Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve regeneration quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

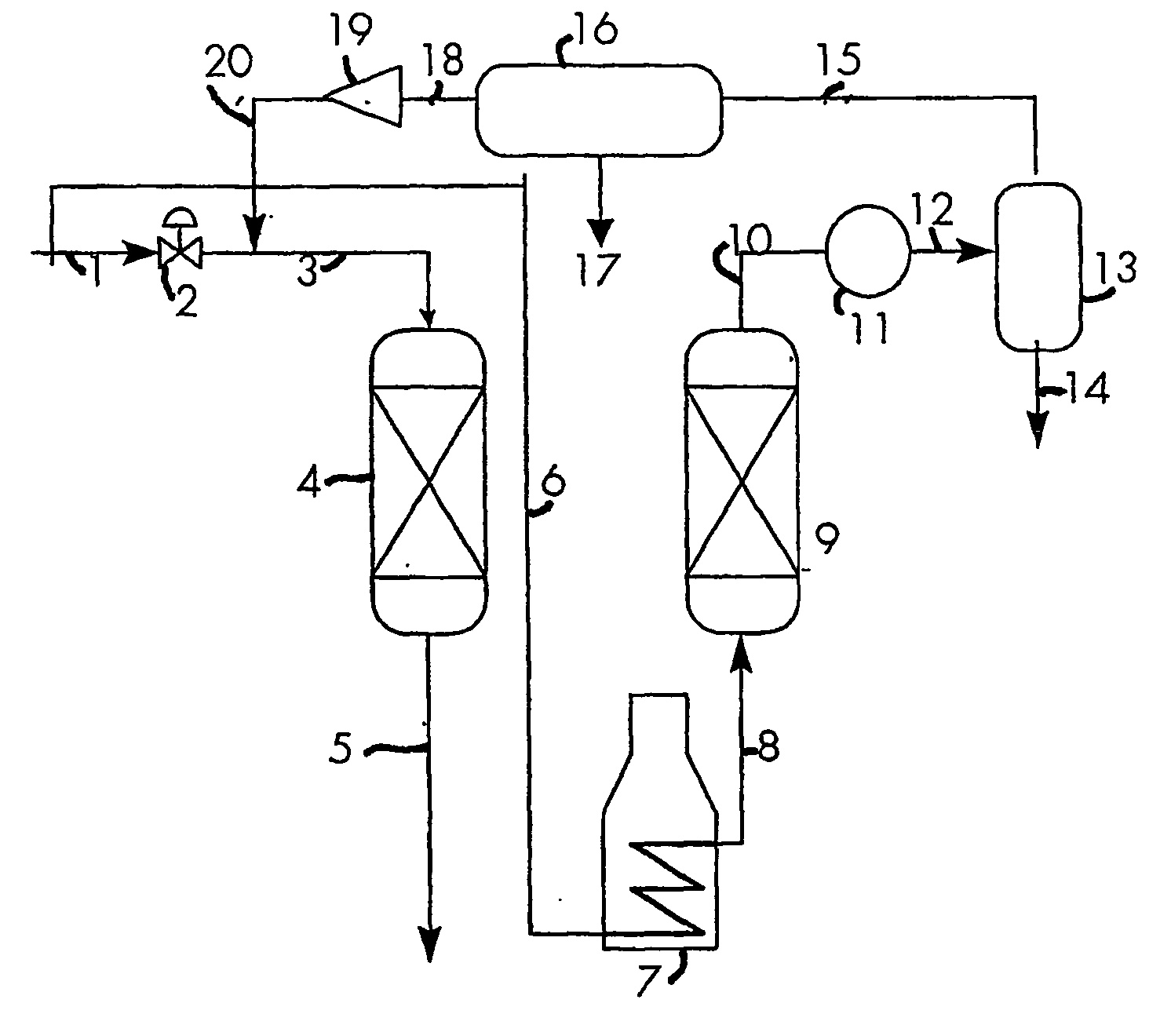

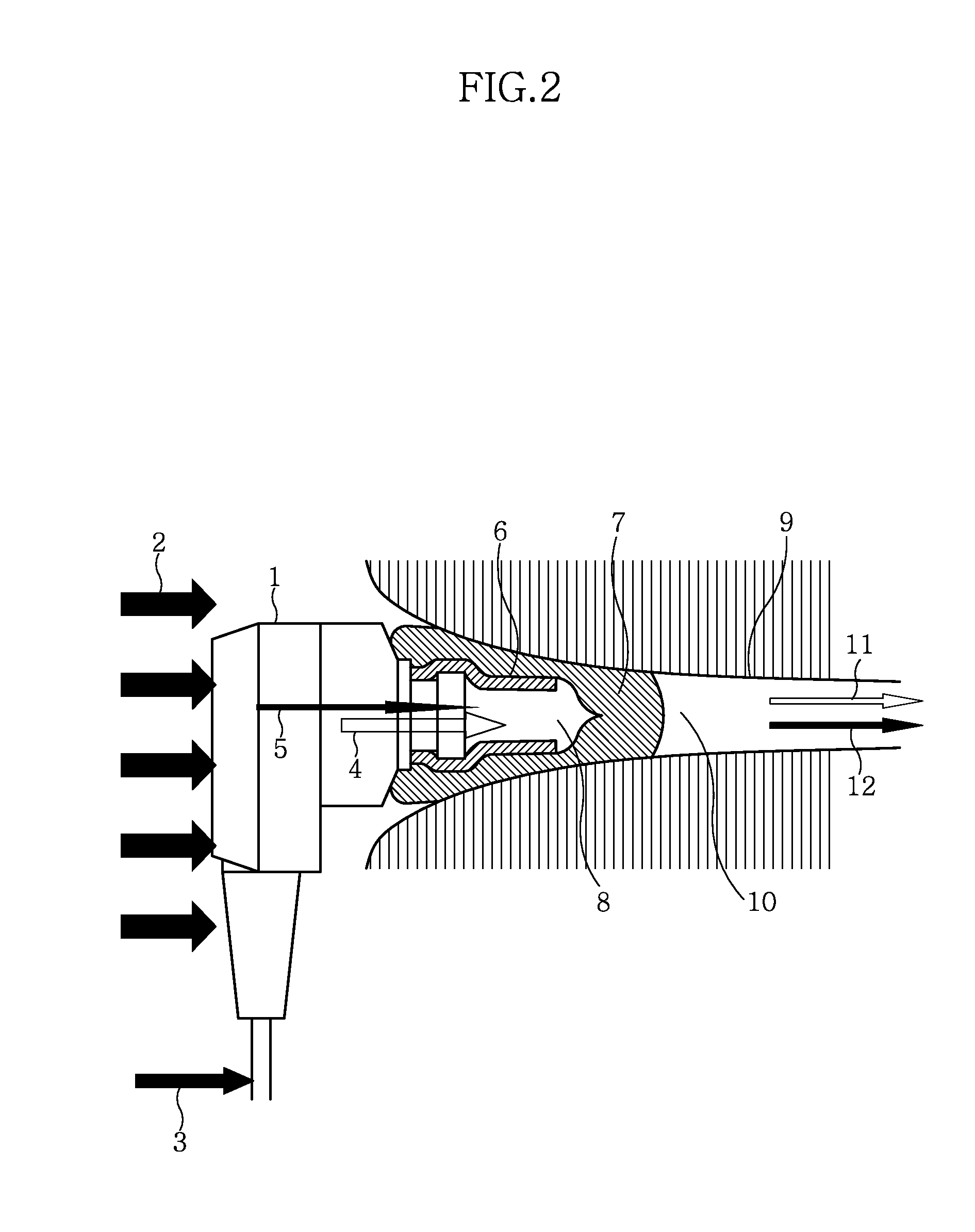

Process and System for Removing Contaminants from a Natural Gas Stream

InactiveUS20070267328A1Advantageous and efficient treatmentBad qualityGaseous fuelsLiquid hydrocarbon mixture recoveryChemistryPollutant

A process and system for removing contaminants from a natural gas stream, the process comprising the steps of: (a) contacting part of the natural gas stream as a first gas stream at an elevated temperature with a first adsorbent bed in regeneration mode, to remove contaminants present on the first adsorbent bed, and to obtain a second gas stream that is enriched in contaminants compared to the first gas stream; (b) submitting the second gas stream to a gas / liquid separation step comprising cooling the second gas stream to a temperature such that at least some contaminants begin to condense into a first liquid phase that is rich in contaminants, and separating the first liquid phase from the second gas stream to create a third gas stream; wherein the gas / liquid separation step forms a first gas / liquid separation step, and wherein the process further comprises (c) submitting the third gas stream to a second gas / liquid separation step to obtain a second liquid phase that is rich in contaminants, and a lean gas stream.

Owner:SHELL OIL CO

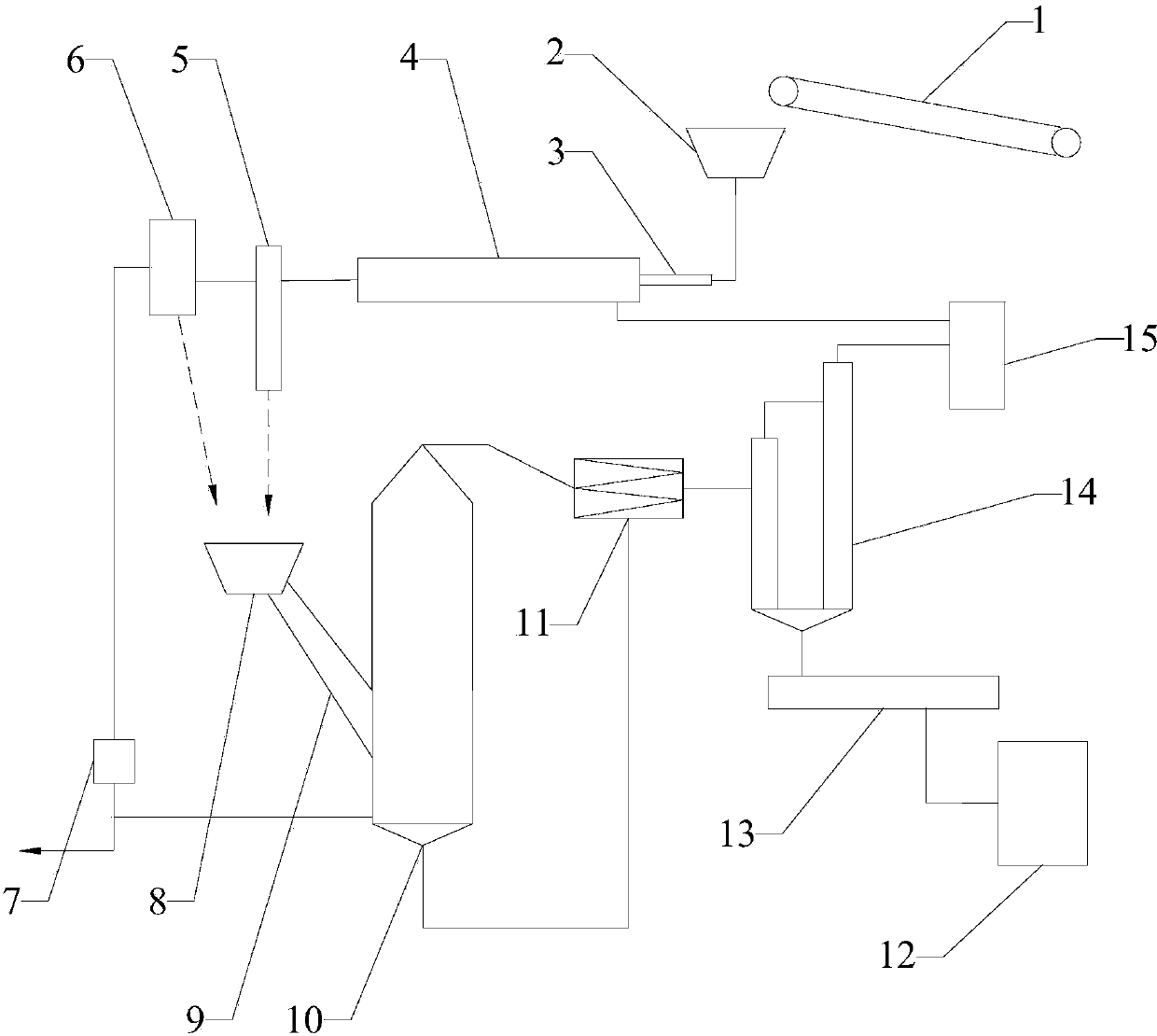

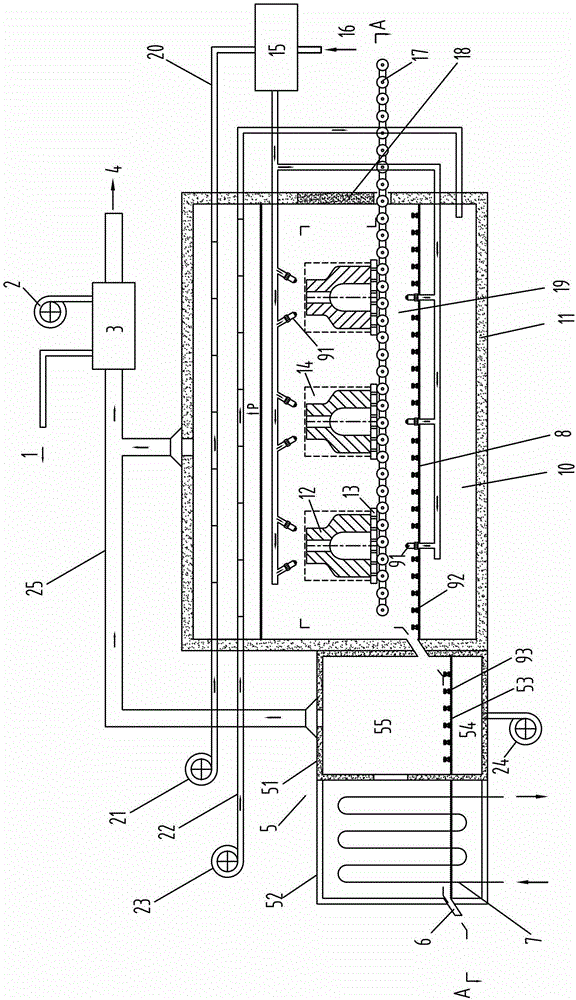

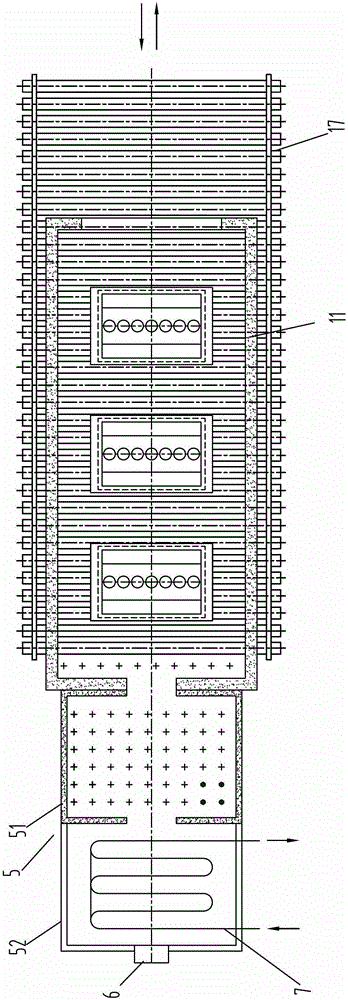

Activated carbon regeneration device and method

ActiveCN104001488AHas an activation effectNot easy to burnOther chemical processesCombustible gas purificationActivated carbonBiological activation

The invention relates to the field of preparation for activated carbon, and in particular relates to an activated carbon regeneration device and method. The method comprises the following steps of feeding waste powdery activated carbon to a drying converter by using a feeding system, enabling the waste powdery activated carbon to pass through a carbon collector, a dust collector, a hopper and a charger, feeding dried powder into a boiling activation furnace, and activating the waste powdery activated carbon in the high-temperature boiling activation furnace; and enabling the formed powdery activated carbon and furnace gas to pass through a superheated steam heater in a pipeline, reheating steam, feeding the relatively high-temperature powdery activated carbon and furnace gas to a cyclone separator, and enabling the collected activated carbon to pass through a cooling feeder to be packaged or post-treated. According to the technical scheme, the activated carbon regeneration cost is low, the regeneration quality is high, a configured activated carbon drying and superheated steam boiling activation equipment system is reasonable in integral design, easy to run and environmentally-friendly, energy resources are recycled, the production cost is lowered, and the activated carbon can be automatically regenerated in a large scale.

Owner:FUJIAN XINSEN CARBON

Resin gel waste core sand reproduction line

InactiveCN102873269AReduce manufacturing costWith purityMould handling/dressing devicesProduction lineMagnetic separator

The invention relates to a resin gel waste core sand reproduction line which comprises a pre-coated sand reproduction device and a resin gel core sand processing device. The pre-coated reproduction device comprises a pretreatment system, a hot-method reproduction method, a dust removal system and an electric control system. The electric control system is connected with the pretreatment system, the hot-method reproduction device and the dust removal system. The pretreatment system comprises a crushing screening machine and a magnetic separator. The hot-method reproduction device comprises a feeding machine, a waste sand calcinator, a cooling bed and a reproductive pre-coated sand storage bin, which are connected sequentially. The dust removal system is connected with the crushing screening machine, the waste sand calcinator and the cooling bed through a pipeline. The resin gel core sand processing device comprises a feeding device, a resin gel core sand hot-method reproduction device, a resin gel core sand delivery device and a screening device, the feeding device is connected with the reproductive pre-coated sand storage bin, and the resin gel core sand hot-method production device comprises a pre-coated sand calcinator which is provided with a pre-coated sand feeding hopper and a resign feeding hopper. Reproduction of waste sand is achieved, waste is turned into treasure, cost is economized and environmental friendliness is achieved.

Owner:温州市康霸洁具有限公司

Production line for regenerating wood based powdered activated carbon

ActiveCN102553554AAchieve regenerationLow loss on ignitionCombustible gas purificationFilter regenerationProduction lineActivated carbon

The invention relates to a production line for regenerating wood based powdered activated carbon. The production line comprises a grinding and drying device, a cyclone seperation device, a high-temperature shaft kiln activation furnace and a cooling bag filtering device, wherein the grinding and drying device is used for heating, drying and mechanically grinding peat, the cyclone seperation device is used for separating out peat grains, the high-temperature shaft kiln activation furnace is used for reactivating the peat grains, the cooling bag filtering device is used for carrying out cooling temperature reduction on the activated peat, and the activated peat is led to pass through a bag filter and then is discharged, thereby the activated carbon is completely regenerated, the ignition lost rate is low, the regeneration cost is low, the regeneration quality is good, and the large-scale automation control production is realized.

Owner:福建省芝星炭业股份有限公司

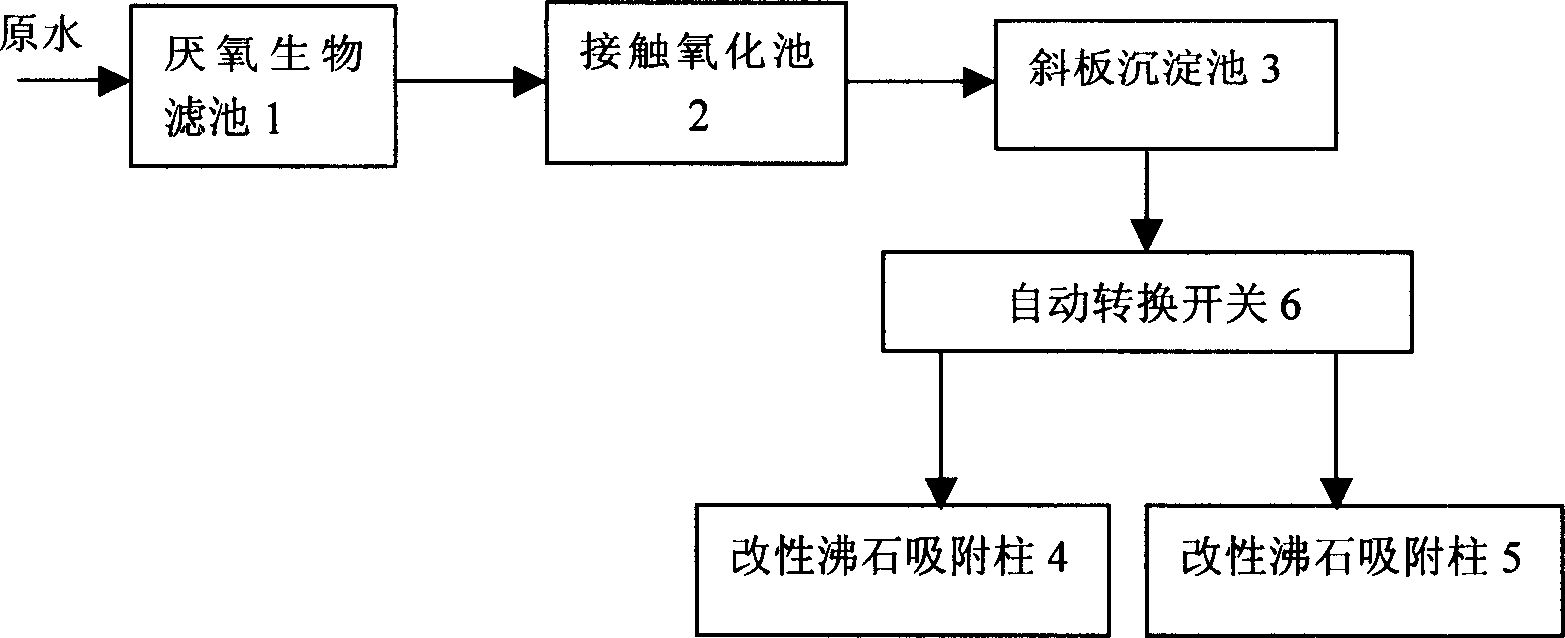

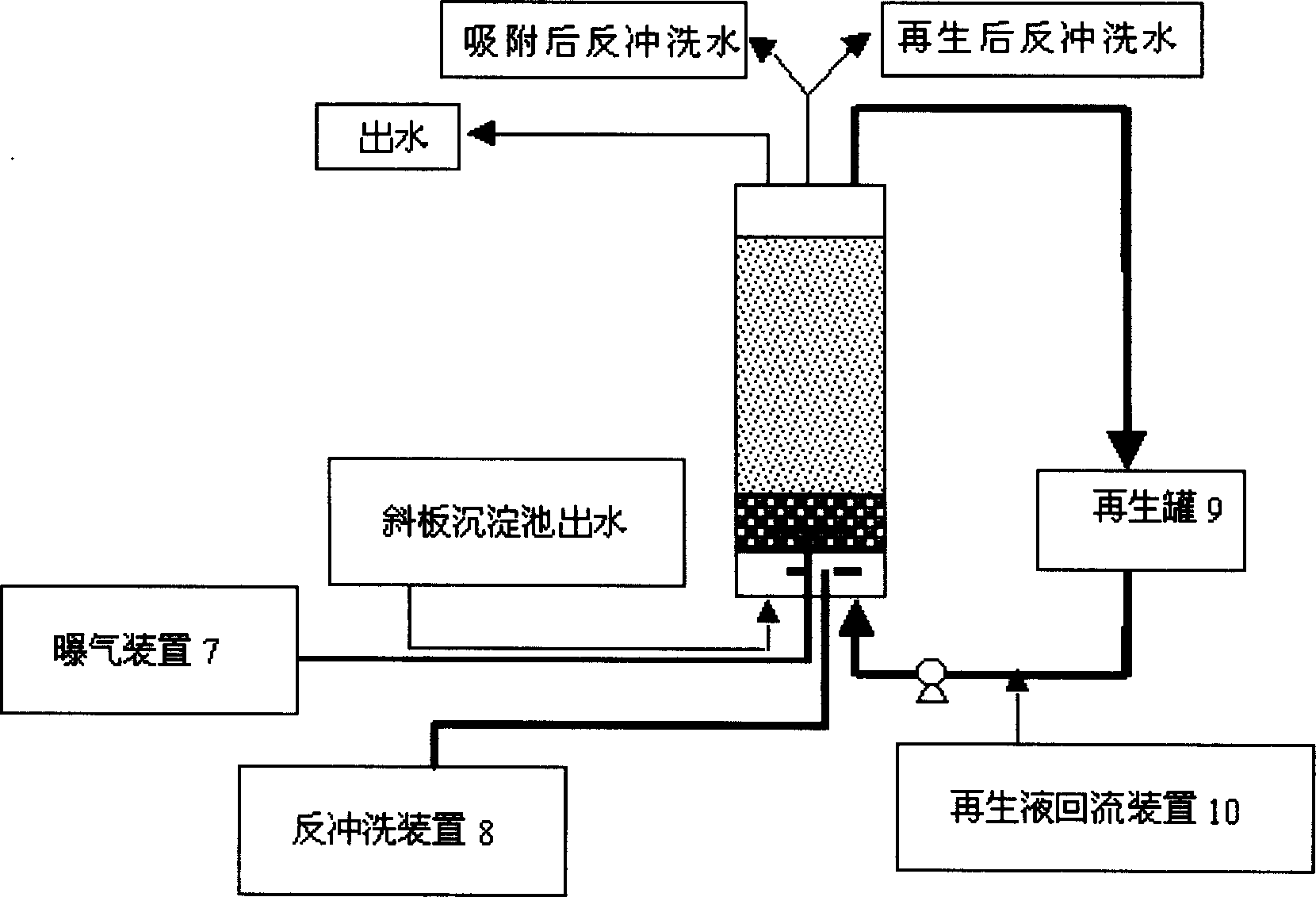

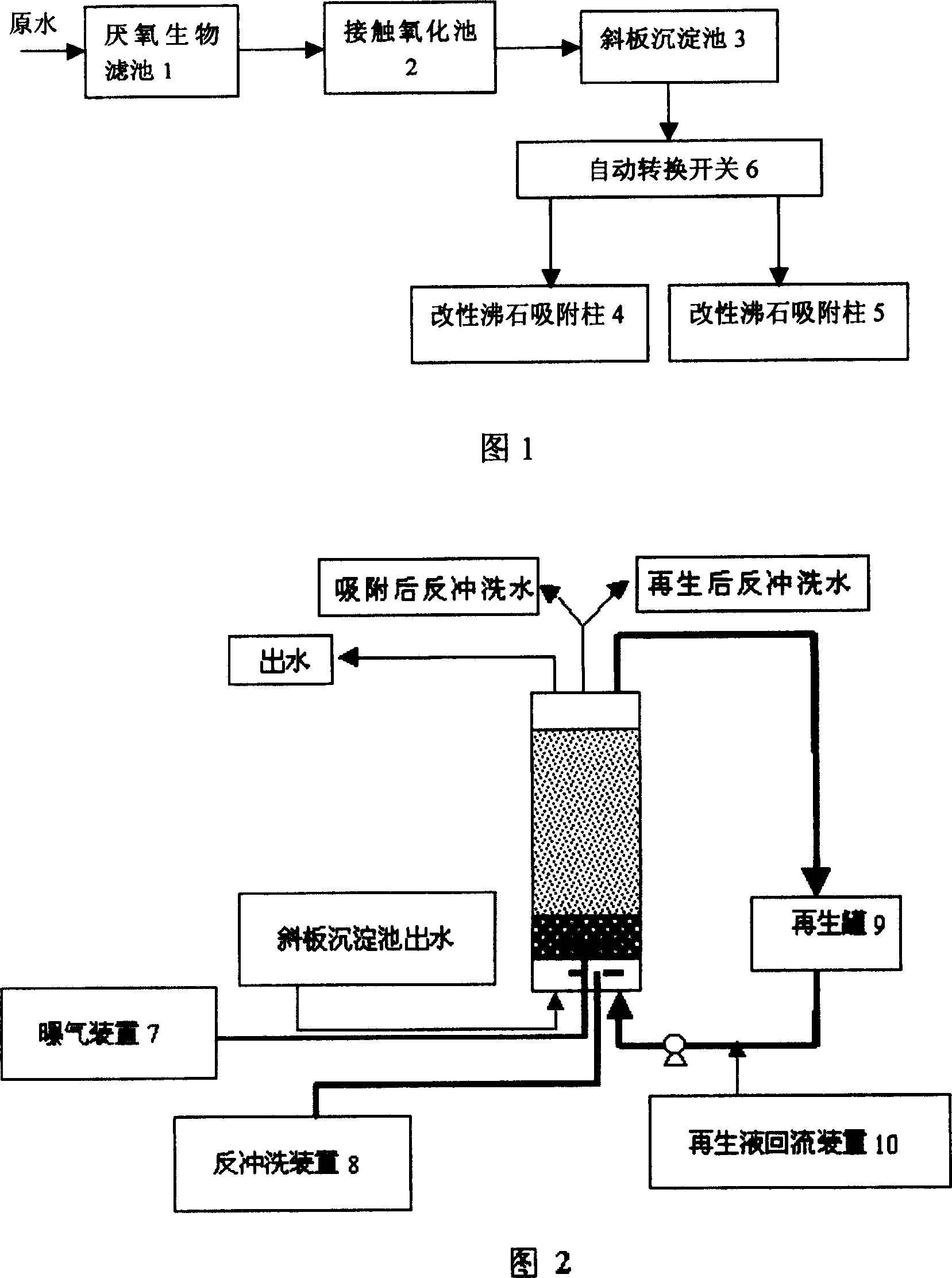

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1686872AAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

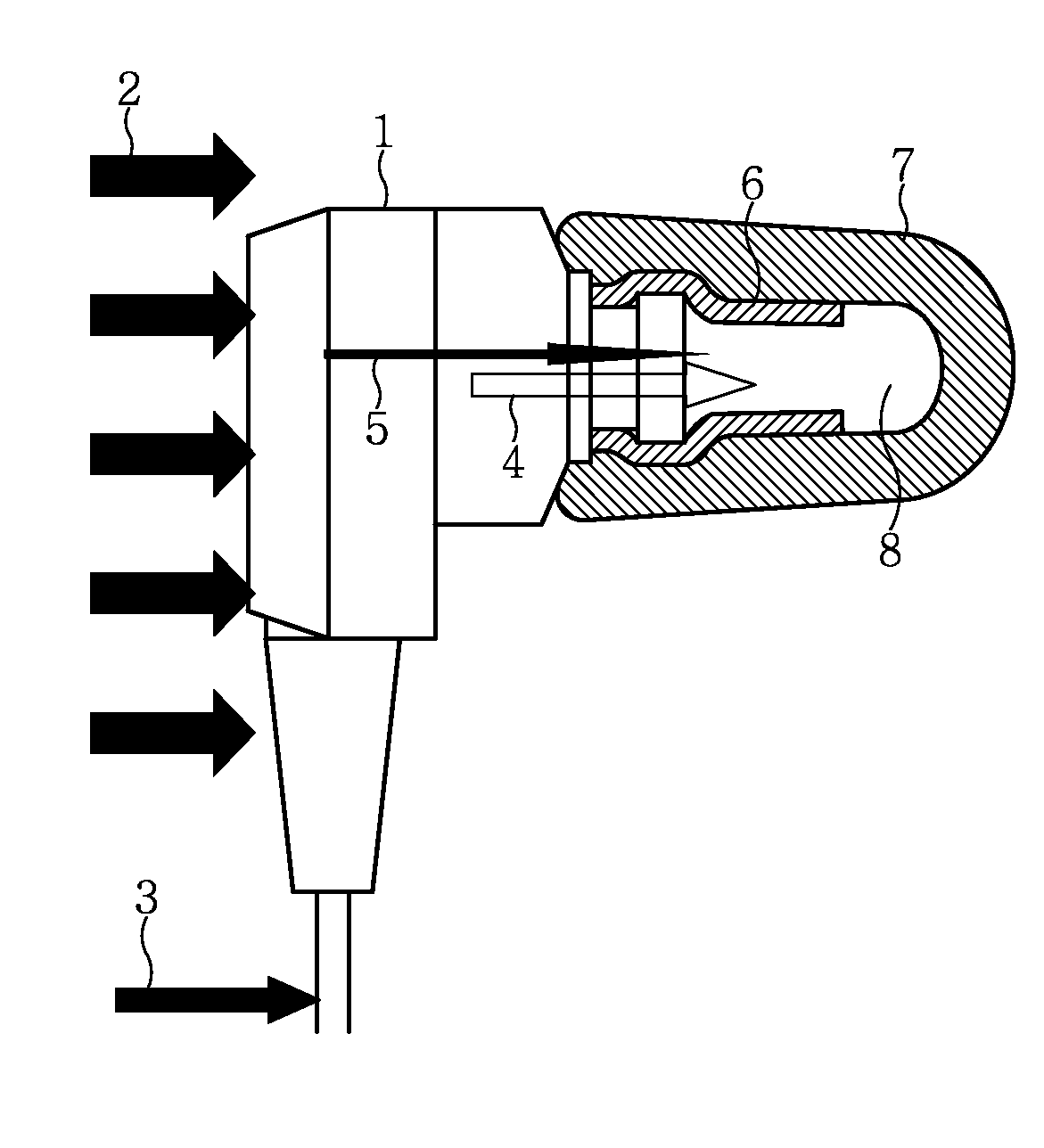

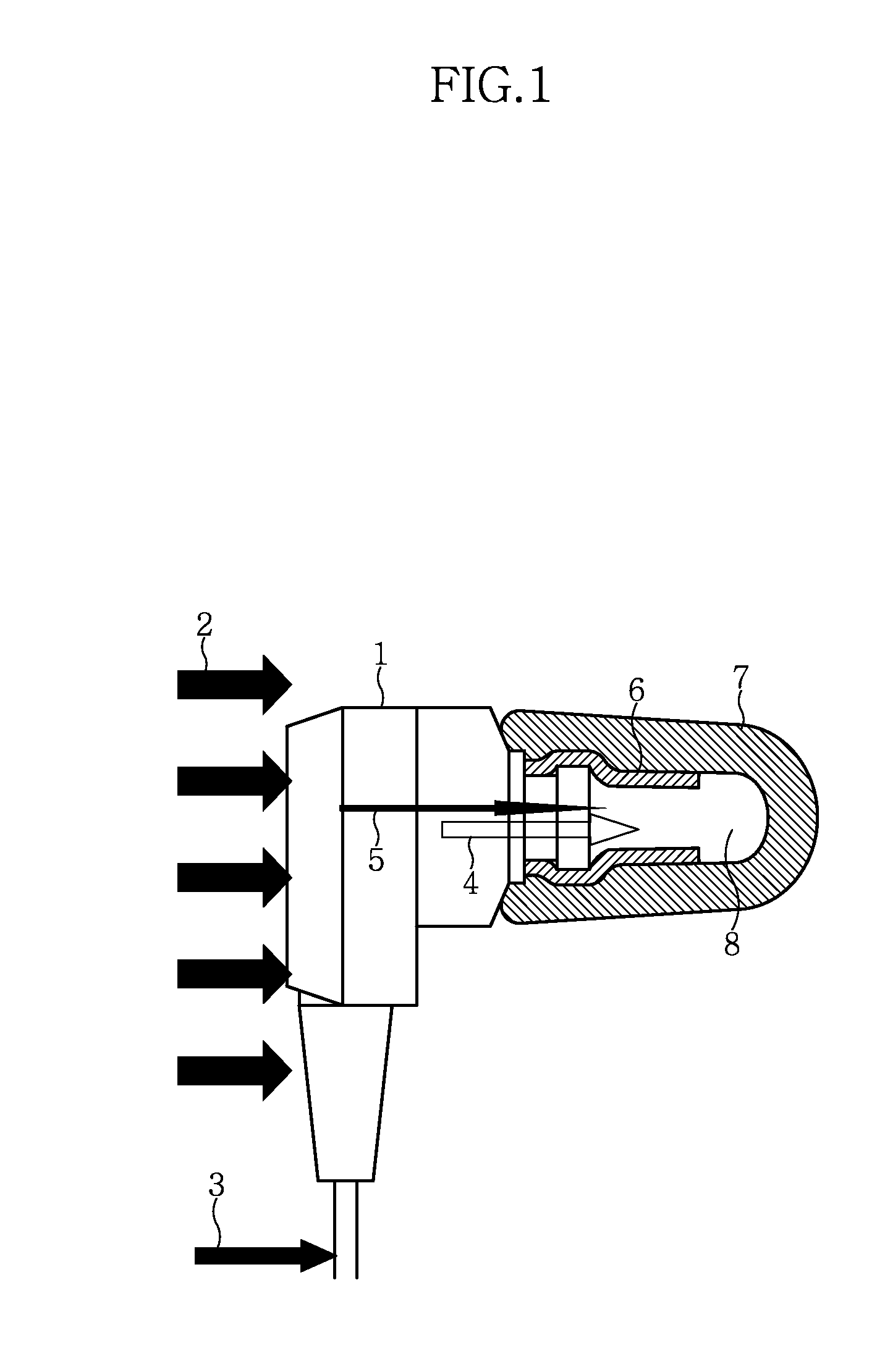

Earphone having sound insulation means

InactiveUS20120033822A1Reduce hearing fatigueLower the barrierIntra aural earpiecesEarplugsEnvironmental noiseEngineering

The present invention relates to an inexpensive environmental noise reduction type inner earphone which allows a user to listen music with high quality of sound and with a small volume under noisy environments making noise of 86 dB or more such as in aircraft seats, subways, trains and so on, and particularly which is capable of blocking a high level of environmental noise and regeneration sound passing through the inner earphone by filling a space formed between an ear and the inner earphone with a sound insulation element made of porous soft plastic. The earphone includes a frequency characteristic correction circuit which serves to correct a sound insulation characteristic of the sound insulation element between a voice coil of the earphone and a plug of the earphone and includes a resistor and a capacitor.

Owner:KAKUMOTO JUN ICHI

Powder active carbon prepared by using turf as raw material and preparation method of powder active carbon

The invention provides a powder active carbon, which is prepared by using turf as a raw material. The powder active carbon is characterized in that the specific surface area of the powder active carbon is 1200-1400 m<2> / g, the iodine adsorption capacity is 1000-1200mg / g, and the methylene blue absorbing value is 130-200mg / g. The powder active carbon is prepared by the method provided by the invention. The preparation method comprises the following steps of 1) removing impurities by using a turf sieve, drying and crushing the sieved turf; 2) putting the crushed turf into sodium carbonate solution with a weight ratio of (3-5) to 1, mixing the mixture evenly into mud immersion, and drying the mixture; 3) raising the temperature of the dried mixture to 500 DEG C a program of 10 DEG C / min, taking out the cooled mixture to be grinded, and washing away excessive anhydrous sodium carbonate and surface residue with dilute nitric acid, and washing the mixture with deionized water to a pH value of 4.5-4.8, performing suction filtering and drying for the mixture to obtain powder active carbon. The invention further discloses a method for preparing the powder active carbon.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

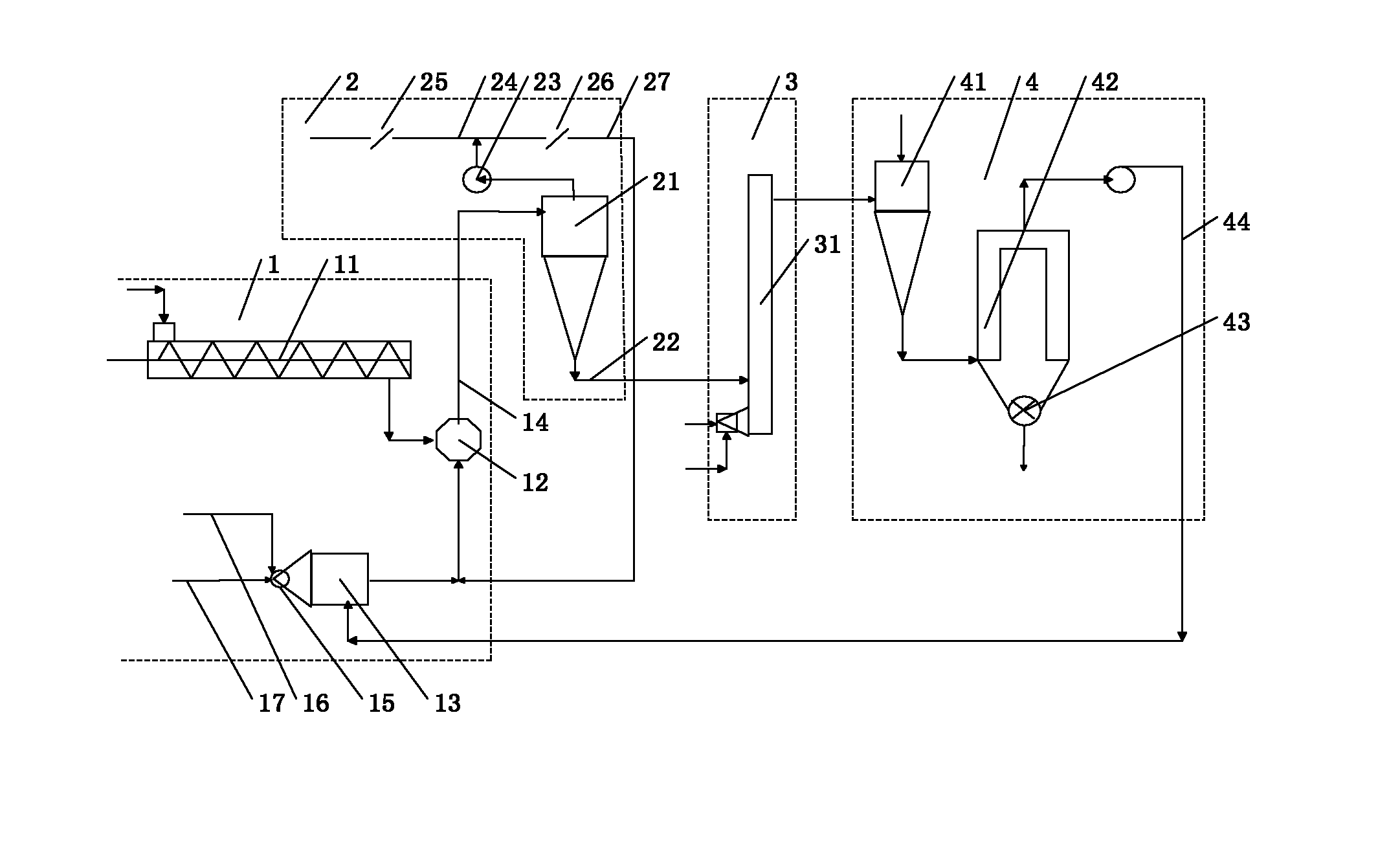

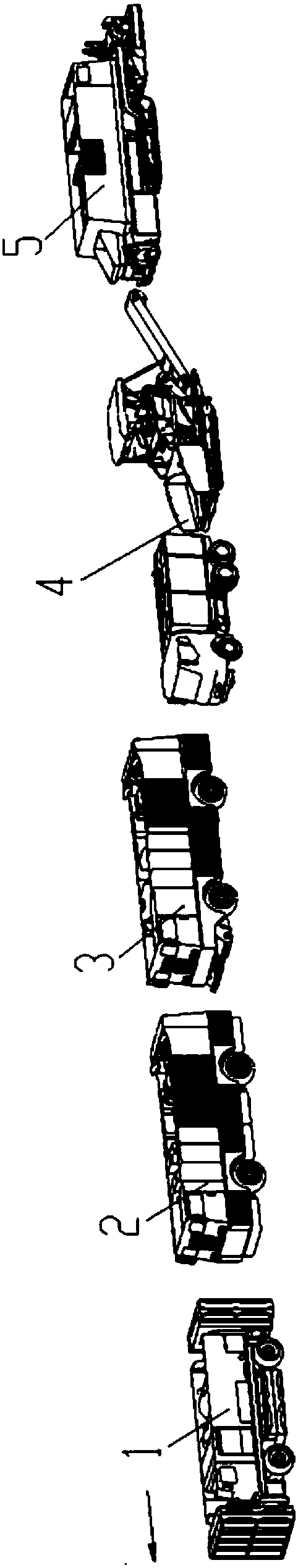

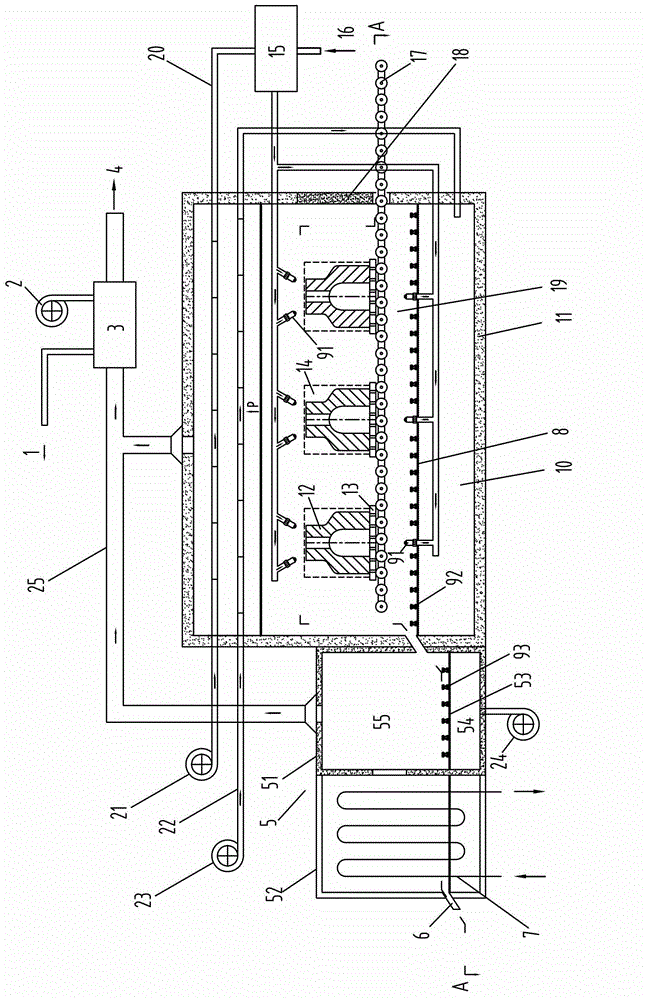

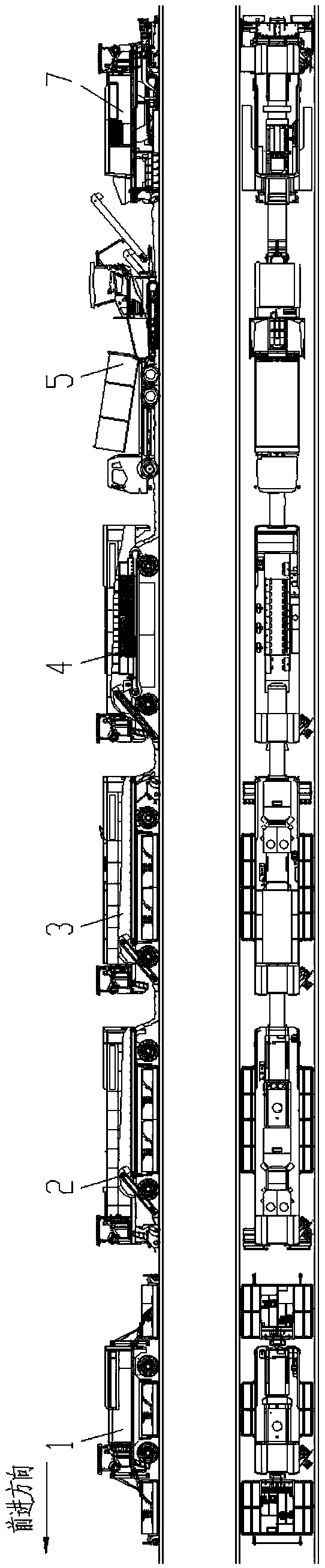

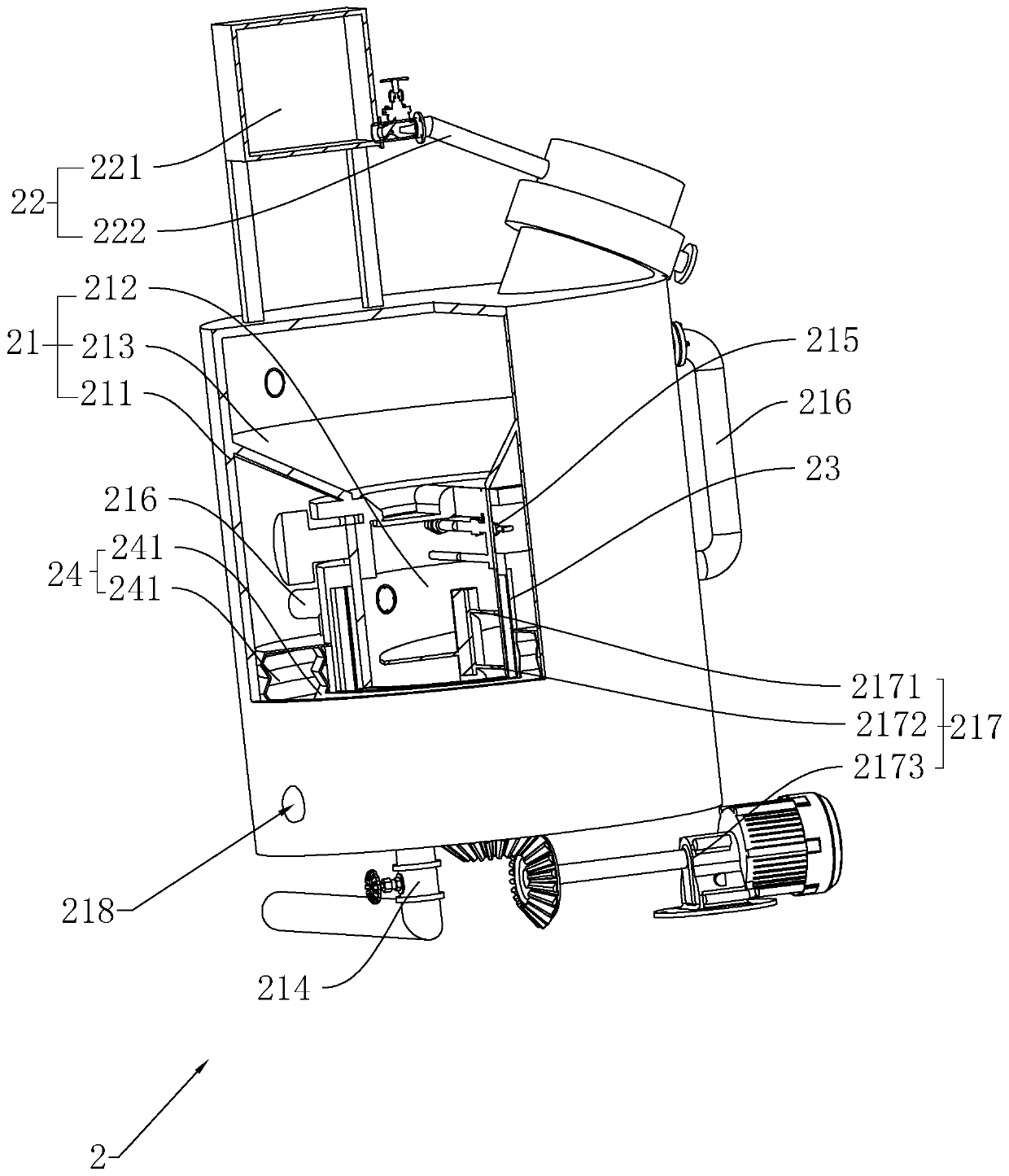

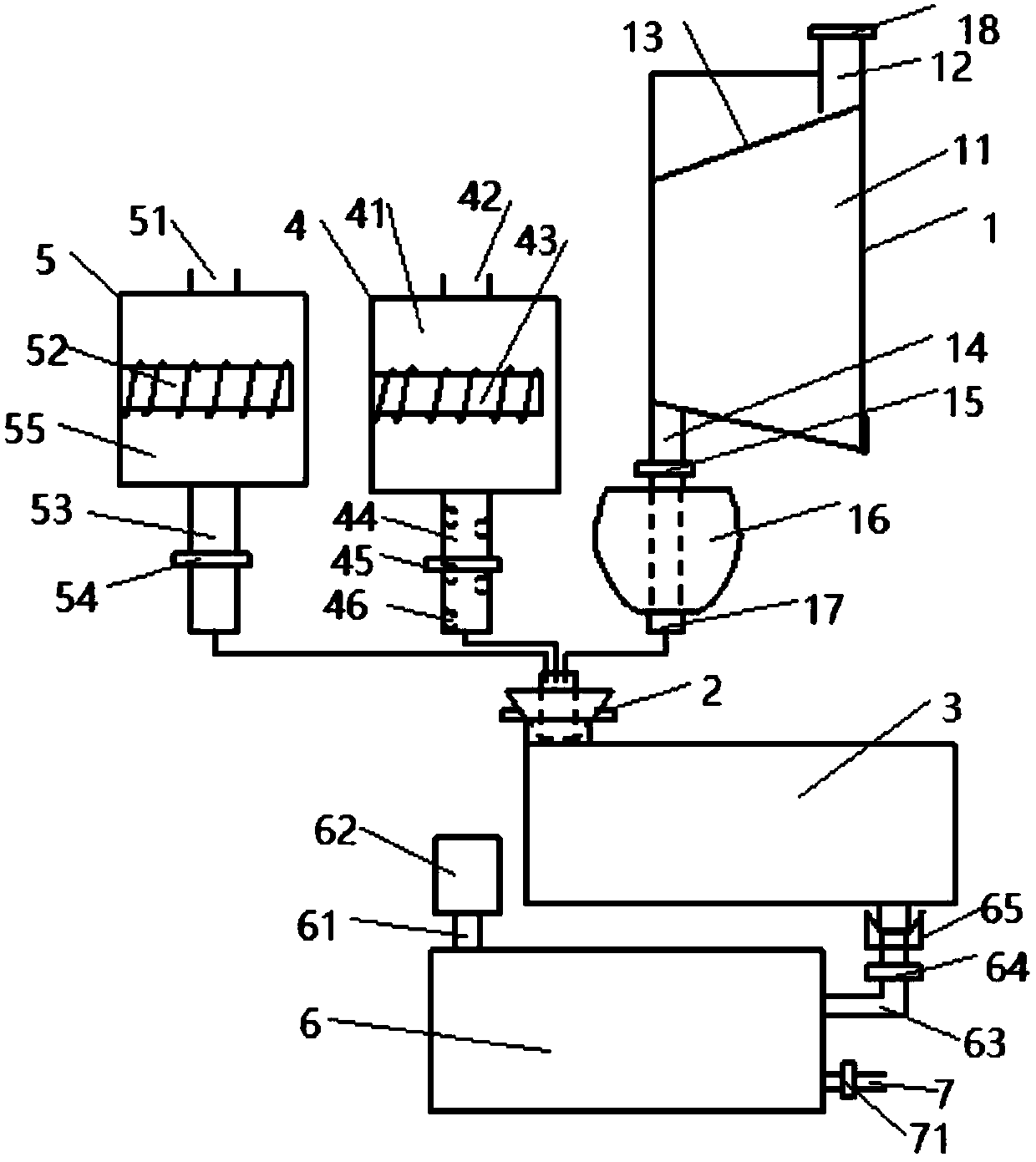

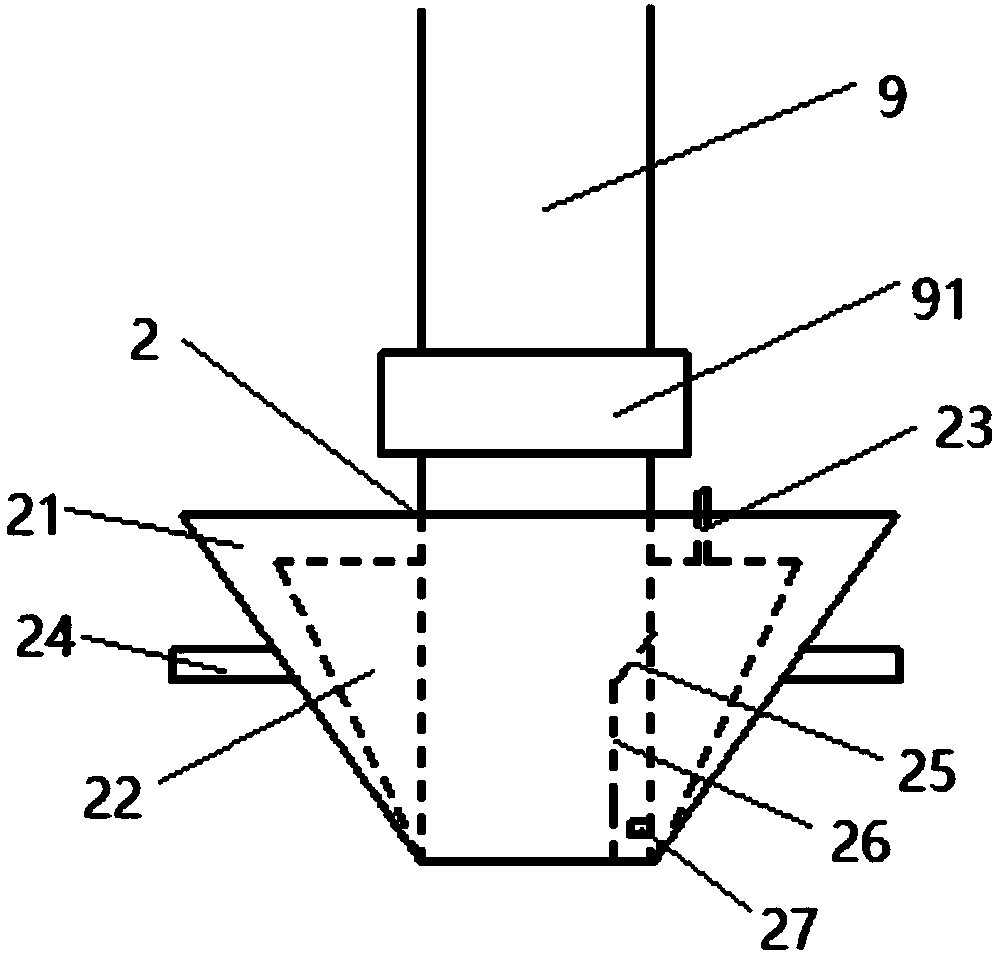

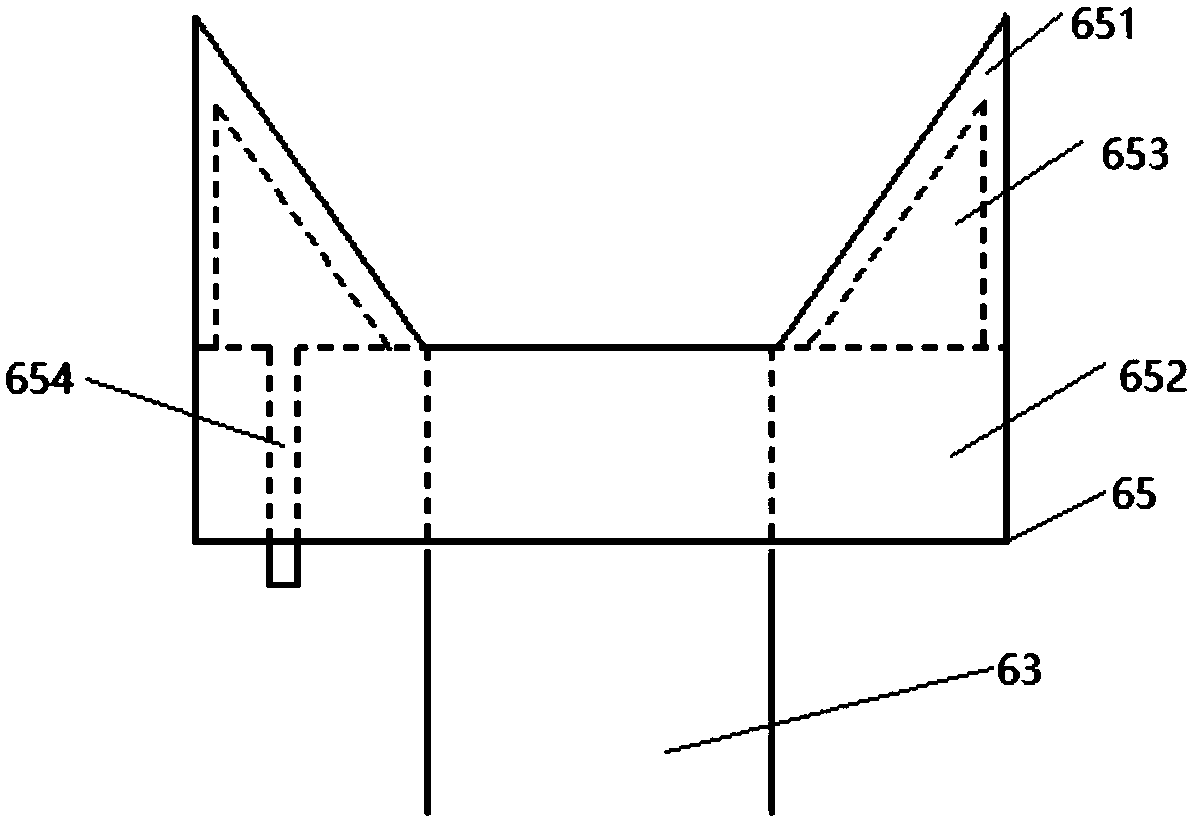

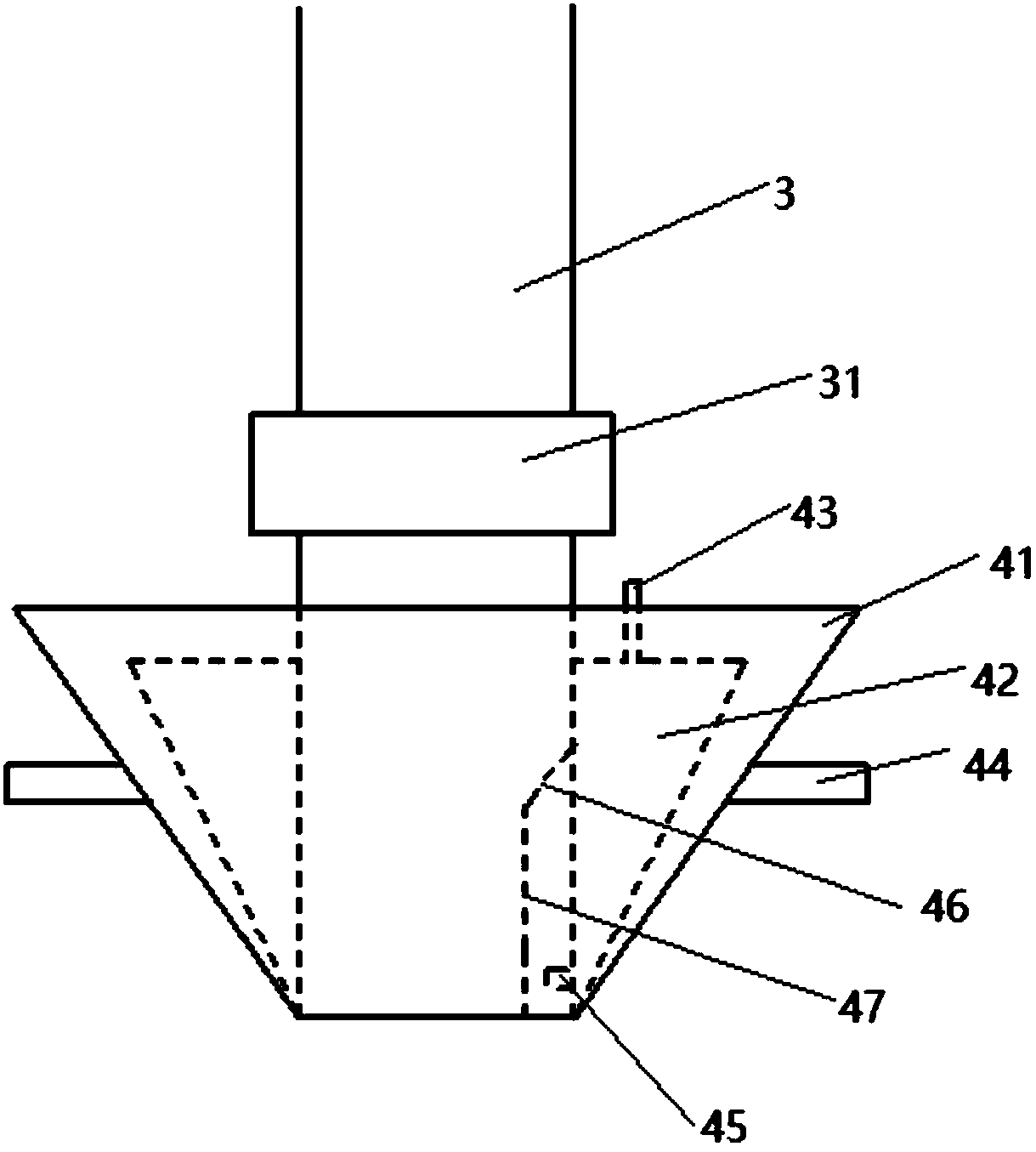

Novel hot air-microwave composite in-place hot recycling complete set and construction technology thereof

PendingCN108252188ASolve pollutionSolve the problem of road performance degradationRoads maintainenceMicrowaveEngineering

The invention discloses a novel hot air-microwave composite in-place hot recycling complete set. The novel hot air-microwave composite in-place hot recycling complete set comprises a hot air heater (1) arranged at the foremost end of the complete set, wherein a microwave heater (2) is arranged at the back end of the hot air heater (1); a microwave heating milling machine (3) is arranged at the back end of the microwave heater (2); a dump truck and multifunctional feeder adding combination (4) is arranged at the back end or on the side surface of the microwave heating milling machine (3); a remixing recycling machine (5) is arranged at the foremost end of the complete set. The invention further discloses a construction technology of the novel hot air-microwave composite in-place hot recycling complete set. Through the novel hot air-microwave composite in-place hot recycling complete set and the construction technology thereof, provided by the invention, accurate control of the modular zone heating temperature is achieved and the uniformity of a whole heating surface is guaranteed; the novel hot air-microwave composite in-place hot recycling complete set has good adaptability to large-bend construction, large-angle climbing, transfer transportation and the like; power-variable and intermittent heating of a modular heating wall and machine group control are achieved, the heating efficiency is high, the heating depth is high and adaptability to the disease condition is strong.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

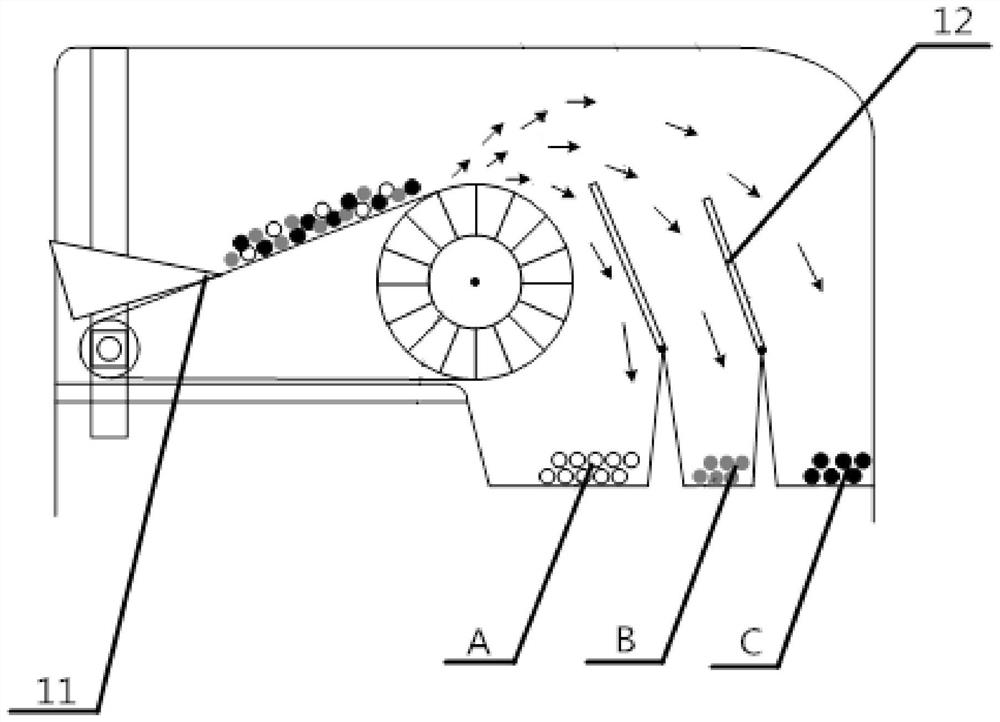

Device and method for pneumatically removing sands from casting and recovering sands

ActiveCN104096823ALess investmentReduce manufacturing costMould handling/dressing devicesCombustion chamberFluidized bed

The invention provides a device and a method for pneumatically removing sands from a casting and recovering sands. A furnace body of a sand removing furnace is divided into a boiling pressure room and a fluidized bed room by a closed partition board, a plurality of high-temperature hot air nozzles are arranged in the fluidized bed room and are connected to a combustion room outside the furnace body, and the combustion room is further connected with a combustion air pipe and a first high-pressure fan; the boiling chamber room is communicated with a second high-pressure fan, and a plurality of air nozzles are arranged on the closed partition board towards the fluidized bed room; an air cooling room is provided with a closed plate with a plurality of blowing nozzles, the closed plate is used for dividing the air cooling room into a lower air pressure room and an upper grading room, the air pressure room is connected with a third high-pressure fan, the side wall of the grading room is provided with a door and is communicated to a sand outlet, the grading room is communicated with the fluidized bed room, and the top of the grading room is provided with a door and is connected with a dust remover through a dust removing pipeline. According to the device and the method for pneumatically removing the sands from the casting and recovering the sands, the working processes of shaking out the sands, removing the sands and recovering the used sands can be carried out in a centralized manner.

Owner:马鞍山海森控电气有限公司

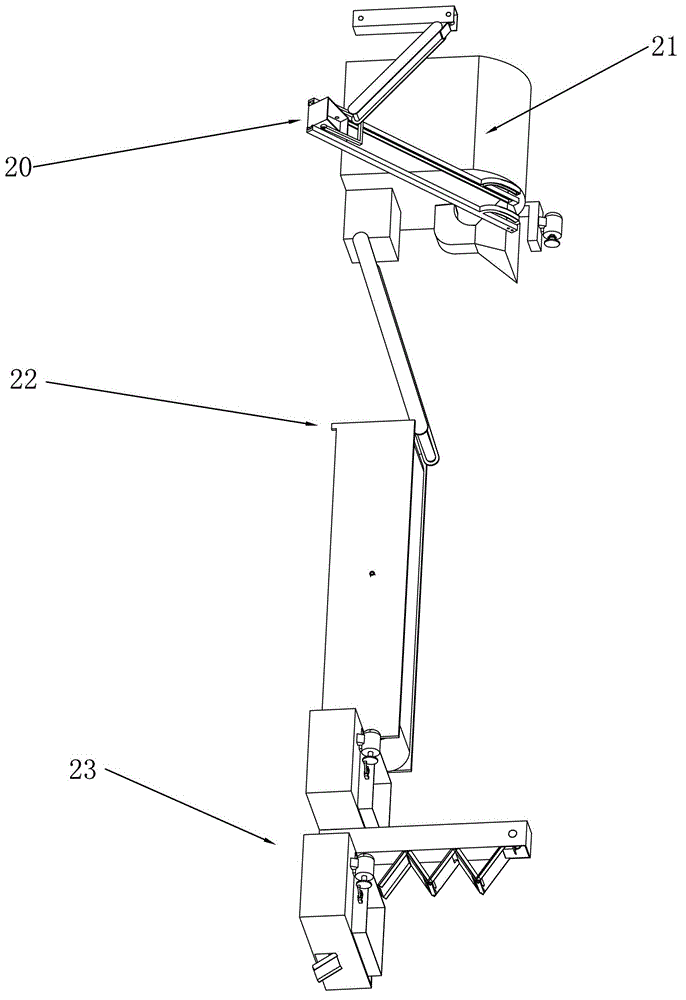

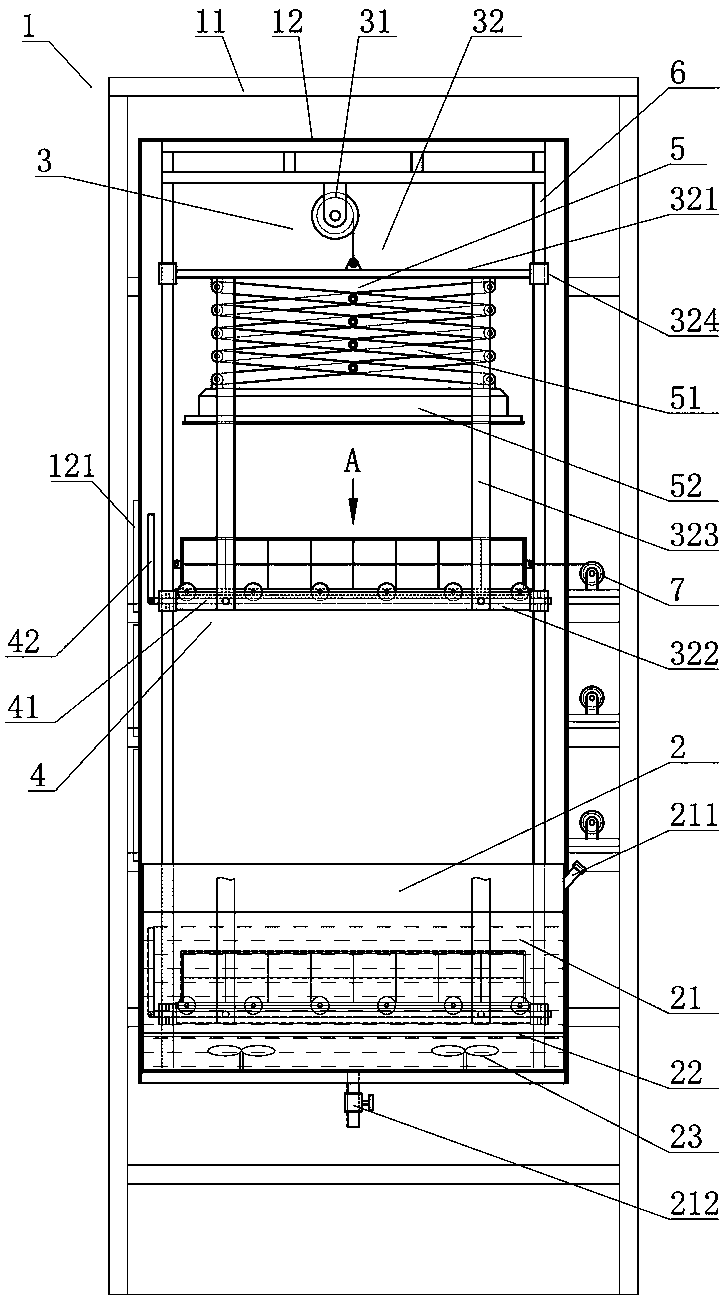

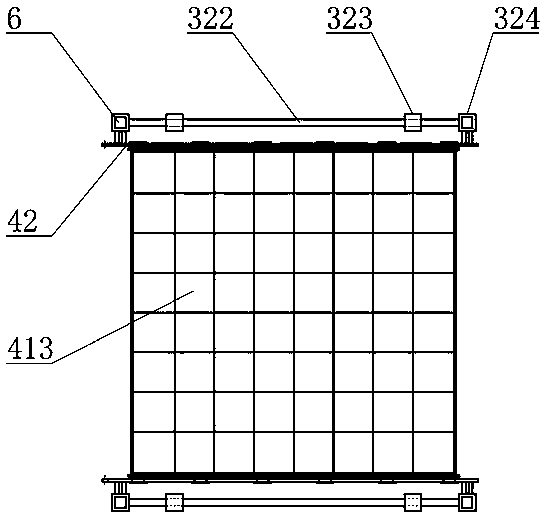

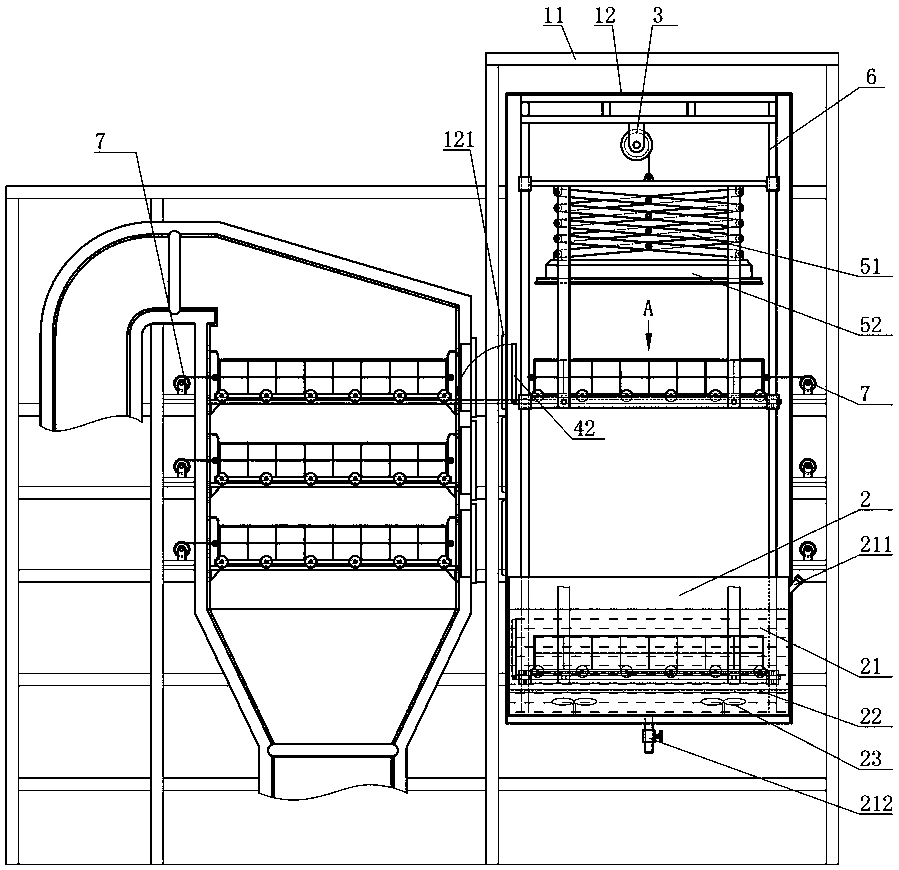

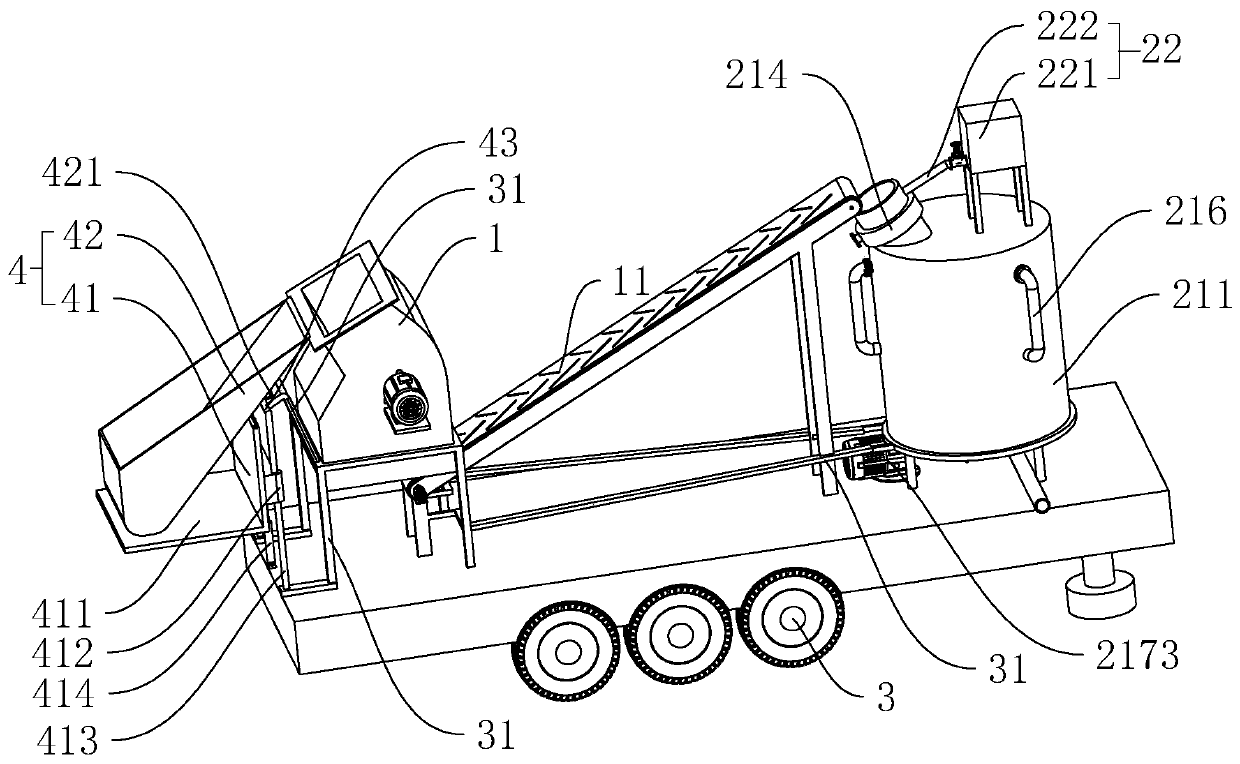

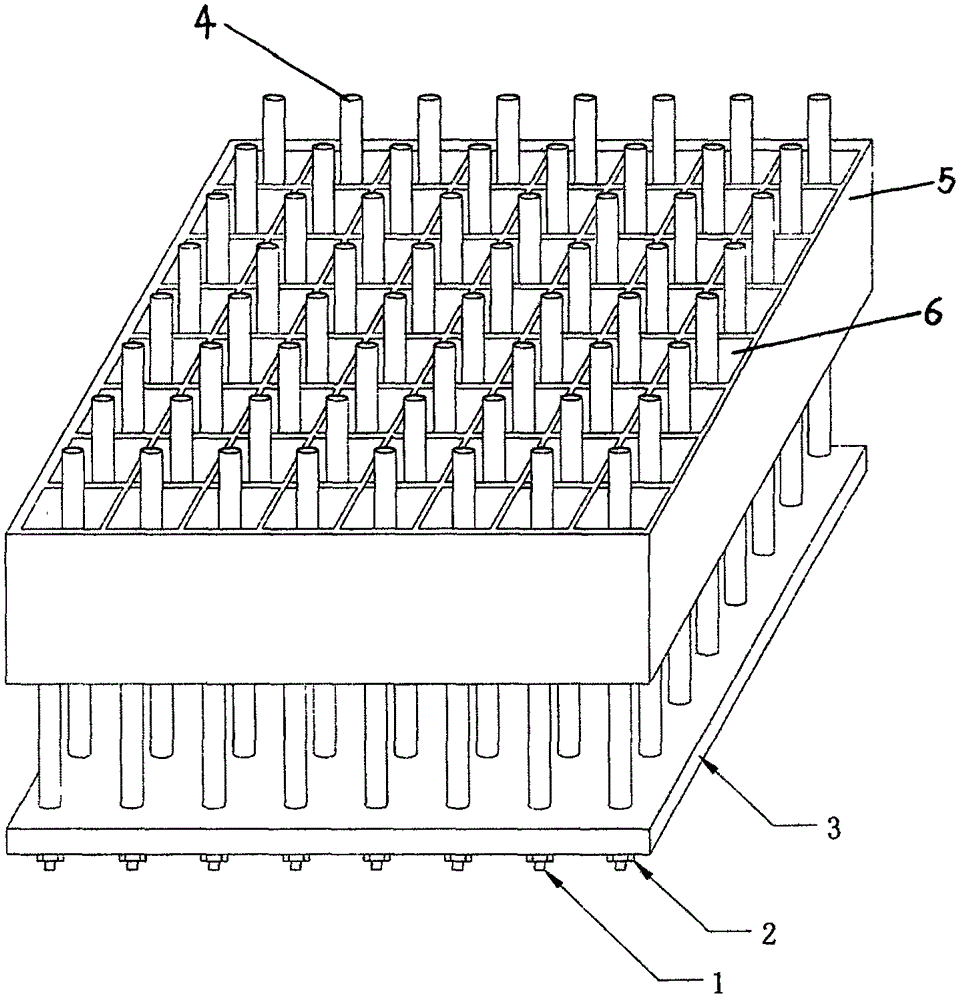

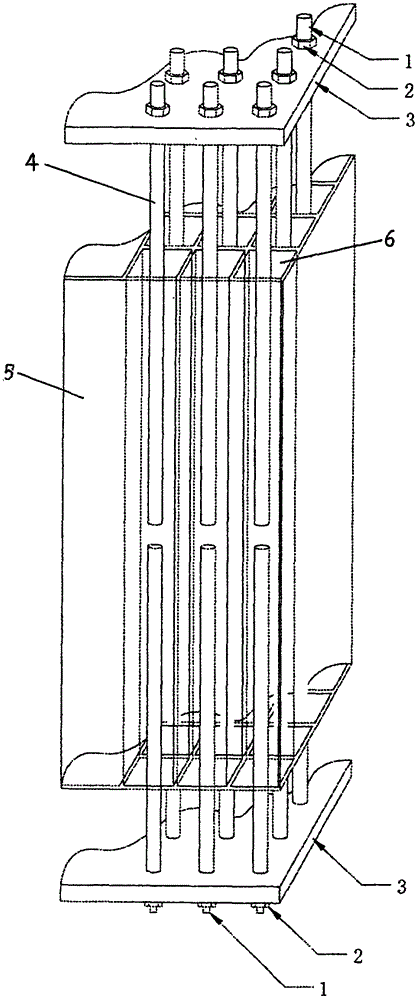

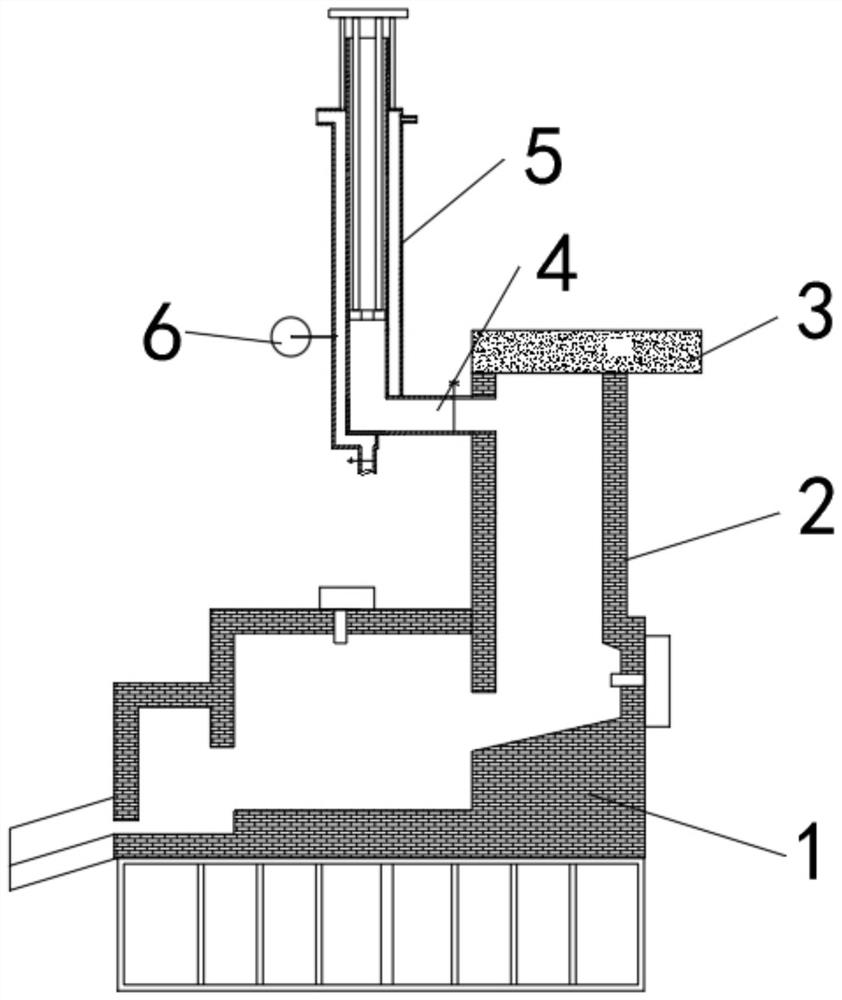

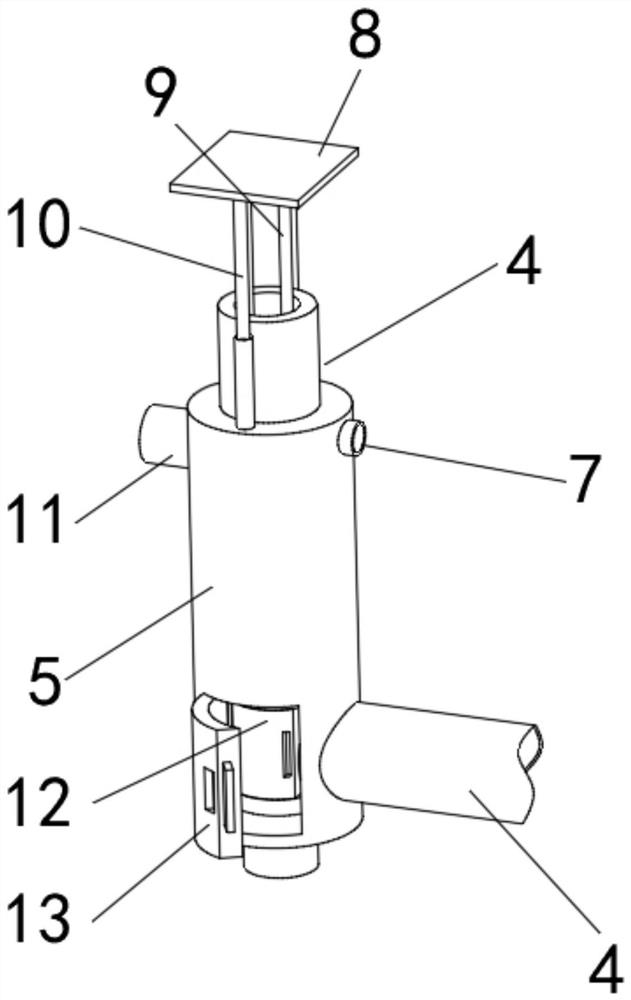

Lifting type on-site regeneration device for SCR (Selective Catalytic Reduction) catalyst

ActiveCN108298459AShort cycleLow costDispersed particle separationLifting framesEngineeringSupport plane

The invention discloses a lifting type on-site regeneration device for an SCR (Selective Catalytic Reduction) catalyst. The device comprises a fixing supporting frame which is abutted with an SCR catalyst on-site reaction station, wherein a liquid storing assembly is arranged at the bottom end of the fixing supporting frame; a conveying lifting assembly which can extend into the liquid storing assembly is arranged in the fixing supporting frame; an abutting assembly which is abutted with an SCR catalyst at the reaction station is arranged at the bottom end of the conveying lifting assembly; aheating lifting assembly for heating the SCR catalyst is arranged above the abutting assembly on the conveying lifting assembly. The device has the advantages of being simple and compact in structure,short in period, low in cost, small in workload, and high in regeneration quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

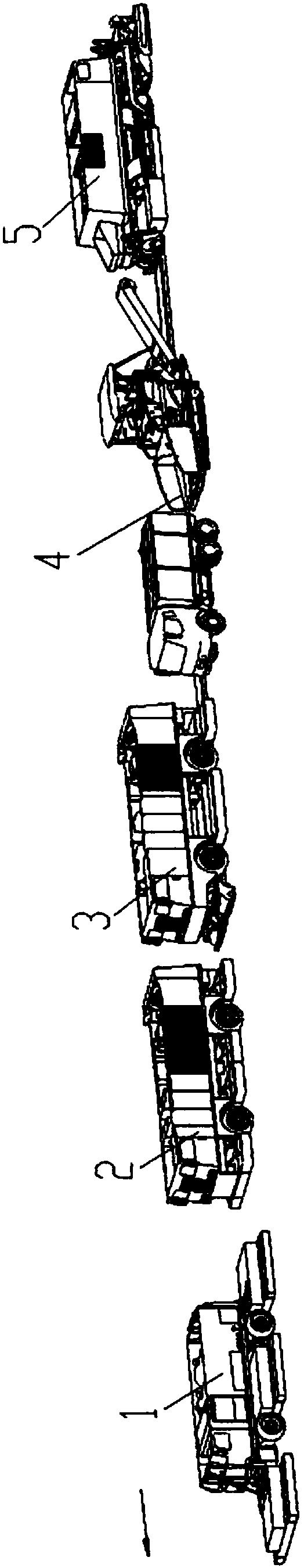

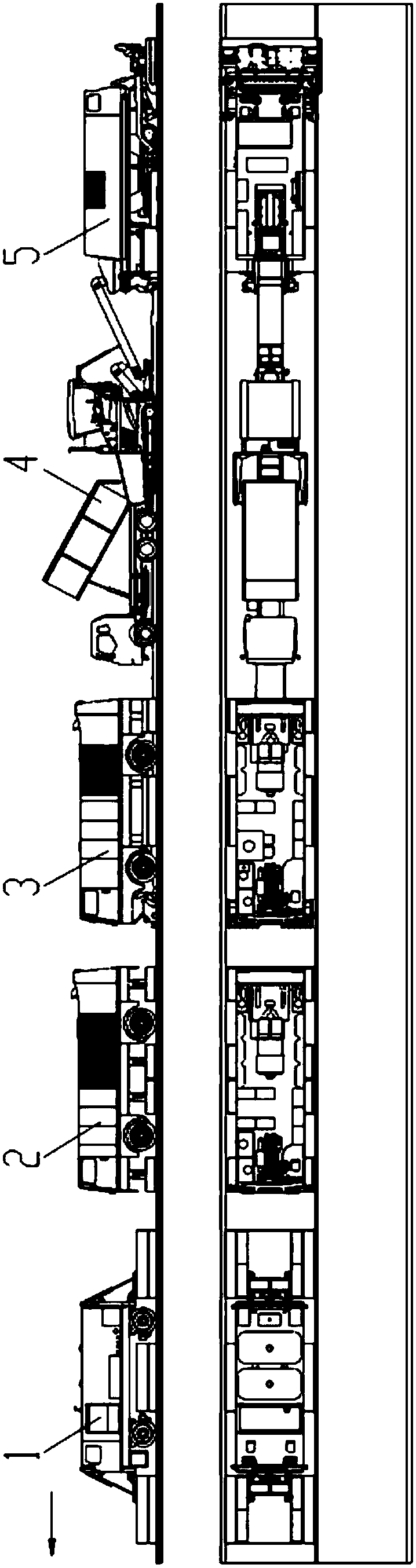

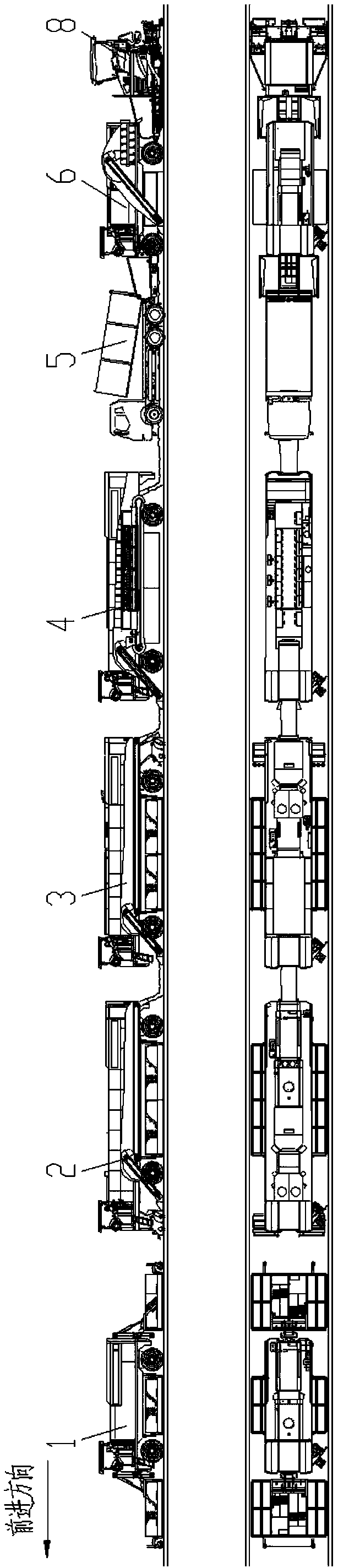

Layered hot-milling device, hot-air microwave composite in-situ heat regeneration complete set, and layered construction method thereof

The invention discloses a layered hot milling device, a hot-air microwave composite in-situ heat regeneration complete set and a layered construction method thereof. The layered hot milling device comprises a hot-air heating machine, a front milling heating machine, a rear milling heating machine, a microwave tunnel heating machine, a feeding machine, a remixing machine and a remixing and regeneration machine, wherein the asphalt pavement is heated by local hot air layered heating, layered hot milling and layered conveying, which realizes semi-closed and low temperature construction, reduces energy consumption and improves construction efficiency. The new modular heating technology of hot wind variable power and microwave composite heating is adopted to realize the asphalt pavement non-destructive, uniform and high efficient heating, recover the asphalt pavement performance, smokeless and environmental protection, moderate heating depth, small temperature gradient between layers, no gradation damage in hot milling, the temperature of asphalt material in each link up to the standard, and high construction quality. The new material is added by dump truck and multi-function feeder, which realizes multi-degree of freedom, multi-direction feeding, accurate and continuous feeding, and small temperature drop of asphalt material.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1312063CAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

Road milling asphalt waste recycling device

ActiveCN111455777AReduced likelihood of quality issuesOptimize quality product quantityRoads maintainenceProcess engineeringAsphalt

The invention relates to a road milling asphalt waste recycling device. The device comprises a crusher and a stirring mechanism, a walking mechanism is further included, the crusher and the stirring mechanism are fixedly connected to the walking mechanism; the stirring mechanism comprises a stirring part and a feeding part; the stirring part comprises a stirring box, a stirring barrel and a partition plate; the stirring box is provided with a discharging end and a feeding end, and the feeding end of the stirring box communicates with the crusher. First valves are arranged at the discharging end and the feeding end of the stirring box; the discharging end of the feeding part is communicated with the stirring box; the partition plate is of an annular structure, the outer ring edge of the partition plate is fixedly connected to the inner wall of the stirring box; the inner ring edge of the partition plate is fixedly connected to the edge of an upper opening of the stirring barrel, a second valve for opening and closing the stirring barrel is arranged in the edge of the upper opening of the stirring barrel, the discharging end of the stirring barrel communicates with the discharging end of the stirring box, a heating piece is arranged around the stirring barrel, and stirring blades are arranged in the stirring barrel. The regeneration quality of the asphalt mixture can be improvedwhile the production site is changed along with the construction site.

Owner:义伦建设有限公司

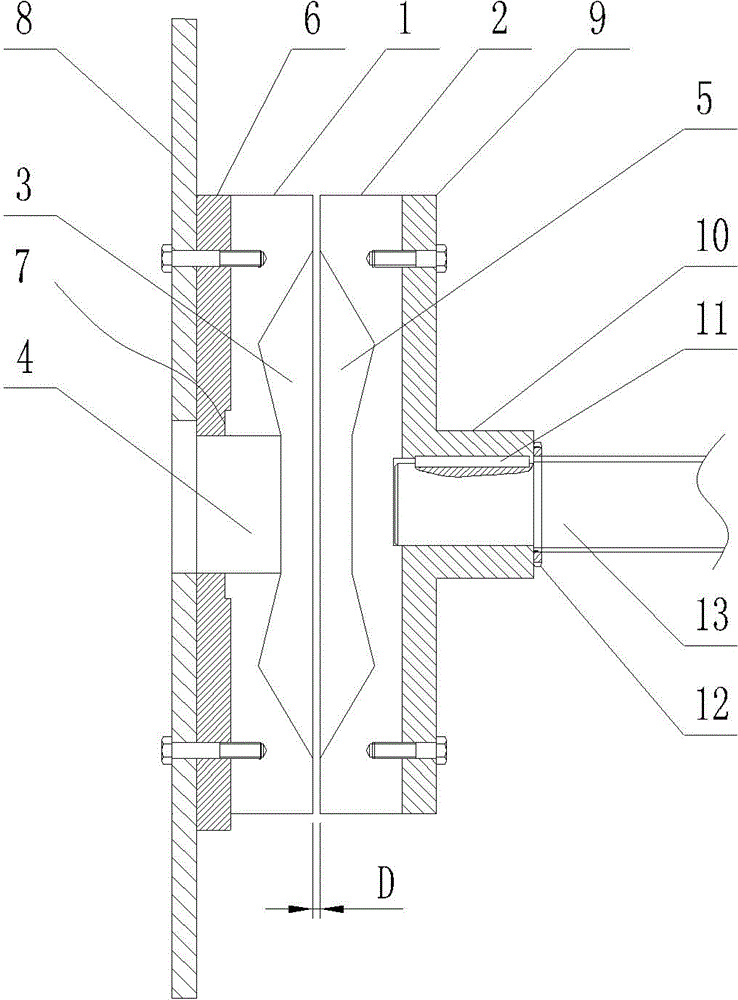

Ultrasonic device for cleaning denitration catalyst

InactiveCN104548936AImprove regeneration qualityNo damageDispersed particle separationCatalyst regeneration/reactivationBiomedical engineeringUltrasonic generator

The invention relates to an ultrasonic device for cleaning a denitration catalyst. The device comprises an ultrasonic generator, one or more than one ultrasonic bars and a porous flange plate, wherein the ultrasonic generator is connected with the ultrasonic bars; the multiple ultrasonic bars are arranged in parallel; the ultrasonic bars are inserted into the holes of the denitration catalyst; each ultrasonic bar can be inserted into the hole of the denitration catalyst from one end or two ends of the denitration catalyst; and one end of each ultrasonic bar is connected with the porous flange plate. The device disclosed by the invention is good in cleaning effect, and the ultrasonic bars stretch into the interiors of the holes of the catalyst for cleaning; the ultrasonic energy distribution is uniform, and structural damage of the catalyst is avoided; and moreover, the ultrasonic energy emission is mainly performed in the radial direction, the pores are completely cleaned, and the catalyst is high in regeneration quality, stable and reliable.

Owner:CHENGDU JIUZHOU LIYUAN TECH

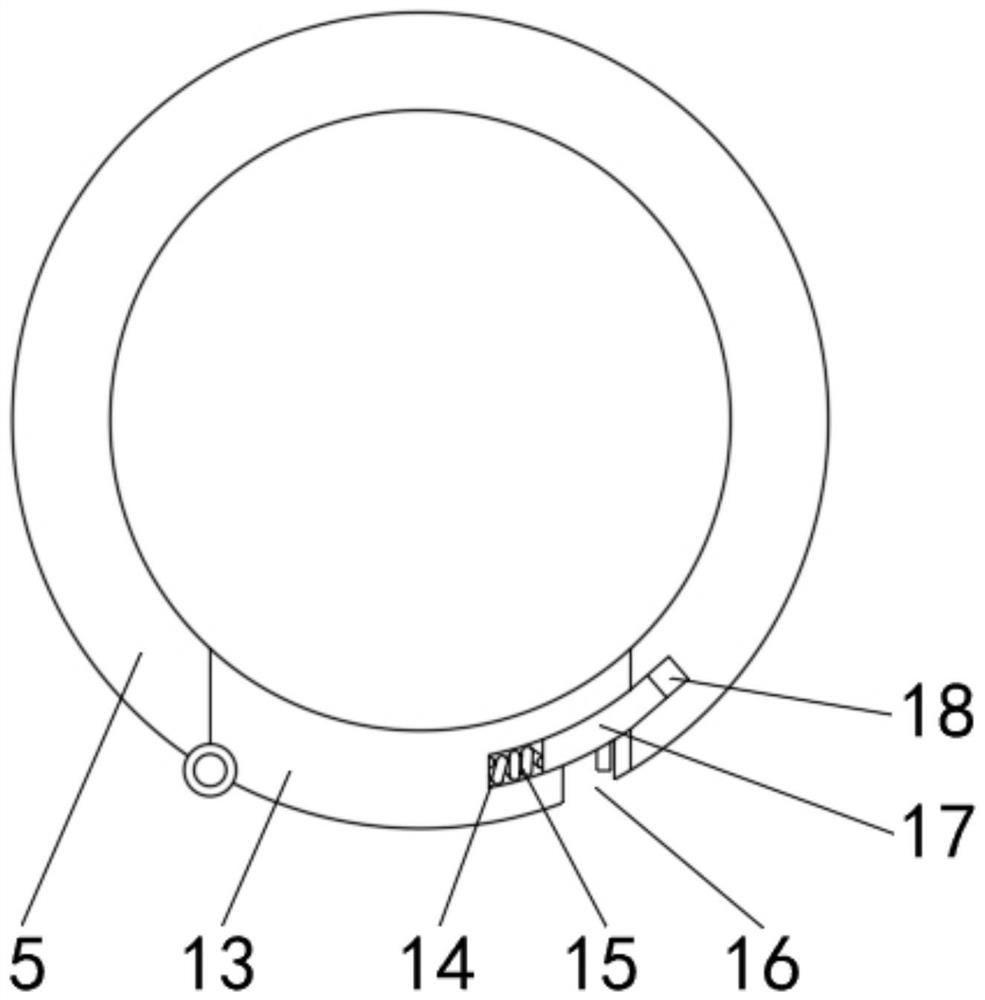

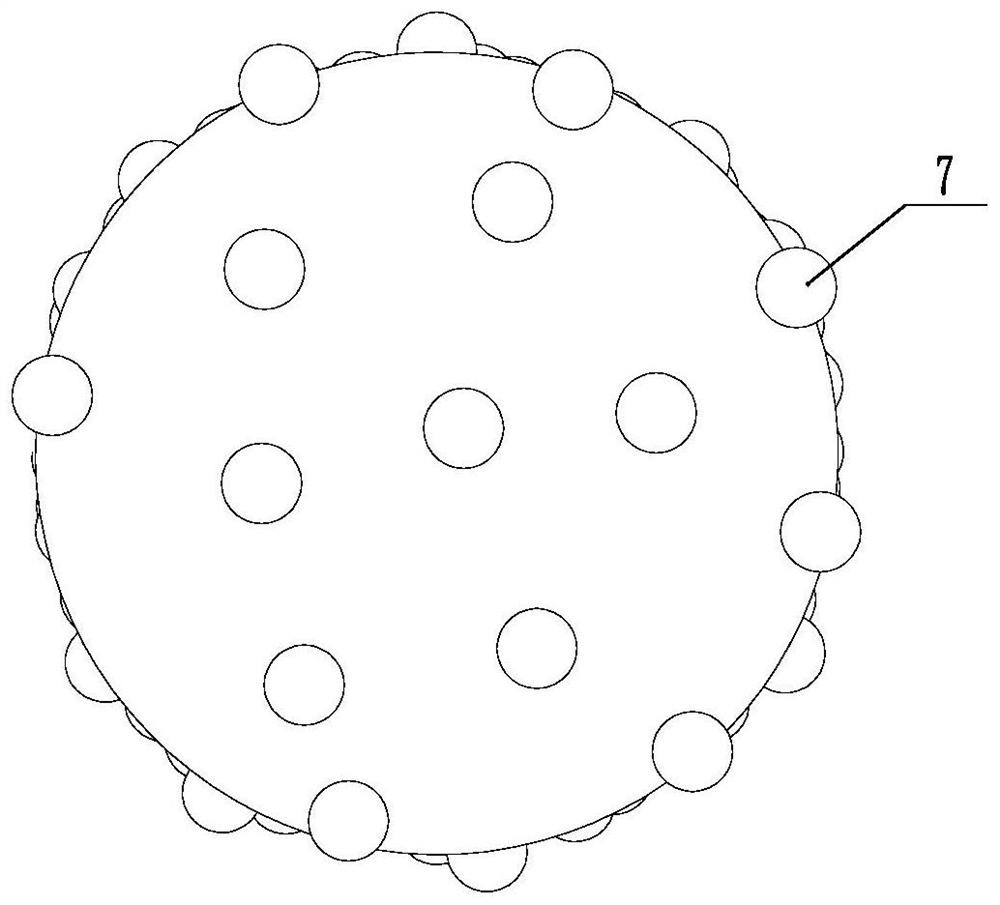

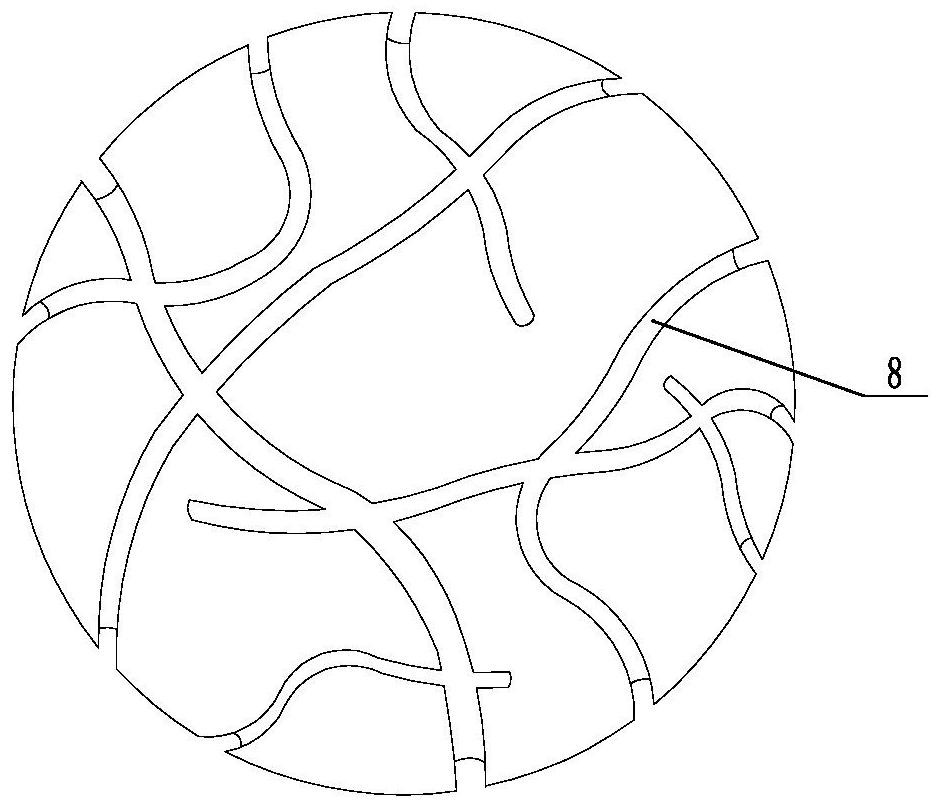

Efficient double rotation regeneration device for foundry used sand

InactiveCN106493288AEasy to enter sandNot deflectedMould handling/dressing devicesFoundrySpiral blade

The invention discloses an efficient double rotation regeneration device for foundry used sand. The efficient double rotation regeneration device for the foundry used sand comprises a vertically arranged sand cylinder, a rotating shaft arranged on the center axis of the sand cylinder, a first rotary motor coaxially connected to the top end of the rotating shaft, a transmission gear arranged at the position of the geometric center of the bottom of the sand cylinder, a second rotary motor in transmission cooperation with the transmission gear, and a sand cylinder support; first downwards-inclined crushing and stirring rods are arranged above the rotating shaft; the position, below the first crushing and stirring rods, on the rotating shaft is provided with spiral blades; the inner wall of the sand cylinder is provided with second downwards-inclined crushing and stirring rods; slide rails are arranged on the sand cylinder in a horizontal encircling manner; and slide grooves matched with the slide rails are arranged on the sand cylinder support. According to the efficient double rotation regeneration device for the foundry used sand, due to opposite rotation of the sand cylinder and the rotating shaft, the foundry used sand achieves sufficient friction, an inert membrane on the surface of the used sand is more effectively removed, the regeneration quality and efficiency of the used sand is improved, and regeneration of the used sand can be continuously performed.

Owner:绵阳易简环保科技有限公司

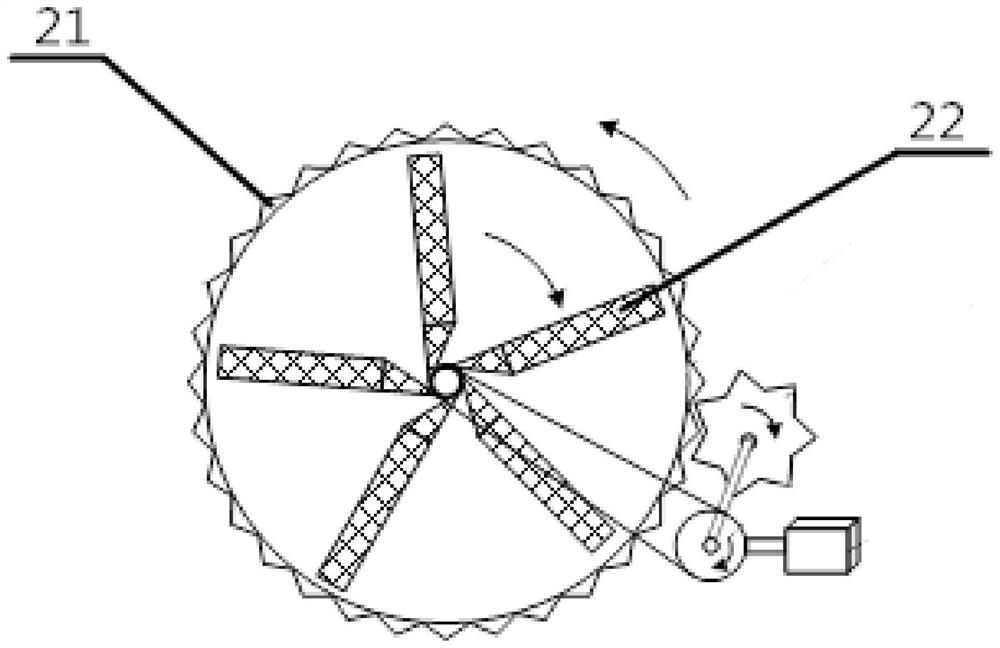

Polishing structure for old sand regeneration

InactiveCN104668450AEasy to handleReduce energy consumptionMould handling/dressing devicesEngineeringEnergy consumption

The invention provides a polishing structure for old sand regeneration. The polishing structure is high in regeneration quality and low in energy consumption and can be used for screening sand particles. The polishing structure comprises a fixed static polishing disk and a rotatable movable polishing disk, wherein the static polishing disk and the movable polishing disk are arranged in parallel; a sand storage slot I and a sand storage slot II are respectively formed in the opposite end faces of the static polishing disk and the movable polishing disk; a sand guide hole for communicating the outer side of the static polishing disk with the sand storage slot I is also formed in the static polishing disk; a screening clearance is also formed between the static polishing disk and the movable polishing disk.

Owner:WUXI SHUANGQUAN MECHANICAL FACTORY

Control cable used for nuclear power station

InactiveCN107033470AImprove regeneration qualityUniform textureRubber insulatorsInsulated cablesNuclear engineeringAntioxidant

The invention discloses a control cable used for a nuclear power station. The control cable comprises a cable core and an outer sheath which wraps the outer side of the cable core, wherein the outer sheath is prepared form, by weight, 130-150 parts of main ingredients, 0.3-0.6 part of dibenzoyl peroxide, 1-2 parts of 1,1,3,3-tetramethyl benzene peroxide oxygroup butyl acetate, 0.5-0.8 part of 1,1-double-(tert-butyl peroxide) cyclohexane, 1-2 parts of accelerant TMTD, 8-16 parts of melamine pyrophosphate, 20-30 parts of microencapsulated red phosphorus, 15-25 parts of melamine cyanurate acid, 10-20 parts of cyanoguanidine, 50-70 parts of grass carbon tobacco stem compounds, 4-8 parts of silane coupling agents, 3-5 parts of lubricant and 2-4 parts of antioxidant. The control cable is good in corrosion resistance property, aging resistance property, wear resistance property and high temperature resistance property, high in mechanical strength, and long in service life.

Owner:安徽省无为县经纬电缆附件有限公司

Vacuum ink injection machine

InactiveCN107599637AIncrease the number of refillsImprove regeneration qualityOther printing apparatusTemperature controlWater storage tank

The invention discloses a vacuum ink injection machine. The vacuum ink injection machine comprises a shell, a plurality of ink storage devices, a water storage device, a first temperature control device, an air inlet device, a second temperature control device, a vacuum tank and a controller. Any one ink storage device comprises an ink holder and a temporary storage tank, wherein a flow guide plate tilting downwards is arranged in the ink holder, the storage tank is arranged below the ink holder, a vent hole is formed in the top of the temporary storage tank, and the bottom of the temporary storage tank communicates with an ink inlet of an ink box through a second ink outlet tube, a multi-way valve, an ink inlet tube and an ink inlet connector. The water storage device comprises a water storage tank communicating with the ink inlet tube through the multi-way valve. The air inlet device comprises an air inlet tank which communicates with the ink inlet tube through the multi-way valve. An ink lead tube is arranged on the upper portion of the vacuum tank in a communicating mode and communicates with an ink outlet of the ink box through an ink lead connector. The vacuum ink injection machine has the advantages that ink can be re-injected into the ink box repeatedly, the ink injection amount is accurate, and the ink injection quality is high.

Owner:北海市天硌打印耗材有限公司

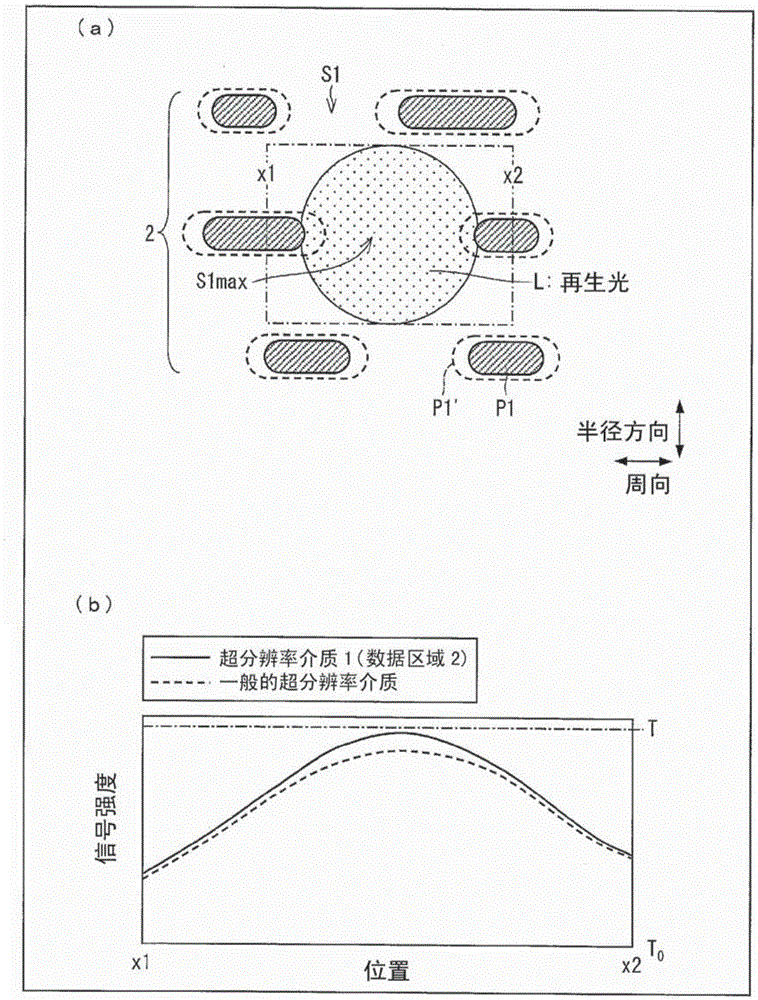

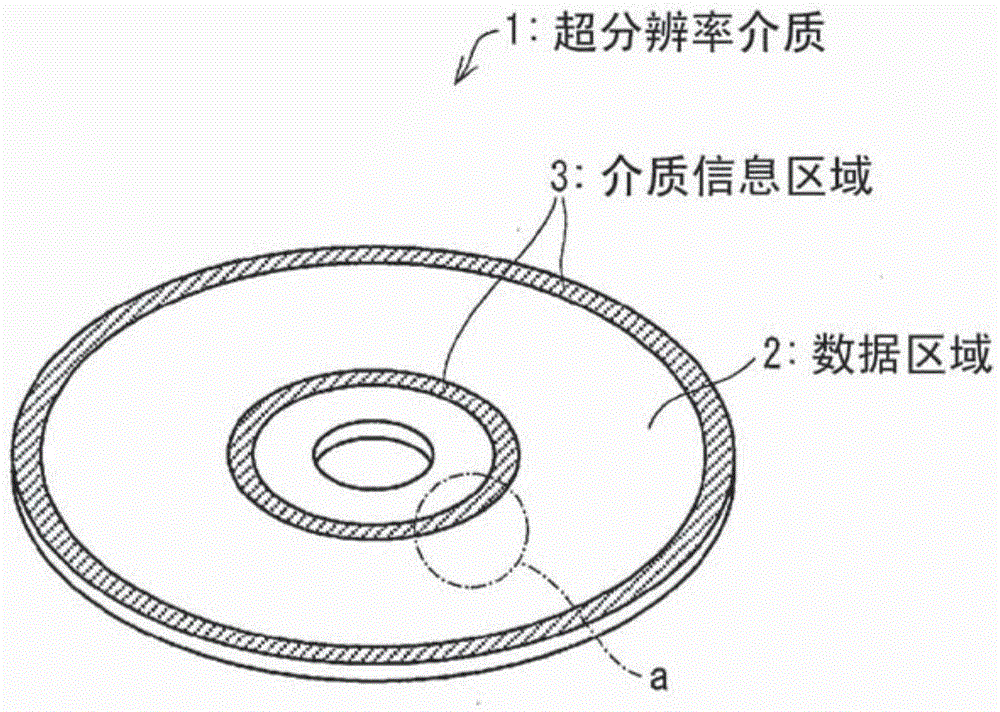

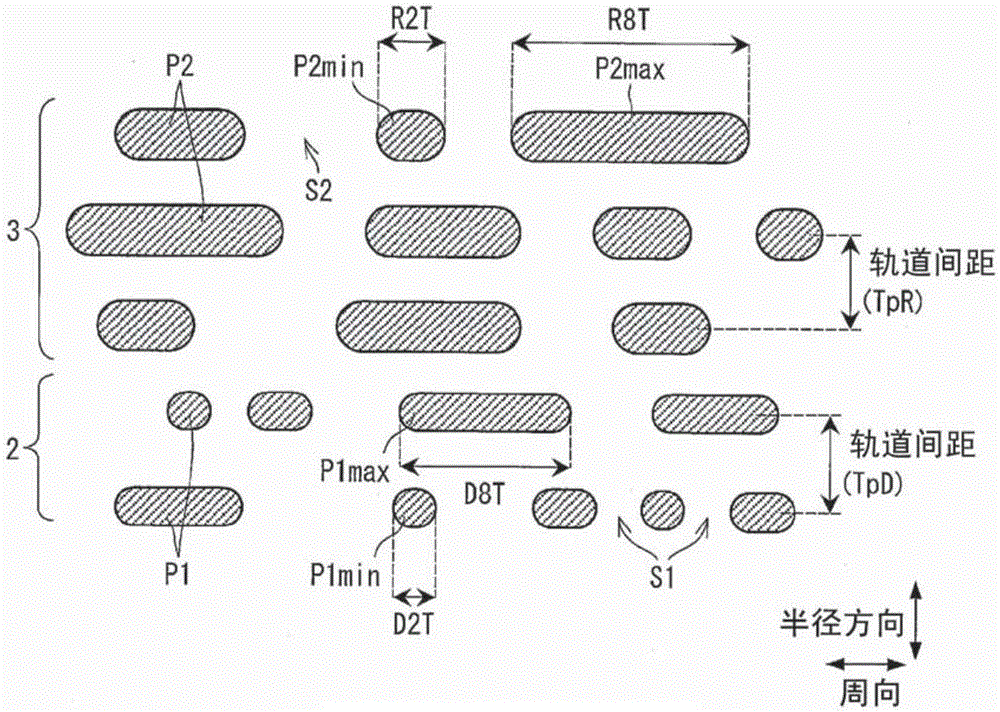

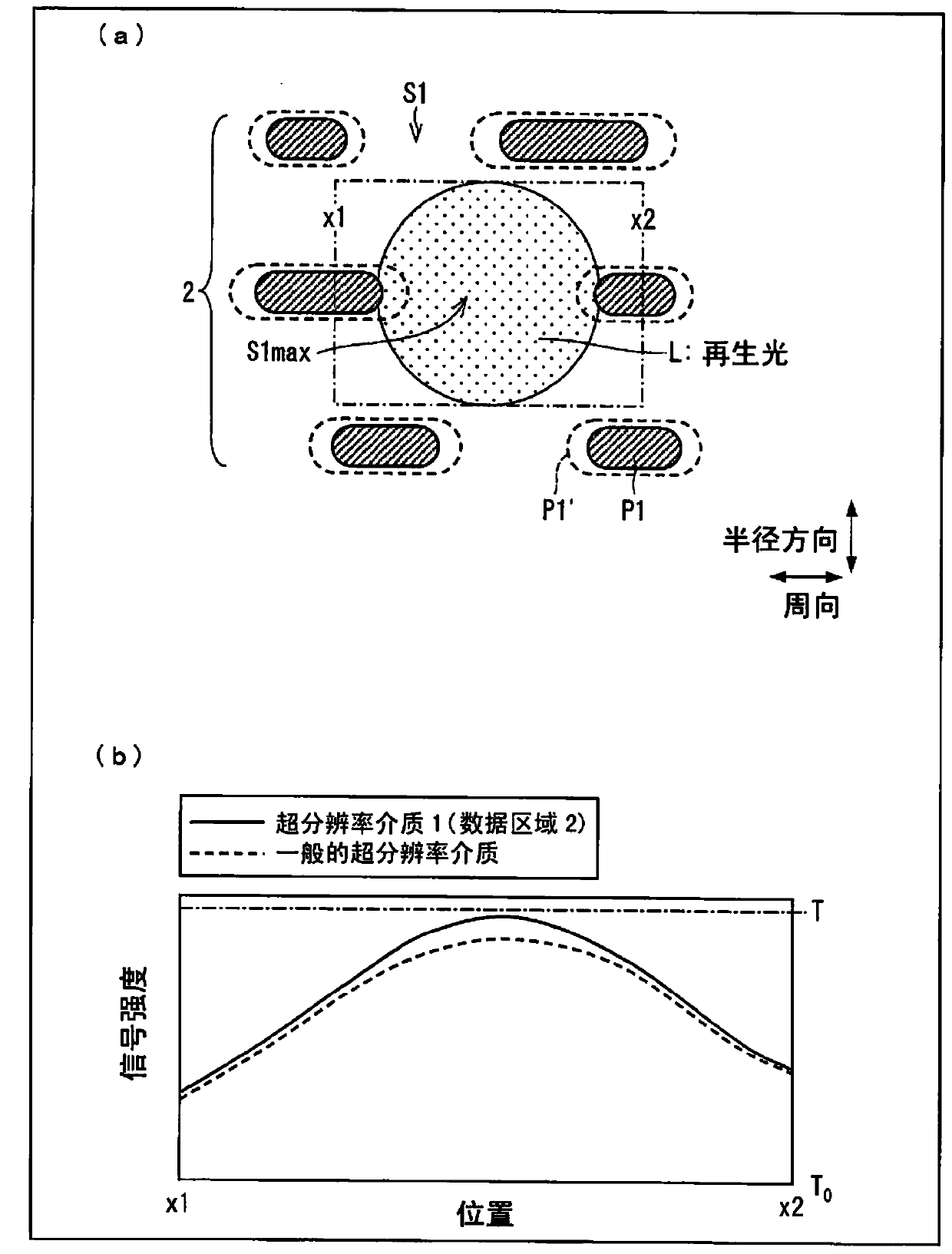

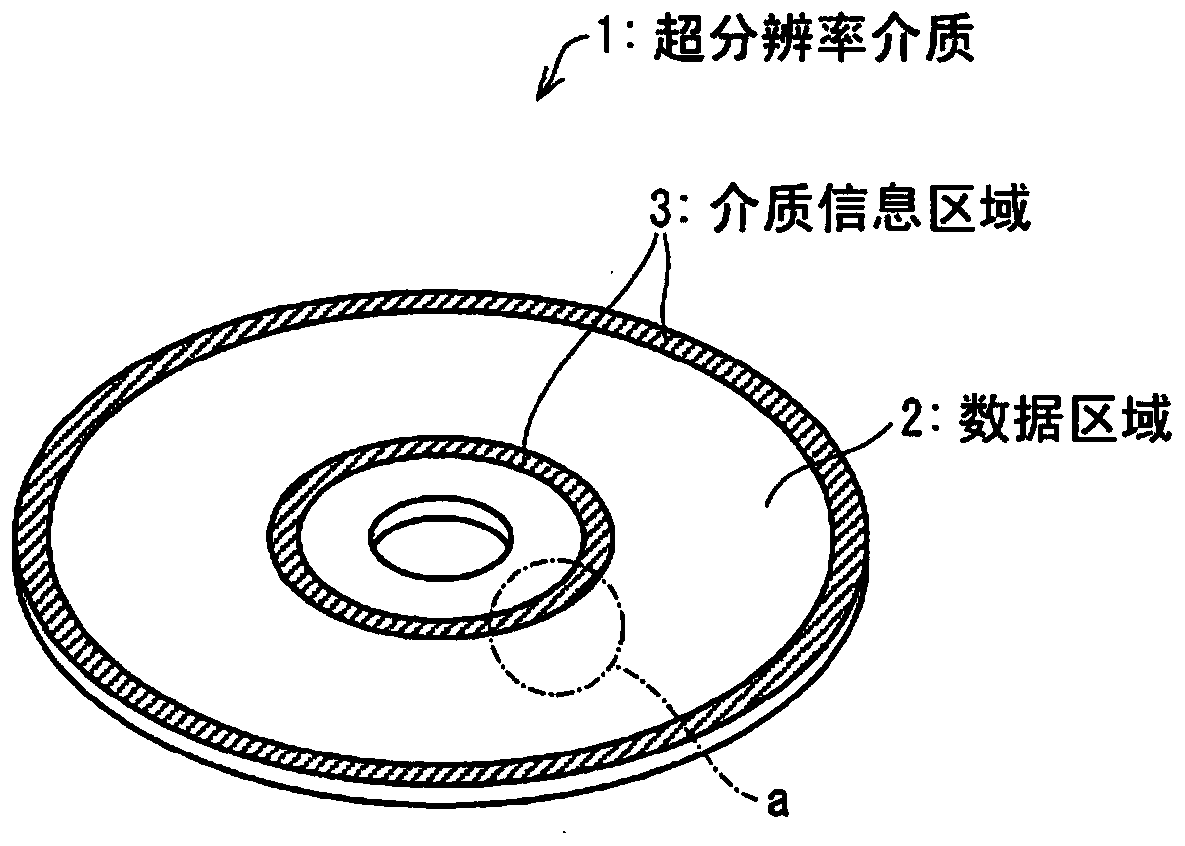

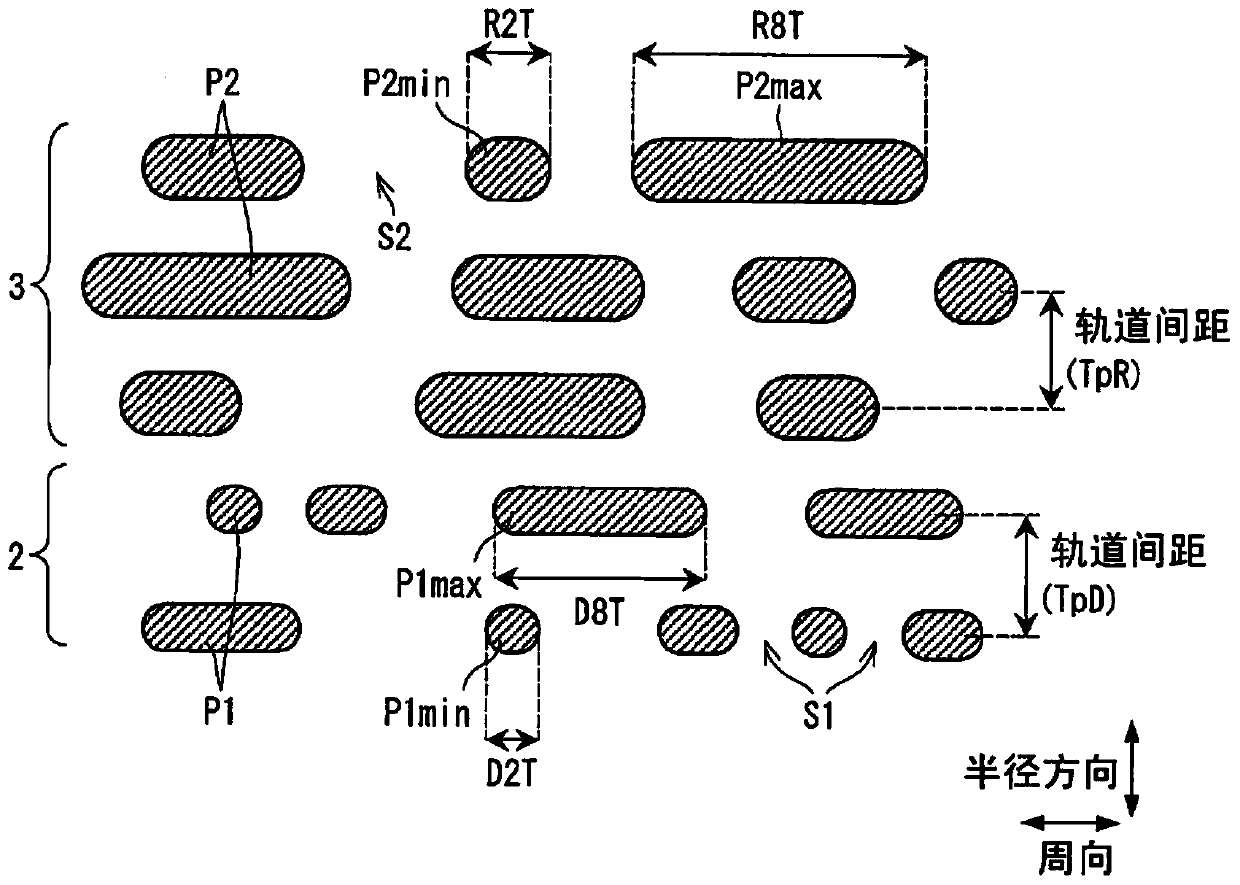

Optical information recording medium, reproduction method, and reproduction device

ActiveCN105264602AImprove regeneration qualityRecord information storageReproducing involving reflectivity/absorption/color-changeReflectivityOptoelectronics

Owner:SHARP KK +1

Aluminum alloy continuous melting furnace utilizing waste heat to regenerate resin sand

PendingCN113203284AIncrease profitReach the purpose of recyclingRemovable covers for furnacesCharge composition/stateFlueWaste heat

The invention discloses an aluminum alloy continuous melting furnace utilizing waste heat to regenerate resin sand, and relates to a melting furnace. The aluminum alloy continuous melting furnace specifically comprises a furnace body and a feeding tower installed at the top of the furnace body, a furnace cover is fixed at the top of the feeding tower, and the side face of the top end of the feeding tower is fixedly connected with one end of an L-shaped discharge flue. A sleeve fixedly sleeves the vertical part of the discharge flue, a sand inlet is formed in the side face of the top end of the sleeve, a discharge port is formed in the bottom of the sleeve, reclaimed sand is discharged through the discharge port, and an extraction opening is formed in the top of the sleeve. According to the aluminum alloy continuous melting furnace utilizing the waste heat to regenerate the resin sand, the waste heat of the melting furnace is utilized, so that the heat utilization rate of the melting furnace is effectively increased, additional resin sand heating equipment is not needed, the purpose of recycling the resin sand is achieved, and the production cost of an enterprise is reduced.

Owner:江苏迅隆铝业有限公司

High-pressure ink joiner for regenerated ink box

InactiveCN107584891AIncrease the number of refillsImprove regeneration qualityPrintingWater storage tankEngineering

The invention discloses a high-pressure ink joiner for a regenerated ink box. The high-pressure ink joiner comprises a shell, a plurality of ink storage devices, a water storage device, an air inlet device, a vacuum tank and a controller, wherein any one ink storage device comprises an ink cylinder which is divided into a high pressure bin and a vacuum bin through a partition plate device horizontally arranged inside the ink cylinder; the water storage device comprises a water storage tank and a first temperature control device which is horizontally arranged in the middle of the water storagetank; the air inlet device comprises an air inlet tank and a second temperature control device which is horizontally arranged in the middle of the air inlet tank. The high-pressure ink joiner has theadvantages of repeated ink refilling for the ink box, accurate ink refilling amount, high ink refilling quality, and the like.

Owner:北海市天硌打印耗材有限公司

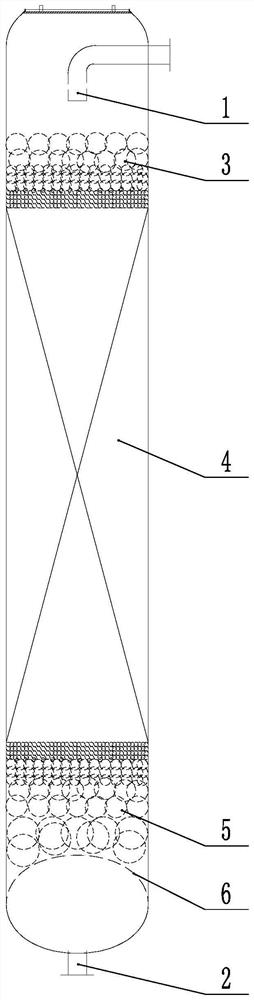

Method for performing semiconductor etching by using high-purity hexafluoroethane

ActiveCN114823326AHigh purityExtend the life cycleDispersed particle separationSemiconductor/solid-state device manufacturingHexafluoroethaneDevice material

The invention relates to the field of semiconductor devices, and discloses a method for performing semiconductor etching by using high-purity hexafluoroethane, which comprises the following steps of: drying hexafluoroethane raw material gas, introducing the dried gas into an adsorber with a special structure for adsorption and impurity removal, and sequentially performing liquefaction and rectification purification to obtain the high-purity hexafluoroethane, and after plasma is formed by etching gas containing high-purity hexafluoroethane, dry etching is carried out on the semiconductor substrate covered with the patterned mask. According to the invention, the adsorber with a special structure is adopted to perform adsorption and impurity removal on the hexafluoroethane dry gas, and the distribution uniformity of the dry gas in the adsorber can be improved, so that the adsorption and impurity removal effect is improved, the hexafluoroethane with higher purity can be obtained, and the influence of impurities in the hexafluoroethane on the performance of a semiconductor device is reduced; meanwhile, the adsorber can improve the distribution uniformity of regeneration gas, so that the regeneration period of the molecular sieve is shortened, and the regeneration quality is improved.

Owner:宿州伊维特新材料有限公司

Purification and regeneration process and equipment of waste refrigerator plastic

PendingCN113618965AReduce pollutionImprove regeneration qualityPlastic recyclingMechanical material recoveryProcess engineeringIcebox

The invention relates to a purification and regeneration process of waste refrigerator plastic, which comprises the following steps: S1, crushing and sorting; S2, dry sorting; S3, wet sorting; and S4, purifying and granulating. By implementing the embodiment of the invention, the purification and regeneration process for the waste refrigerator plastic provided by the invention has the following beneficial effects that foam cotton is separated in advance by adopting a dry grinding-winnowing method in the S2, so that the pollution of the foam cotton to a solution medium in the subsequent wet sorting is reduced, and in the step S3, residual chloride ions (chlorine salt) and the foam cotton on the surface of the plastic are removed through multiple times of flotation system treatment, so that the plastic regeneration quality is improved, and the problems of low sorting efficiency and poor purification grade of existing waste refrigerator plastic are effectively solved.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

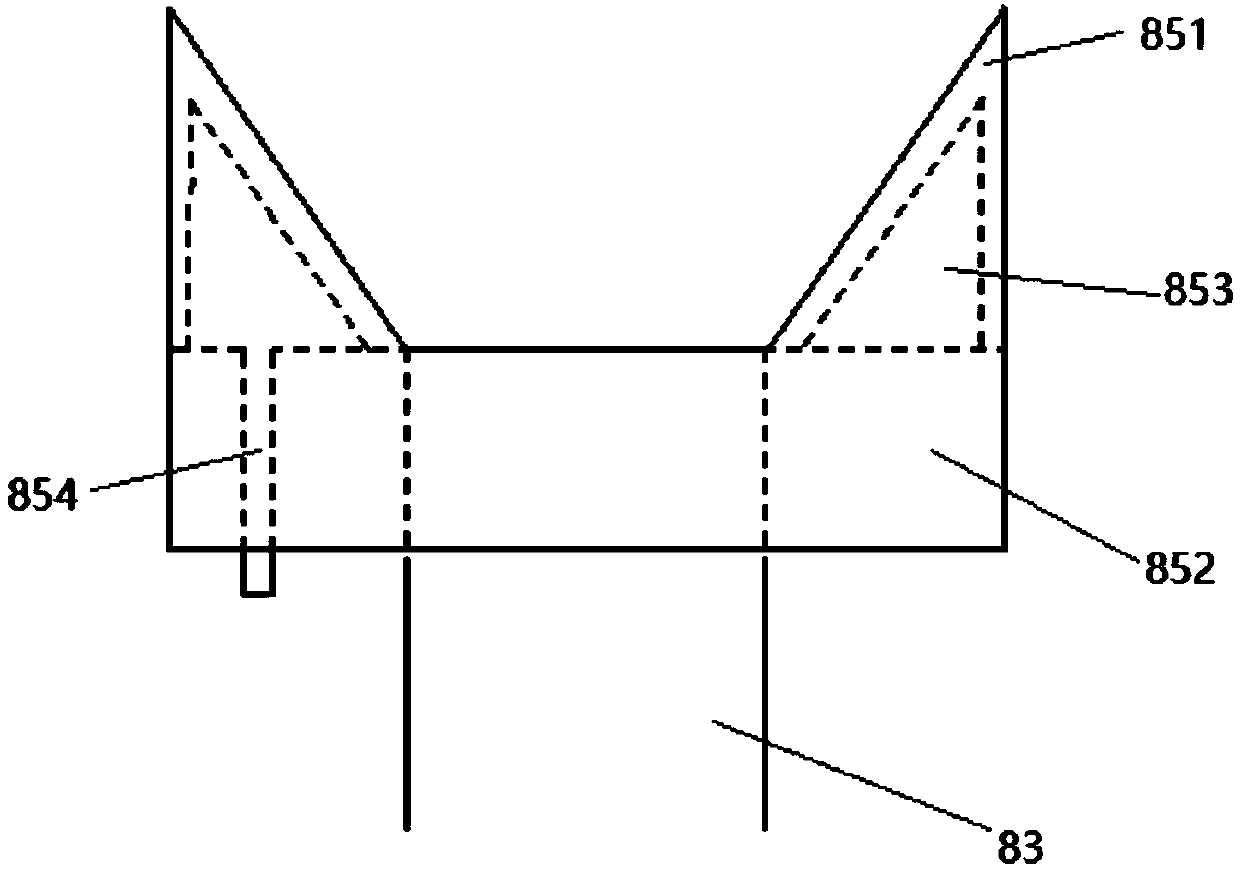

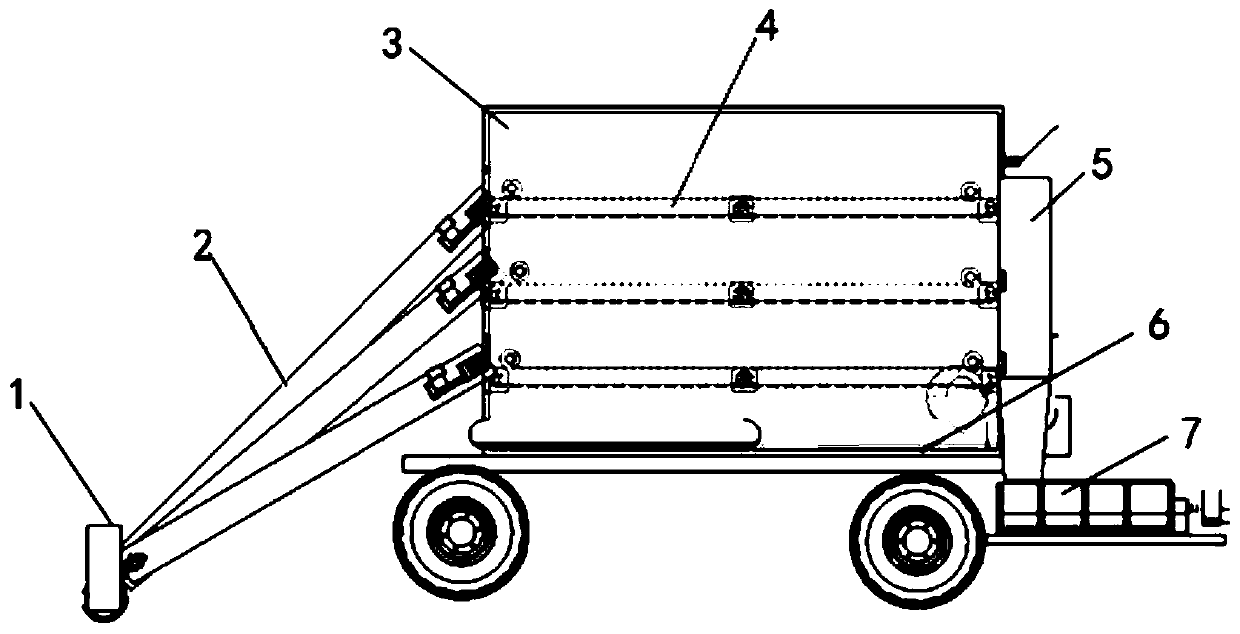

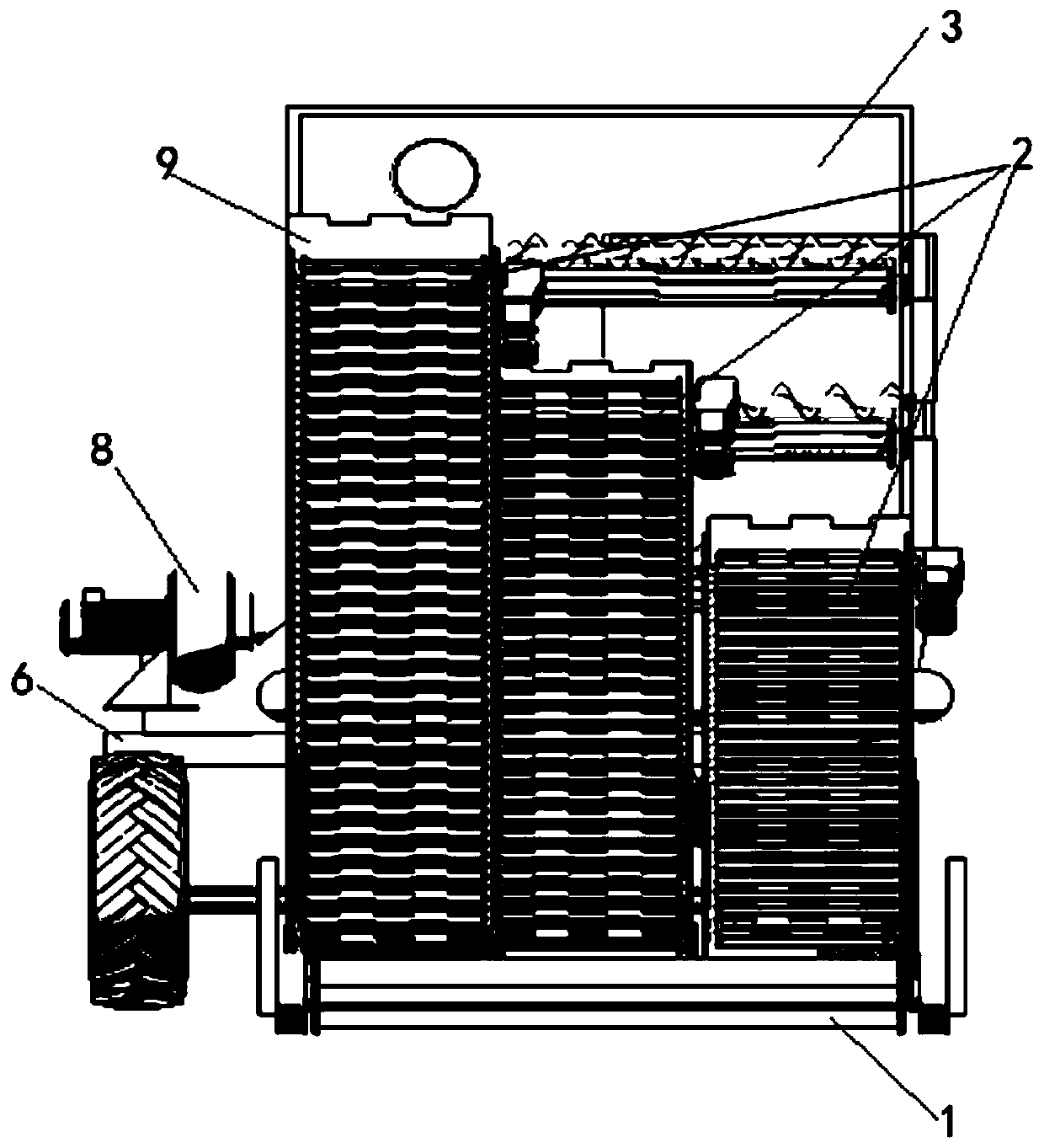

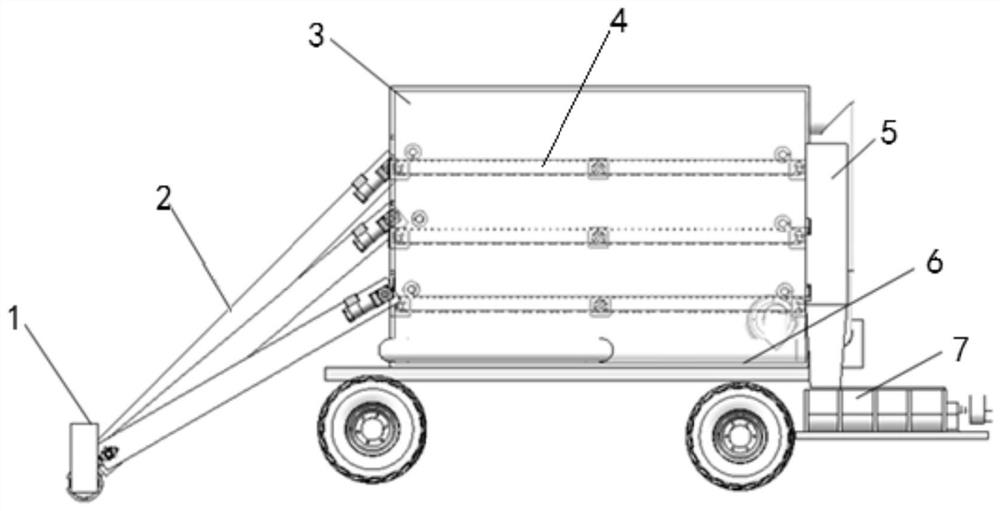

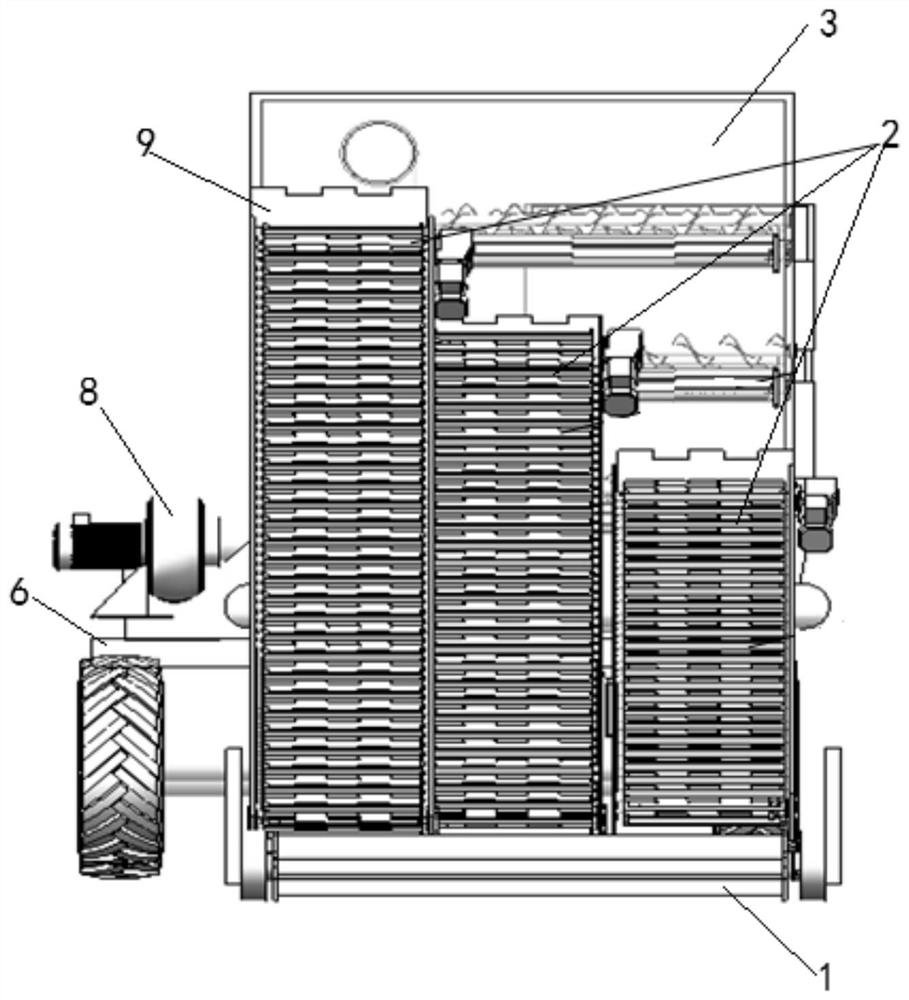

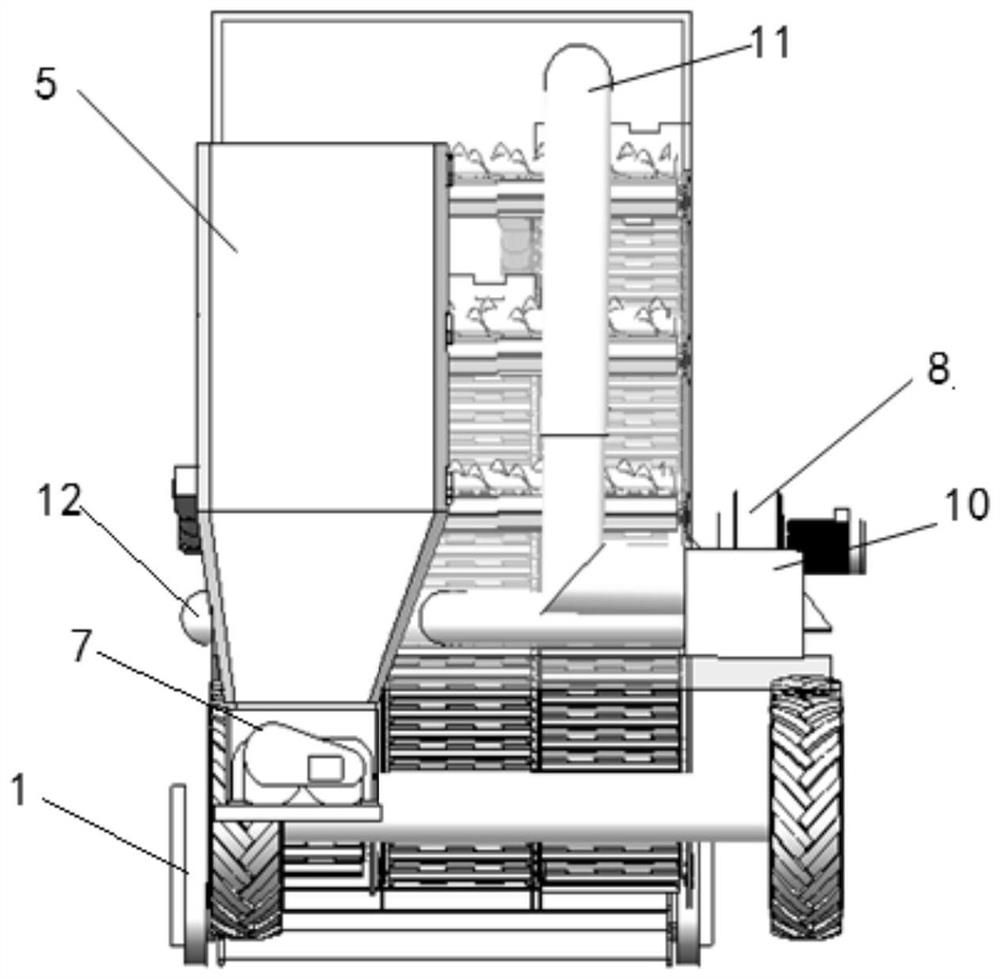

Multi-layered heating device for heating bituminous pavement milling material

ActiveCN110158428AReduce thicknessIncrease the heating areaRoads maintainenceEngineeringRoad surface

The invention discloses a multi-layered heating device for heating a bituminous pavement milling material. The heating device comprises a frame, wheels are arranged at the bottom of the frame, a heating box is arranged above the frame, a plurality of layers of conveying devices are arranged inside the heating box from top to bottom and are used for conveying an asphalt mixture to fully heating theasphalt mixture, a scraper feeder is arranged at the position, close to the pavement, of the front of the frame, the scraper feeder is used for conveying the asphalt mixture on the pavement to a feeding opening in front of each layer of conveying device through a plurality of scraper lifting machines, a hot blast stove and a circulating fan are arranged on the rear of the frame through a mountingframe, the rear part of the heating box is provided with a hopper used for collecting the heated asphalt mixture output by discharge ports, a stirring cylinder is arranged at the lower part of the rear part of the frame, and the lower part of the hopper is connected with a feeding port of the stirring cylinder.

Owner:CHANGAN UNIV

Optical information recording medium, reproduction method, and reproduction device

ActiveCN105264602BImprove regeneration qualityRecord information storageReproducing involving reflectivity/absorption/color-changeMechanical engineeringMaterials science

Owner:SHARP KK +1

Device and method for pneumatic desanding and sand regeneration of castings

ActiveCN104096823BAvoid wastingReduce processing timeMould handling/dressing devicesCombustion chamberFluidized bed

The invention provides a device and a method for pneumatically removing sands from a casting and recovering sands. A furnace body of a sand removing furnace is divided into a boiling pressure room and a fluidized bed room by a closed partition board, a plurality of high-temperature hot air nozzles are arranged in the fluidized bed room and are connected to a combustion room outside the furnace body, and the combustion room is further connected with a combustion air pipe and a first high-pressure fan; the boiling chamber room is communicated with a second high-pressure fan, and a plurality of air nozzles are arranged on the closed partition board towards the fluidized bed room; an air cooling room is provided with a closed plate with a plurality of blowing nozzles, the closed plate is used for dividing the air cooling room into a lower air pressure room and an upper grading room, the air pressure room is connected with a third high-pressure fan, the side wall of the grading room is provided with a door and is communicated to a sand outlet, the grading room is communicated with the fluidized bed room, and the top of the grading room is provided with a door and is connected with a dust remover through a dust removing pipeline. According to the device and the method for pneumatically removing the sands from the casting and recovering the sands, the working processes of shaking out the sands, removing the sands and recovering the used sands can be carried out in a centralized manner.

Owner:马鞍山海森控电气有限公司

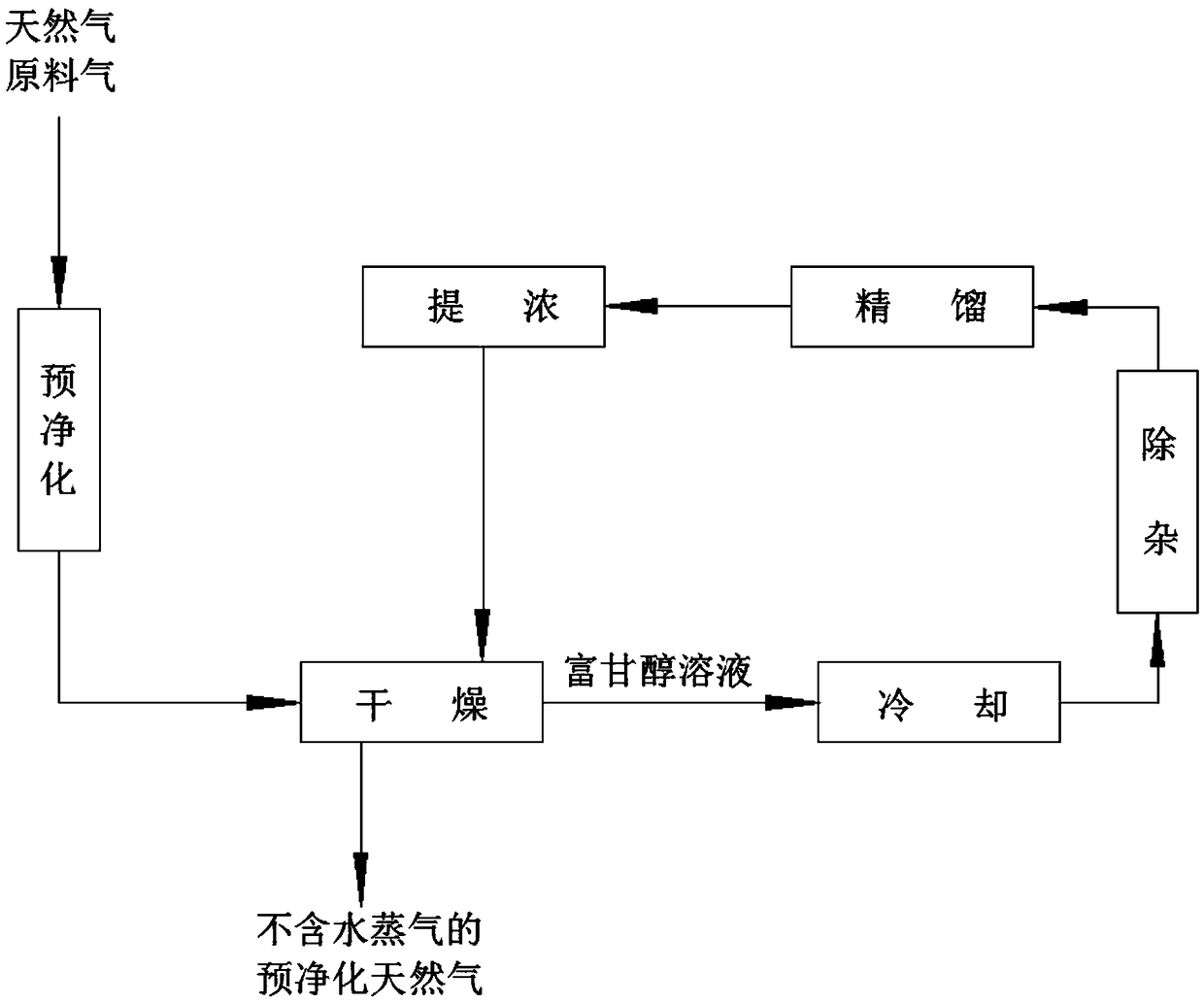

Natural gas triglycol dehydrating process

The invention discloses a natural gas triglycol dehydrating process, and belongs to the field of natural gas chemical industry. The process comprises the following steps: pre-purifying, drying, cooling, removing impurities, rectifying and concentrating. The natural gas triglycol dehydrating process has the beneficial effects that the natural gas dehydrating effect is good, triglycol consumption issmall, triglycol regenerating efficiency is high, evaporation loss is less, and investment and operation cost is low.

Owner:何瑛

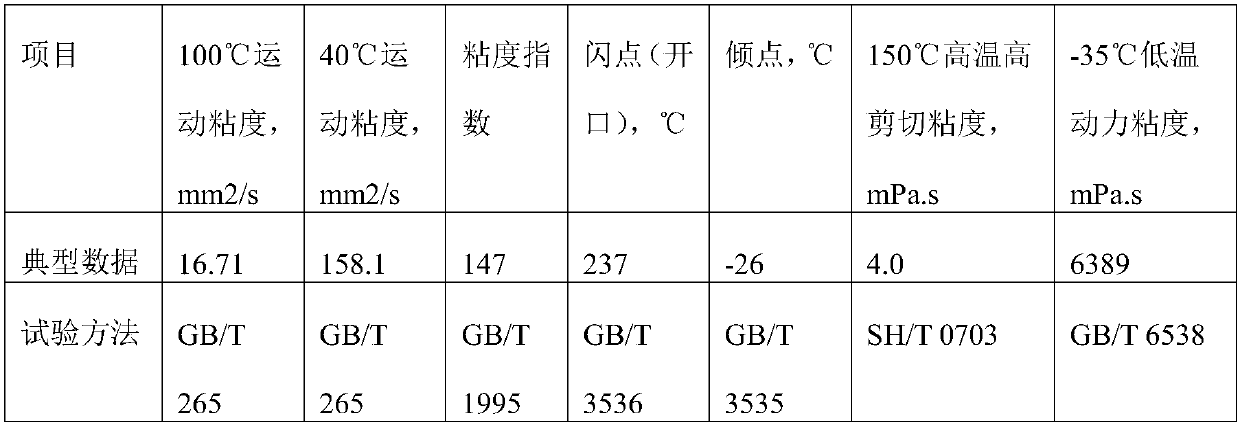

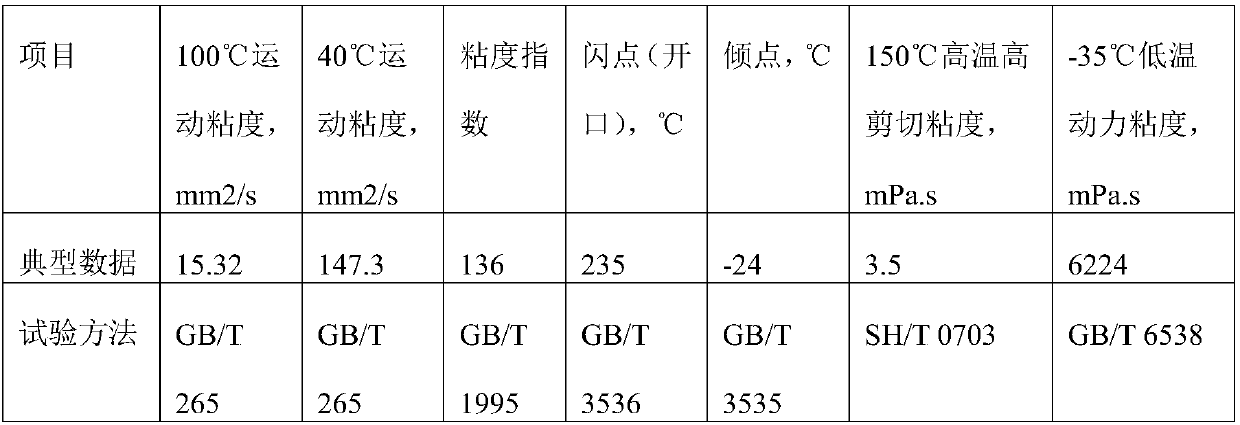

Regeneration method of semisynthesis waste engine oil

InactiveCN107903995AShort regeneration periodHigh regeneration qualityLubricant compositionPre treatmentMagnesium

A method for the regeneration of semi-synthetic waste engine oil, through the pretreatment of waste engine oil flocculation precipitation, pickling, water washing, and dehydration, and then use optimized organic bentonite, a mixture of magnesium trisilicate and mesoporous silicon, and activated carbon to separate The regenerated engine oil with better performance parameters can be obtained through step-by-step adsorption and filtration; the method of the present invention for regenerating semi-synthetic waste engine oil has the characteristics of short regeneration period and high regeneration quality.

Owner:SUZHOU BOJIN BIOLOGICAL TECH

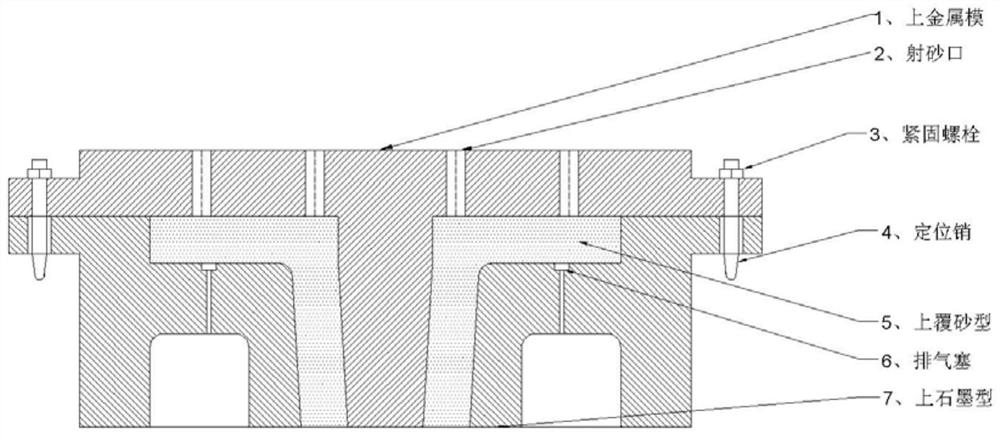

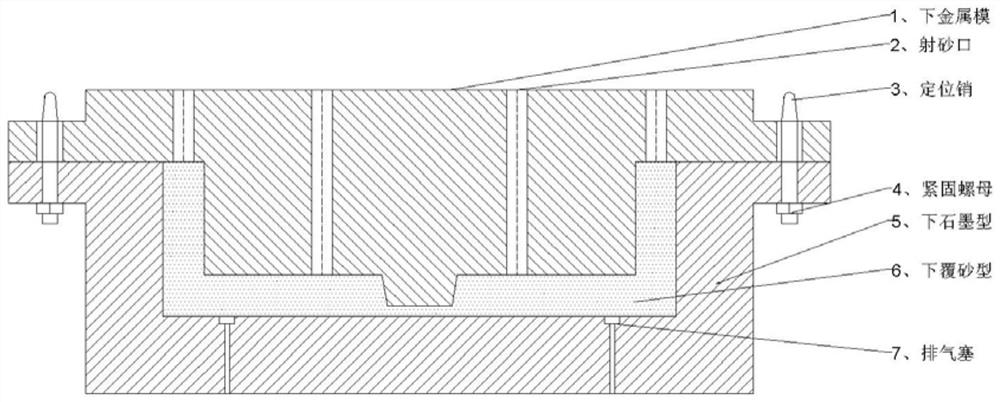

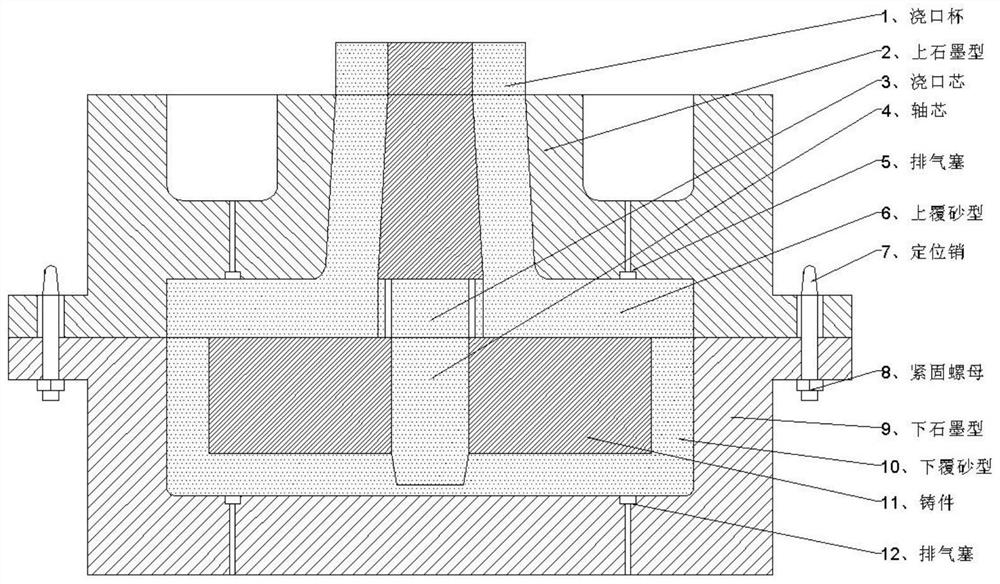

Graphite mold for sand-coated molding and application of graphite mold

PendingCN114101582AWide variety of sourcesLow priceFoundry mouldsMoulding machinesAdhesiveCasting mold

The invention belongs to the technical field of casting, and particularly relates to a graphite mold for sand-coated molding and application of the graphite mold. The method comprises the following steps: uniformly mixing graphite chips with an adhesive, filling a female mold with the mixture, tamping, heating to 110-180 DEG C, preserving heat for 40-60 minutes, and drawing after thermocuring molding, so as to obtain the graphite mold for sand-coated molding, and the graphite mold is applied to preparation of a graphite mold water-glass-coated sand casting mold. The graphite scraps are wide in source and low in price, the investment of a sand-coated molding production line is reduced by replacing an iron mold with a graphite mold, and the graphite mold is stable in performance after being heated. According to the sand-coated molding technology for composite blowing hardening of the sodium silicate-bonded sand, the over-blowing defect of the sodium silicate-bonded sand is avoided, the addition amount of the sodium silicate is low, the collapsibility is good, the strength is high, and the gas forming amount is small.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Multi-level heating device for heating milled asphalt pavement material

ActiveCN110158428BEliminate frictionGuaranteed stabilityRoads maintainenceThermodynamicsVehicle frame

The invention discloses a multi-layer heating device for heating asphalt pavement milling material, which comprises a vehicle frame, wheels are arranged at the bottom of the vehicle frame, and a heating box is installed above the vehicle frame; the interior of the heating box is installed from top to bottom There is a multi-layer conveying device, which is used to transport the asphalt mixture for sufficient heating; a scraper feeder is installed near the road surface in front of the frame, and the scraper feeder lifts the asphalt mixture on the road surface through multiple scrapers The machine is transported to the feed inlet in front of each layer of conveying device; the rear of the frame is equipped with a hot blast stove and a circulating fan through the mounting frame, and the rear of the heating box is installed for collecting the air that is output through the outlet. A hopper for heated asphalt mixture; a mixing tank is installed at the lower part behind the vehicle frame, and the lower part of the hopper is connected with the feeding port of the mixing tank.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com