Extract deep purification and edulcoration process in manufacturing technology of papermaking tobacco sheets

A tobacco sheet, deep purification technology, applied in the direction of tobacco, tobacco preparation, separation methods, etc., can solve the problems of inevitable entry or retention, uncomfortable taste, large irritation, etc., achieve accurate and efficient directional macromolecule separation, and improve mechanical sedimentation Efficiency, the effect of preventing the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

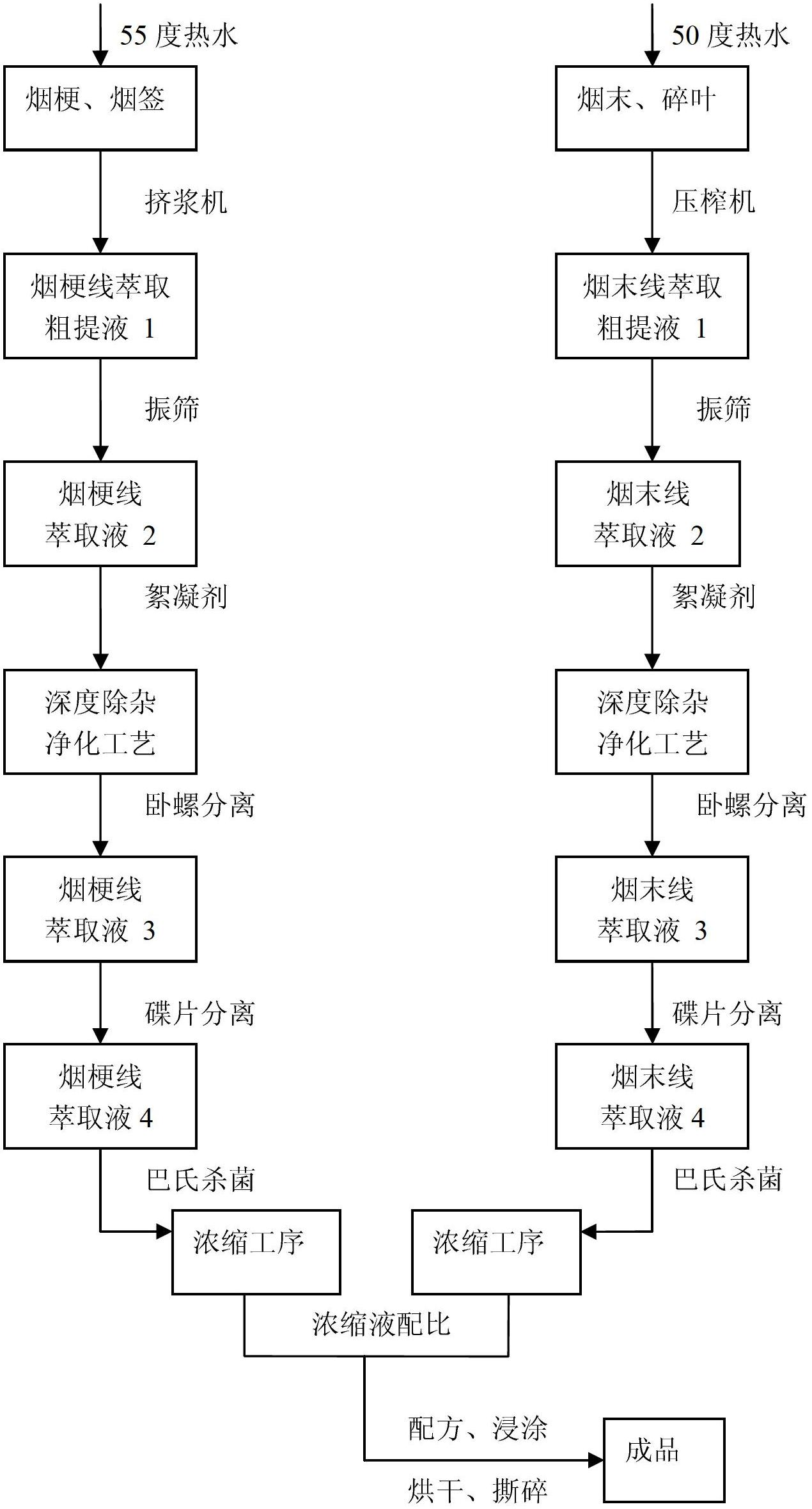

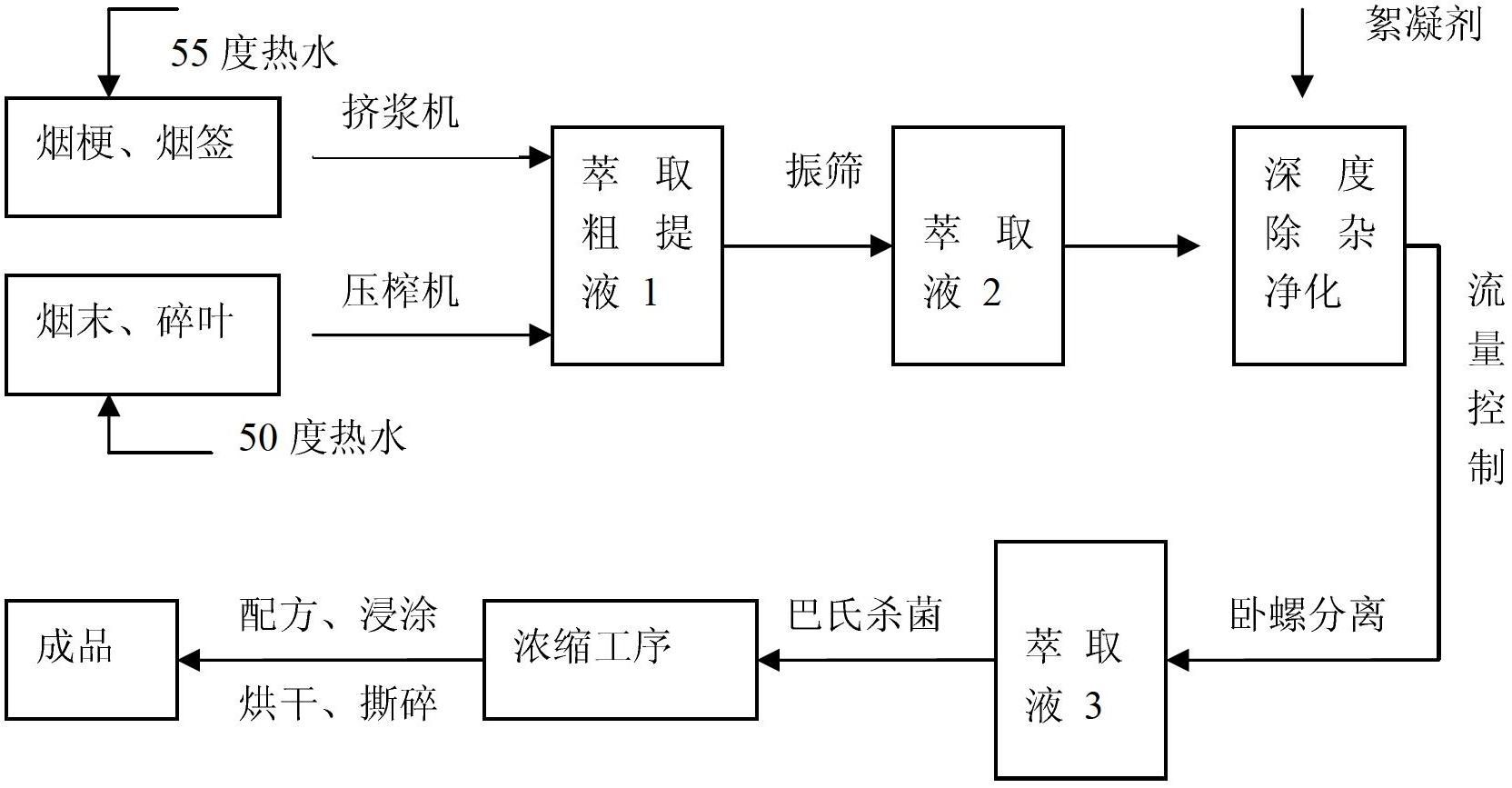

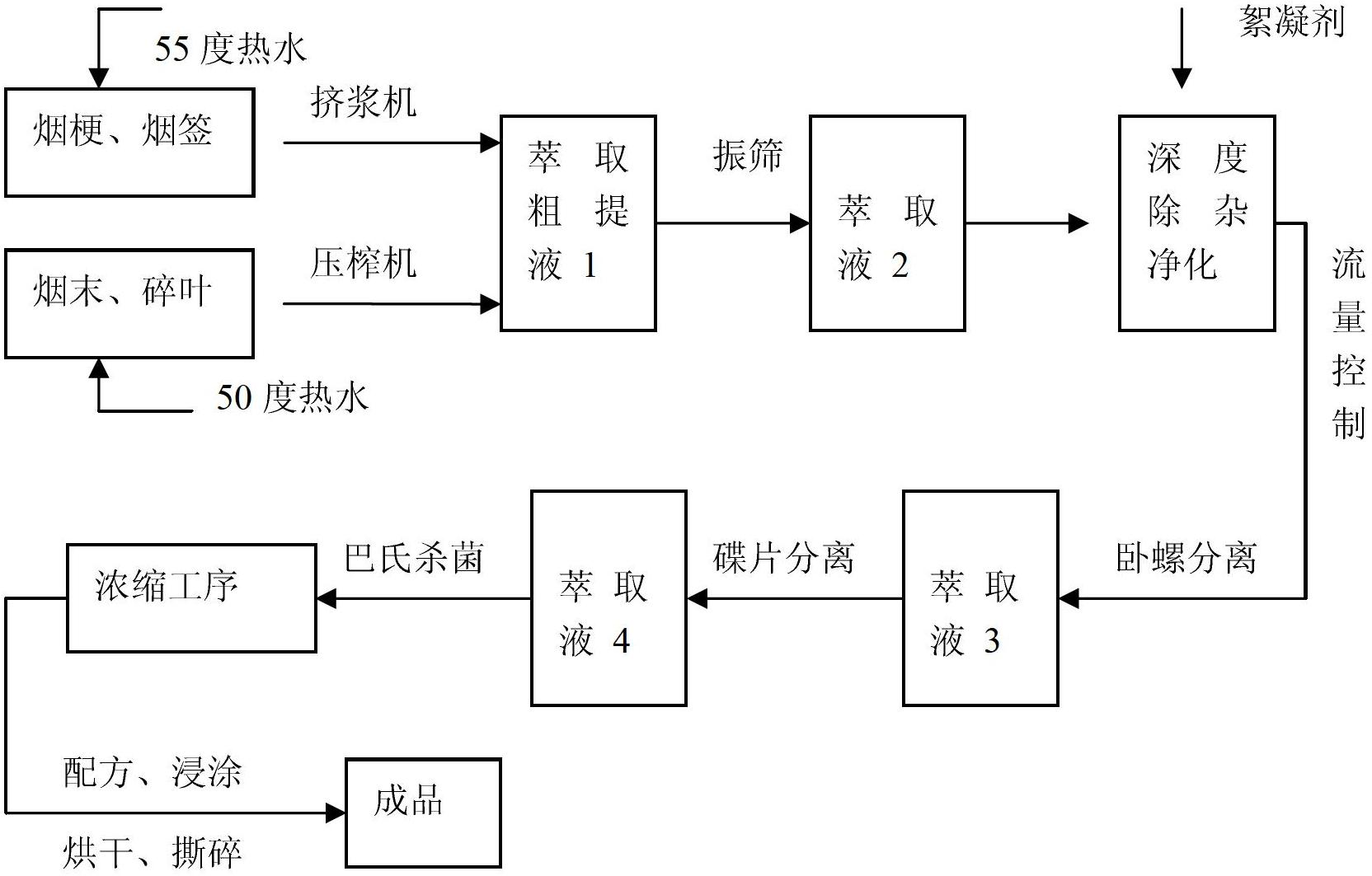

[0025] See attached figure 11,000 kg of tobacco stems and 1,000 kg of tobacco powder are soaked in hot water at 55 degrees and 50 degrees for 40 minutes, respectively, fully stirred and infiltrated, and the tobacco powder and sheets are directly fed into the single-screw press, and the tobacco stems and sticks are defibrated Afterwards, the conveying screw enters the pulping machine for pulping to obtain tobacco fiber solids and tobacco extract 1 respectively. Solid absolute dry slag content tobacco end line is 33.8%, tobacco stem line is 37.2% (tested by oven method at 105 degrees to constant weight), liquid slag content tobacco end line is 2.0%, tobacco stem line is 1.2%, solid slag is mixed Then make a film base. The tobacco powder liquid 1 and the tobacco stem liquid 1 were respectively passed through a linear vibrating sieve to obtain the tobacco powder liquid 2 (with a slag content of 1.0%) and the tobacco stem liquid 2 (with a slag content of 0.8%). The liquid 2 was r...

Embodiment 2

[0027] 1,000 kg of tobacco stems and 1,000 kg of tobacco powder are soaked in hot water at 55 degrees and 50 degrees for 40 minutes respectively. After fully stirring and infiltrating, the tobacco powder and sheets are directly fed into the single-screw press. The conveying screw enters the pulping machine for pulping to obtain tobacco fiber solids and tobacco extract 1 respectively. Solid absolute dry slag content tobacco end line is 33.8%, tobacco stem line is 37.2% (tested by oven method at 105 degrees to constant weight), liquid slag content tobacco end line is 2.0%, tobacco stem line is 1.2%, solid slag is mixed Then make a film base. The tobacco powder liquid 1 and the tobacco stem liquid 1 were respectively passed through a linear vibrating sieve to obtain the tobacco powder liquid 2 (with a slag content of 1.0%) and the tobacco stem liquid 2 (with a slag content of 0.8%). The liquid 2 was respectively put into the deep purification and impurity removal treatment secti...

Embodiment 3

[0029] The difference from Example 1 is that the flocculant used is seaweed extract solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com