Homogenized slab continuous casting production method under external field cooperative control effect

A control-action, slab continuous casting technology, applied in the field of steelmaking and continuous casting, which can solve the problems of white bright strips, distance between installation positions, reduction of center segregation and porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, instead of using the secondary cooling electromagnetic stirring technology, using mechanical reduction technology, the reduction amount of mechanical reduction is 10mm, and the reduction position is the seventh and eighth sector of the secondary cooling zone. Other parameters are shown in Table 1 and Table 2 and shown in Table 3. The porosity of the cast slab obtained in this embodiment is shown in Table 5, and the center C segregation rate is as follows image 3 and as shown in Table 5, the low-magnification histogram as Figure 4 As shown in (a), the equiaxed crystal ratio is 12.7%.

Embodiment 2

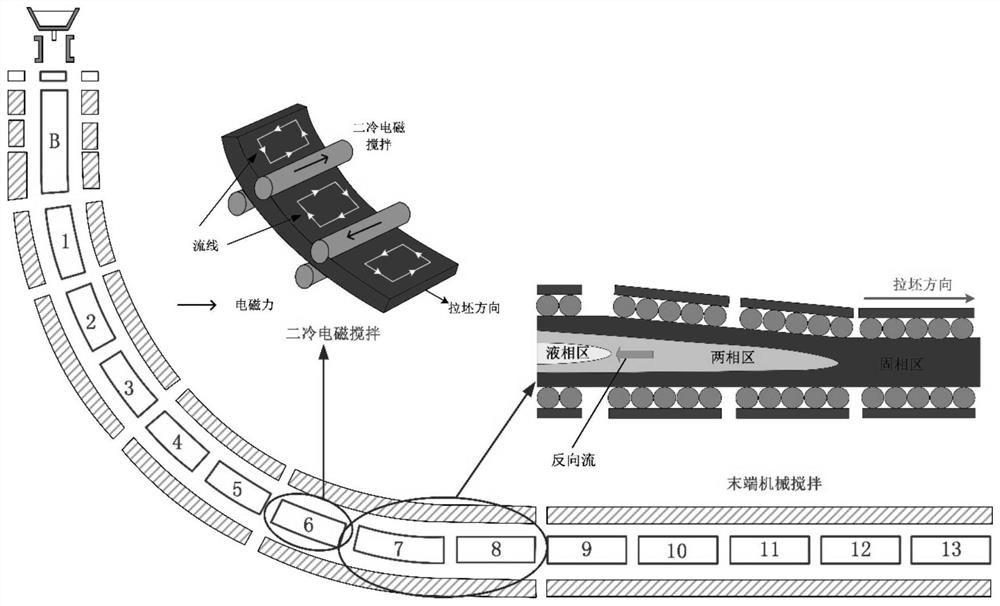

[0034] Embodiment 2, using the secondary cooling electromagnetic stirring technology, without using the mechanical pressing technology, the installation position of the secondary cooling electromagnetic stirring is the second section of the secondary cooling zone, the solid phase ratio of the billet center at the installation place is 0, and the coil turns of the electromagnetic stirring roll The number is 50 turns, and the schematic diagram of the current direction applied to the electromagnetic stirring roller coil is as follows figure 2 As shown, the current intensity is 300A, the current frequency is 7Hz, and other parameters are shown in Table 1 to Table 3. The porosity of the cast slab obtained in this embodiment is shown in Table 5, and the center C segregation rate is as follows image 3 and shown in Table 5.

Embodiment 3

[0035] Embodiment 3, using the secondary cooling electromagnetic stirring technology, using the mechanical pressing technology, the installation position of the secondary cooling electromagnetic stirring is the second section of the secondary cooling zone, the solid phase ratio of the billet center at the installation place is 0, and the number of turns of the electromagnetic stirring roller coil is 50 turns, and the schematic diagram of the current direction applied to the electromagnetic stirring roller coil is as follows figure 2 As shown, the current intensity is 300A, the current frequency is 7Hz, the reduction amount of mechanical reduction is 10mm, and the reduction position is the seventh and eighth sectors of the second cold zone. Other parameters are shown in Table 1~Table 3 . The porosity of the cast slab obtained in this embodiment is shown in Table 5, and the center C segregation rate is as follows image 3 and shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com