Cooling filter stick as well as preparation method and application thereof

A filter rod and rod body technology, applied in the application, e-liquid filter, tobacco and other directions, can solve the problems that the heat cannot be dissipated in time, is not suitable for low temperature heating, affects the smoking experience, etc., and achieves a significant cooling effect and a good cooling effect. , the effect of more energy attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this example:

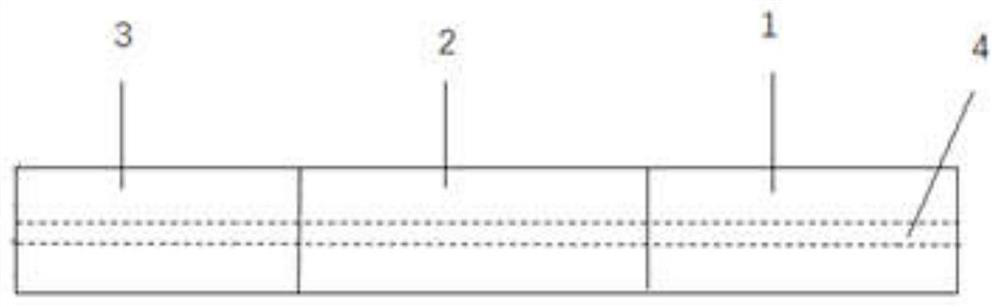

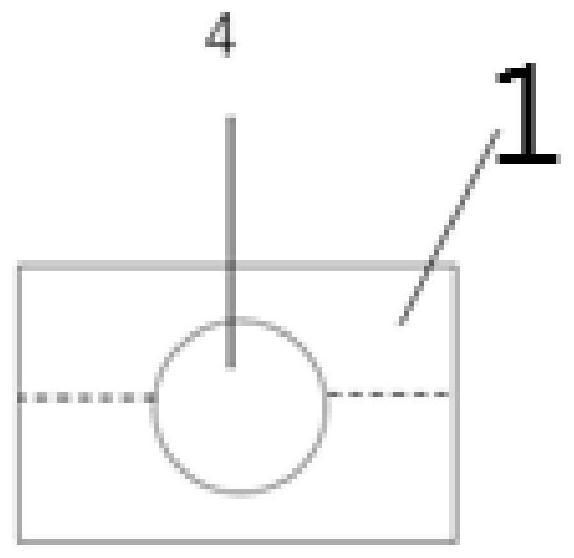

[0044]1) Preparation method of cooling granules: In terms of parts by mass, take 20 parts of 80-mesh polyethylene and 80 parts of ethylene / vinyl acetate copolymer. After mixing evenly, use a commercial screw extruder to blend, melt, extrude, granulate and spheronize. Take 20-35 mesh particles to obtain low-adsorption cooling particles, and the particle bulk density is 3.0g / ml; 2) Preparation method of cooling particle sticks: The prepared low-adsorption cooling particles are continuously sent to three serially distributed through the conveyor belt. Cavity components (structural schematic diagram as figure 2 shown), the center of the mold cavity is a circular channel with a circumference of 23.5mm. The first mold cavity is provided with a negative pressure to compress and accumulate the particles in it. After being wrapped with cloth tape, it is sent to the second mold cavity with a heating device. The granules in the mold cavity are heated to 120°C,...

Embodiment 2

[0046] 1) Preparation method of cooling granules: In parts by mass, take 70 parts of 100-mesh ethylene / vinyl acetate copolymer, 10 parts of polyethylene oxide, and 10 parts of polyvinyl alcohol. After mixing evenly, use a commercial screw extruder to blend and melt extrude After granulation and rounding, take 15-25 mesh particles to obtain low-adsorption cooling particles, and the bulk density of the particles is 2.5g / ml; 2) Preparation method of cooling particle rods: The prepared low-adsorption cooling particles are continuously fed into the Three mold cavity components distributed in series, the center of the mold cavity is a circular channel with a circumference of 23.5mm, the first cavity is provided with a negative pressure to compress and accumulate the particles in it, wrapped with cloth tape and sent to the second with a heating device The second cavity, in which the particles are heated to 115°C, the particles are partially softened and initially bonded, and then sent...

Embodiment 3

[0048] 1) Preparation method of cooling granules: In parts by mass, take 65 parts of 150-mesh polylactic acid, 10 parts of polyethylene glycol, 10 parts of polyvinyl alcohol, 10 parts of polyethylene, and 5 parts of paraffin wax, mix them evenly, and extrude them with a commercial screw Extrude, blend, melt, extrude, granulate and spheronize, take 30-60 mesh particles to obtain low-adsorption cooling particles, and the particle bulk density is 2.0g / ml; 2) Preparation method of cooling particle rods: Pass the prepared low-adsorption cooling particles through The conveyor belt is continuously fed into the three mold cavity components distributed in series. The center of the mold cavity is a circular channel with a circumference of 23.5mm. The first mold cavity is equipped with a negative pressure to compress and accumulate the particles in it. The cloth belt is wrapped and sent to The second cavity with a heating device, in which the particles are heated to 105°C, the particles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com