Method for producing wire and bar materials

A production method and wire rod technology, applied in the field of online rod production, can solve the problems of high production cost, large energy consumption and environmental pollution, and achieve the effects of reducing energy consumption, improving center segregation, and avoiding center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] Example 1 of the production method of the wire rod of the present invention, it comprises the step of converter smelting, the step of secondary refining in refining furnace, the step of continuous casting of billet in 6-strand billet continuous casting machine, the step under heavy pressure, the step of high-speed wire rod rolling mill Steps of wire rolling, controlled cooling and coil collection.

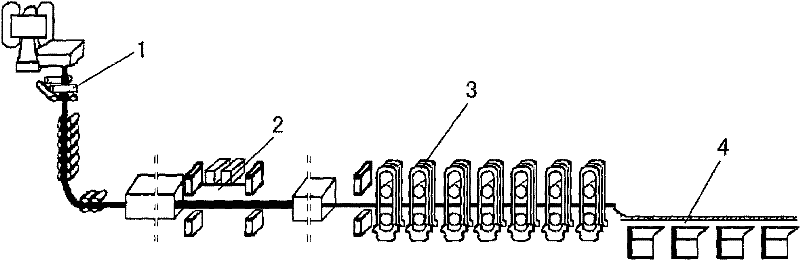

[0021] Such as figure 1 As shown, the equipment used in the production method of the wire and bar of the present invention includes a heavy reduction device, a soaking furnace 2, a wire rolling mill 3, a controlled cooling and coiling equipment 4, and the like.

[0022] The heavy reduction device in the step of heavy reduction is installed in the solidification end region where the liquid ratio after the billet continuous casting step is 10-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com