Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve center segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

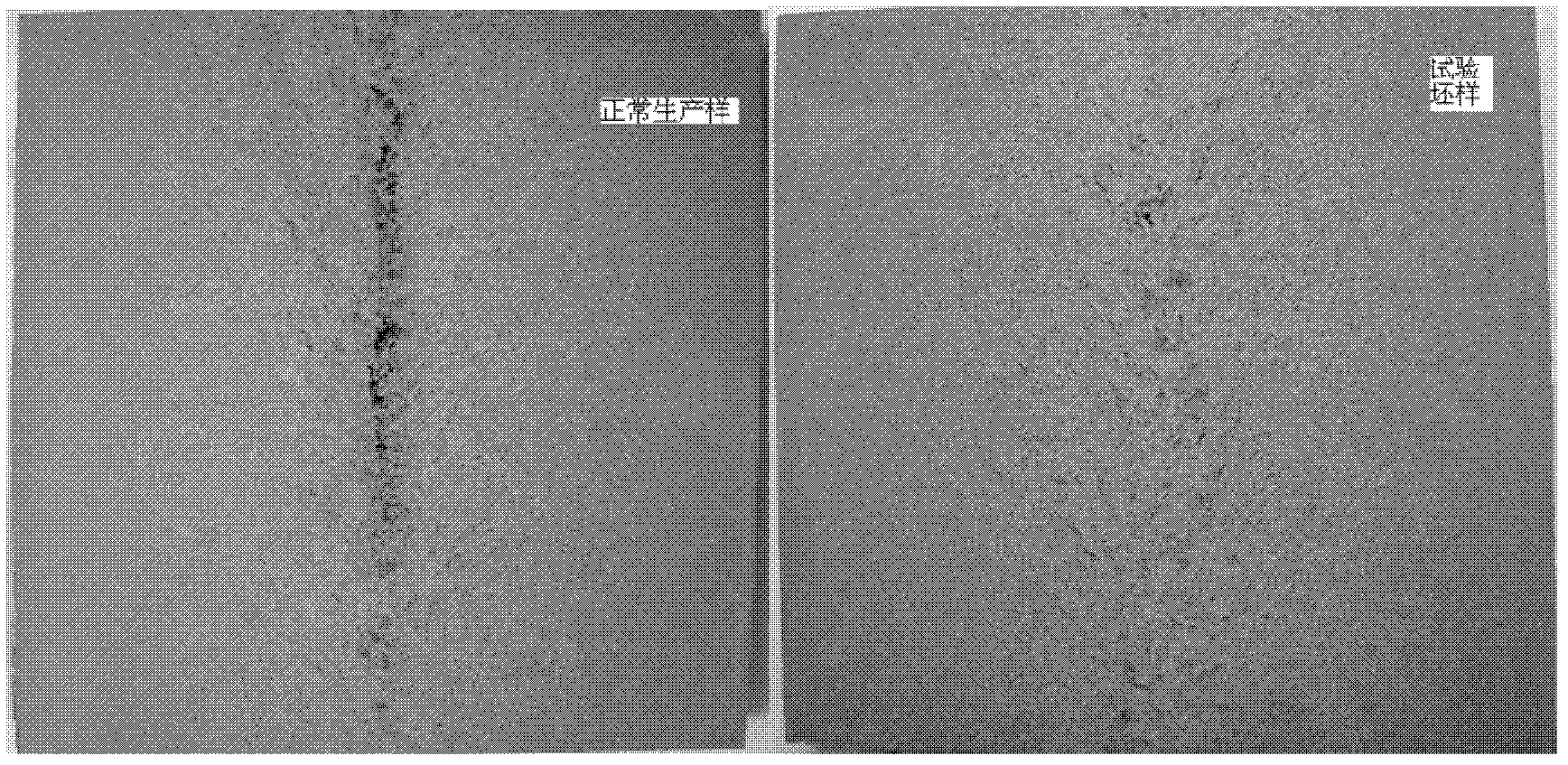

Method for improving center segregation of extra thick slab with thickness of 400mm

The invention relates to a method for improving center segregation of an extra thick slab with a thickness of 400mm, and belongs to the technical field of continuous casting of steelmaking. Degree of the center segregation of the extra thick slab with the thickness of 400mm is improved by a dynamic soft reduction technology, so that rating of the center segregation is free from above C2.0 so as to improve the inner quality of the extra thick slab. The specific steps are as follows: determining an optimal reduction position and an optimal rolling reduction: after determining the optimal reduction position, testing different rolling reductions in the reduction area: 5-6mm and 6-8mm and applying a certain rolling reduction of 0-0.5mm to a solid phase area; and combining lower power rating and C, S segregation ratios to determine the optimal rolling reduction.

Owner:SHOUGANG CORPORATION

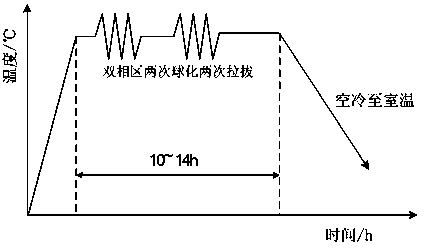

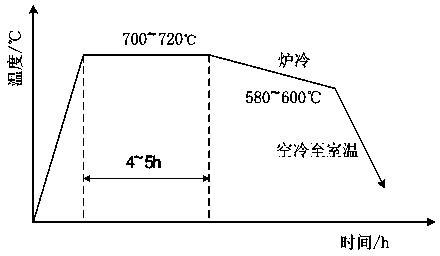

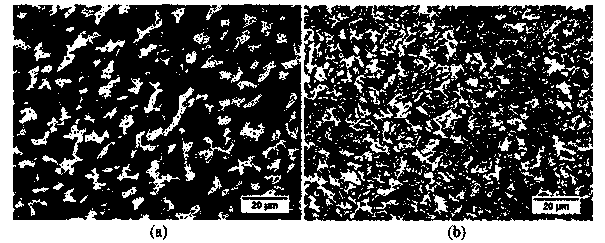

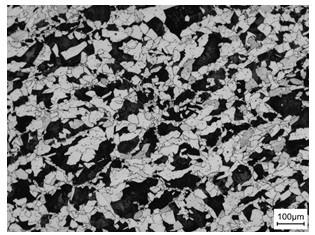

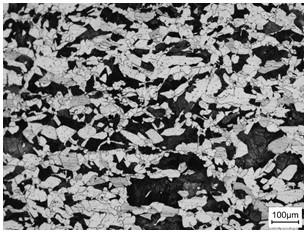

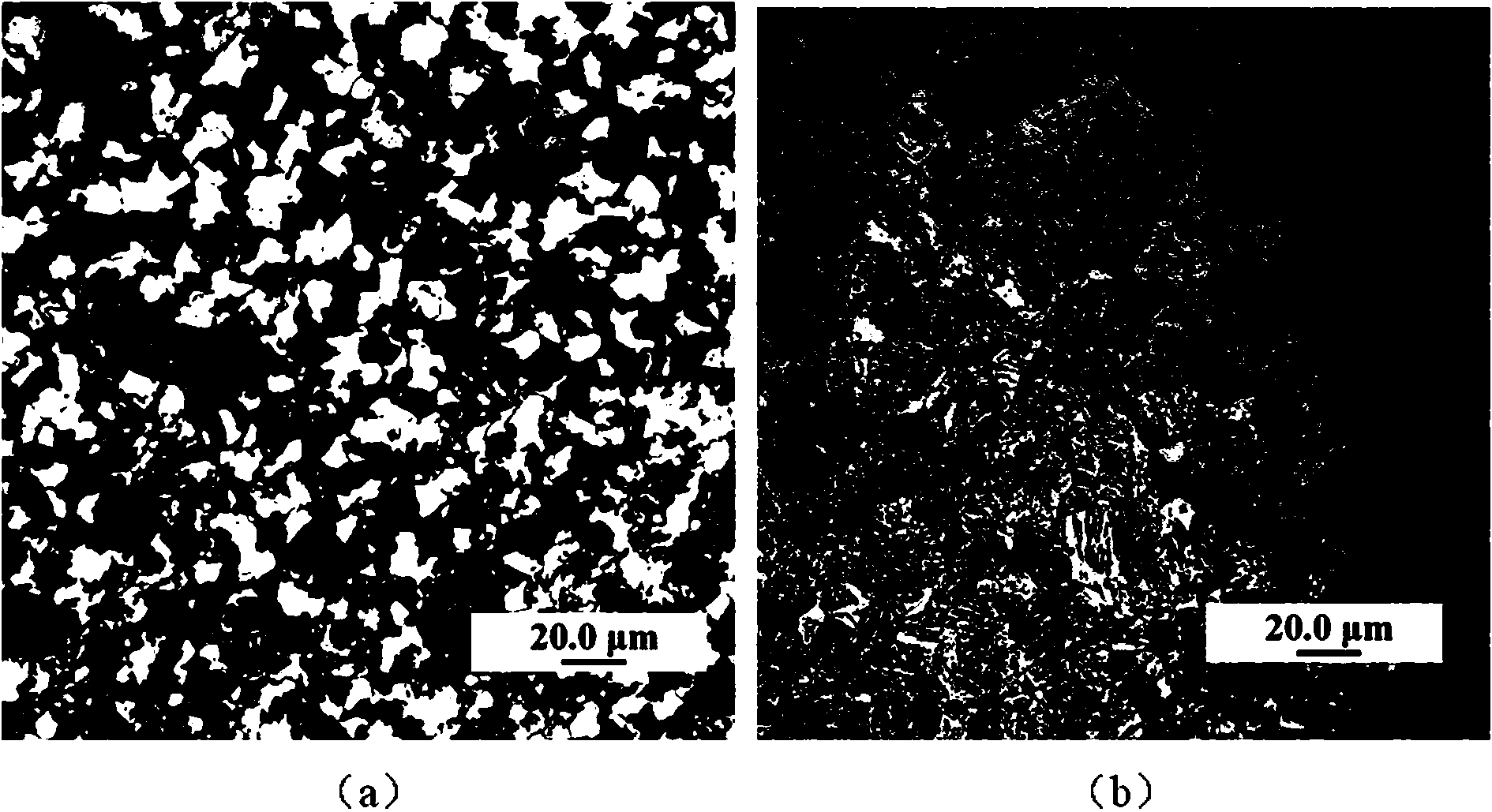

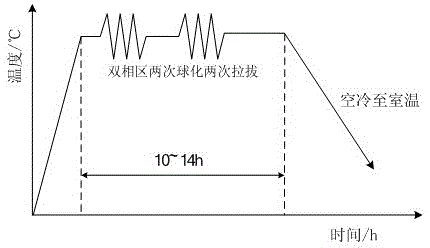

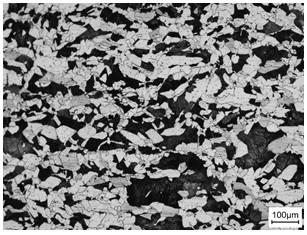

Spheroidizing annealing method for Cr and Mo steel with sheet type microstructure

The invention belongs to the technical field of metallurgy, and in particular relates to a spheroidizing annealing method for Cr and Mo steel with a sheet type microstructure. The spheroidizing annealing method comprises the steps of putting a Cr and Mo steel rolled product sample into a heating furnace, heating to 700-720 DEG C, preserving the temperature for 4-5 hours, then performing furnace cooling to 580-600 DEG C, taking out the Cr and Mo steel rolled product from the furnace, and cooling to room temperature, wherein the microhardness of the Cr and Mo steel rolled product subjected to spheroidizing annealing is 162.20-175.35HV, and the microstructure of the Cr and Mo steel rolled product consists of granular carbides dispersed on a ferritic matrix; the granular carbides have spheroidized structures in the level 5-6. According to the method, sub-medium temperature is preserved for certain time, and then the furnace cooling time is controlled, so that spheroidizing-annealed steel with high performance is obtained. The high preserved temperature is lower than the preserved temperature of the original technology, and the heat preservation time is shortened by almost three times, so that the energy consumption is obviously reduced, and the spheroidizing annealing efficiency is improved; the hardness of the steel subjected to the spheroidizing annealing technology is obviously reduced, the structure of a spheroidal pearlite is dispersive and fine, and the spheroidizing rate is high; the Cr and Mo steel subjected to spheroidizing annealing is high in cold heading performance and has a good application prospect.

Owner:NORTHEASTERN UNIV

Steel plate having thickness of 150 mm, low compression ratio and low Z-direction performance, and production method thereof

ActiveCN109252108AReduce manufacturing costEffective welding looseChemical compositionMechanical property

The invention discloses a steel plate having a thickness of 150 mm, a low compression ratio and a low Z-direction performance, and a production method thereof. The steel plate comprises, by mass, 0.12-0.17% of C, 1.25-1.70% of Mn, 0.002-0.009% of S, 0.008-0.020% of P, 0.30-0.41% of Si, 0.032-0.042% of Als, 0.038-0.045% of Nb, 0.015-0.030% of Ti, 0.0030-0.0050% of N, and the balance of Fe and otherinevitable impurities. The production method comprises the following steps: smelting, continuous casting, heating, controlled rolling and controlled cooling. The rolling compression ratio of the produced steel plate is 1.77-1.80, the production method has the advantages of low production cost and fast production pace, and the steel plate has the characteristics of high flaw detection qualified rate, excellent mechanical properties and high performance uniformity of the microstructure in a thickness direction.

Owner:TANGSHAN HEAVY PLATE CO LTD +2

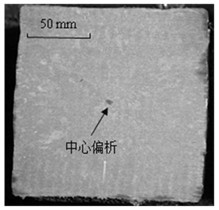

Method for improving segregation and shrinkage of center of square and round billet

InactiveCN102527975AImprove center segregation and shrinkage cavityRemarkable resultsElectromagnetic stirringCooling methods

The invention discloses a method for improving the segregation and shrinkage of the center of a square and round billet; when a cast billet is cooled, the growth rate of solidified shells of the cast billet in an inner arc direction and an outer arc direction is relatively higher while the growth rate of solidified shells of the cast billet in a left side direction and a right side direction is relatively lower through a cooling method according to which the cooling strength in the inner arc direction and the outer arc direction of the cast billet is consistent, the cooling strength in the left side direction and the right side direction is consistent but the cooling strength in the inner and the outer arc directions is higher than that in the left and the right side directions, so that a liquid core on a solidified tail end of the cast billet is a rectangular area which is squashed in the inner and the outer arc directions and elongated in the left and the right side directions. According to the method for improving the segregation and shrinkage of the center of the square and round billet, because segregation solute elements and the distribution methods of solidification and shrinkage are controlled, the center of the cast billet is prevented from being segregated and enriched in a small area, so that the segregation and shrinkage of the center of the square and round billet and other continuous casting billets with similar width and thickness of cross sections are effectively improved, the effect is significant and stable, the use is simple and easy, the cost is low, and the cost performance in implementation is high. Simultaneously, a dynamic slight compression technology in continuous casting and a tail end electromagnetic stirring technology can be implemented.

Owner:CHONGQING UNIV

Continuous casting method for controlling center carbon segregation of small high-carbon hard-wire steel square billet

The invention discloses a continuous casting method for controlling center carbon segregation of a small high-carbon hard-wire steel square billet. Crystallizer electromagnetic stirring is adopted in the method. According to the process of the method, the superheat degree of molten steel ranges from 10 DEG C to 35 DEG C, the current of crystallizer electromagnetic stirring ranges from 320 A to 350 A, and the frequency ranges from 3 Hz to 4 Hz; aerial fog cooling is adopted for secondary cooling and the specific water flow ranges from 0.5 L / kg to 0.7 L / kg; and the casting speed ranges from 1.5 m / min to 1.7 m / min. By the adoption of the method, process parameters in the continuous casting process are reasonably adjusted and optimized, the center segregation of the high-carbon hard-wire steel small square billet is obviously improved, a cast blank is sampled for detection, a carbon segregation coefficient KC is controlled between 0.95 and 1.05, and therefore it can be guaranteed that the accidents, caused by center segregation, of net-shaped cementite appearing and breaking are not generated in the following rolling process of the steel billet. Under the conditions that tail-end electromagnetic stirring and soft press are not available, the proper parameters are selected for reasonable adjustment so as to control the continuous casting process, the cast blank defects of center segregation and the like of the small square billet are overcome, and the continuous casting method has the beneficial effects of being simple in process and effective.

Owner:HEBEI IRON AND STEEL

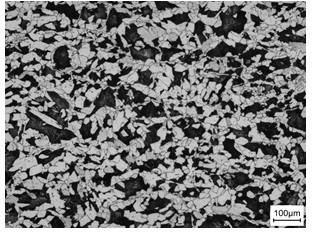

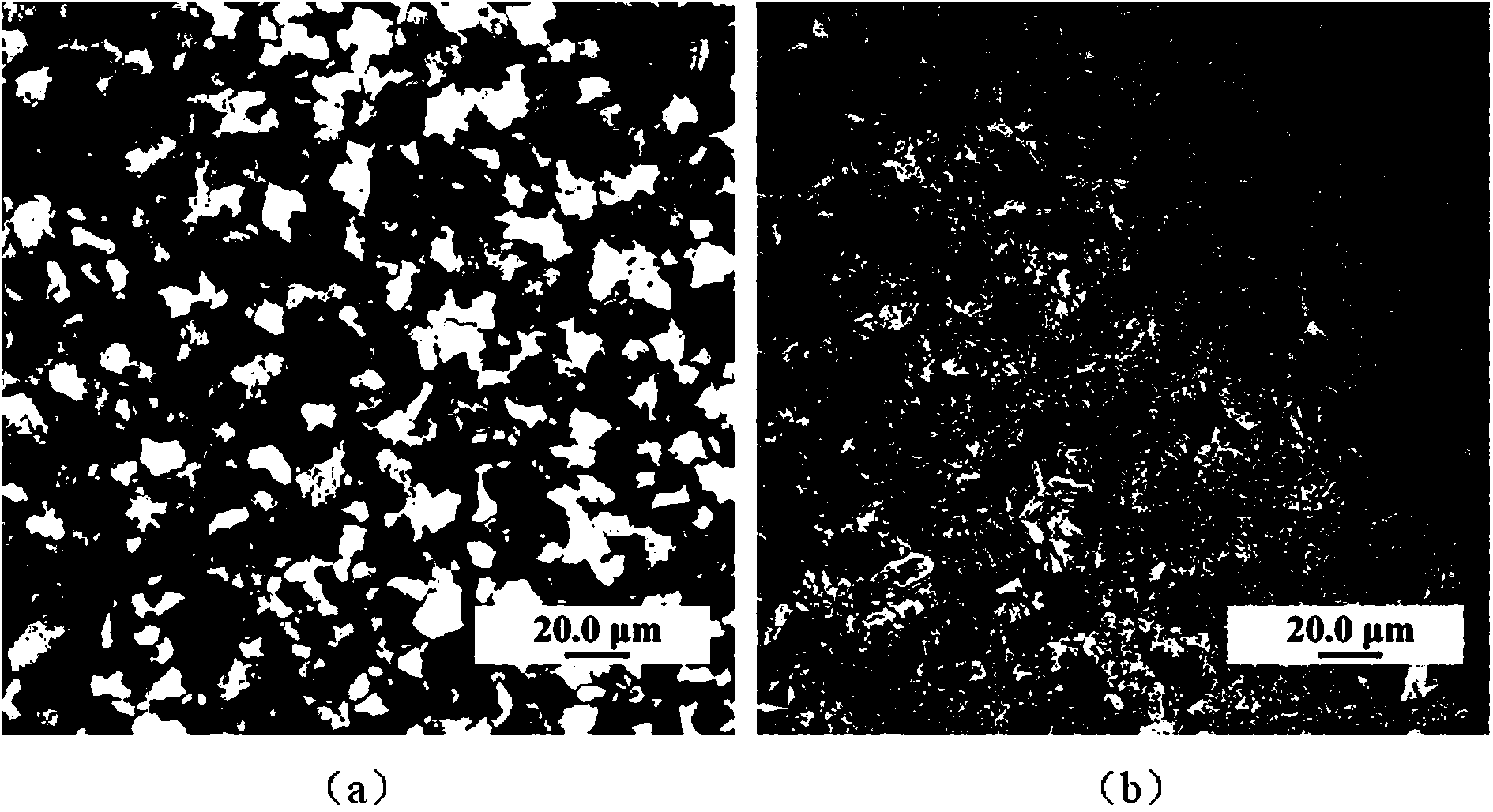

Rolling process beneficial to spheroidizing annealing of Cr and Mo steel

InactiveCN103350116AInhibit growthImprove segregationTemperature control deviceTemperature controlCarbide

The invention belongs to the technical field of metallurgy and particularly relates to a rolling process beneficial to spheroidizing annealing of a Cr and Mo steel. The rolling process is carried out according to the following steps of: carrying out cogging, rolling and spinning on a continuously cast steel billet; then always carrying out heat preservation to about 300 to 350 DEG C on a roll table cooling line and carrying out coil collection so as to obtain a Cr and Mo steel rolled product. According to the invention, by cogging heating control, steel rolling temperature control and after-rolling cooling control, segregation at the position of one second of R and center segregation are improved, grains are refined and growth of abnormal grains is avoided. Meanwhile, generation of large granular ferrite and pearlite is controlled, martensite is controlled below 35 percent; tissues mainly comprising bainite is formed, and carbide of the tissues is more uniformly distributed on a matrix. Moreover, according to a product produced by using the process, time of spheroidizing annealing is greatly shortened, an annealing process is simplified and spheroidized cementite is more dispersively and finely distributed.

Owner:NORTHEASTERN UNIV +1

Preparation process of composite casting blanks for high-toughness thick steel plate

The invention discloses a preparation process of composite casting blanks for a high-toughness thick steel plate. The preparation process adopts continuous casting blanks with different furnace numbers, the same steel grades and different carbon contents to compound so as to meet the requirements for overall strength and core toughness, thus the composite continuous casting blanks for an extra-thick steel plate with high surface quality and excellent core impact toughness are obtained. The low carbon design of an inner layer greatly improves the metallurgical quality of the central portion andprovides strong support for improving the toughness of the center and the whole. The high carbon design of an outer layer provides a carbon source for the whole compositions to ensure the whole strength, the uniformity of the compositions is achieved through diffusion, finally the whole compositions with both toughness and strength are obtained, and the occurrence rate of surface cracks is reduced.

Owner:SD STEEL RIZHAO CO LTD

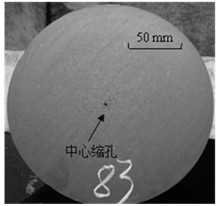

Continuous casting process capable of relieving internal quality defects of bearing steel bloom

The invention discloses a continuous casting process capable of relieving internal quality defects of bearing steel boom. The continuous casting process adopts a large chamfering crystallizer, a chamfering angle of the obtained large chamfered continuously cast bloom is 50-75 degrees, and length of a chamfered inclined surface is 60-90 mm. The adopted following pressing-down process is as follows: at a pressed-down start point position, central solid fraction fs is 0.55-0.65, and pressing-down amount is 1.0-2.0 mm; at a second pressing-down roller, central solid fraction fs is 0.65-0.75 and pressing-down amount is 3.0-5.0 mm; at a third pressing-down roller, central solid fraction fs is 0.75-0.85, and pressing-down amount is 2.0-4.0 mm; at a fourth pressing-down roller, central solid fraction fs is 0.85-0.95, and pressing-down amount is 2.0-3.0 mm; and at a fifth pressing-down roller, central solid fraction fs is 0.95-1.0, and pressing-down amount is 0-2.0 mm. The continuous casting process reduces casting, rolling and pressing-down force in a casting blank pressing-down process, and improves pressing-down efficiency, so that the effects of stably controlling quality defects such as center segregation, V-shaped segregation, central loosening and hole shrinkage of the bearing steel boom are achieved.

Owner:XINGTAI IRON & STEEL

Non-steady state continuous casting process capable of damaging small steel ingot structure

InactiveCN102554168AImprove internal qualityAvoid vibration marksProduction lineMaterials preparation

The invention discloses a non-steady state continuous casting process capable of damaging a small steel ingot structure, and belongs to the technical field of metal material preparation. A drawing velocity is based on the conventional drawing velocity Vo, and is vertically fluctuated at small amplitude in a certain period T, namely V=Vo+a; and after continuous casting is started normally and becomes stable, a certain conventional drawing velocity Vo is determined according to a superheat degree, the drawing velocity is improved to Vo+a, billets are continuously drawn for time of T1, the drawing velocity is reduced to Vo-a in time of T3, the billets are continuously drawn for time of T2, and the drawing velocity is improved to Vo+a in time of T4 to complete a billet drawing period T. The non-steady state continuous casting process has the advantages that: the small steel ingot structure can be damaged and dendrite is inhibited from bridging, so that the compactness of continuous castings is improved, a non-steady state continuous casting process with center segregation is improved, and the non-steady state continuous casting process is suitable for continuous casting production lines for square billets, plate billets, round billets and the like.

Owner:CENT IRON & STEEL RES INST +1

Method for improving segregation and shrinkage of center of square and round billet

Owner:CHONGQING UNIV

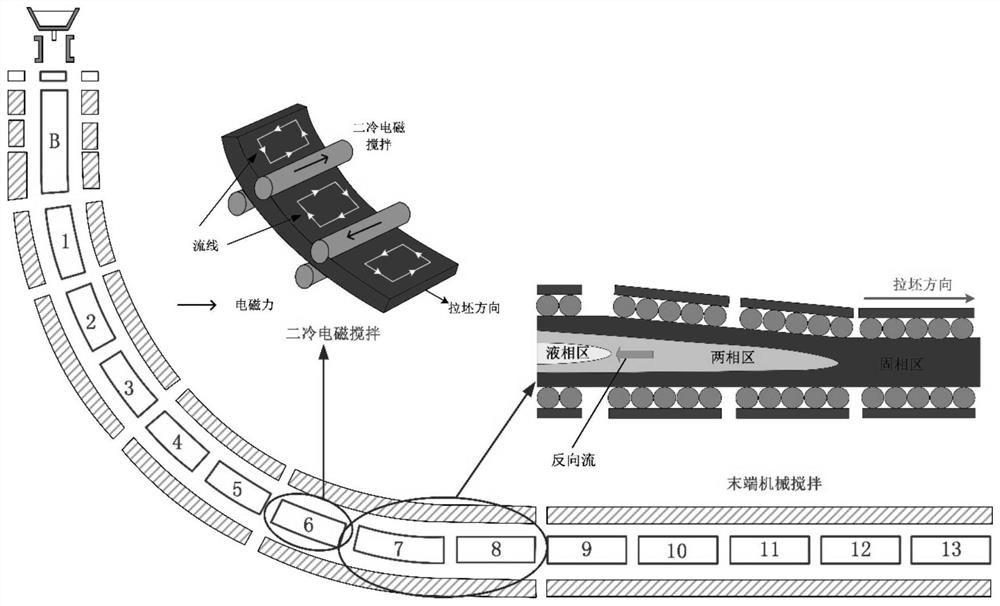

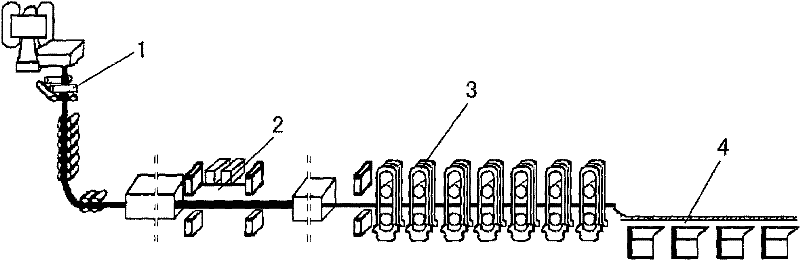

Homogenized slab continuous casting production method under external field cooperative control effect

The invention discloses a homogenized slab continuous casting production method under the external field cooperative control effect, and belongs to the field of steelmaking-continuous casting. According to the method, electromagnetic stirring rollers are installed on fan-shaped sections of a secondary cooling area of a slab continuous casting machine, and meanwhile, the two fan-shaped sections after being subjected to electromagnetic stirring in the secondary cooling area at the slab continuous casting solidification tail end are mechanically pressed down, so that the homogenized slab is obtained. Molten steel can be stirred and mixed uniformly through secondary cooling electromagnetic stirring, so that the temperature of the molten steel and a solidified blank shell are made uniform, the equiaxed crystal ratio is increased, and the surface quality is improved. And the molten steel rich in solute elements can be promoted to be discharged to the upstream through mechanical downward pressing at the solidification tail end, center segregation is improved, solidification shrinkage of a casting blank is compensated for, and shrinkage hole growth is restrained. And meanwhile, secondary cooling electromagnetic stirring can further uniformly mix the concentrated molten steel discharged by means of mechanical downward pressing, and secondary cooling electromagnetic stirring and solidification tail end mechanical downward pressing are mutually combined, so that the purpose of improving the internal quality of the casting blank is achieved.

Owner:NORTHEASTERN UNIV

Method for producing wire and bar materials

InactiveCN101704034BReduce consumptionReduce manufacturing costMethods of productionEnergy consumption

Owner:武钢集团有限公司

Production method of steel S355NL commercial blank for wind power flange

The invention discloses a production method of a steel S355NL commercial blank for a wind power flange. The production method comprises the following steps: the constant superheat degree and the constant pulling speed of a casting machine are guaranteed; the superheat degree of molten steel needs to be ensured to be 15-28 DEG C; the pulling speed is stabilized at 0.7-0.9 m / min; the wide-side water volume of a crystallizer is 4500 L / min, the narrow-side water volume is 370 L / min, and the water temperature of the crystallizer is 36+ / -2 DEG C; the specific water amount of secondary cooling water is 0.57 L per kilogram of steel, and the temperature of the secondary cooling water is maintained at 25+ / -3 DEG C; the electromagnetic stirring parameters are as follows: the current is 380A, and the frequency is 5Hz; soft pressing is performed on three sections of 6, 7 and 8, and each section is pressed by 2mm; and the cut casting blank is immediately put into a slow cooling area for slow cooling. The method is simple and easy to operate, residual internal stress of the casting blank can be eliminated without heat treatment of the casting blank, and the problem that the S355NL commercial blank is broken during cutting by an electric saw is solved.

Owner:BAOTOU IRON & STEEL GRP

A spheroidizing annealing method for cr and mo steels with lamellar microstructure

The invention belongs to the field of metallurgical technology, and particularly relates to a spheroidizing annealing method for Cr and Mo steel with flaky microstructure. Place the Cr and Mo steel rolled material samples in the heating furnace, raise the temperature to 700~720℃, keep the temperature for 4~5 hours, then cool the furnace to 580~600℃, then take the Cr and Mo steel rolled material out of the furnace and air-cool to room temperature, and pass through the ball The microhardness of chemically annealed Cr and Mo steel rolled products is 162.20~175.35HV, and its microstructure is granular carbides dispersed on the ferrite matrix. The granular carbides are spheroidized structures, rated 5~6. The method of the present invention obtains spheroidized annealed steel with good performance by maintaining the temperature at sub-temperature for a certain period of time and then controlling the furnace cooling time. The high-temperature insulation temperature used in the invention is lower than that of the original process, and the insulation time is shortened by nearly 3 times. Significantly save energy consumption and improve the efficiency of spheroidizing annealing; after the spheroidizing annealing process of the present invention, the hardness of the steel is significantly reduced, the spheroidized pearlite structure is more dispersed and fine, the spheroidizing rate is higher, and it has good cold heading performance and application prospects. .

Owner:NORTHEASTERN UNIV LIAONING

Non-steady state continuous casting process capable of damaging small steel ingot structure

The invention discloses a non-steady state continuous casting process capable of damaging a small steel ingot structure, and belongs to the technical field of metal material preparation. A drawing velocity is based on the conventional drawing velocity Vo, and is vertically fluctuated at small amplitude in a certain period T, namely V=Vo+a; and after continuous casting is started normally and becomes stable, a certain conventional drawing velocity Vo is determined according to a superheat degree, the drawing velocity is improved to Vo+a, billets are continuously drawn for time of T1, the drawing velocity is reduced to Vo-a in time of T3, the billets are continuously drawn for time of T2, and the drawing velocity is improved to Vo+a in time of T4 to complete a billet drawing period T. The non-steady state continuous casting process has the advantages that: the small steel ingot structure can be damaged and dendrite is inhibited from bridging, so that the compactness of continuous castings is improved, a non-steady state continuous casting process with center segregation is improved, and the non-steady state continuous casting process is suitable for continuous casting production lines for square billets, plate billets, round billets and the like.

Owner:CENT IRON & STEEL RES INST +1

Preparation method of high-quality plastic mold steel extra-thick plate continuous casting master billet

Owner:TANGSHAN IRON & STEEL GROUP +2

High-sulfur free-cutting steel square billet continuous casting method

The invention discloses a high-sulfur free-cutting steel square billet continuous casting method. Molten steel comprising, by mass, 0.1-0.3% of C, 0.1-0.3% of S, 0.02-0.1% of Si, 1.0-1.5% of Mn, and the balance Fe and impurities is subjected to continuous casting through a continuous casting machine, and the section of a casting billet manufactured by the continuous casting machine is 250-350 mm wide and 400-500 mm high. According to the characteristics of the high-sulfur free-cutting steel continuous casting billet and the continuous casting machine, the casting speed of the continuous casting billet is reasonably controlled, the water distribution amount of a secondary cooling zone is optimized, the secondary cooling area is divided into a plurality of loops, the water amount of each loop is adjusted independently, the size of a columnar zone and the size of a center equiaxed zone of the continuous casting billet are controlled by changing heat transfer of all cooling zones, thus, the structure solidification process during continuous casting can be controlled, the high-sulfur free-cutting steel continuous casting billet is prevented from generating intercrystalline cracks and center cracks, the center equiaxed crystal ratio of the casting billet is increased, and center segregation and center porosity of the continuous casting billet are perfected.

Owner:NANJING IRON & STEEL CO LTD

Method for improving center segregation of extra thick slab with thickness of 400mm

The invention relates to a method for improving center segregation of an extra thick slab with a thickness of 400mm, and belongs to the technical field of continuous casting of steelmaking. Degree of the center segregation of the extra thick slab with the thickness of 400mm is improved by a dynamic soft reduction technology, so that rating of the center segregation is free from above C2.0 so as to improve the inner quality of the extra thick slab. The specific steps are as follows: determining an optimal reduction position and an optimal rolling reduction: after determining the optimal reduction position, testing different rolling reductions in the reduction area: 5-6mm and 6-8mm and applying a certain rolling reduction of 0-0.5mm to a solid phase area; and combining lower power rating and C, S segregation ratios to determine the optimal rolling reduction.

Owner:SHOUGANG CORPORATION

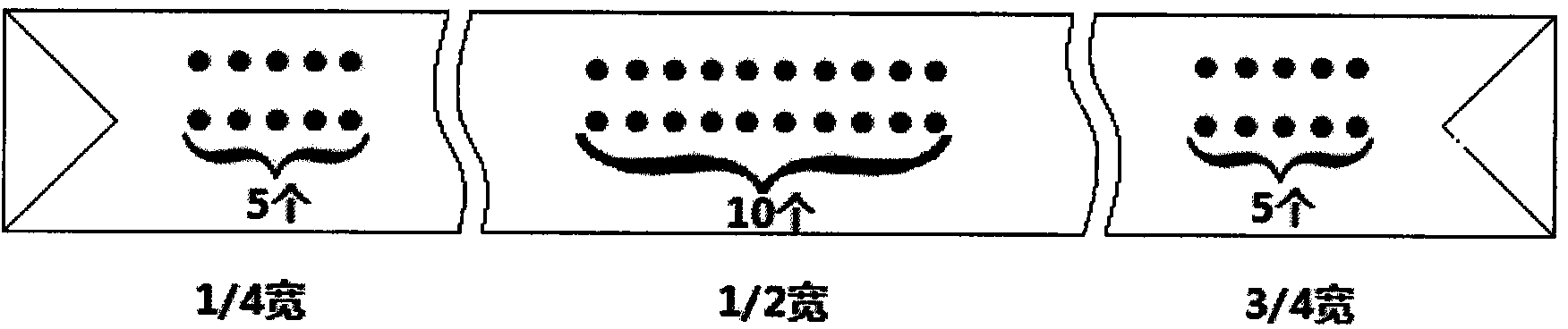

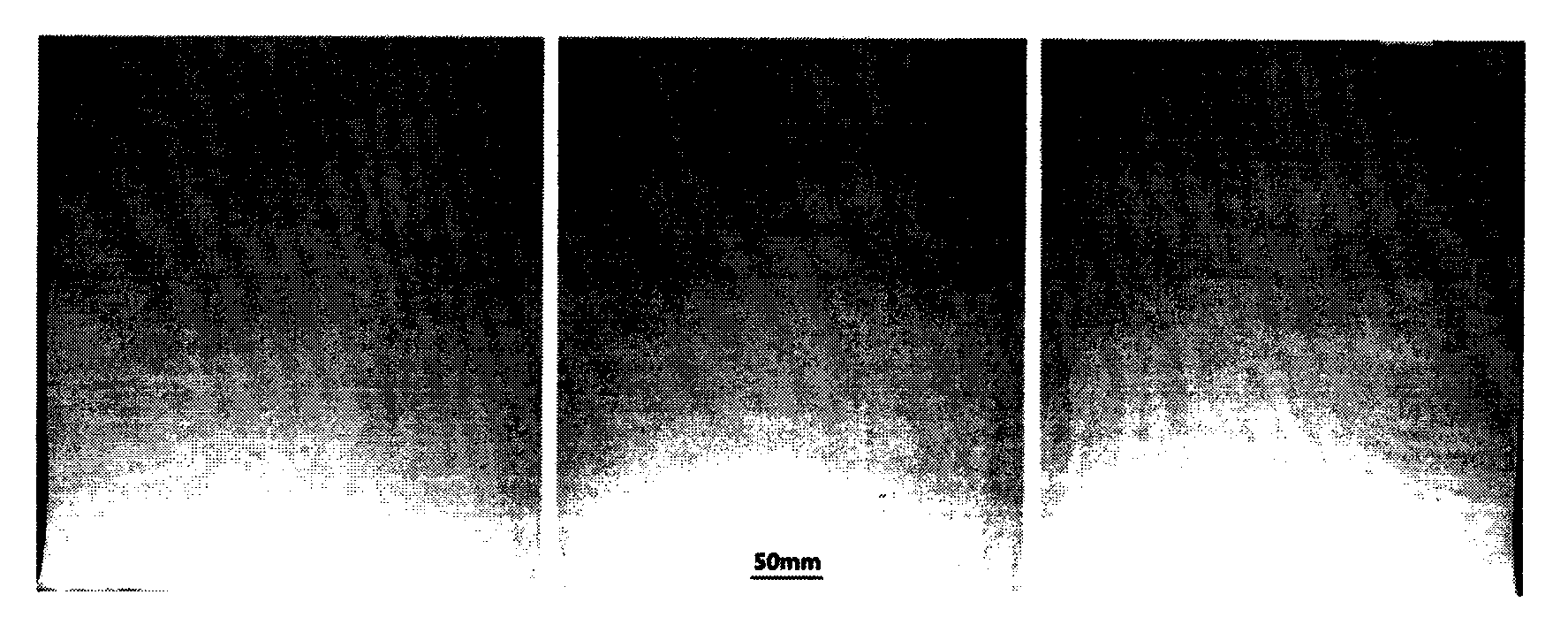

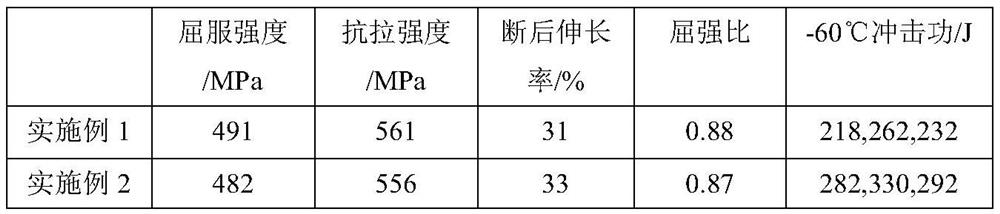

An ultra-thin high-strength steel plate capable of being used at -60°C and its manufacturing method

ActiveCN109047692BImprove center segregationImprove low temperature toughnessManufacturing convertersMetal rolling arrangementsSheet steelSlow cooling

The invention discloses an ultra-thin high-strength steel plate that can be used under the condition of -60°C. The chemical composition is calculated as mass percent: C≤0.05, Si 0.20-0.40, Mn≤1.0, Nb+Ti+V≤0.15 , Cr≤0.30, P≤0.008, S≤0.0008, N≤0.002, O≤0.0010, H≤0.0001, P+S+[N]+[O]+[H]≤100ppm; Ni≤0.30, Cu≤0.30, Mo≤0.30, the balance is Fe and unavoidable impurities; the structure of the steel plate is uniform quasi-polygonal ferrite; the thickness is 4‑8mm, the yield strength is 460‑560MPa, the tensile strength is 550‑630MPa, and the impact energy at ‑60°C ≥200J. The technological process is KR hot metal pretreatment-converter-LF refining-RH vacuum degassing-slab continuous casting-slow cooling-rolling-cooling. The application fills up the production blank of high-strength, low-temperature and high-toughness ultra-thin steel plates in the market.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A billet continuous casting method for free-cutting steel with high sulfur content

Owner:NANJING IRON & STEEL CO LTD

A 150mm thick low compression ratio z-direction performance steel plate and its production method

The invention discloses a steel plate having a thickness of 150 mm, a low compression ratio and a low Z-direction performance, and a production method thereof. The steel plate comprises, by mass, 0.12-0.17% of C, 1.25-1.70% of Mn, 0.002-0.009% of S, 0.008-0.020% of P, 0.30-0.41% of Si, 0.032-0.042% of Als, 0.038-0.045% of Nb, 0.015-0.030% of Ti, 0.0030-0.0050% of N, and the balance of Fe and otherinevitable impurities. The production method comprises the following steps: smelting, continuous casting, heating, controlled rolling and controlled cooling. The rolling compression ratio of the produced steel plate is 1.77-1.80, the production method has the advantages of low production cost and fast production pace, and the steel plate has the characteristics of high flaw detection qualified rate, excellent mechanical properties and high performance uniformity of the microstructure in a thickness direction.

Owner:TANGSHAN HEAVY PLATE CO LTD +2

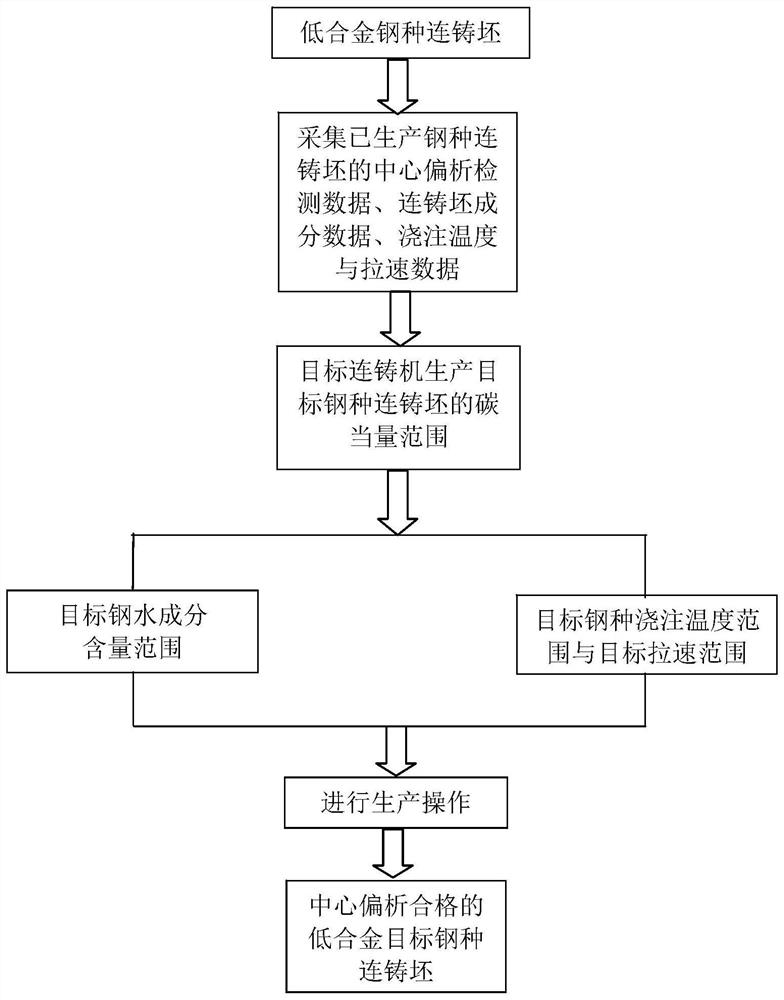

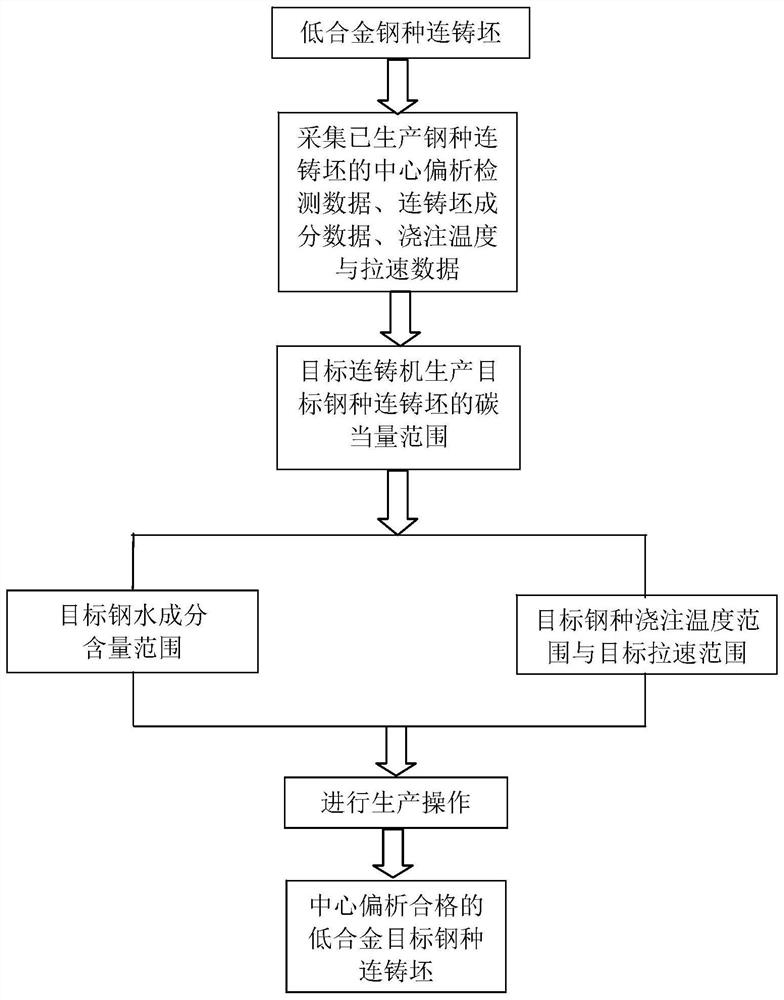

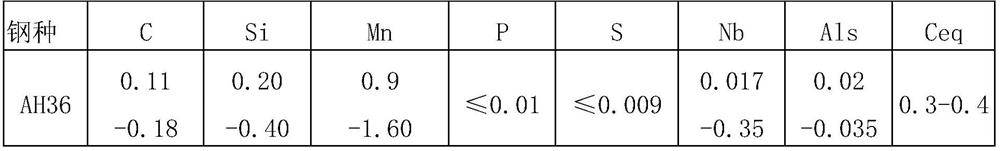

Method for Reducing Center Segregation of Low Alloy Steel Continuous Casting Billet

ActiveCN113198993BImprove center segregationImprove internal segregation qualityMolten steelContinuous caster

Owner:ANSTEEL BEIJING RES INST

A kind of smelting method of titanium micro-alloyed No. 45 steel extra-thick plate

ActiveCN112391573BReduce Mn contentSmall sizeManufacturing convertersProcess efficiency improvementThick plateSmelting process

The invention discloses a method for smelting titanium microalloyed No. 45 steel extra-thick plate, which is based on the metallurgical process flow of molten iron pre-desulfurization-converter smelting-LF out-of-furnace refining-RH vacuum treatment-thick slab continuous casting. Smelting to produce No. 45 steel extra-thick slab, and then rolling to produce 50-100mm extra-thick plate, the characteristics are: double-slag smelting in the converter smelting process, Ti microalloying during RH vacuum treatment, and continuous casting Reasonable process parameters are adopted in the stage to control the precipitation of TiN, and effectively reduce inclusions and their precipitation size, reduce segregation, reduce the quantity of large-size TiN, and then improve the quality of No. 45 steel; the smelting method of No. 45 steel provided by the present invention. , greatly improve the qualified rate of the surface quality of the 45th steel casting billet, the qualified rate of the first-level flaw detection, improve the degree of central segregation of the steel, reduce the scrap rate of the steel, improve the production efficiency and the finished product rate, and realize the production cost of the steel. reduce.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Method for reducing center segregation of low-alloy steel continuous casting billet

ActiveCN113198993AImprove center segregationImprove internal segregation qualityMolten steelContinuous caster

The invention provides a method for reducing center segregation of a low-alloy steel continuous casting billet. The method aims at solving the problem that the qualification rate of internal segregation of the low-alloy high-strength steel casting billet is low. The method comprises the following steps that firstly, according to continuous casting billet production data of a target continuous casting machine, a carbon equivalent range of a target steel type continuous casting billet with qualified center segregation of the target steel type continuous casting billet is obtained through analysis, the component content of the target steel type continuous casting billet is subjected to back calculation, and the optimal molten steel component content range corresponding to the carbon equivalent range of the target steel type in production and the optimal pouring parameter range of the target molten steel are optimized; and therefore, according to the optimal component content range and the optimal pouring parameter range, the low-alloy target steel type continuous casting billet with qualified center segregation can be produced. The molten steel components and the pouring parameters are optimized according to the carbon equivalent range, the production conditions for preparing the target steel type continuous casting billet with qualified internal segregation quality can be found out more accurately, and therefore the center segregation of the low-alloy steel continuous casting billet can be effectively improved, and the internal segregation quality of the low-alloy steel continuous casting billet is improved.

Owner:ANSTEEL BEIJING RES INST

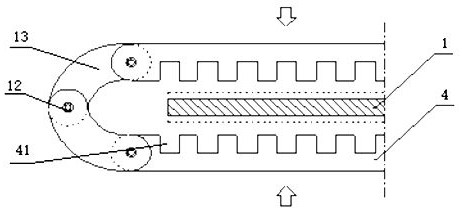

Electromagnetic Stirring Device and Method for Secondary Cooling Zone of Slab Continuous Casting

ActiveCN112077272BImprove the effect of electromagnetic stirringImproved ability to scour the solidification interface frontOpen adjustmentEngineering

The invention discloses an electromagnetic stirring device and a method for a secondary cooling zone of slab continuous casting. The device comprises a main body of the electromagnetic stirring device, an opening adjustment assembly and a secondary cooling assembly. The main body of the stirring device includes a protective shell (3), a phase sequence control component, an iron core (4) and an electromagnetic coil (5), and electromagnetically stirs the molten steel in a direction-changing manner by changing the phase sequence of the three-phase current; the opening adjustment component includes a cylinder (7) , the fixed seat (8), the movable joint shaft (12) and the silicon steel sheet group insert (13), the opening degree of the closed annular iron core can be adjusted online through the movable joint structure; the secondary cooling assembly includes the cooling water inlet (9) and the cooling The water nozzle (10) soaks the cooling water to cool the electromagnetic coil and the iron core, and then is sprayed onto the surface of the billet (1) through the cooling water nozzle for secondary cooling. The invention has less magnetic field leakage or loss, high electromagnetic stirring efficiency, online adjustment of the opening degree of the stirrer, alternate change of stirring direction, and improves the internal quality and performance of the slab.

Owner:BAOSHAN IRON & STEEL CO LTD

Continuous casting process for producing free-cutting steel through converter

PendingCN114433807APrevents intergranular and central cracksIncrease the central equiaxed crystal rateSlagTundish

The invention discloses a continuous casting process for producing free-cutting steel through a converter, and relates to the technical field of steel production, full protection pouring is adopted for continuous casting, long nozzle argon seal protection is adopted from a steel ladle to a tundish, submersed nozzle protection pouring is adopted from the tundish to a crystallizer, a covering agent is used for molten steel in the steel ladle and the tundish, and covering slag is used in the crystallizer; during pouring, a crystallizer is used for electromagnetic stirring, secondary cooling, vibration and tail end stirring parameters are controlled, and the casting speed of a continuous casting billet and the tundish molten steel temperature are controlled. By optimizing the continuous casting billet cooling process, the quality of the free-cutting steel can be effectively improved on the premise that the cost is not increased, and the rolling defects of the continuous casting billet are overcome.

Owner:NANJING IRON & STEEL CO LTD

A rolling process favorable for spheroidizing annealing of cr and mo steel

InactiveCN103350116BInhibit growthImprove segregationTemperature control deviceTemperature controlCarbide

The invention belongs to the technical field of metallurgy and particularly relates to a rolling process beneficial to spheroidizing annealing of a Cr and Mo steel. The rolling process is carried out according to the following steps of: carrying out cogging, rolling and spinning on a continuously cast steel billet; then always carrying out heat preservation to about 300 to 350 DEG C on a roll table cooling line and carrying out coil collection so as to obtain a Cr and Mo steel rolled product. According to the invention, by cogging heating control, steel rolling temperature control and after-rolling cooling control, segregation at the position of one second of R and center segregation are improved, grains are refined and growth of abnormal grains is avoided. Meanwhile, generation of large granular ferrite and pearlite is controlled, martensite is controlled below 35 percent; tissues mainly comprising bainite is formed, and carbide of the tissues is more uniformly distributed on a matrix. Moreover, according to a product produced by using the process, time of spheroidizing annealing is greatly shortened, an annealing process is simplified and spheroidized cementite is more dispersively and finely distributed.

Owner:NORTHEASTERN UNIV LIAONING +1

Preparation Technology of Composite Slab for High Toughness Thick Steel Plate

The invention discloses a preparation process of composite casting blanks for a high-toughness thick steel plate. The preparation process adopts continuous casting blanks with different furnace numbers, the same steel grades and different carbon contents to compound so as to meet the requirements for overall strength and core toughness, thus the composite continuous casting blanks for an extra-thick steel plate with high surface quality and excellent core impact toughness are obtained. The low carbon design of an inner layer greatly improves the metallurgical quality of the central portion andprovides strong support for improving the toughness of the center and the whole. The high carbon design of an outer layer provides a carbon source for the whole compositions to ensure the whole strength, the uniformity of the compositions is achieved through diffusion, finally the whole compositions with both toughness and strength are obtained, and the occurrence rate of surface cracks is reduced.

Owner:SD STEEL RIZHAO CO LTD

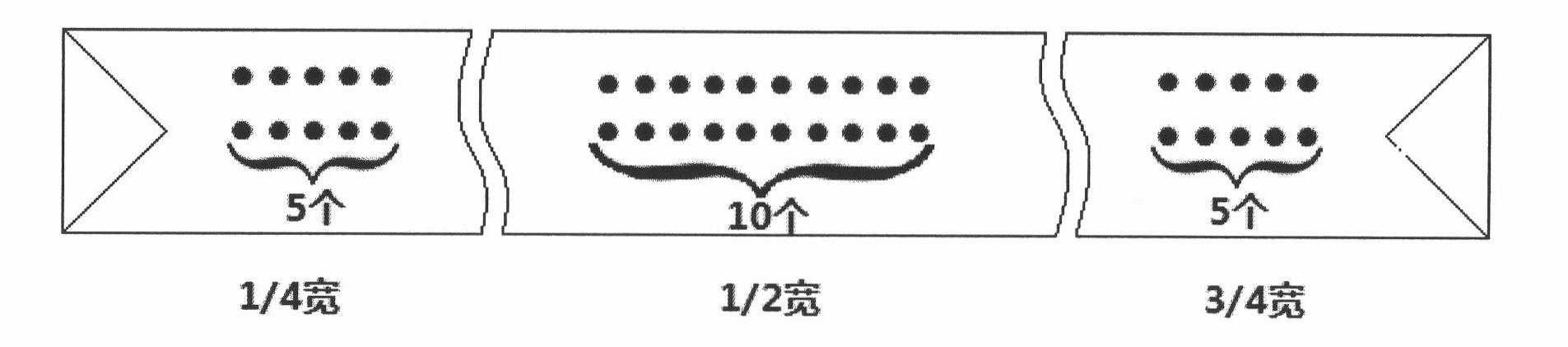

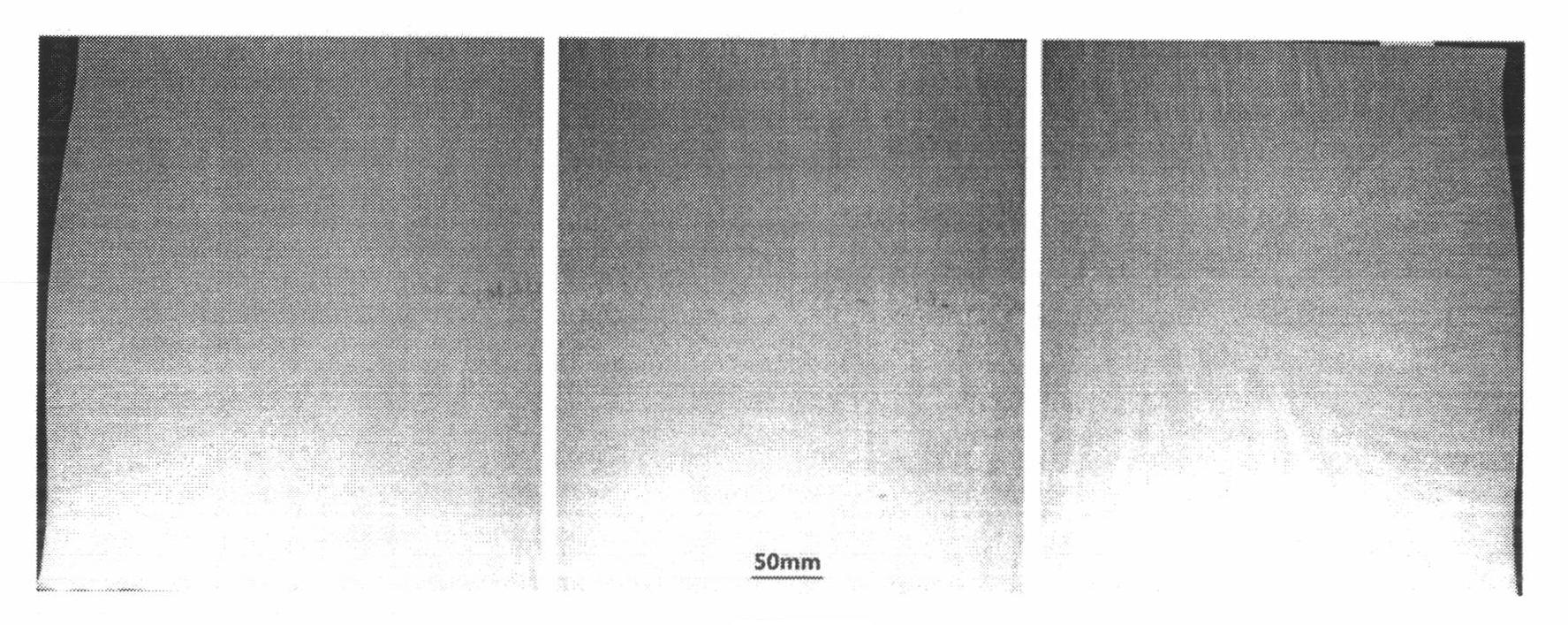

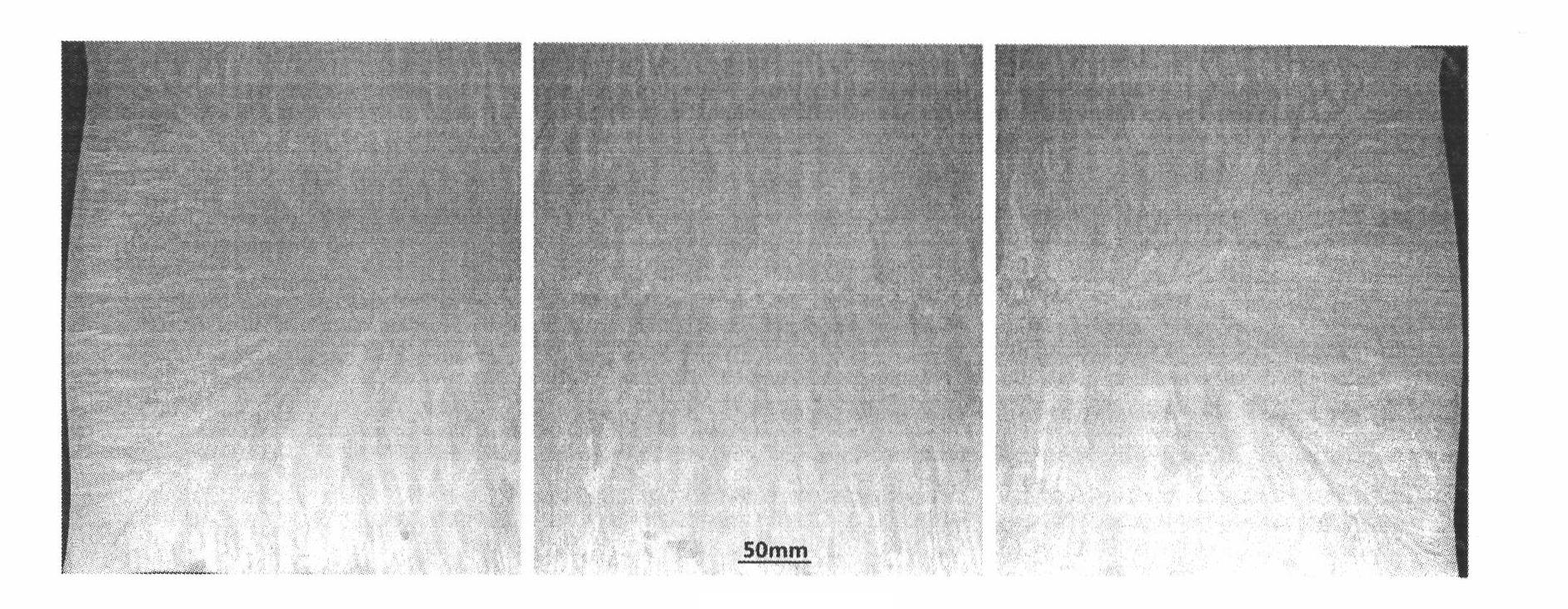

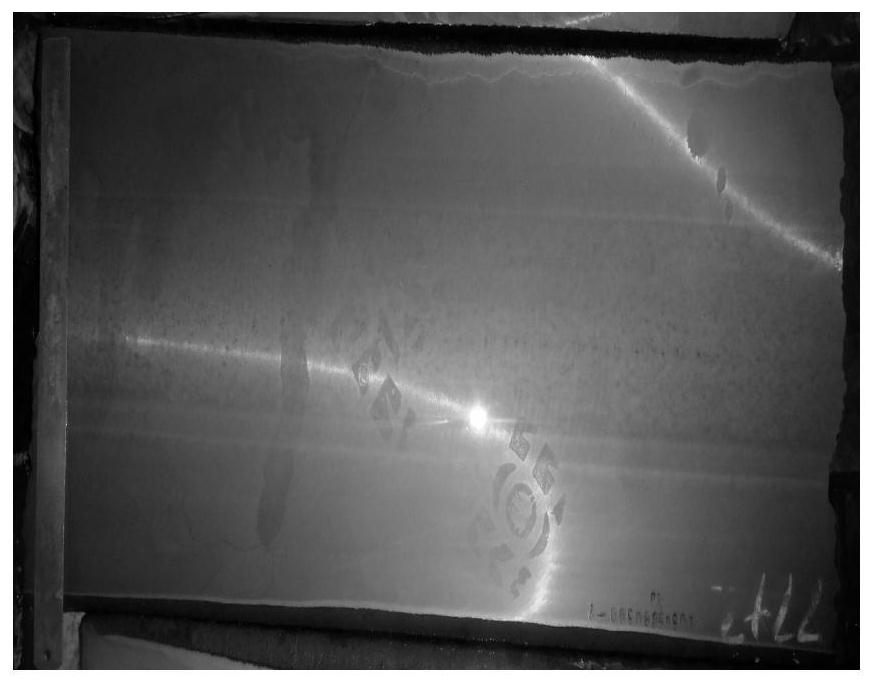

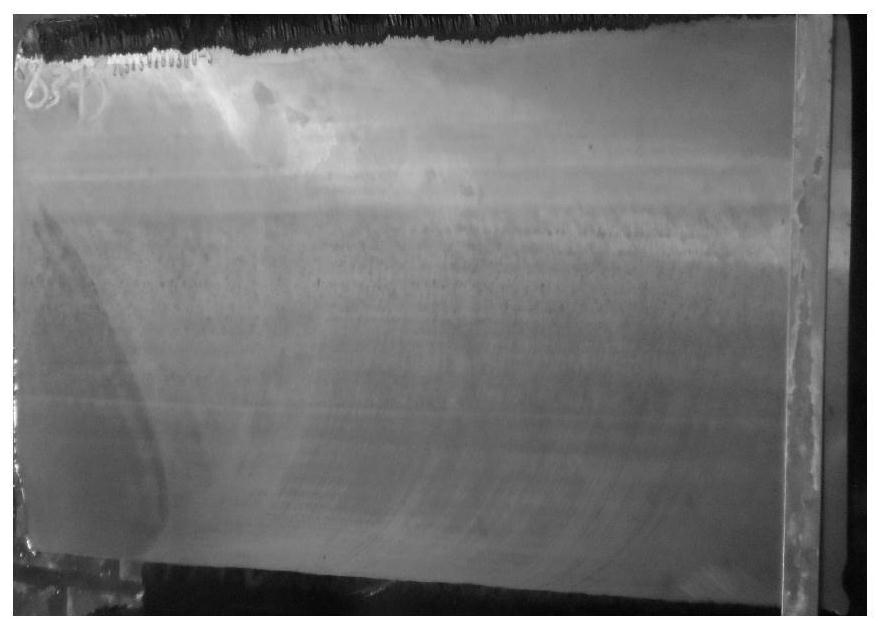

Preparation method for high-quality continuously cast mother billets of plastic mould steel extra-thick plate

ActiveCN107081412AImprove internal qualityCenter segregation and center porosity improvementSolid phasesMetallurgy

The invention discloses a preparation method for high-quality continuously cast mother billets of a plastic mould steel extra-thick plate. The preparation method is characterized in that in a continuous casting process, billet pulling speed is controlled to be 0.80m / min-0.90m / min; solidification end is heavily pressed down; and press-down amount is distributed according to a solid phase rate under light pressing and heavy pressing. The preparation method disclosed by the invention improves internal quality of cast billets by a solidification end dynamic heavy-pressing technology, so that the center segregation defect and the center porosity defect of cast billets are improved; under the target of producing the extra-thick plate with specification of 120 mm (compression ratio only being 2.12 to 1), internal quality of a flaw detection thick plate with a low compression ratio is effectively improved, and a flaw detection qualification rate of the flaw detection thick plate with the low compression ratio in a production process is controlled to be 99% or higher. Cast billets industrially produced by the method are good in effect after being implemented, and can efficiently meet use requirements of mould steel.

Owner:TANGSHAN IRON & STEEL GROUP +2

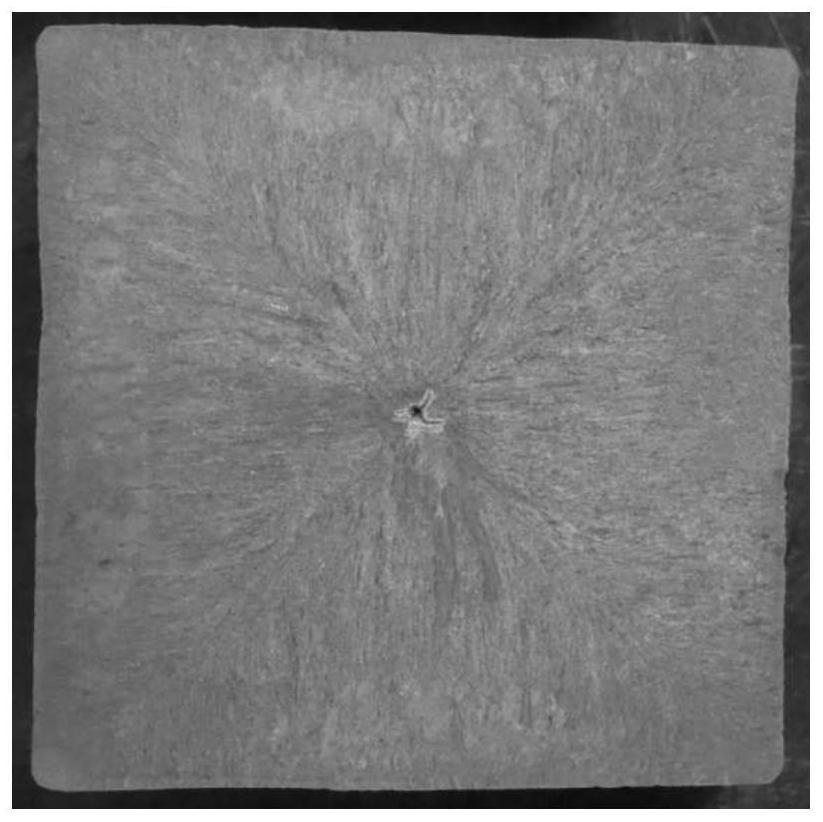

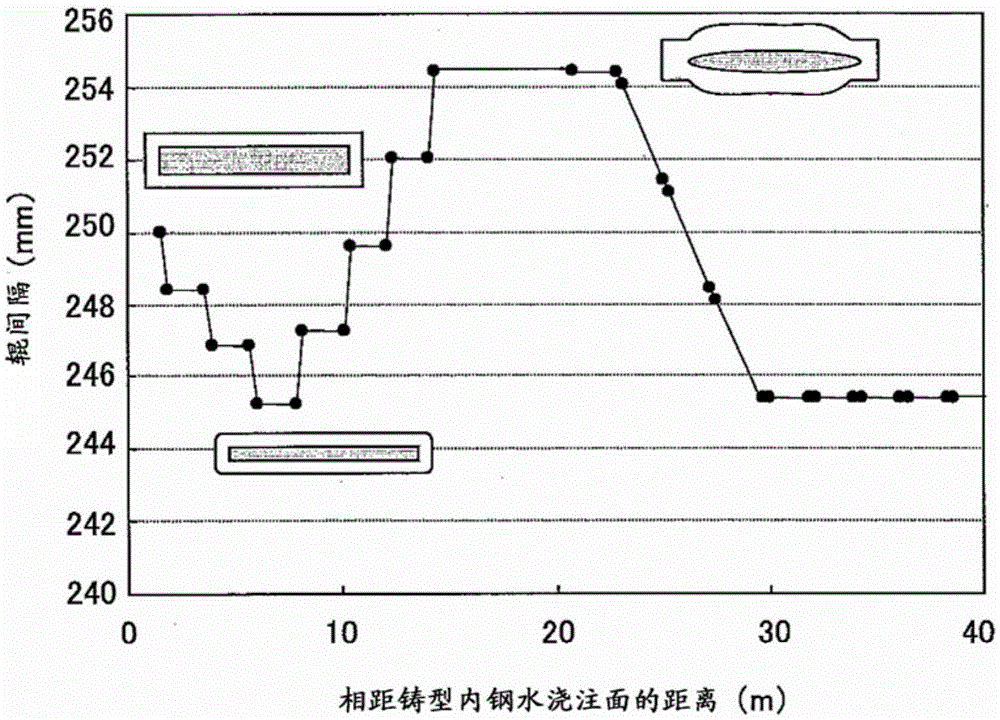

continuous casting method for steel

A slab is continuously cast in such a manner that the slab is intentionally bulged and thereafter the slab having an unsolidified layer is compressed under conditions controlled to prevent the bulging from causing a breakout of the slab and from causing internal cracks in a solidified shell of the slab to reduce central segregation in the slab and positive segregation near a core portion of the slab. A slab 10 is guided on slab-supporting rolls 6 disposed with constant roll gaps from immediately below a casting mold to a point where the thickness of a solidified shell 11 of the slab reaches 15 mm. Thereafter, the slab is bulged on rolls disposed with gradually increased roll gaps with a total amount of bulging of 3 to 20 mm, and is thereafter guided on rolls disposed with constant roll gaps in a zone 0.5 to 5.0 m in length toward the downstream in the casting direction. Subsequently, when the solid phase fraction in a core portion of the slab is from 0.2 to 0.9, the slab is compressed by at least one pass through reduction rolls 7 under such conditions that the product of the compressing rate multiplied by the casting speed is 0.3 to 1.0 mm·m / min 2 .

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com