Method for performing semiconductor etching by using high-purity hexafluoroethane

A technology of pure hexafluoroethane and hexafluoroethane, which is applied in the field of semiconductor etching using high-purity hexafluoroethane, can solve problems such as affecting the purification effect of molecular sieves, difficult to fully remove impurities, and uneven temperature of molecular sieves. Achieve the effect of improving the uniformity of gas distribution, improving the effect of adsorption and removal of impurities and the regeneration effect of molecular sieve, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for semiconductor etching utilizing high-purity hexafluoroethane, comprising the following steps:

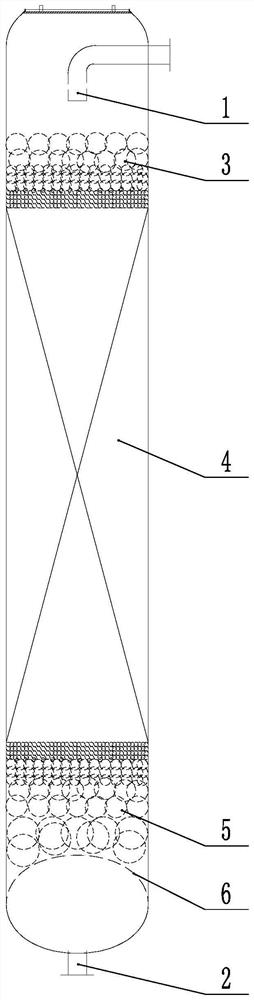

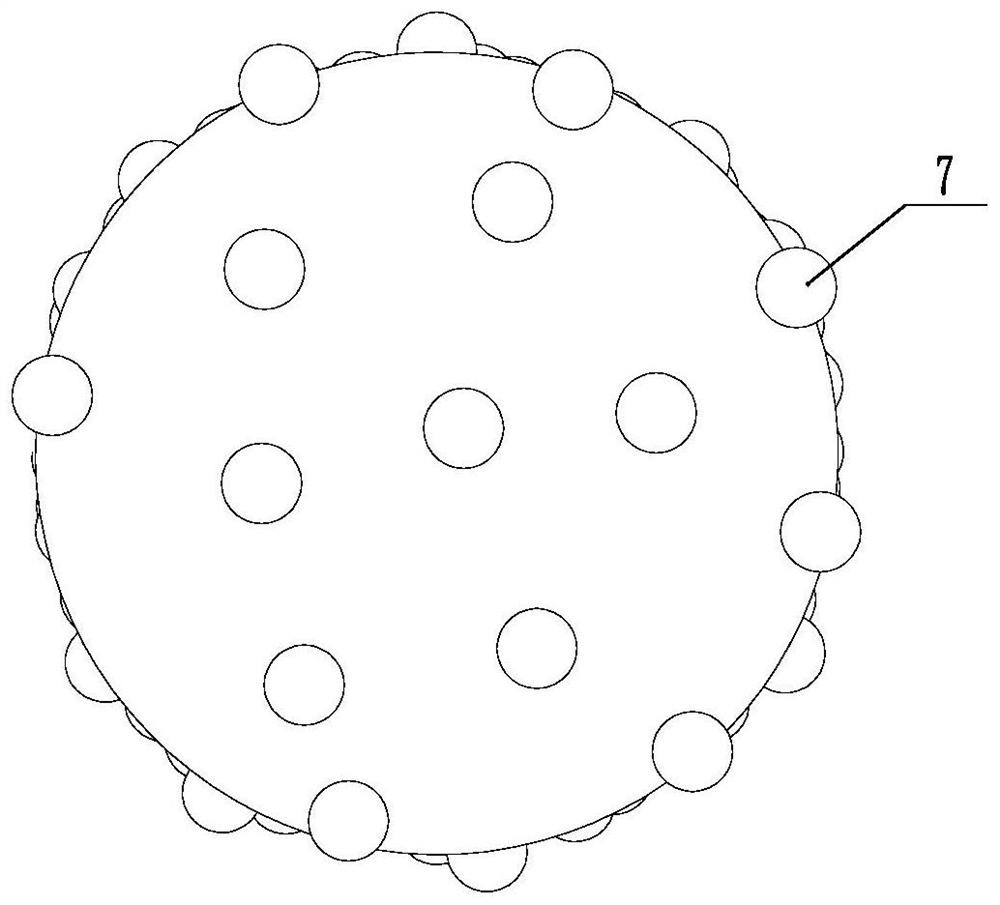

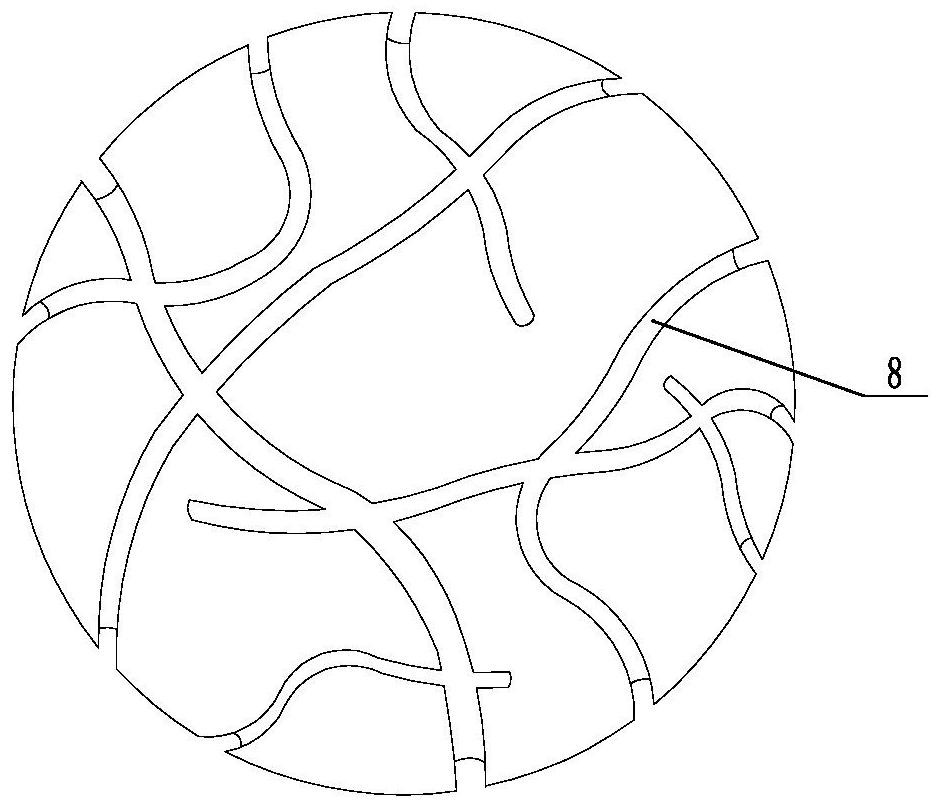

[0043] (1) Hexafluoroethane purification: after the hexafluoroethane raw material is vaporized by the vaporizer, the hexafluoroethane raw material gas is obtained; after the hexafluoroethane raw material gas is decompressed to 0.35±0.15MPa through the pressure reducing valve, the flow rate is controlled The temperature is 125±3kg / h, the temperature is 30±2.5℃, pass into the dryer for drying to obtain dry gas; pass the dry gas into the adsorber for adsorption and impurity removal, and then pass into the compressor to compress to 2.35±0.15 MPa, then pass into the condenser for liquefaction, pass the obtained crude hexafluoroethane into the intermediate product storage tank for storage; finally pass the crude hexafluoroethane in the intermediate product storage tank into the rectification device for rectification Purification to obtain high-purity hexafluoroethane; ...

Embodiment 2

[0051] A method for semiconductor etching utilizing high-purity hexafluoroethane, comprising the following steps:

[0052] (1) Hexafluoroethane purification: after the hexafluoroethane raw material is vaporized by the vaporizer, the hexafluoroethane raw material gas is obtained; after the hexafluoroethane raw material gas is decompressed to 0.35±0.15MPa through the pressure reducing valve, the flow rate is controlled The temperature is 125±3kg / h, the temperature is 30±2.5℃, pass into the dryer for drying to obtain dry gas; pass the dry gas into the adsorber for adsorption and impurity removal, and then pass into the compressor to compress to 2.35±0.15 MPa, then pass into the condenser for liquefaction, pass the obtained crude hexafluoroethane into the intermediate product storage tank for storage; finally pass the crude hexafluoroethane in the intermediate product storage tank into the rectification device for rectification Purification to obtain high-purity hexafluoroethane; ...

Embodiment 3

[0059] A method for semiconductor etching utilizing high-purity hexafluoroethane, comprising the following steps:

[0060] (1) Hexafluoroethane purification: after the hexafluoroethane raw material is vaporized by the vaporizer, the hexafluoroethane raw material gas is obtained; after the hexafluoroethane raw material gas is decompressed to 0.35±0.15MPa through the pressure reducing valve, the flow rate is controlled The temperature is 125±3kg / h, the temperature is 30±2.5℃, pass into the dryer for drying to obtain dry gas; pass the dry gas into the adsorber for adsorption and impurity removal, and then pass into the compressor to compress to 2.35±0.15 MPa, then pass into the condenser for liquefaction, pass the obtained crude hexafluoroethane into the intermediate product storage tank for storage; finally pass the crude hexafluoroethane in the intermediate product storage tank into the rectification device for rectification Purification to obtain high-purity hexafluoroethane; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com