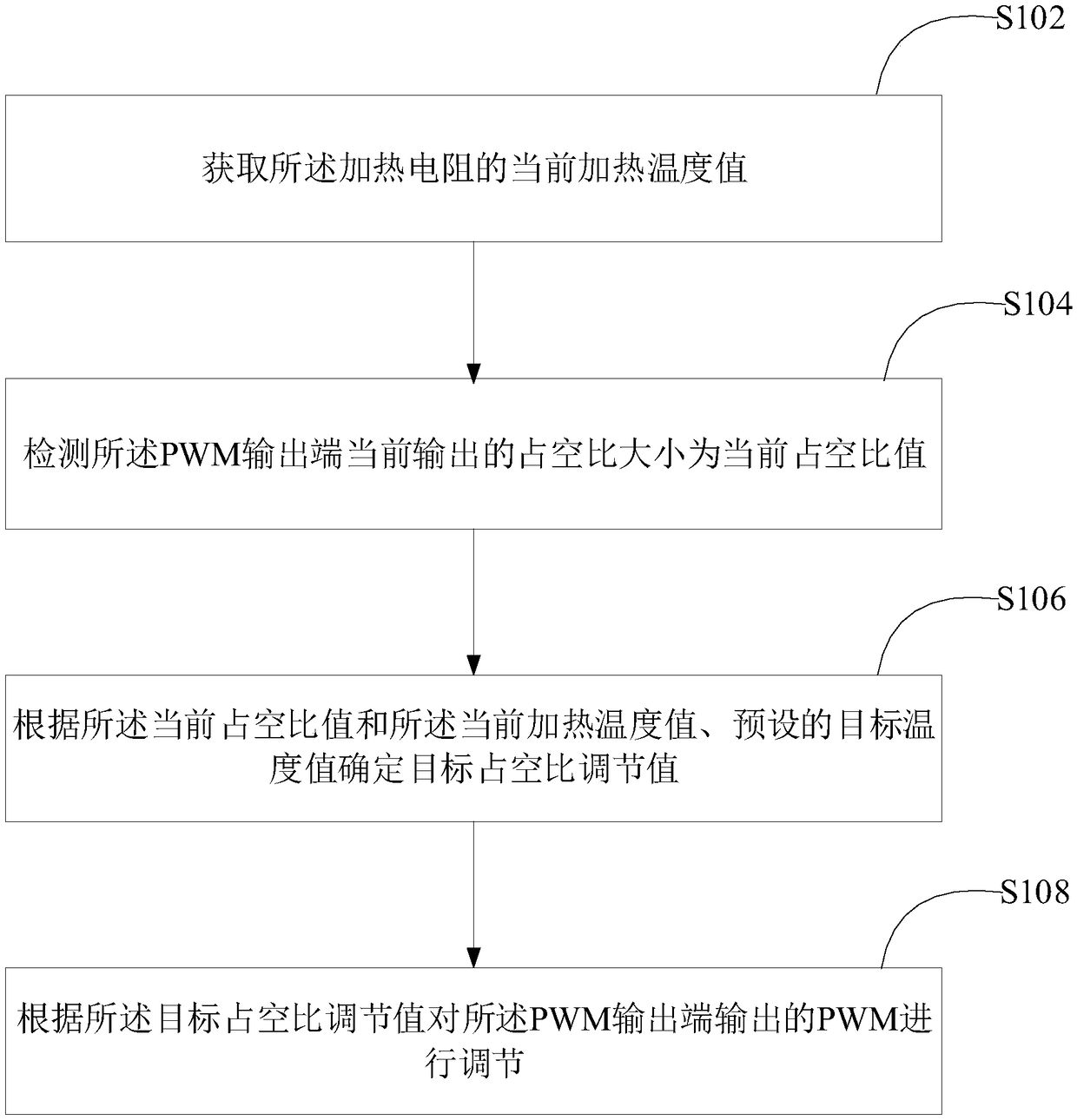

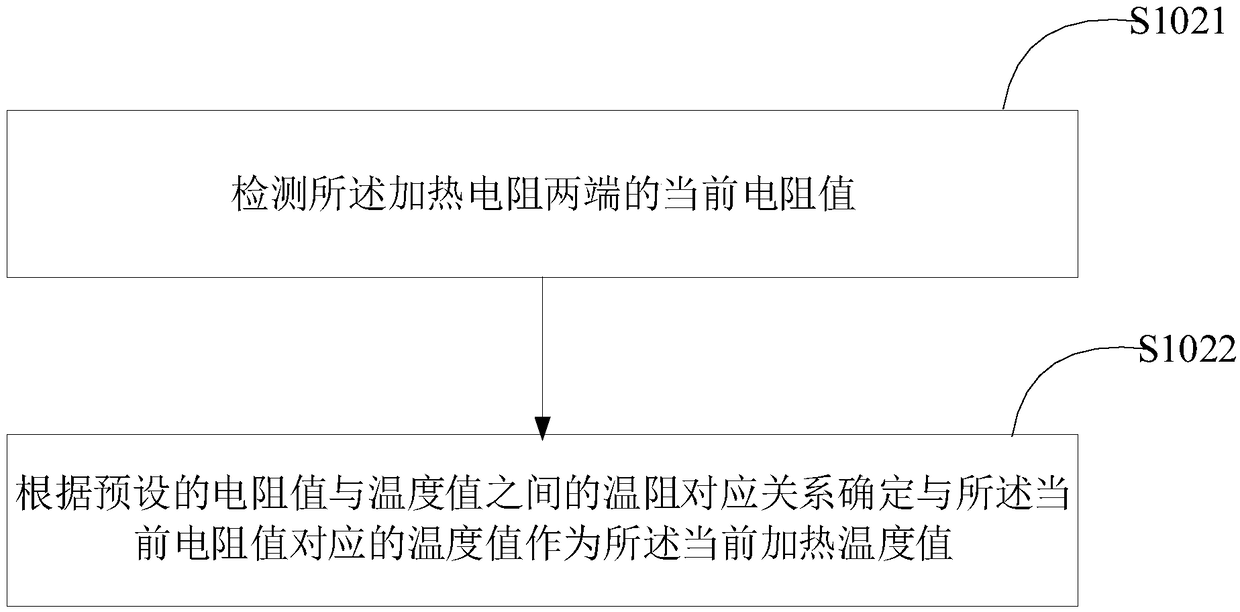

Control method and device for electronic cigarette heating temperature

ActiveCN108873981AEasy to controlImprove accuracyAuxillary controllers with auxillary heating devicesFlueEngineering

The embodiments of the invention provide a control method for electronic cigarette heating temperature. The method is based on an electronic cigarette apparatus which comprises a heating circuit; theheating circuit comprises a heating resistor; an input end of the heating circuit is connected with a PWM output end; power is supplied to the heating resistor via the heating circuit to heat a smokable material in the electronic cigarette apparatus so that a user can smoke. The method comprises the steps of: acquiring a current heating temperature value of the heating resistor; detecting the dutyratio currently output by the PWM output end, which is regarded as the current duty ratio; determining a target duty ratio adjusting value according to the current duty ratio, the current heating temperature value and a preset target temperature value; adjusting the PWM output by the PWM output end according to the target ratio adjusting value. According to the invention, the accuracy of heatingtemperature value of flue-cured tobacco type electronic cigarettes can be improved and the experience of users can be improved.

Owner:深圳佳聚电子技术有限公司

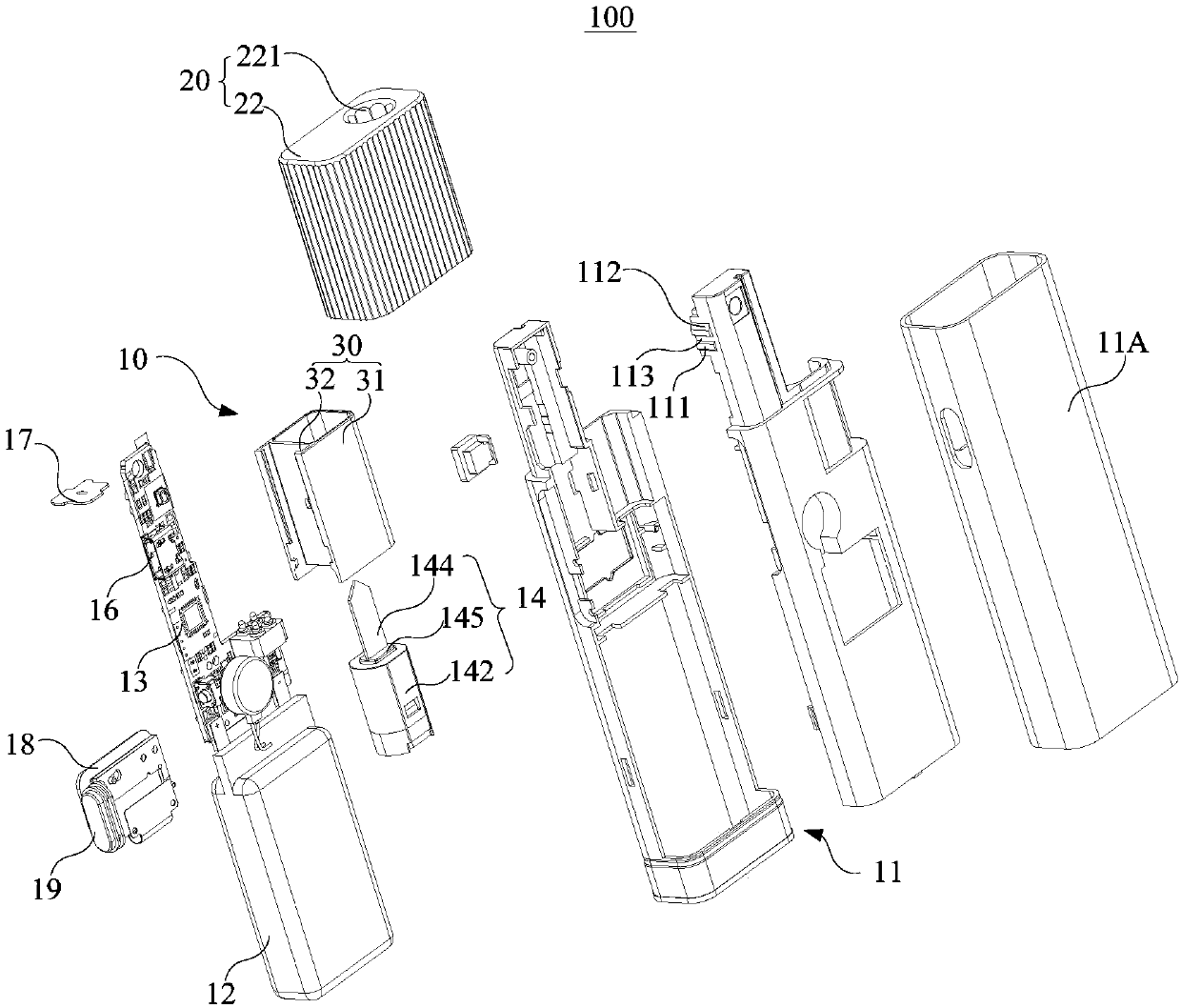

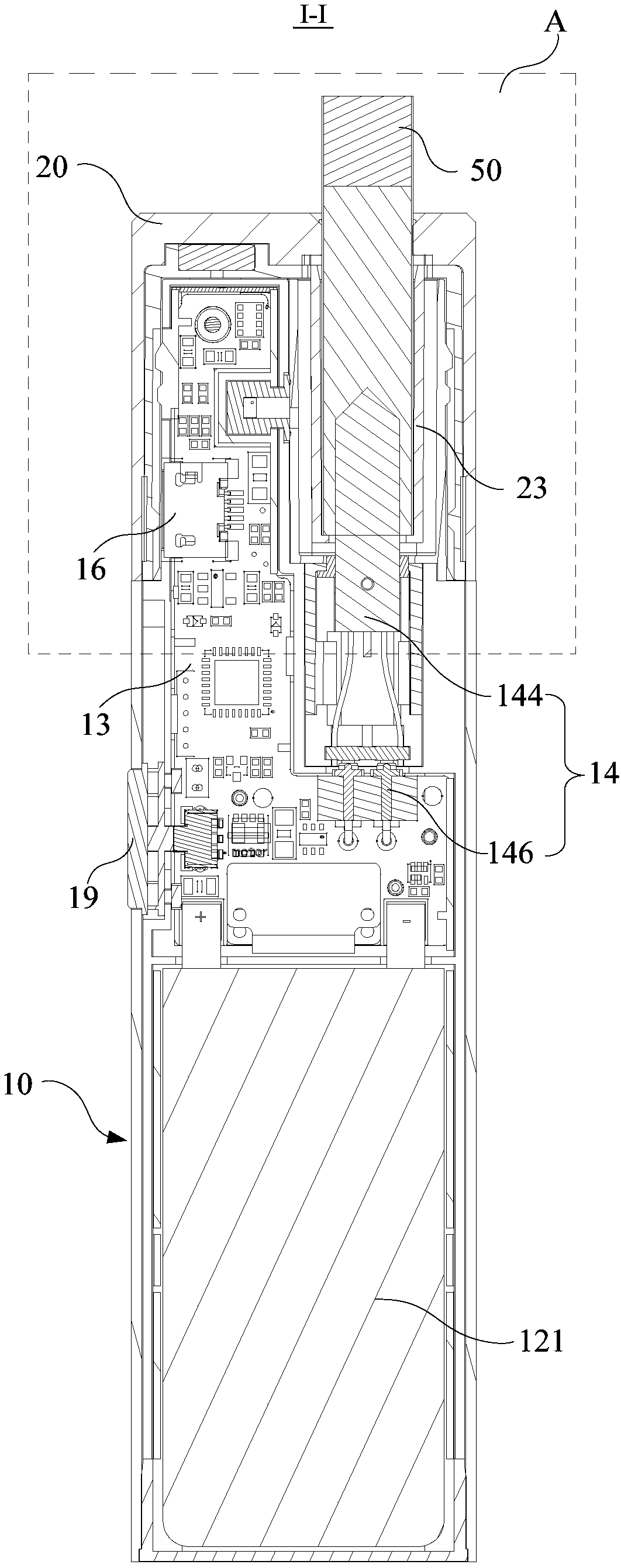

Disposable electronic cigarette

InactiveUS20140311506A1Improve ventilationEasy to adjustTobacco pipesTobacco devicesElectronic cigaretteEngineering

This invention discloses a disposable electronic cigarette, comprising a cigarette holder and a cigarette rod, the cigarette holder defining an air outlet hole, wherein, at least three air inlet holes are defined in a cigarette rod wall of the cigarette rod, the air inlet holes and the air outlet hole cooperatively form an airflow loop, and at least one indicator light corresponding to the air inlet holes is mounted on the cigarette pipe to indicate positions of the air inlet holes and / or operation states of the electronic cigarette. When users holds the electronic cigarette, the indicator light will indicate the positions of the air inlet holes, and users can adjust the air inflow amount to keep a smooth airflow.

Owner:KIMREE HI TECH

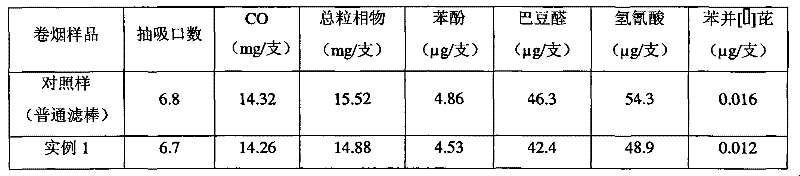

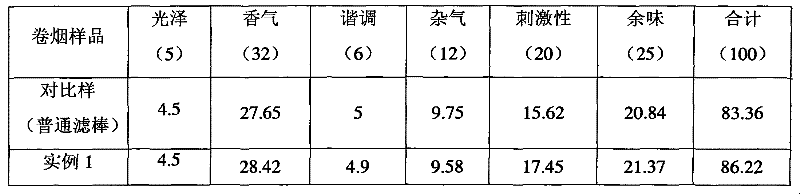

Paper cigarette filter stick and manufacturing method thereof

InactiveCN106617288AImprove the taste of smokingCause collapseTobacco smoke filtersPulp and paper industryPaper filter

The invention relates to a paper cigarette filter stick and a manufacturing method of the paper cigarette filter stick. The manufacturing method comprises the steps of pretreatment on tobacco raw materials, preparation of coating materials, preparation of plant fiber layers, spraying and drying, and the like. Compared with the traditional paper filter stick, the paper filter stick provided by the invention is free of paper taste and good in smoking mouthfeel, and has good moisture retention function, and the moist feel of smoke is promoted; the paper cigarette filter stick has the aroma enhancement function, so that the smoke has strong intrinsic aroma of tobacco, and is suitable for low-tar cigarettes; the paper cigarette filter stick has good appearance and special color, and thus certain visual impact can be formed.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

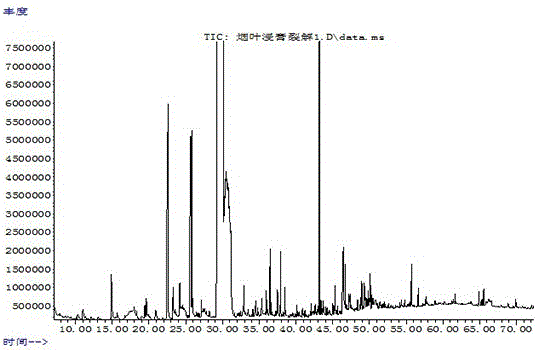

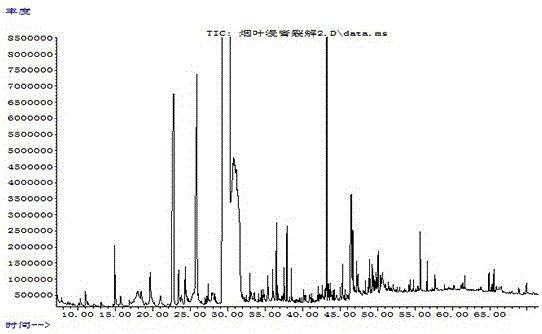

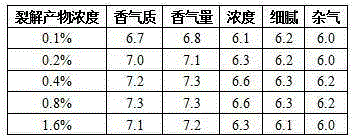

Tobacco extract pyrolysis product and application thereof in novel tobacco product

The invention belongs to the technical field of cigarette production, and particularly relates to a tobacco extract pyrolysis product and an application thereof in a novel tobacco product. The tobacco extract pyrolysis product is applied to the novel tobacco product, a preparation method comprises the steps of preparing tobacco extract, conducting pyrolysis on the tobacco extract, conducting evaporation and concentration through vacuum rotating and the like. According to the tobacco extract pyrolysis product and the application thereof in the novel tobacco product, the tobacco extract pyrolysis product is added to the novel cigarette product, the smoking quality of the novel cigarette product is better improved, the taste is close to that of a traditional cigarette, natural incense of smoke is obvious, satisfaction of the smoke is strong, the feel of engendering liquid is obviously enhanced for the novel cigarette product, the degree of comfort is improved, the smoking characteristic is almost the same as that of the traditional cigarette, the requirements of customers for smoking taste, physiology and psychology on the novel cigarette product are better met, and the novel cigarette product has better application and promotion value.

Owner:CHINA TOBACCO HENAN IND +1

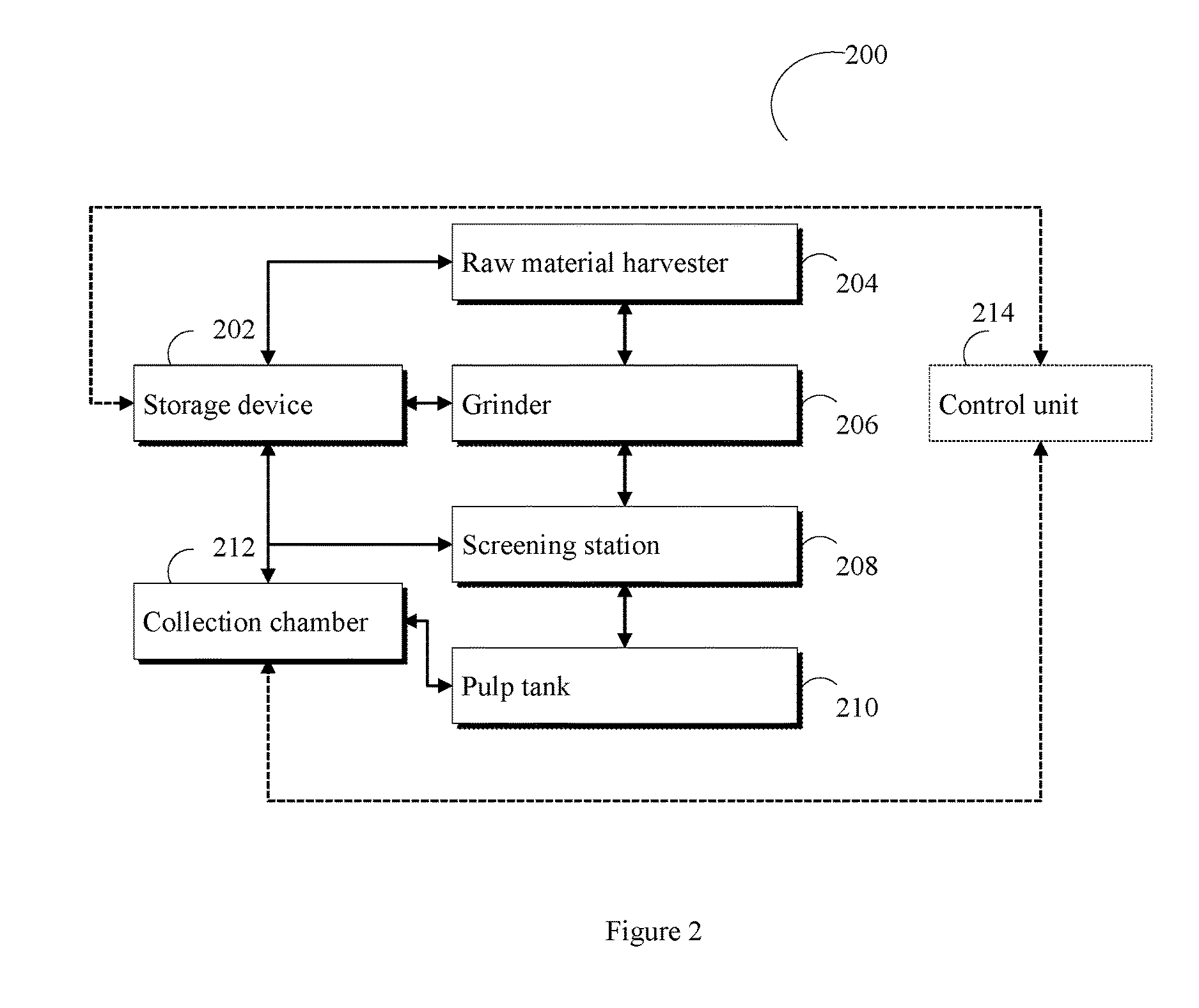

Method capable of remarkably increasing softness and absorptivity of papermaking-method reconstituted tobaccos

Disclosed is a method capable of remarkably increasing softness an absorptivity of papermaking-method reconstituted tobaccos. Water is added in quick lime, so that clarification lime aqueous solution with the concentration of 0.04% to 0.16% is produced after reaction; solid-phase tobacco materials extracted in a pulping working section in a papermaking-method reconstituted tobacco work flow are pulped, and the concentration of the pulp ranges from 2% to 5%; the pulp is in alkali treatment by the clarification lime aqueous solution, during treatment, the ratio of solid to liquid is 1:4 to 1:6, treatment temperature ranges from 25 DEG C to 60 DEG C, and treatment time ranges from 20 minutes to 45 minutes; and finally, the pulp after being in alkali treatment is formed in a paper making manner. Extracted solid fibers are treated by softer alkali reagent, the softness and the absorptivity of the papermaking-method reconstituted tobaccos can be improved, the fibers cannot be destroyed, and offensive and irritancy of the prepared reconstituted tobaccos are low.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Preparation method of tobacco oil additive and tobacco oil

InactiveCN106063583ALess irritatingImprove the taste of smokingTobacco treatmentTobacco devicesBenzoic acidAlcohol

The invention discloses a preparation method of a tobacco oil additive and tobacco oil. The preparation method comprises the following steps: diluting benzoic acid with alcohol to obtain an alcohol benzoate solution; diluting nicotine with propylene glycol to obtain a nicotine propylene glycol solution; mixing the alcohol benzoate solution with the nicotine propylene glycol solution to obtain the tobacco oil additive. According to the technical scheme, the tobacco oil additive can reduce the irritation of nicotine-containing tobacco oil to the sense organs of a consumer smoking the tobacco oil, improve the smoking taste of the tobacco oil and increase the softness and the smoothness of smoking.

Owner:深圳昱朋科技有限公司

Atomizer and electronic cigarette thereof

ActiveCN105876868AFill in the blanks selectedChange intake modeTobacco devicesElectronic cigaretteEngineering

The invention provides an atomizer and an electronic cigarette thereof. The atomizer provided by the invention comprises a liquid storage assembly, an atomizing and heating assembly and an air adjusting assembly, wherein the liquid storage assembly comprises a liquid storage pipe and a lower cover mounted at the bottom end of the liquid storage pipe; the atomizing and heating assembly is mounted in the liquid storage pipe and a liquid storage cavity is enclosed by the atomizing and heating assembly and the lower cover; the air adjusting assembly comprises an upper cover, a connection part and an adjusting ring; air inlet holes are formed in the two sides of the periphery of the upper cover; the upper cover is mounted at the top in the liquid storage pipe and an atomization space is formed between the upper cover and the atomizing and heating assembly; the connection part is mounted in the liquid storage pipe and is connected with the bottom end of a covering part; the connection part is used for guiding airflow entering the air inlet holes into the bottom end of the atomization space; the bottom end of the connection part is inserted onto the atomizing and heating assembly; the adjusting ring rotatably sleeves a pipe part; the adjusting ring is provided with a ventilation hole; and the ventilation hole can be selectively communicated with the air inlet holes in the two sides of the periphery through rotating the adjusting ring. According to the atomizer, upper and lower air inlet modes can be converted through rotating the adjusting ring and a consumer can select the air inlet manner according to requirements.

Owner:JOYETECH EURO HLDG

Heating method for electronic cigarette

InactiveCN109998182AEasy temperature controlImprove the taste of smokingTobacco devicesElectrical resistance and conductanceComputer module

The invention provides a heating method for an electronic cigarette. The heating method for the electronic cigarette has advantages of high economy, sufficient heating and good taste. The heating method includes the following steps: (1) establishing a TCR curvilinear relationship of the electronic cigarette; (2) outputting a high level to exert voltage to a heating core through a PWM module with an adjustable duty cycle, and using the heating core to heat the electronic cigarette; (3) reading voltage values of two electrodes of the heating core through an MCU of the electronic cigarette instantly when a square wave outputted by the PWM module is the high level, obtaining an actual heating voltage VH and a heating current value IH of the heating core, obtaining a resistance value RH of theheating core according to a formula of R=U / I, and obtaining a temperature value TH of the heating core by means of the resistance temperature coefficient formula; and (4) adjusting input voltage and current after the temperature of the heating core is obtained to enable the temperature of the heating core to be gradually close to a temperature target value T1 of the electronic cigarette heating, and so on, the temperature of the heating core can be consistent with the temperature target value of the electronic cigarette heating and remains at T1. The heating method can be applied to the fieldof electronic cigarettes.

Owner:ZHUHAI LUCKYMAN TECH CO LTD

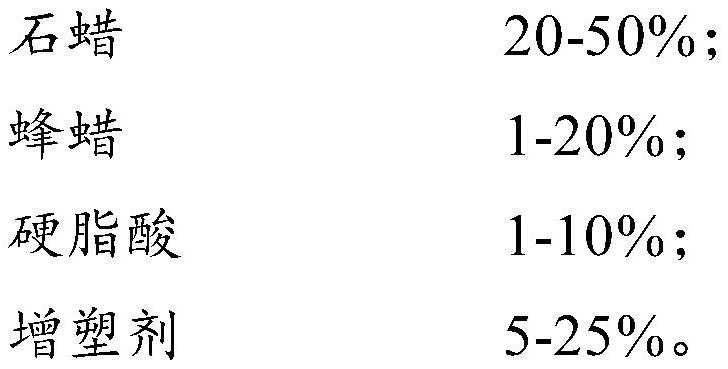

Mint tobacco filter stick and preparation method thereof

ActiveCN101912161BIncrease the amount of aromaImprove the taste of smokingTobacco smoke filtersFiberHazardous substance

The invention discloses a filter material of a cigarette filter stick and a composite filter stick made of the same. The filter material comprises a fiber base material and a plasticizer, wherein a Chinese herbal medicinal mixture of 3 to 4 weight parts of mint and 2 to 3 weight parts of blackberrykiky rhizome and 4 weight parts of tobacco leaf powder particles are added into the fiber base material; the granularity of the mixed particles is 40 to 80 meshes; and the additive amount is that each millimeter of filter stick contains 1.0 to 1.5mg of Chinese herbal medicinal mixed particles. The mint and blackberrykiky rhizome mixed particles are used as the adsorbing material of the functional composite filter stick, and factors such as the additive proportion and additive amount of the mint and the blackberrykiky rhizome, the granularity of the particles, the additive amount of the plasticizer and the like are determined. A cigarette finished product consists of the composite filter stick, cut tobacco and cigarette paper rolls and can effectively reduce harmful substances in smoke, cannot influence the flavor of cigarettes, and has the effects of moistening throat, hydrating, reducing the stimulation of the smoke to the throat and the like.

Owner:CHINA TOBACCO GUANGDONG IND

Smoking set

The invention discloses a smoking set. The smoking set comprises a housing and a smoking pipe, the smoking pipe is located in the housing, the smoking pipe is connected with the housing and used for accommodating tobacco products, an avoidance hole is formed in the bottom wall of the smoking pipe, the avoidance hole is used for inserting a heating member to heat and atomize the tobacco products, gaps are arranged between the side wall enclosing the avoidance hole and the outer wall of the heating member, and an air inlet hole is formed in the side wall of the smoking pipe. By forming the air inlet hole in the side wall of the smoking pipe which accommodates the tobacco product, the tobacco products which are located further away from the heating member can be thoroughly heated by combininglateral air inlet and bottom air inlet to improve the utilization rate of the tobacco products, the smell of burning generated by the excessive heating of the tobacco products which are located excessively close to the heating member is avoided, and therefore the smoking taste is improved.

Owner:SHENZHEN SMOORE TECH LTD

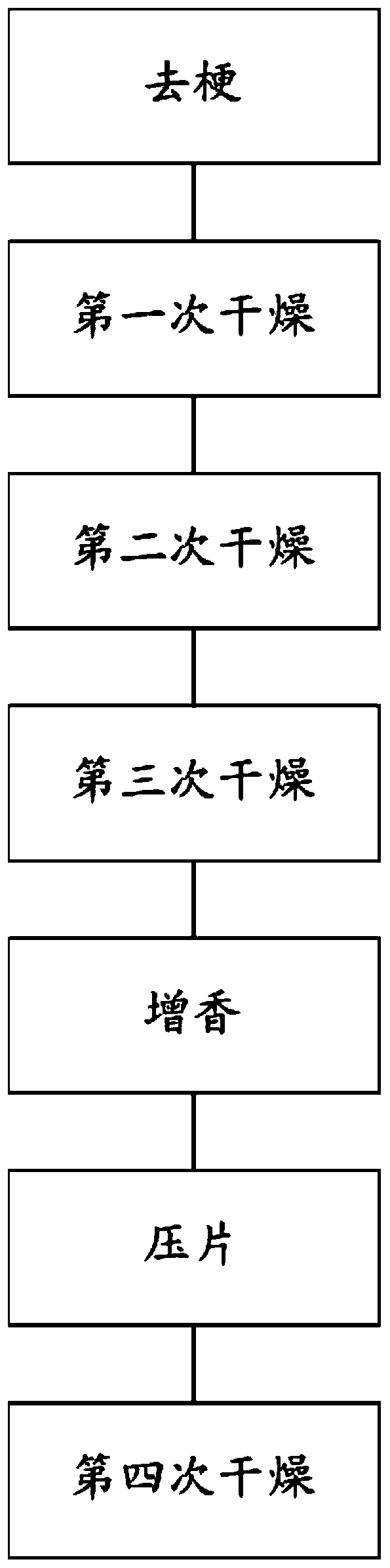

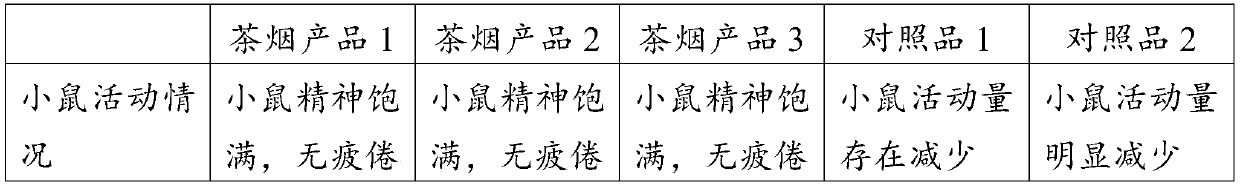

Preparation method and application of shredded tea leaves to preparation of tea cigarette cartridge

PendingCN109757761ALow lignin contentImprove the taste of smokingTobacco preparationTobacco treatmentCombustionMoisture

The invention belongs to the field of research and development of tea products and particularly relates to a preparation method and application of shredded tea leaves to the preparation of a tea cigarette cartridge. The invention provides the preparation method of the shredded tea leaves, which is a segmented drying method; the segmented drying method is that after stems of tea leaves are removed,primary drying, secondary drying, tertiary drying, tabletting and quaternary drying are sequentially performed, so that a product with a moisture content of 7-15 percent is obtained. The invention further provides the application of the shredded tea leaves prepared by the preparation method to the fields such as rolled cigarette-like structure smoking and / or brewing drinking. In the technical scheme provided by the invention, the content of lignin can be effectively reduced after stem removal, so that smoke during combustion is reduced, and the smoking taste is improved; further, the productcan be obtained by performing animal experiment determination; compared with that of a commercially-available tea cigarette, a refreshing effect is significantly improved; through smoking determination by an evaluator, the smoking score of the product is higher; the technical defects of larger smoke of the commercially-available tea cigarette, poor smoking and refreshing effects and poor smoking experience in the prior art are overcome.

Owner:FUJIAN GREEN GOLD BIOTECH CO LTD

Atomizing agent for electronic cigarette and electronic cigarette liquid

The invention relates to an atomizing agent for an electronic cigarette and electronic cigarette liquid, in particular to an atomizing solvent for the electronic cigarette, and belongs to the field of novel tobaccos. The atomizing solvent is free of obvious sweet and greasy taste. According to the technical scheme, the atomizing agent for the electronic cigarette comprises a fogging element, a smoke thickening element and a viscosity adjusting element. The viscosity adjusting element comprises propylene carbonate which accounts for 10%-40% of the total mass of the atomizing agent. The atomizing agent is free of the obvious sweet and greasy taste. The thick and full feeling of smoke can be guaranteed, the viscosity of the atomizing agent can be greatly reduced, the fluidity and instant atomizing capacity of the atomizing agent are improved, the large smoke amount is guaranteed, and the influences of water and / or ethyl alcohol on the suction effect and safety can be avoided. The atomizing solvent can be widely applied to preparing the electronic cigarette liquid.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Porous ceramic composition and preparation method thereof and electronic cigarette atomization core using ceramic composition

InactiveCN112679202AImprove flexural strengthHigh affinityTobaccoCeramicwareElectronic cigaretteSmoke Emission

The invention discloses a porous ceramic composition and a preparation method thereof and an electronic cigarette atomization core using the ceramic composition, and relates to the technical field of porous ceramics. The porous ceramic composition comprises the components in percentage by mass: 0-40% of purple clay, 30-70% of diatomite, 1-20% of quartz sand, 1-20% of glass powder, and 10-50% of a pore forming agent, wherein the sum of the total amount of the quartz sand and the glass powder is less than or equal to 25%. The purple clay is added into the porous ceramic composition to improve the affinity of porous ceramic and tobacco tar, and the smoking taste is improved. The flexural strength of the porous ceramic is improved by adding the quartz sand and the glass powder. The problems that in the prior art, porous ceramic is poor in strength, the porous ceramic is prone to damage and powder falling in the assembling process, the binding force between the porous ceramic and a metal heating circuit is poor, and the metal heating circuit is prone to being separated from the porous ceramic to be burnt are solved. The porous ceramic provided by the invention is simple in preparation method and high in production efficiency.

Owner:SHENZHEN JIYOU TECH CO LTD

Tobacco sheet and tobacco product

InactiveCN105212260AImprove smoking qualityAvoid wastingTobacco treatmentCigar manufactureEngineeringTobacco product

The invention provides a tobacco sheet and a tobacco product. Tobacco fruits are added as an additive into the tobacco sheet, wherein the weight ratio of the additive to the tobacco sheet is 0.01% to 5%. By adding the additive, miscellaneous gas in smoke can be reduced on the whole, smoke irritation is reduced, smoke concentration and smoke grouping can be improved, tobacco fragrance can be optimized, smoking taste can be improved, and elegant fragrance of tobacco smoke can be improved. The smoking quality of cigarettes can be improved, the tobacco fruits are made effective use, and resource waste is avoided.

Owner:何氪 +4

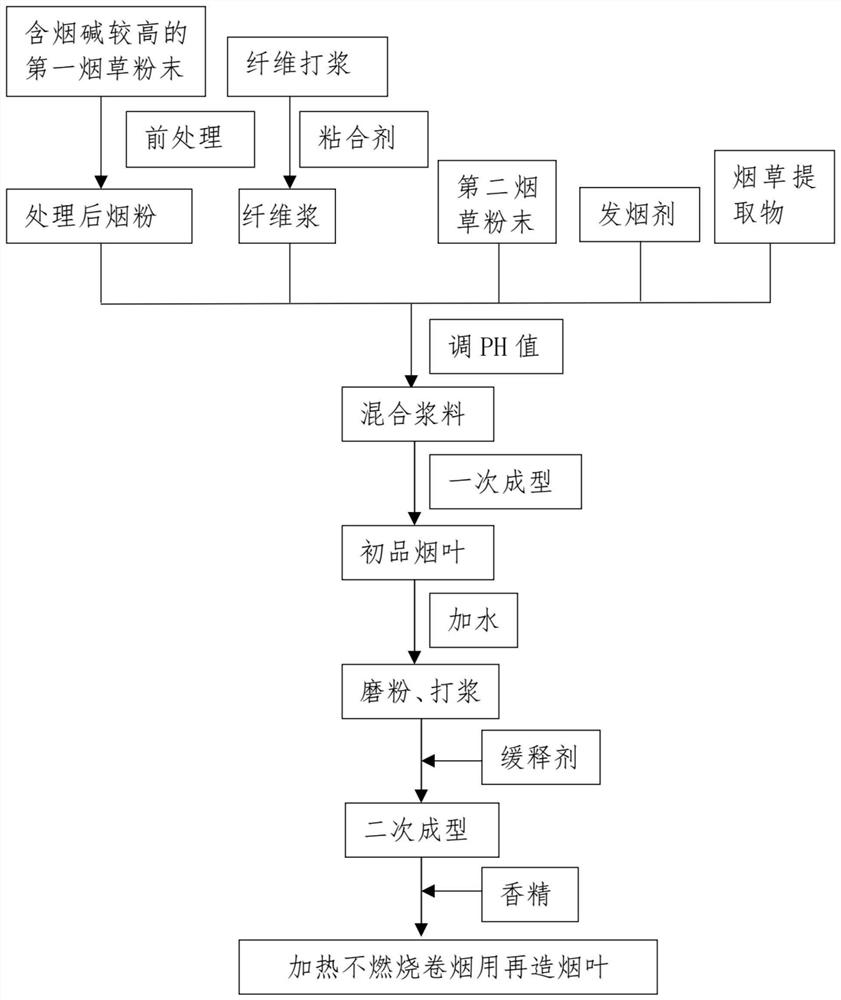

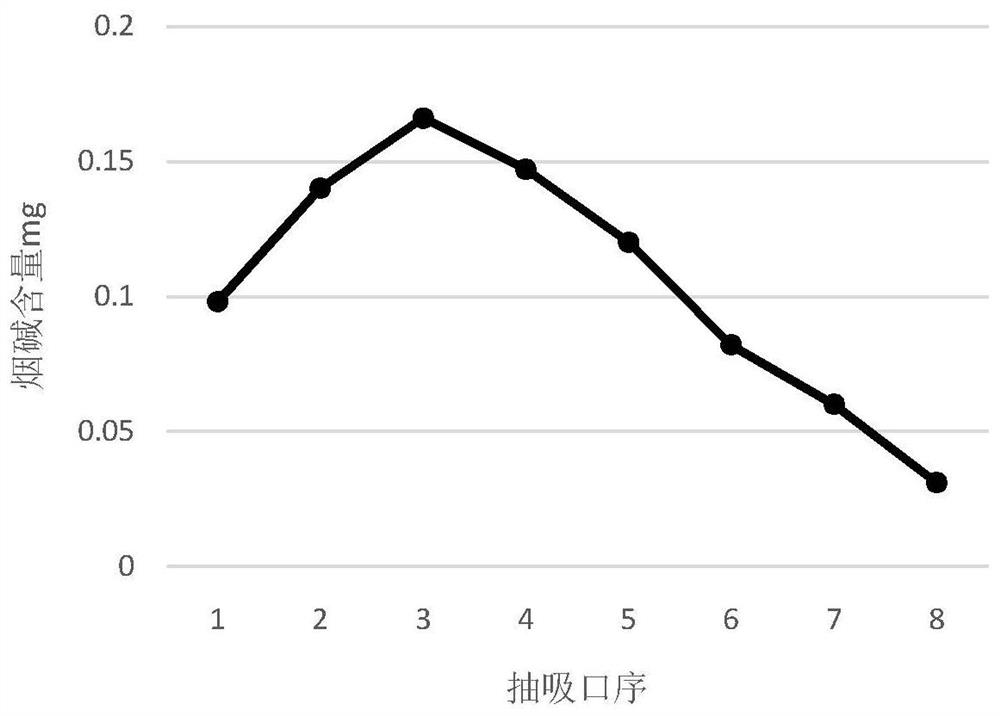

Preparation method of reconstituted tobacco for heat-not-burn cigarette, cigarette cartridge and heat-not-burn cigarette

The invention relates to a preparation method of reconstituted tobacco for a heat-not-burn cigarette, a cigarette cartridge and the heat-not-burn cigarette. The preparation method comprises the steps of uniformly mixing first tobacco powder, a pretreatment agent and water, sealing and storing for 15-30 hours, and baking at the temperature of 100-140 DEG C for 0.5-2 hour to obtain treated tobacco powder for later use; pulping by taking fibers, an adhesive and water as raw materials to obtain fiber pulp for later use; uniformly mixing second tobacco powder, a smoke agent, a tobacco extract, the treated tobacco powder and the fiber pulp to obtain mixed pulp; preparing primary tobacco leaves through a thick pulp method; grinding and pulping the primary tobacco leaves to prepare primary tobacco pulp; and preparing the primary tobacco pulp into the reconstituted tobacco for the heat-not-burn cigarette by a thick pulp method. According to the method, an original thick pulp method reconstituted tobacco preparation process is improved, under the condition of an original thick pulp method production line, the aroma richness of the heat-not-burn cigarette is improved, the smoke irritation is reduced, the smoking satisfaction is improved, and a thick pulp method reconstituted tobacco raw material is provided for the heat-not-burn cigarette through a tobacco powder pretreatment process and a two-time forming process.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Double-layer reaction type filter capsule cigarette

PendingCN108576923AImprove the taste of smokingEnhance cigarette smoking tasteTobacco smoke filtersBiomedical engineeringEngineering

The invention discloses a double-layer reaction type filter capsule cigarette which comprises a filter tip and a cut tobacco rod. The double-layer reaction type filter capsule cigarette is characterized in that double layers of filter capsules are arranged in the cut tobacco rod, matters in the inner layer filter capsule and the outer layer filter capsule can perform deprotection to release aldehyde flavor reaction matters in instant contact or perform maillard spice manufacturing reaction in instant contact. Compared with the prior art, the cigarette disclosed by the invention is characterized in that the double layers of the filter capsules are arranged in the cut tobacco rod, the filter capsules are extruded and broken to release contents in use, the contents of all the filter capsulescan generate chemical reaction to release fragrance in contact, and cigarette fragrance is further improved. By means of the double-layer reaction type filter capsule cigarette disclosed by the invention, a use boiling range of filter capsule flavor is widened. The double-layer reaction type filter capsule cigarette is not only suitable for ordinary cigarettes, but also suitable for heating non-combustible cigarette structures.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for preparing flue-cured aromatic recycled tobacco leaf by target extraction

ActiveCN109222201AImprove the taste of smokingImprove comfortTobacco preparationTobacco treatmentCalcium complexCoating

The invention relates to a method for preparing flue-cured aromatic recycled tobacco leaf by targeted extraction, belonging to the technical field of tobacco auxiliary materials. The method is to combine Flastro-Coco-Creoro-Coco, Trinidad cocoa, a polyol and a calcium complex are reacted together in an oil bath at 150 to 250 DEG C for 0.5 to 3 hours, the resulting product is in an organic solvent,extraction followed by centrifugation, A liquid of that upper lay is filtered by an organic filt membrane, and then the filtrate is distilled under reduced pressure to obtain a target extraction curing flavor material, which is added into a recycled tobacco leaf coating liquid, baicalin is added into the coating liquid, stirred at room temperature for 20 to 30 minutes, and then alcoholized, and then the alcoholized liquid is coated on a chip base, dried and cut into shreds, thereby obtaining the cured tobacco leaf. The preparation method of the invention is simple and reliable, the cost is low, the prepared recycled tobacco leaves are flavored, the free radical content in the flue gas can be remarkably reduced, and the invention is easy to be popularized and applied. The invention has theadvantages of simple and reliable preparation method, low cost, high curing fragrance of the recycled tobacco leaves, and remarkable reduction of free radical content in the flue gas.

Owner:CHINA TOBACCO YUNNAN IND

Cooling filter stick as well as preparation method and application thereof

PendingCN112438429AReduce adsorptionReduce suction resistanceTobacco smoke filtersThermodynamicsSmoke Emission

The invention relates to a cooling filter stick as well as a preparation method and application thereof. The cooling filter stick is of an integrated stick-shaped structure formed by bonding and curing low-adsorption particles, has stable network-shaped porous morphological characteristics, can provide a complex and smooth smoke channel, and can greatly reduce the temperature of smoke entering anoral cavity mainly based on a physical cooling principle on the premise of not adopting a ventilation and dilution means. The cooling filter stick prepared on the basis of low-adsorption particle forming has little influence on the smoke amount, and the smoking taste is good. The full-particle rod formed by curing the low-adsorption particles is simple in form and novel in structure, industrial continuous production can be achieved, the suction resistance is small, and the suction resistance and the cooling amplitude can be adjusted.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com