Method for improving center segregation of extra thick slab with thickness of 400mm

A technology for extra-thick slab and segregation, applied in the field of improving center segregation of 400mm extra-thick slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

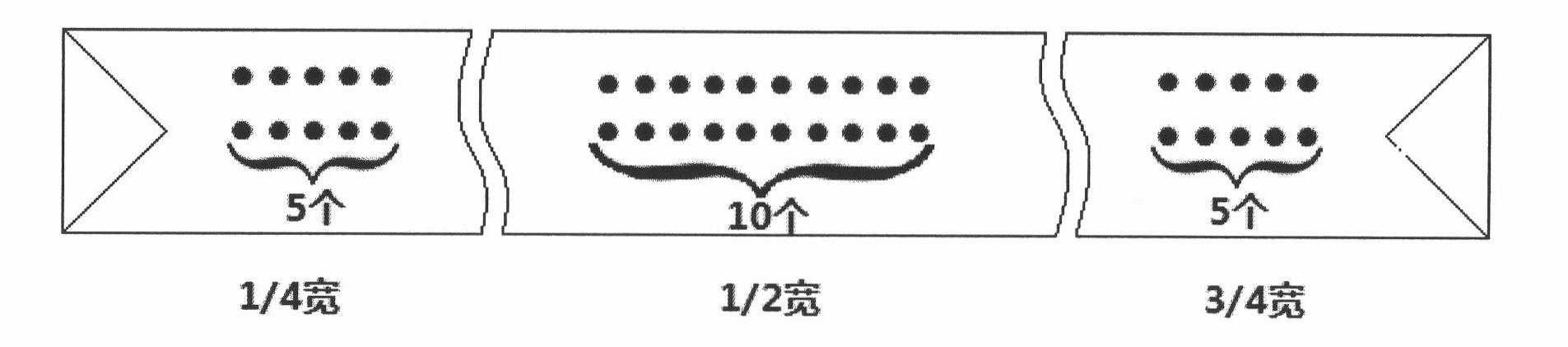

[0011] figure 1 Schematic diagram of chip removal for drilling. The drilling sampling method is to use a drill bit with a diameter of 8 mm to take 5, 10 and 5 steel shavings at the thickness 1 / 2 and 1 / 4 of the slab width 1 / 4, 1 / 2 and 3 / 4, respectively. C, S chemical analysis, the C and S segregation ratios of the two light reduction schemes were obtained respectively.

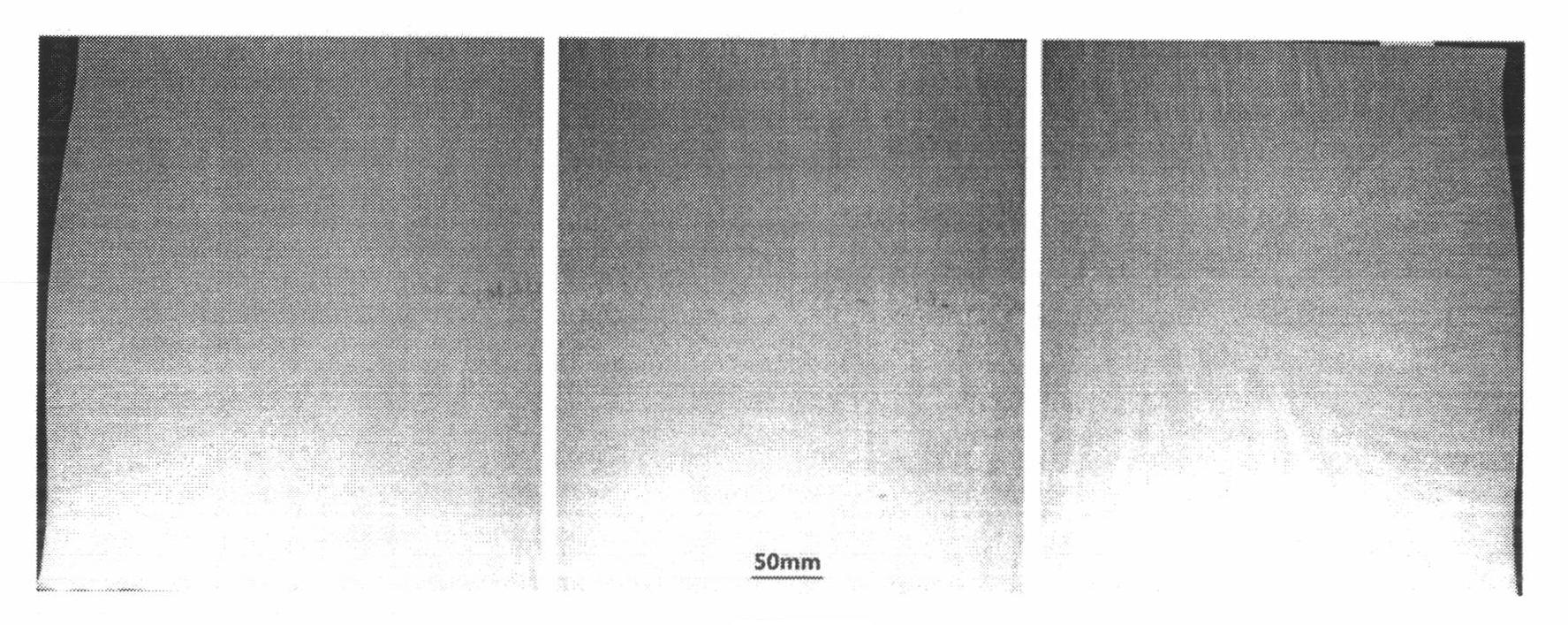

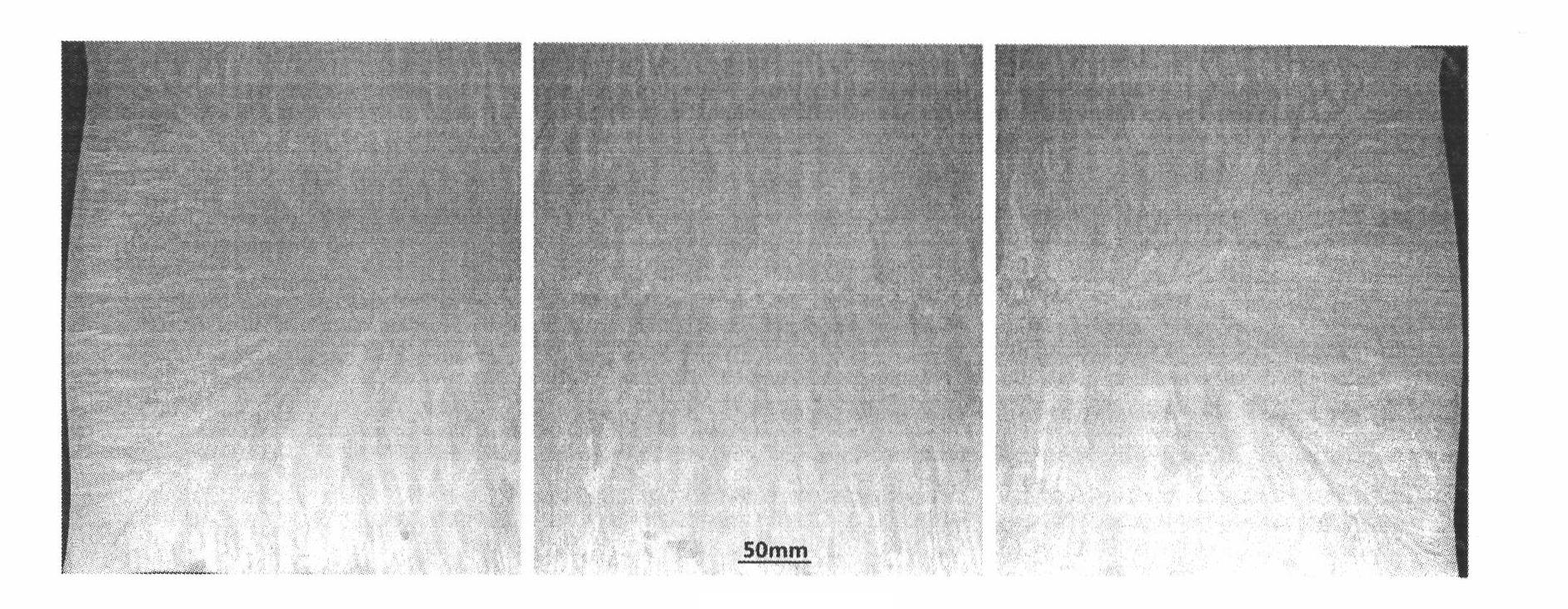

[0012] (1) For medium carbon steel with a thickness specification of 400mm, taking Q345DH as an example, two sets of light reduction test schemes are designed. The slab section size is 400×2400mm. Table 1 shows the soft reduction parameters of different schemes, and Table 2 shows the test furnace The average composition of times. figure 2 , image 3 In order to adopt different light reduction schemes, the low-magnification photos of acid leaching of extra-thick slabs were observed by naked eyes, and it was found that the segregation of scheme 2 was better, and there was no obvious segregation zone in the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com