Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Improve anti-slip performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ice surface anti-slip rubber sports shoe soles and manufacturing method thereof

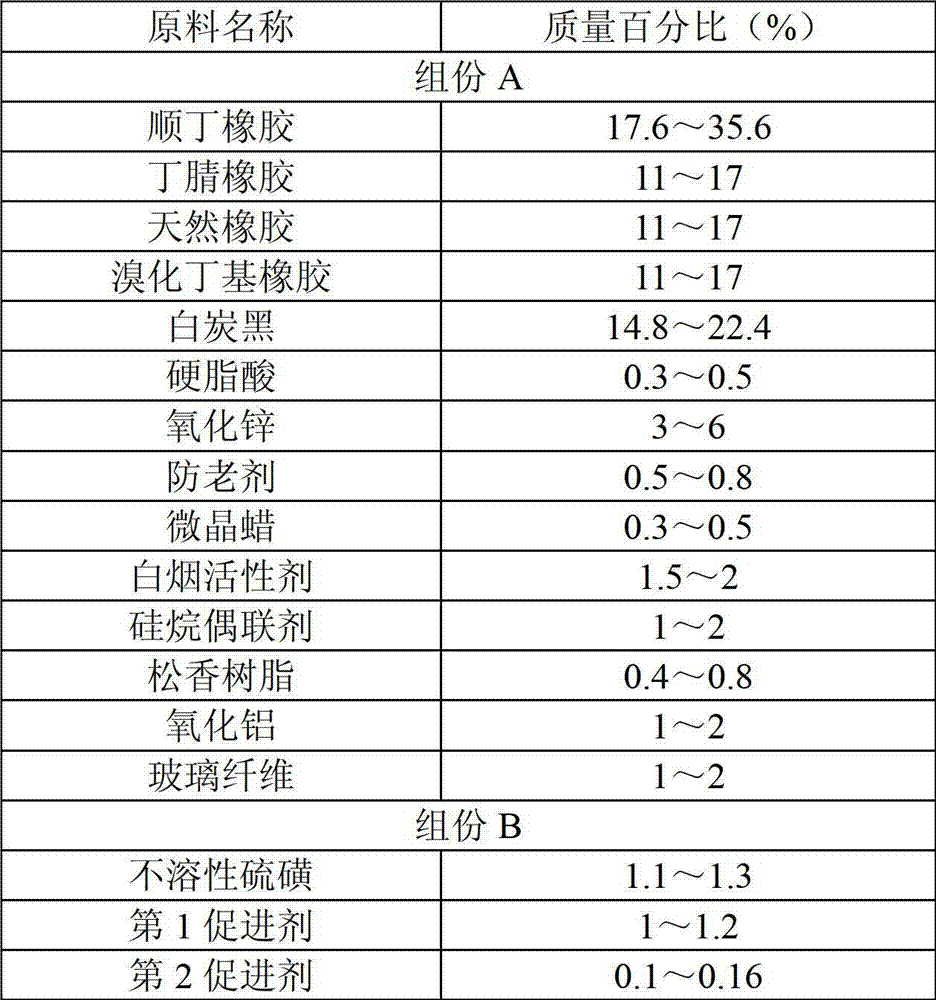

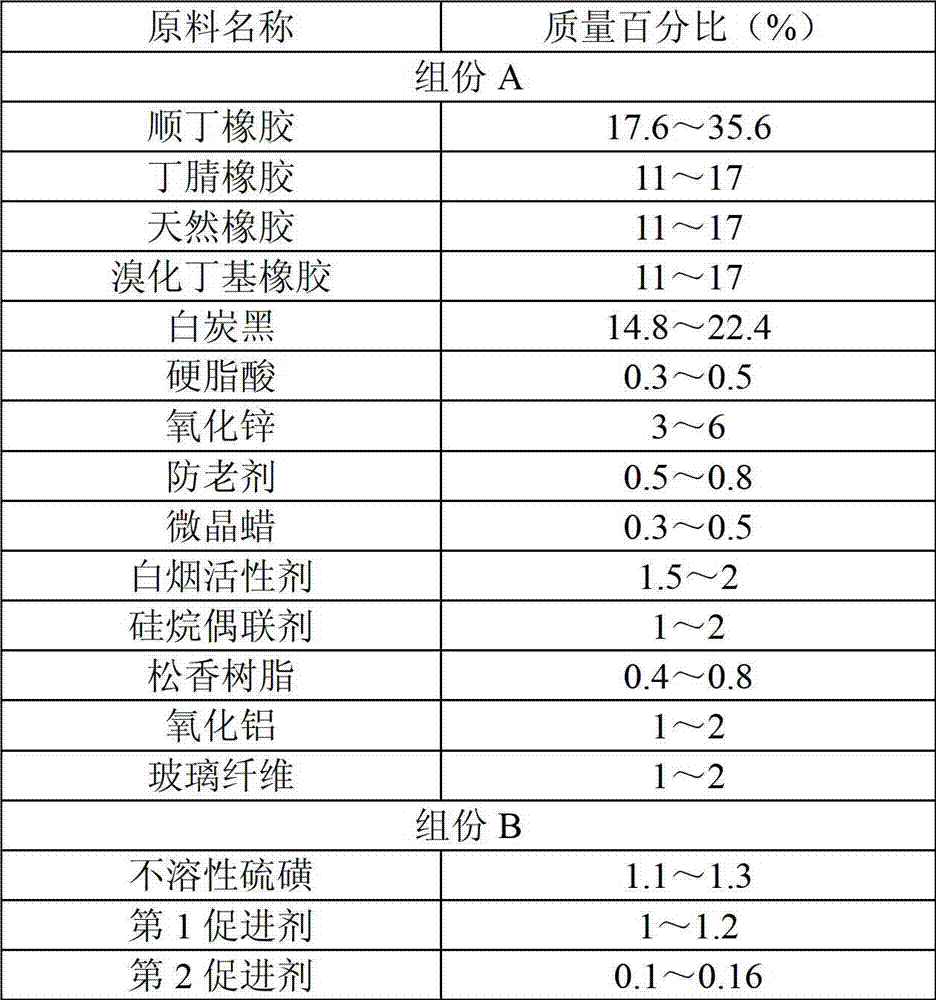

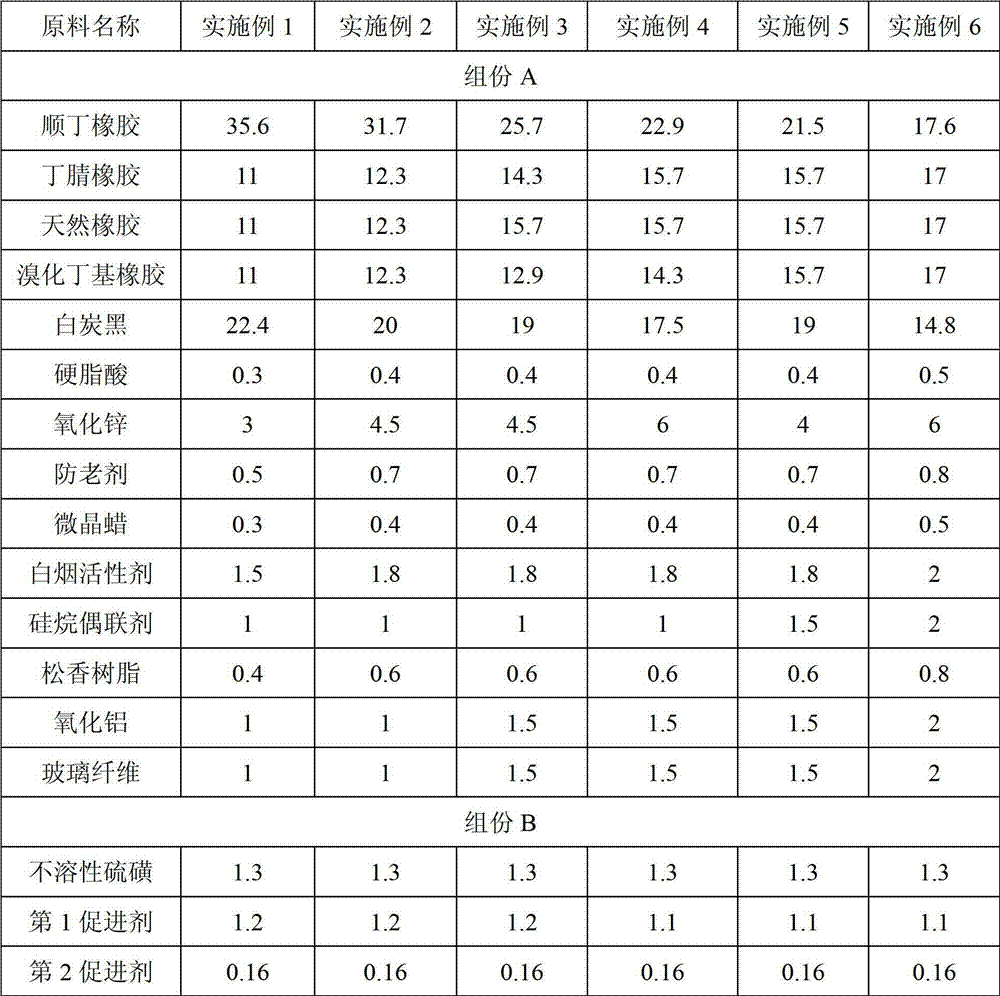

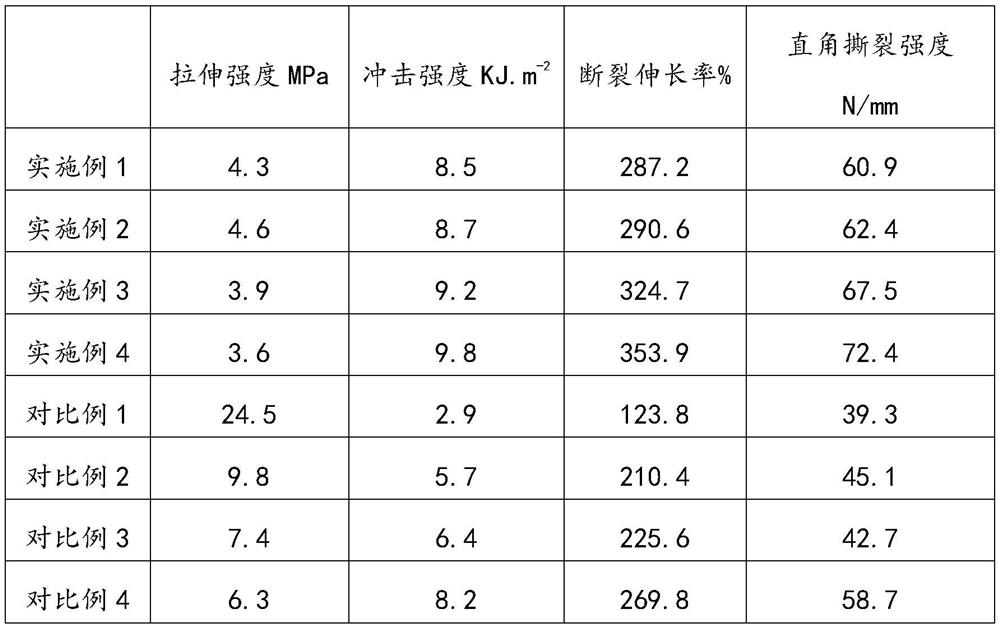

The invention and relates to a pair of soles and discloses a pair of ice surface anti-slip rubber sports shoe soles which has a good anti-slip effect on road surface interfaces of thin ice, snowfield and tundra and long service life and a manufacturing method thereof. The raw materials of the ice surface anti-slip rubber sports shoe soles include components A and components B, wherein the component A consists of butadiene rubber, nitrile rubber, natural rubber, brominated butyl rubber, white carbon black, stearic acid, zinc oxide, anti-aging agent, microcrystalline wax, white smoke active agent, silane coupling agent, rosin resin, alumina and glass fiber; and the component B consists of insoluble sulfur, a first accelerant, a second accelerant. The manufacturing method comprises the following steps of: weighing the materials, banburying, open milling, dosing, measuring a vulcanization curve and oil-pressure forming.

Owner:ANQING TAIYA SHOES CO LTD

Oil-proof antiskid rubber sole and preparation method thereof

ActiveCN104277274AImprove wear resistanceImprove wet skid resistanceSolesPolymer scienceVulcanization

The invention relates to a sole, and discloses an oil-proof antiskid rubber sole and a preparation method thereof. The oil-proof antiskid rubber sole comprises: butadiene-acrylonitrile rubber, epoxidized rubber, brominated butyl rubber, nanosilicon dioxide, a plasticizer, an antiaging agent, a white smoke activator, a silane coupling agent, polyethylene wax, zinc oxide, sulfur and a vulcanization accelerant. Compared with the prior art, by adopting the epoxidized rubber as base rubber and combining the butadiene-acrylonitrile rubber with high acrylonitrile content, the sole is excellent in oil-proof property, has good antiskid performance on the oil-polluted interfaces, can keep excellent wear-resistant property while having high oil-proof and antiskid properties, and is wide in application range including places such as ships, petrochemical plants, motor car repair shops, oil plants where oil is accumulated or splashes, the oil-proof antiskid rubber sole can protect people who walk and work on oil dirt areas from difficultly falling down, and the oil-proof antiskid rubber sole is simple in production procedures, easy in industrial production and has good market prospects.

Owner:MAOTAI FUJIAN SOLES CO LTD

A kind of anti-sagging thermal insulation mortar based on β-hemihydrate gypsum

The invention discloses an anti-sagging heat-insulation mortar based on beta-hemihydrated gypsum. The mortar comprises the following components in parts by weight: 100 parts of beta-hemihydrated gypsum, 5-30 parts of white cement, 60-100 parts of vitrified microsphere, 10-40 parts of quartz sand, 3-10 parts of re-dispersible latex powder, 0.1-0.5 part of cellulose ether, 0.1-0.5 part of poval, 0.05-0.3 part of citric acid, 0.05-0.5 part of polypropylene fiber, 0.05-0.3 part of starch ether, 0.05-0.3 of montmorillonite powder and 120-200 of water. According to the invention, the heat-insulation mortar has extremely good anti-sagging property and good anti-skating property through improvement of heat-insulation mortar components; and the heat-insulation mortar has good workability, thereby greatly improving the construction efficiency and bringing obvious progress for the field of modern building energy conservation materials.

Owner:NANJING CENGO ENERGY SAVING MATERIAL

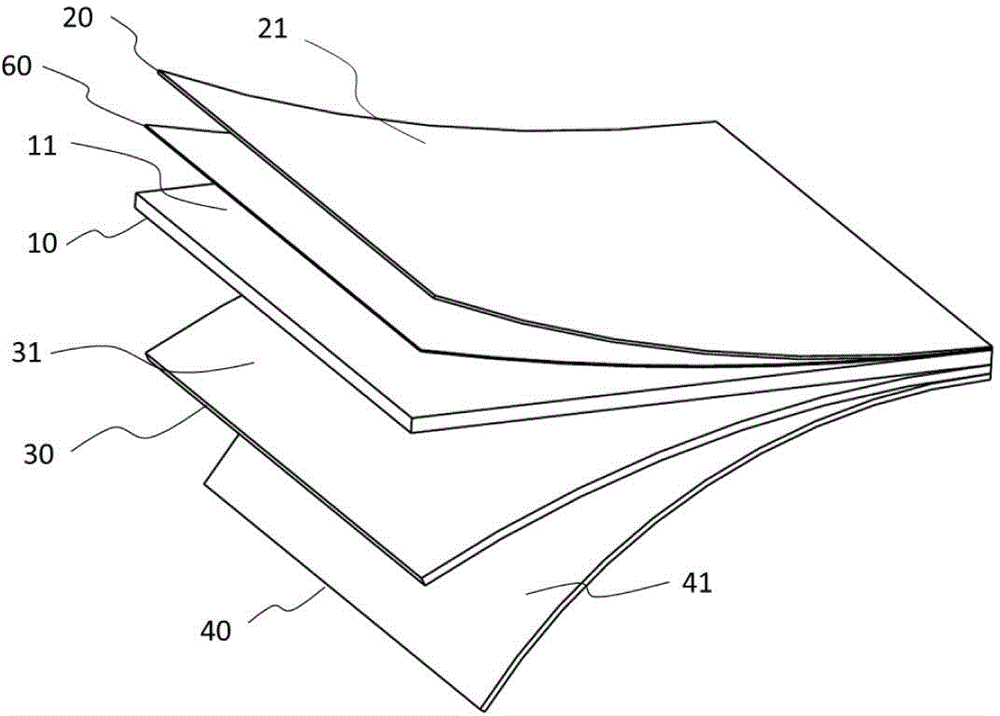

Glue-free PVC (polyvinyl chloride) limited slip floor tile of ring structure and preparation method thereof

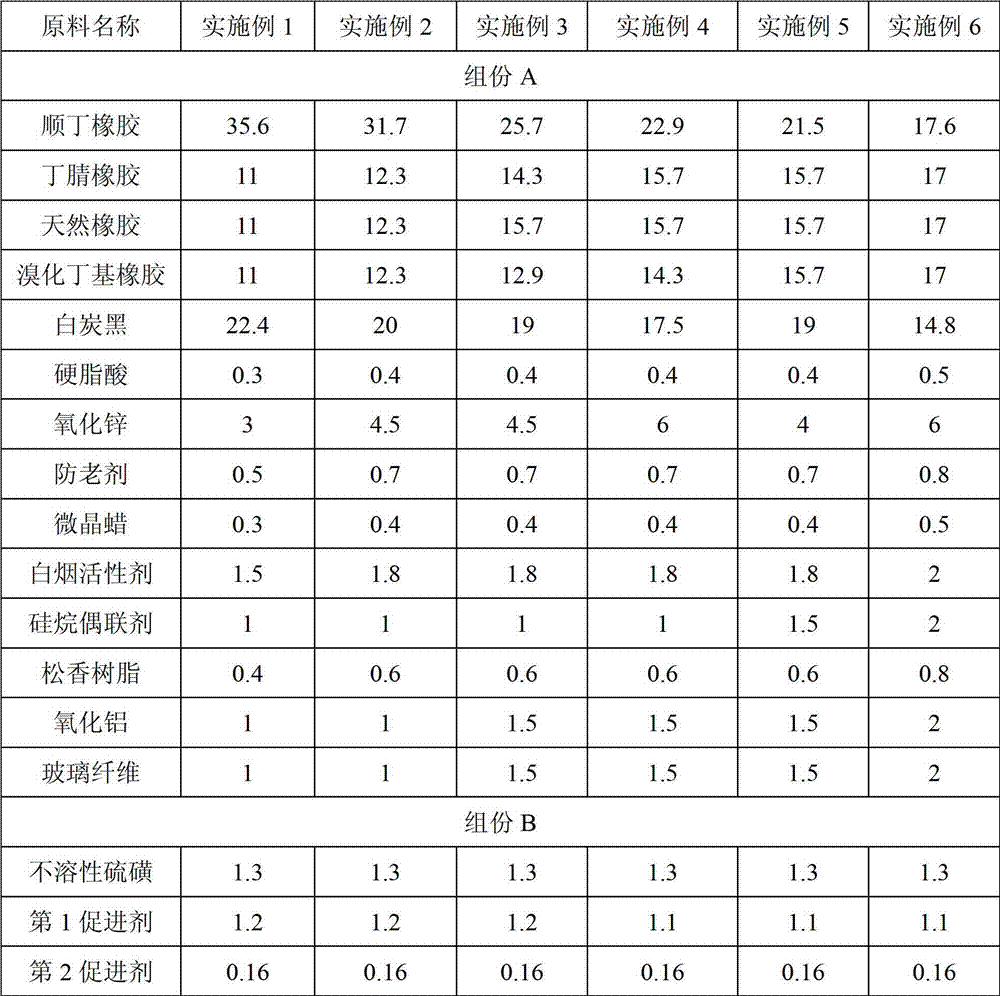

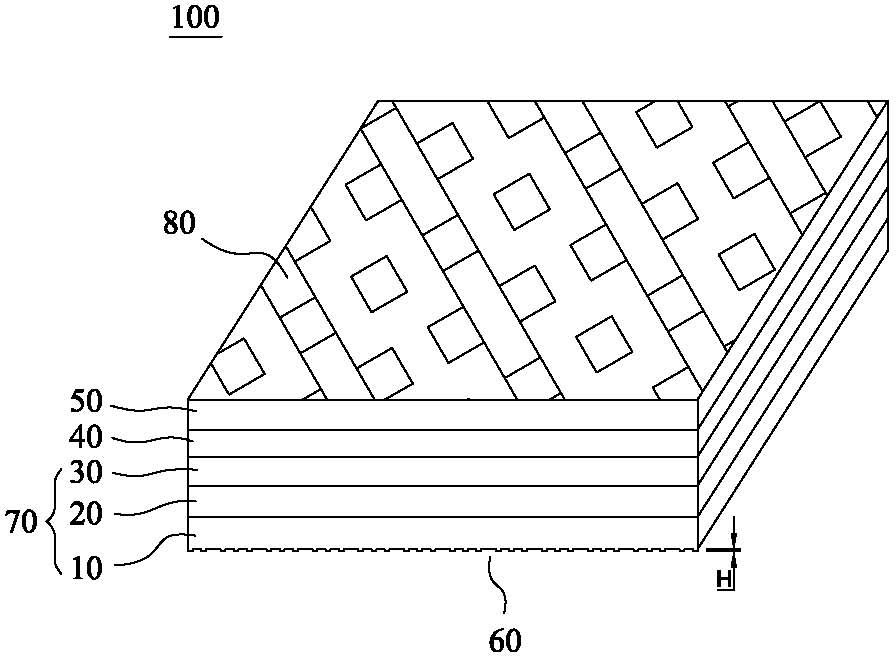

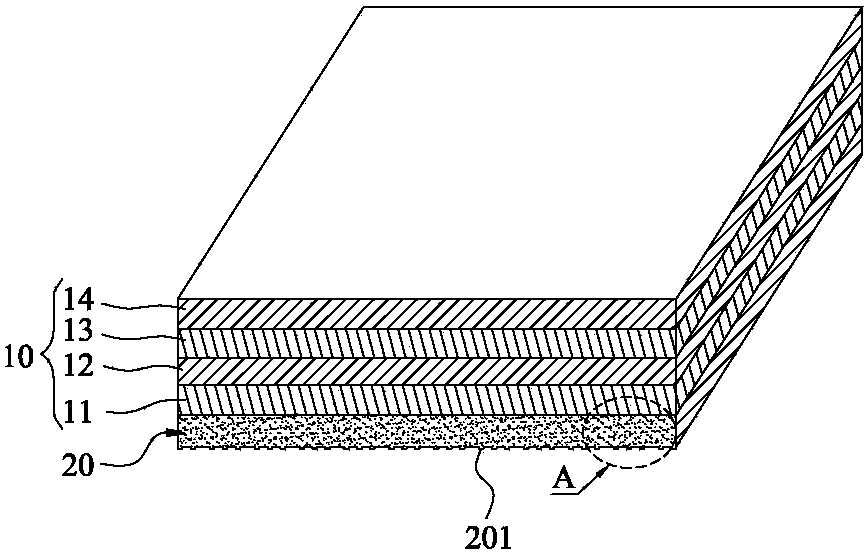

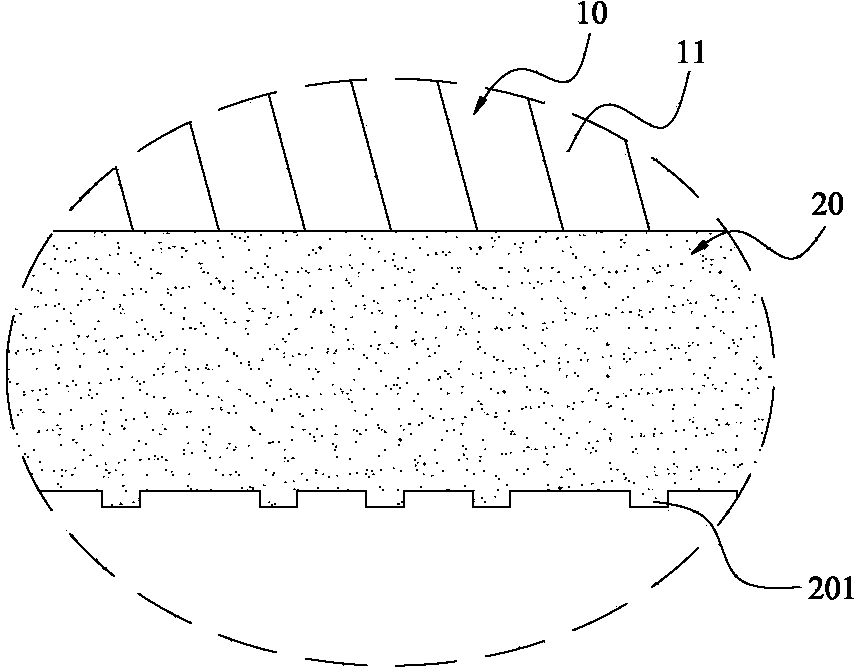

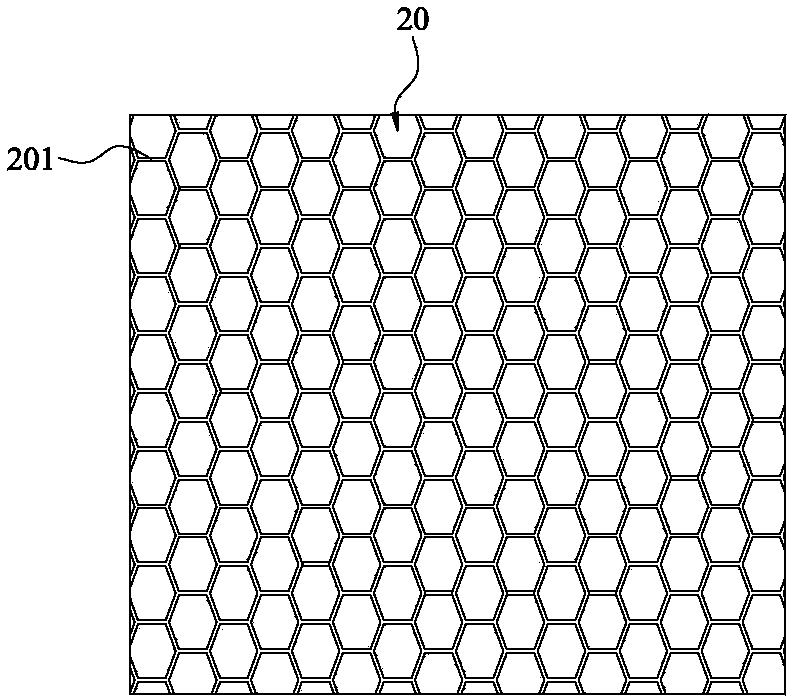

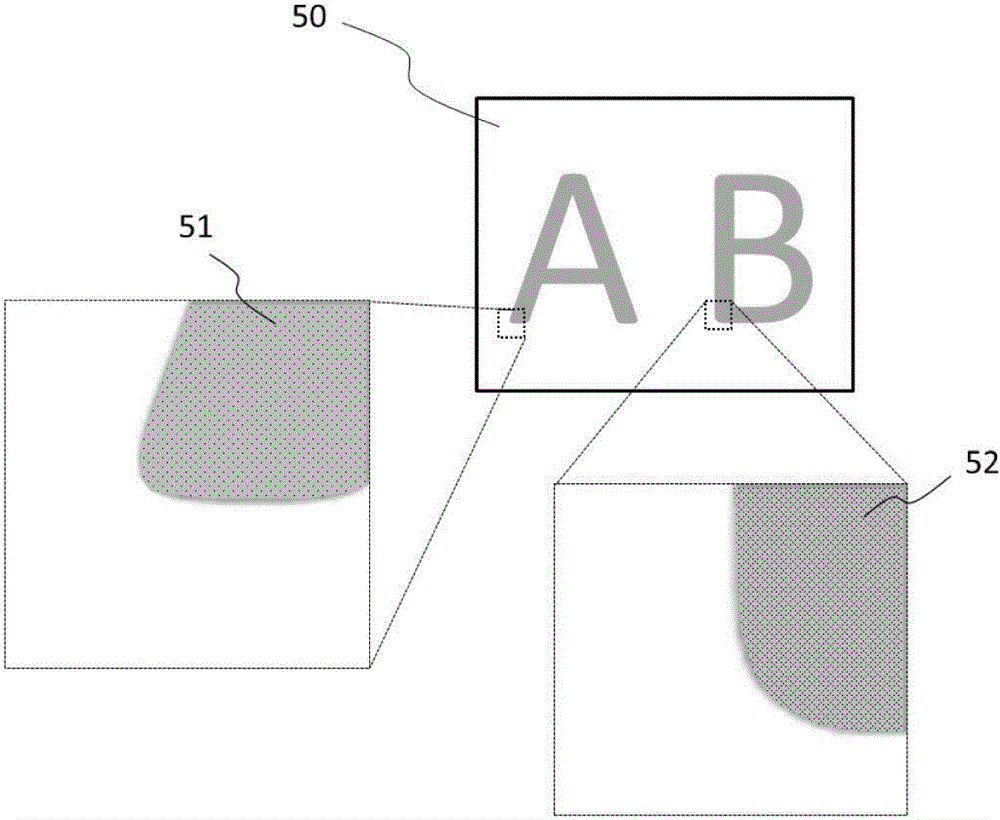

ActiveCN102561657AImprove anti-slip performanceRemove security concernsFlooringSlip lineSlip coefficient

The invention discloses a glue-free PVC (polyvinyl chloride) limited slip floor tile of a ring structure and a preparation method thereof. as for the limited slip floor tile, a flexible thermocompression line is formed on the bottom surface of a PVC limited slip layer in a thermocompression manner; the thermocompression line comprises a plurality of seal hexagon protruding ribs which are continuously and repetitively connected and seal round protruding ribs which are positioned in each hexagon protruding rib; the material formulation of the PVC limited slip layer comprises the following components by weight: 58.5%-63.5% of PVC with polymerization degree of 1000, 34.9-39% of plasticizing agent, 0.95%-2.1% of stabilizing agent, 0.5%-0.69% of toner, and 0.06%-0.08% of calcium carbonate of 800 molybdenum; and the required softness obtained by using particular formulation dosage of the limited slip layer is combined with the limited slip line which is composed of non-hexagon of particular size and shape and the round protruding ribs to enable the limited slip coefficient to be more than 1.5, thereby overcoming the bottle neck of improving the limited slip performance in the industry of plastic floor tiles.

Owner:DONGGUAN PULONG PLASTIC PRODS

Formula of rubber with high slip preventing performance for soles of sports shoes

InactiveCN101643562AImprove anti-slip performanceIdeal raw material function combinationSolesNitrile rubberPlasticizer

The invention relates to a formula of rubber with high slip preventing performance for the soles of sports shoes, comprising the following materials according to parts by quality: 19 parts of butyl rubber, 13 parts of butadiene rubber, 6 parts of butadiene nitrile rubber, 23 parts of white carbon black, 3 parts of paraffin oil, 0.3 part of magnesia, 2.3 parts of activating agent, 0.6 part of stearic acid, 0.5 part of plasticizer, 3 parts of calcene, 0.2 part of antifogging agent, 0.75 part of vulcanizing agent and 0.85 part of promoter; after the formula of the rubber for the soles of the sports shoes is adopted, an ideal raw material function combination can be obtained. After the formula is actualized, the slip-preventing coefficient of the produced soles of the sports shoes can reach 1.0 in a dry type and 0.8 in a wet type, the slip-preventing effect of the soles is enhanced, and the safety of the movement process is protected.

Owner:泉州泰亚鞋业有限公司

Non-slip floor

ActiveCN103410296ARemove security concernsEasy to installSynthetic resin layered productsFloor coveringsSlip coefficientPressure sense

The invention discloses a non-slip floor. The non-slip floor comprises a body, a pasting layer is arranged on the bottom surface of the body in a combined and stacked mode, a plurality of protruding ribs are arranged on the bottom surface, in contact with the ground, of the pasting layer in a convex mode, a plurality of closed cavity type suckers are formed by the protruding ribs in an enclosing mode, and the pasting layer is made of pressure-sensing thermosensitive gel. According to the material formula, the pasting layer comprises, by weight, 35-55% of tackifying resin, 10-20% of softener, 2-5% of antioxidant, 10-20% of butyl rubber and 5-10% of naphthenic oil, and the sum of the total amounts of all the above substances is 100%. Thus, the non-slip floor can be used repeatedly, easy to install and convenient to detach by the utilization of the characteristic of being capable of being used repeatedly of the pressure-sensing thermosensitive gel; the non-slip floor can be pasted to the ground through the pasting layer, therefore, the non-slip performance of the non-slip floor is greatly promoted, the non-slip floor has very good self-pasting and absorption effects, the non-slip coefficient of the bottom can reach 1.7-2.0, and safety concerns about the old and children can be relieved in terms of home mat formation.

Owner:DONGGUAN MEI JER PLASTIC PROD CO LTD

Anti-sagging heat-insulation mortar based on silicate cement

InactiveCN102190468AGood anti-sagGood anti-slip performanceSolid waste managementCellulosePolyvinyl alcohol

The invention discloses an anti-sagging heat-insulation mortar based on silicate cement, which comprises the following components in parts by weight: 80-200 parts of silicate cement, 20-50 parts of fly ash, 60-100 parts of vitrified microbeads, 10-20 parts of heavy calcium carbonate, 3-10 parts of redispersible latex powder, 0.1-0.5 part of cellulose ether, 0.1-0.5 part of poly(vinyl alcohol), 0.05-0.3 part of citric acid, 0.05-0.5 part of polypropylene fibers, 0.05-0.3 part of starch ether, 0.05-0.3 part of montmorillonite powder and 120-200 parts of water. According to the invention, the components of the heat-insulation mortar are improved, so that the heat-insulation mortar has the advantages of high sagging resistance, high slipping resistance and good construction performance, thus improving construction efficiency and bringing prominent progress to the energy-saving material field of modern building.

Owner:NANJING CENGO ENERGY SAVING MATERIAL

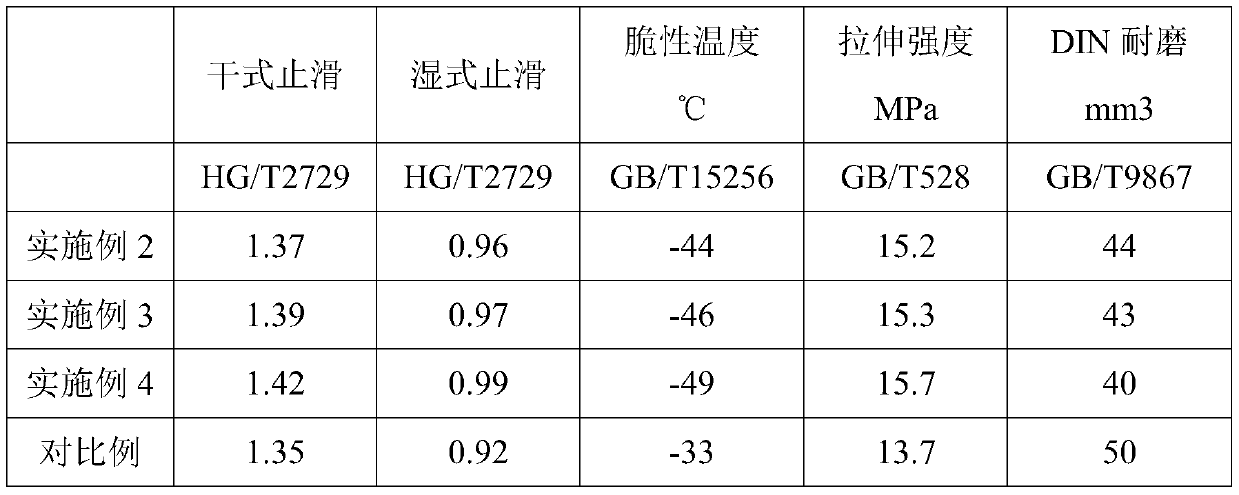

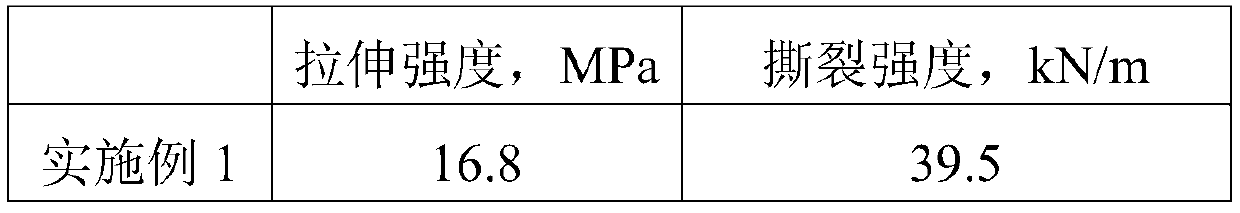

Graphene natural rubber polymer anti-slip mixed foaming material on ice and preparation method of mixed foaming material

ActiveCN110698733AHigh anti-slip coefficientImprove the anti-slip effectSolesCross linkerStearic acid

The invention discloses a graphene natural rubber polymer anti-slip mixed foaming material on ice and a preparation method of the mixed foaming material. The mixed foaming material is prepared from the following raw materials in parts by weight: 50-60 parts of natural rubber, 32-37 parts of butyl rubber, 8-12 parts of cis-polybutadiene, 4-6 parts of white carbon black, 2.4-2.8 parts of basalt fibers, 2-3 parts of nano silicon dioxide, 2.2-2.6 parts of graphene, 1.4-1.7 parts of silicone oil, 1.2-1.5 parts of zinc oxide, 1.5-2.0 parts of zinc stearate, 1.8-2.4 parts of stearic acid, 1.6-1.9 parts of a cross-linking agent, 4.5-5.5 parts of a flow promoting agent, and 1.5-2.0 parts of a foaming agent. The graphene natural rubber polymer anti-slip mixed foaming material on the ice provided bythe invention has a high anti-slip coefficient, a good anti-slip effect, good low-temperature resistance, a good low-temperature anti-slip effect, high tensile strength, good mechanical properties, low abrasion, good wear resistance and long service life.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Noiseless comfortable rubber heel lift and preparation method thereof

The invention relates to the technical field of organic macromolecular compounds and provides a noiseless comfortable rubber heel lift and a preparation method thereof. The noiseless comfortable rubber heel lift comprises natural rubber, butadiene styrene rubber, butadiene-acrylonitrile rubber, high-styrene rubber, rubber powder, white carbon black, mineral oil, anti-aging agent, polyethylene glycol, silane coupling agent, zinc oxide, sulphur and vulcanization accelerating agent. The noiseless comfortable rubber heel lift has the advantages that the heel lift is elastic and noiseless, pressure and discomfort borne by the foot can be reduced, wearing comfort is improved, the trouble of noise is got rid of, and high wear-resisting and anti-slip performance and long service life are achieved.

Owner:MAOTAI FUJIAN SOLES CO LTD

Manufacturing method of anti-slip sole

InactiveCN102218843AImprove anti-slip performanceReduce tensionDomestic footwearMaterials scienceHot press

The invention relates to the technical field of sole manufacturing methods, and specially relates to a manufacturing method of an anti-slip sole. The manufacturing method comprises the following steps of 1, carrying out a hot pressing process on a polyurethane (PU) material and a textile, leather or artificial leather to cure and mold the PU material on the textile, the leather or the artificial leather to obtain a sole initial blank, 2, spraying liquid thermoplastic urethane (TPU) on or bonding a TPU film to a side of the sole initial blank to obtain a sole blank, wherein there is not the textile, the leather or the artificial leather on the side, and 3, putting the sole blank obtained from the step 2 into a sole mould, pouring liquid PU into the sole mould to make the liquid PU combine with TPU on the sole blank, and carrying out a curing and molding process to obtain a finished sole. A sole produced through the manufacturing method has three layers, and textile, leather or artificial leather located at the bottom layer and a thin PU layer are combined together by being cured to form an anti-slip part located at the bottom of the sole. TPU can be combined well with PU of a main part located at the top layer of the sole thus the anti-slip sole is formed finally.

Owner:黄瑞琦 +1

High-wear-resistance anti-slip EVA composite foam material and preparation method thereof

ActiveCN111004434AImprove surface structureUniform particle sizeChemical industryOxide compositeOctene

The invention discloses a high-wear-resistant anti-slip EVA composite foam material and a preparation method thereof, wherein the foam material is prepared from the following components: an ethylene-vinyl acetate copolymer, maleic anhydride grafted EVA, an ethylene-octene copolymer, a terpene resin, a wear-resistant anti-slip agent, naphthenic oil, polyisobutene, a foaming agent, an accelerant, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide and an antioxidant, wherein the wear-resistant anti-slip agent is a modified steel slag / graphene oxide composite material. Compared with the traditional EVA foam material, the high-wear-resistant anti-slip EVA foam composite material prepared by the invention has good wear resistance and good anti-slip performance under the condition of a lowfiller addition amount, has good processability and good mechanical properties, is simple in the operation of the manufacturing process, energy saving and environmentally friendly, and has wide application prospects and market requirements in actual application.

Owner:FUZHOU UNIV

Formula of rubber with high slip preventing performance for soles of sports shoes

InactiveCN101643562BImprove anti-slip performanceIdeal raw material function combinationSolesNitrile rubberPlasticizer

The invention relates to a rubber with high slip preventing performance for the soles of sports shoes, comprising the following materials according to parts by quality: 19 parts of butyl rubber, 13 parts of butadiene rubber, 6 parts of butadiene nitrile rubber, 23 parts of white carbon black, 3 parts of paraffin oil, 0.3 part of magnesia, 2.3 parts of activating agent, 0.6 part of stearic acid, 0.5 part of plasticizer, 3 parts of calcene, 0.2 part of antifogging agent, 0.75 part of vulcanizing agent and 0.85 part of promoter; after the formula of the rubber for the soles of the sports shoes is adopted, an ideal raw material function combination can be obtained. After the formula is actualized, the slip-preventing coefficient of the produced soles of the sports shoes can reach 1.0 in a dry type and 0.8 in a wet type, the slip-preventing effect of the soles is enhanced, and the safety of the movement process is protected.

Owner:泉州泰亚鞋业有限公司

Non-slip polyurethane elastomer stock solution as well as preparation method and application thereof

The invention discloses a non-slip polyurethane elastomer stock solution as well as a preparation method and application thereof. The non-slip polyurethane elastomer stock solution comprises a polyurethane stock solution component A and a polyurethane stock solution component B, wherein the polyurethane stock solution component A comprises polyether ester diol and polyester polyol; the polyurethane stock solution component B comprises hydroxy-terminated liquid rubber modified polyester polyol. The non-slip polyurethane elastomer stock solution can be applied to safety protection soles, non-slip mats and the like, and the safety protection effect is improved.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

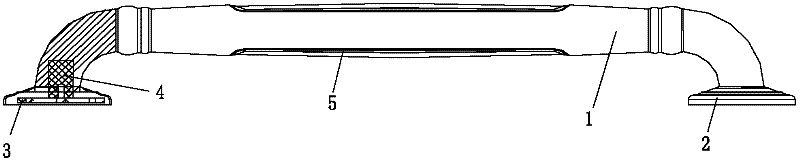

Anti-slip metal-like safety handrail and preparation method thereof

InactiveCN102327090AImprove securityIncrease frictionBathroom accessoriesEngineering plasticEngineering

The invention provides an anti-slip metal-like safety handrail and a preparation method thereof, and relates to a handrail. The anti-slip metal-like safety handrail is equipped with a handrail body, two metal end covers and two metal flanges, wherein, the two metal end covers are respectively inserted into two ends of the handrail body; the two metal flanges are respectively locked with insert pins arranged on two ends of the handrail body; and the surface of the handrail body is in an anti-slip corrugated shape. The preparation method comprises the following steps of: firstly preparing granular composite modified materials for engineering plastics by a double screw extruder; feeding the granular composite modified materials for engineering plastics into an injection molding machine, and forming the composite engineering plastic handrail body two ends of which are embedded with the metal pins by a secondary rubber-coating injection molding process; preparing the metal end covers and the metal flanges; carrying out surface treatment on the handrail body, the metal end covers and the metal flanges; and respectively inserting the two metal end covers into the two ends of the handrail body, and then locking the metal flanges with the insert pins arranged on the two ends of the handrail body so as to finally obtain the anti-slip metal-like safety handrail.

Owner:XIAMEN RUNNER IND CORP

Thermoplastic vulcanized foamed beads, preparation method and application

InactiveCN108047697AGood yellowing resistanceImprove anti-slip performanceSolesCross-linkThermoplastic

The invention relates to thermoplastic vulcanized foamed beads, preparation method and application. The thermoplastic vulcanized foamed beads are prepared from, by mass, 100 parts of a thermoplastic vulcanized material, 0.1-5 parts of a cross-linking agent, 1-3 parts of a nucleating agent and 0.1-0.3 part of an ultraviolet absorbing agent. The thermoplastic vulcanized foamed beads prepared according to the method are high in abrasion resistance, flexibility, resilience, yellowing resistance, aging resistance, environmental friendliness, nontoxicity, recoverability, softness, light weight and slip resistance. The preparation method has advantages that safety and nontoxicity are achieved, so that true environmental friendliness is realized; in addition, simplicity, safety and easiness in realization of continuous industrial production are realized.

Owner:晋江市辉燕塑胶有限公司

Sticker structure

The present invention relates to a sticker structure and especially relates to a sticker structure which can be used with reading equipment and is applied to teaching. The sticker structure comprises a self-adhesive layer for being attached to the inside or outside of a building or an object, a buffer layer which is bonded with the self-adhesive layer and is used for allowing the adhesiveness of the sticker to be better and the touch feel of the sticker to be smoother, and a printing layer which is formed by environment-friendly paper and is bonded to the buffer layer. One side of the printing layer is printed with an optical identification message, polyvinyl chloride is sprayed on the side for glazing after printing, and then the side is subjected to embossing to enhance an anti-slip effect when the sticker is attached to a ground.

Owner:黄南祯

Anti-sagging heat-insulation mortar based on beta-hemihydrated gypsum

The invention discloses an anti-sagging heat-insulation mortar based on beta-hemihydrated gypsum. The mortar comprises the following components in parts by weight: 100 parts of beta-hemihydrated gypsum, 5-30 parts of white cement, 60-100 parts of vitrified microsphere, 10-40 parts of quartz sand, 3-10 parts of re-dispersible latex powder, 0.1-0.5 part of cellulose ether, 0.1-0.5 part of poval, 0.05-0.3 part of citric acid, 0.05-0.5 part of polypropylene fiber, 0.05-0.3 part of starch ether, 0.05-0.3 of montmorillonite powder and 120-200 of water. According to the invention, the heat-insulation mortar has extremely good anti-sagging property and good anti-skating property through improvement of heat-insulation mortar components; and the heat-insulation mortar has good workability, thereby greatly improving the construction efficiency and bringing obvious progress for the field of modern building energy conservation materials.

Owner:NANJING CENGO ENERGY SAVING MATERIAL

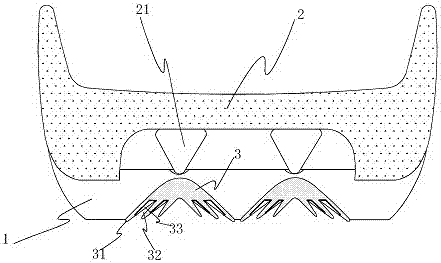

Skid-proof shoe sole

ActiveCN107467782AImprove friction and anti-slip effectImprove anti-slip performanceSolesConoidBiomedical engineering

Owner:晋江巨人商贸有限公司

Production process of ground mat with flat surface

InactiveCN106313574AImprove anti-slip performanceSimple layingDomestic articlesSurface layerRoom temperature

The invention relates to a production process of a ground mat with a flat surface. The production process comprises substrate preparation, foaming formation and cutting formation; a mixed foaming material is poured in a foaming mold for leveling, is foamed by 10-15 min under the condition of 160-170 DEG C for forming, and is cooled to the room temperature; a sheet formed by foaming is taken out from the mold; after foaming formation, the surface layer of the sheet formed by foaming is removed; after the surface layer is removed, lines are pressed on the ground mat with the flat surface through cold and hot pressing; and specifically, the surface layer is removed by a cutting table machining machine according to an actual removal needing thickness. The ground mat with flat surface produced by the ground mat production process is flat, is easy to lay, and greatly enhances the slip stop effect; and meanwhile, the lines on the ground mat with flat surface are clear, cannot darken due to long use time, and achieve the beautifying effect when preventing slip.

Owner:QINGDAO WINCHANCE TECH

Degradable EVA foam material and preparation method thereof

The invention discloses a degradable EVA foam material and a preparation method thereof. The degradable EVA foaming material is prepared from the following raw materials in parts by weight: 35-45 parts of an ethylene-vinyl acetate copolymer, 15-20 parts of a POE elastomer, 8-12 parts of rubber, 6-10 parts of a bio-based polypentamethylene diamine adipate polymer, 20-30 parts of a degradable organic matter, 1-1.5 parts of stearic acid, 1-1.2 parts of zinc oxide, 1-1.5 parts of peroxide and 1-5 parts of an AC foaming agent, wherein the degradable organic matter is tapioca flour or corn starch; the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 32.5%-36.5%; and the POE elastomer is a mixture of an ethylene-octene copolymer and an ethylene-hexene copolymer. The degradableEVA foaming material disclosed by the invention has good wear resistance, high elasticity, good portability, good anti-slip effect, good mechanical properties, favorable comprehensive performance andgood application prospects.

Owner:福建安达福新材料科技有限公司

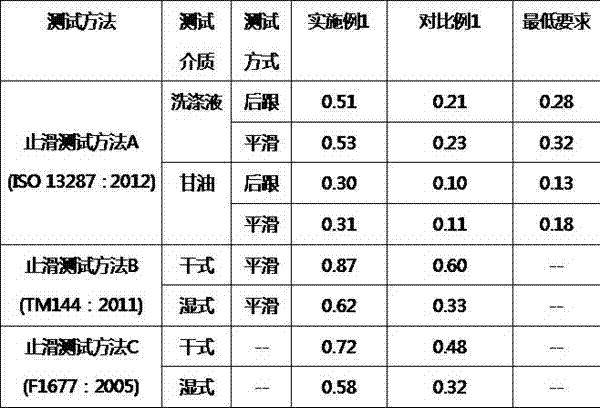

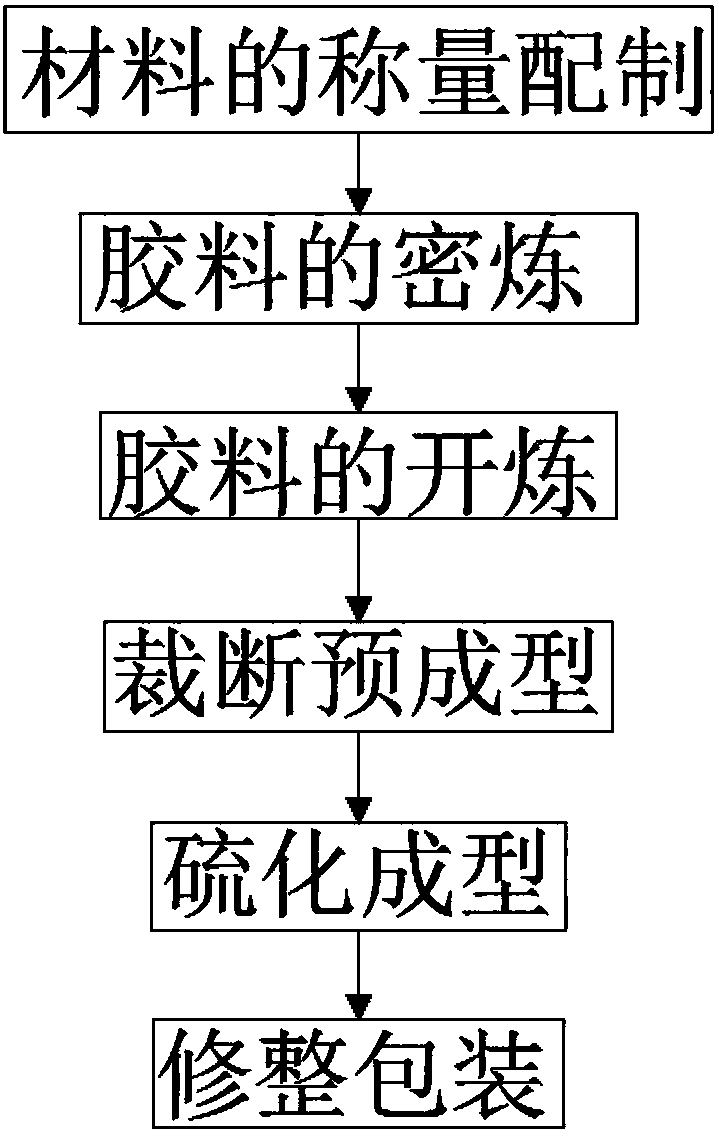

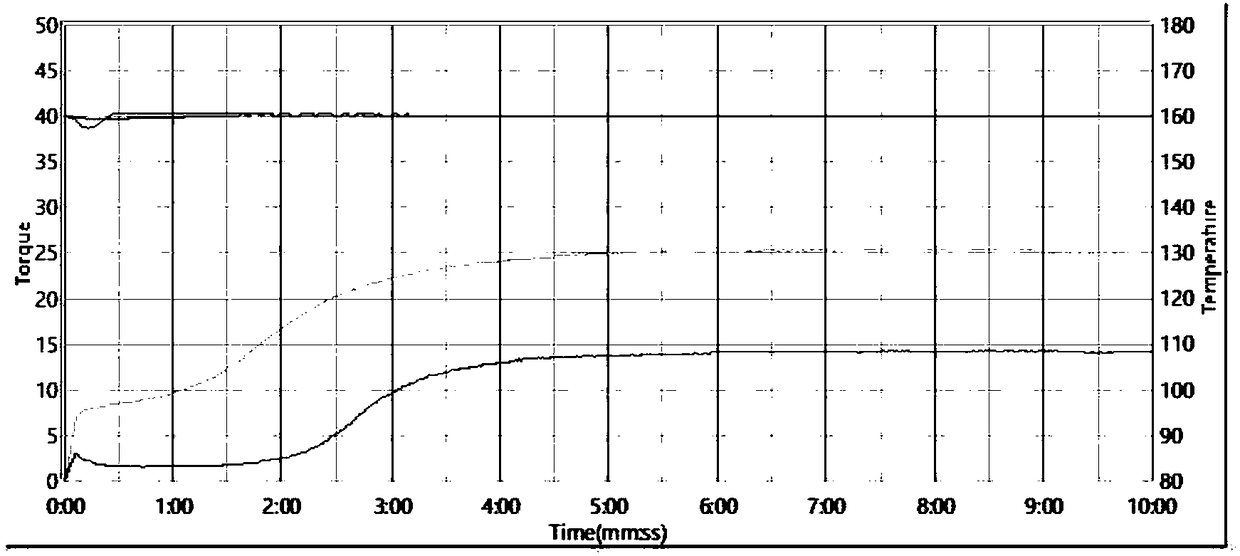

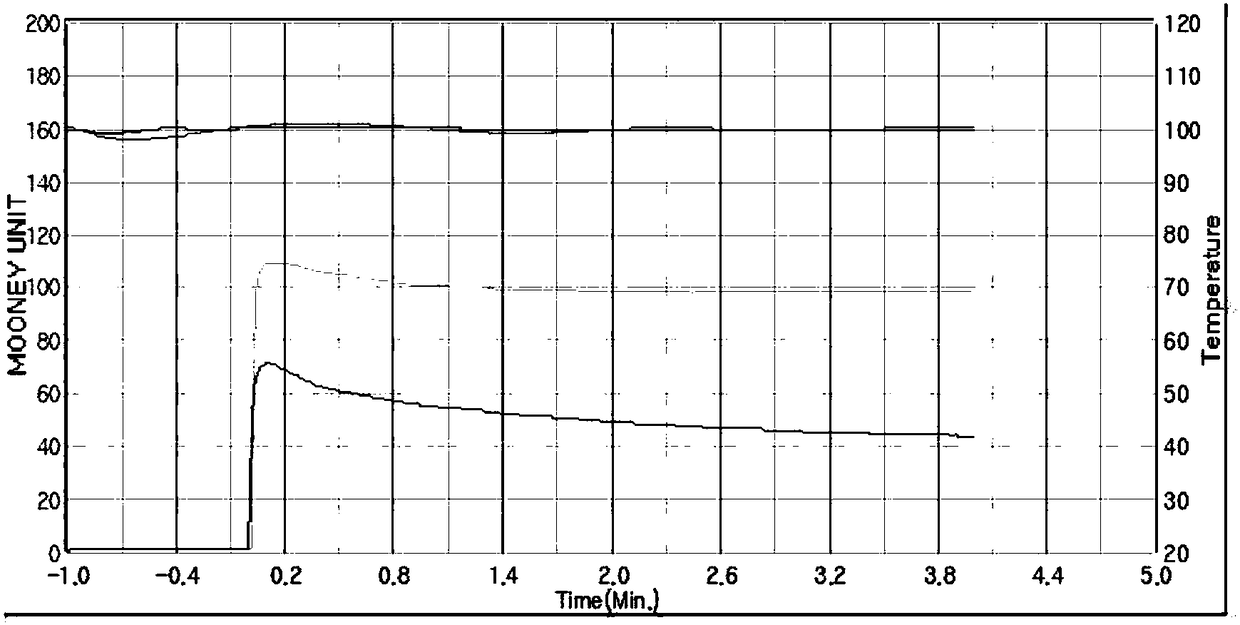

Manufacturing method of non-slip sole

The invention provides a manufacturing method of a non-slip sole, and belongs to the technical field of shoe materials. The method includes the steps of firstly, weighing and preparing materials; secondly, banburying rubber; thirdly, mixing the rubber; fourthly, conducting cutting and performing; fifthly, vulcanizing forming; sixthly, conducting trimming and packaging. The sole manufactured through the technology process is good in non-slip effect and resistant to wear; compared with non-slip soles on the market in the same period, data is better than that of non-slip soles on the market; special-pattern non-slip blocks designed according to the ergonomics are adopted for the sole, so the shoe is better in non-slip effect.

Owner:青岛瑞跃鞋业有限公司 +1

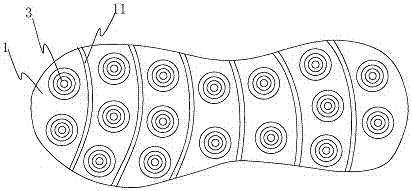

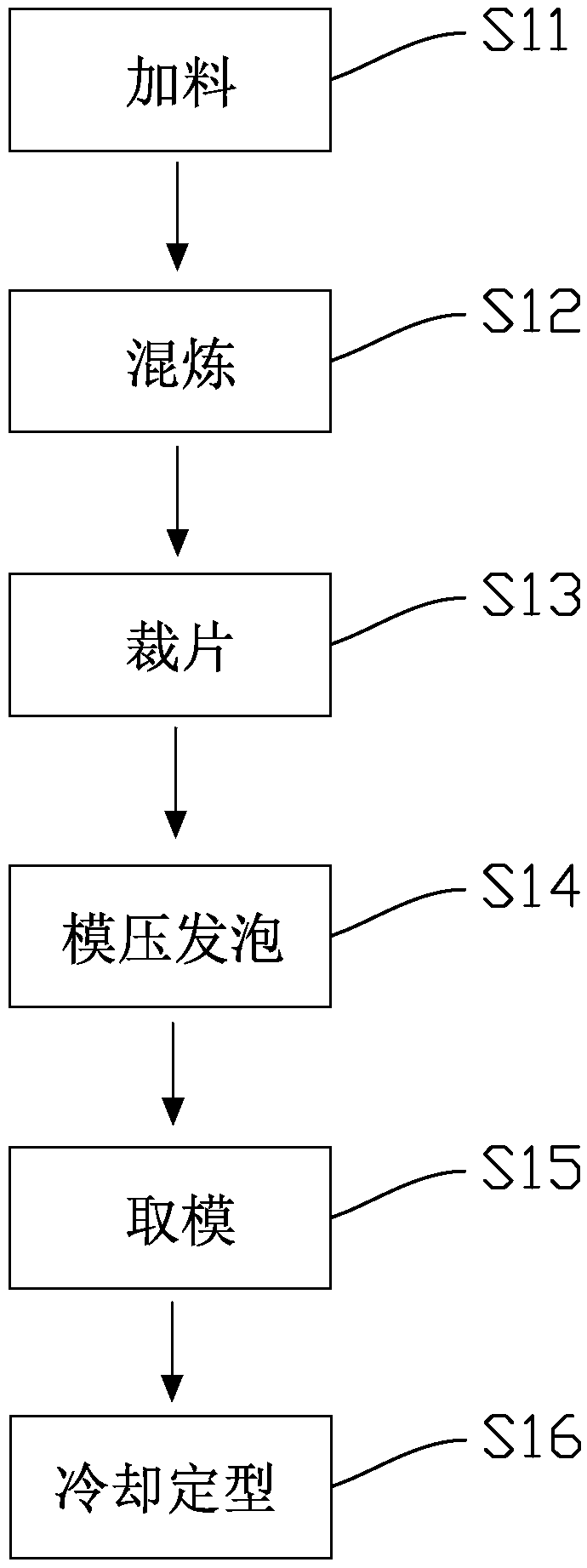

Manufacturing process of shoe soles and healthy shoes

InactiveCN109367091AKeep healthyCompliant with the production chain environmentSolesInsolesSurface layerBiochemical engineering

The invention discloses a manufacturing process of shoe soles. The manufacturing process comprises the following steps of feeding, mixing, slicing, mold pressing and foaming, mold taking and cooling and shaping, and finally obtaining of finished products with a closed pore structure and high mechanical strength. The invention further discloses healthy shoes. The healthy shoes comprise shoe bodiesand shoe soles, wearing cavities for allowing the foot parts of a wearer to enter is formed between the shoe bodies and the shoe soles, healthcare insoles are arranged in the wearing cavities, each healthcare insole comprises a bottom layer made of elastic materials and a surface layer made of breathable materials, traditional Chinese medicine layers are arranged between the bottom layers and thesurface layers, and regular hexagon honeycomb hole-shaped supporting areas are integrally arranged on the lower end surfaces of the bottom layers; and a plurality of magnetic sheet mounting bases arearranged on the positions, corresponding to a foot reflection area of a human body, of each bottom layer, openings are formed in the lower end surfaces of the magnetic sheet mounting bases, the outeredges of the openings extend inwards to form limiting walls, and magnetic sheets are movably installed in the magnetic sheet mounting bases through the openings. The manufacturing process of the shoesoles and the healthy shoes have the advantages and beneficial effects that the shoe soles are manufactured through upper-combined injection, chemical glue is not needed for processing, and the shoe soles have an excellent anti-slip function.

Owner:沈丹

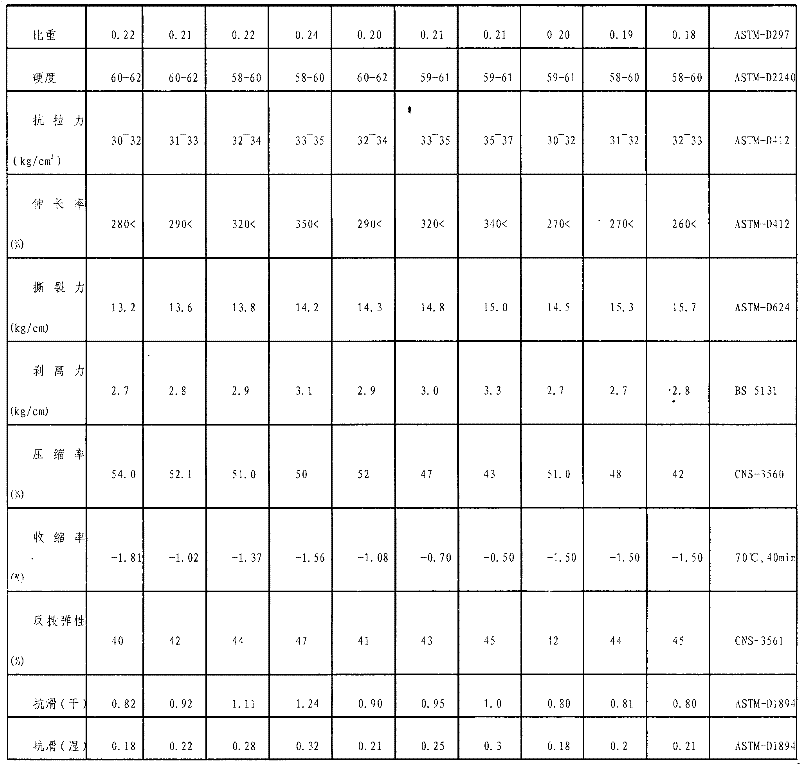

Application of SEBS (styrene-ethylene-butylene-styrene) in sports equipment preparation process as foaming modifier

InactiveCN102532581AImprove compatibilityGood dynamic viscoelasticityDynamic viscoelasticityRetrievability

The invention discloses application of an SEBS (styrene-ethylene-butylene-styrene) in a sports equipment preparation process as a foaming modifier. After being modified with an SEBS foaming material, EVA (ethylene-vinyl acetate) has better dynamic viscoelastic property and meets the testing requirement of human engineering; and the properties of EVA are improved in the aspects of flexibility, compressibility resistance, limited slip resistance, elasticity, material stretchability and the like. The SEBS foaming material has the characteristics of good elasticity, plasticity absent in a thermosetting material and rim leftover retrievability.

Owner:吴水莲

Wear-resistant non-slip rubber for soles and preparation method thereof

The invention discloses wear-resistant non-slip rubber for soles and a preparation method of the wear-resistant non-slip rubber. The wear-resistant non-slip rubber for the sole is prepared from the following raw materials (by weight): 35-45 parts of butyl rubber, 40-50 parts of butadiene rubber, 10-20 parts of natural rubber, 8-12 parts of sepiolite, 4-6 parts of softening oil, 4-6 parts of whitecarbon black, 3-5 parts of a wear-resistant additive, 2-4 parts of dibutyl phthalate, 2-4 parts of an accelerant, 2-4 parts of sulfur, 1-3 parts of zinc oxide, 1-3 parts of an anti-aging agent and 0.8-1.2 parts of stearic acid. The wear-resistant non-slip rubber for soles prepared by the invention has good mechanical properties and processability, has outstanding wear resistance and slip resistance, can be used for preparing various wear-resistant non-slip soles, and has good safety and wide application range.

Owner:山东宏锦鞋业有限公司

Preparation method of leisure shoe sole material with anti-slip performance

The invention discloses a preparation method of a leisure shoe sole material with an anti-slip performance. The preparation method comprises the following steps: (1) obtaining carbon black composite zinc oxide whiskers; (2) obtaining sodium silicate / stearic acid composite halloysite; (3) adding natural rubber, a vulcanizing agent and the carbon black composite zinc oxide whiskers into a rubber mixing mill, performing mixing, then adding the sodium silicate / stearic acid composite halloysite and a coupling agent, performing continuous mixing, then discharging the obtained rubber, injecting the rubber into a sole mold, carrying out hot pressing, and then naturally cooling the hot-pressed rubber to obtain a shoe sample; and (4) vulcanizing the shoe sample obtained in step (3) in a press vulcanizer. The leisure shoe sole material prepared through the preparation method of the leisure shoe sole material with the anti-slip performance has the excellent anti-slip performance.

Owner:界首市盛泽鞋业有限公司

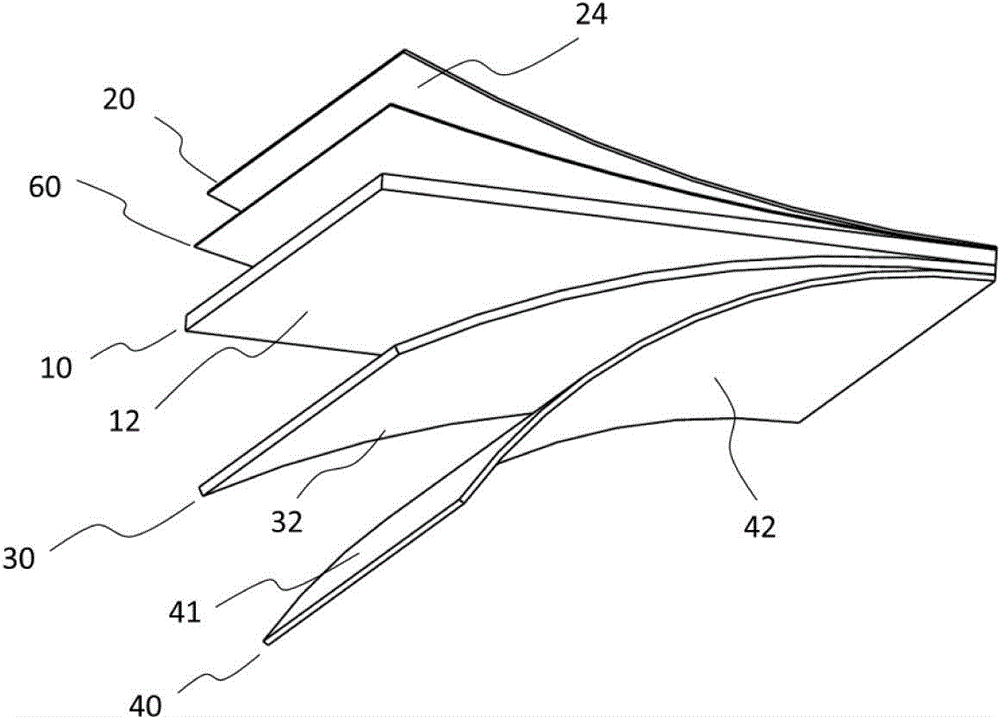

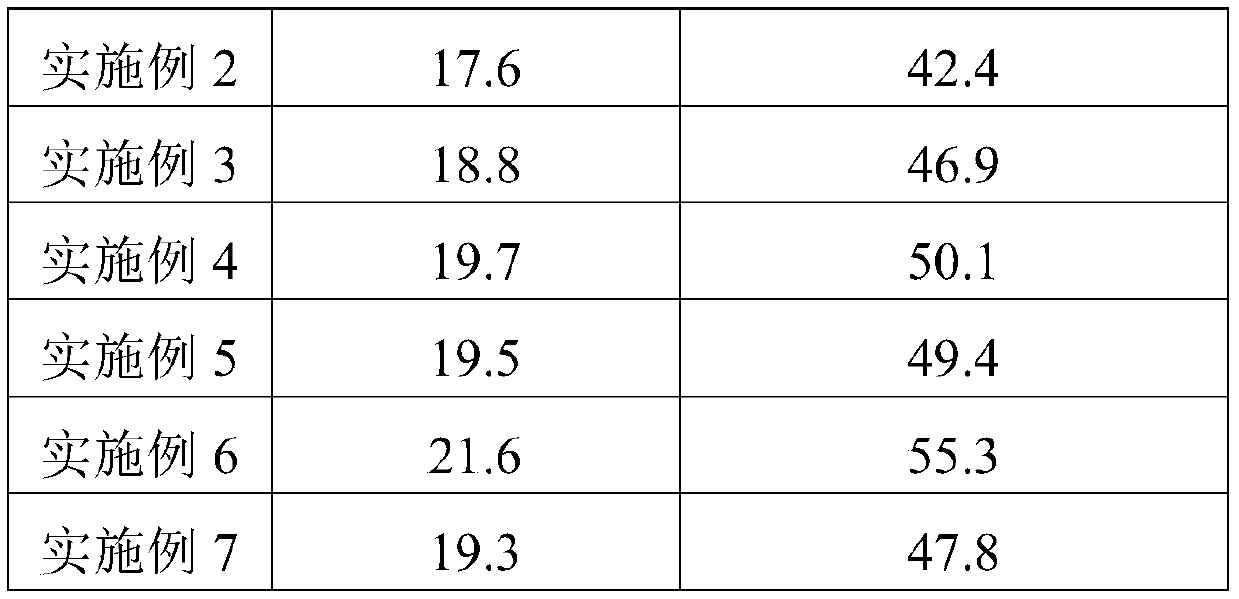

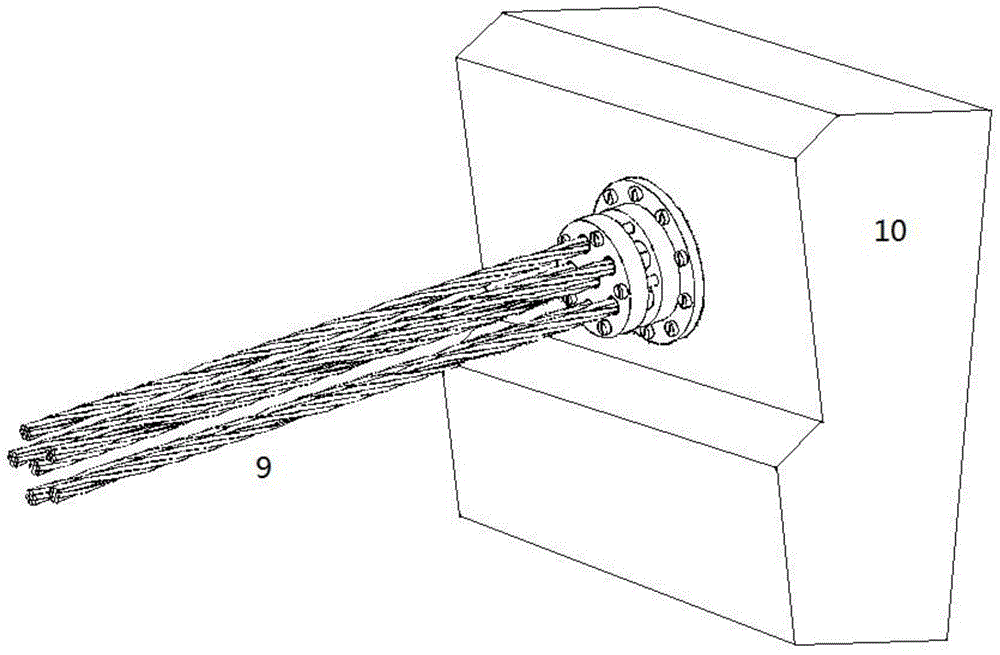

Double-direction movable stay-cable anchoring device for saddle type cable tower zone of low tower cable-stayed bridge

ActiveCN104863059ACan be implementedAchieve anti-slip effectBridge structural detailsCable stayedFusiform shape

The invention discloses a double-direction movable stay-cable anchoring device for a saddle type cable tower zone of a low tower cable-stayed bridge. The double-direction movable stay-cable anchoring device comprises a bottom plate and a double-direction anchoring unit, wherein the double-direction anchoring unit comprises an upper sleeve plate, a lower sleeve plate and fusiform clamping pieces; the bottom plate is fixedly connected with a bridge tower, the upper sleeve plate and the lower sleeve plate are connected through compression bolts, and the double-direction anchoring unit is connected with the bottom plate through the compression bolts; sleeve holes allowing cables to penetrate through are formed in the bottom plate, the upper sleeve plate and the lower sleeve plate, and the fusiform clamping pieces are arranged between the sleeve hole of the upper sleeve plate and the sleeve hole of the lower sleeve plate. Through the adoption of the double-direction movable stay-cable anchoring device disclosed by the invention, the cable can be anchored in two directions and is movable, when moving in two directions, the cable can generate sliding resistance force through the cable force, and after the compression bolts are loosened, the anchoring system can be movable and demountable.

Owner:CHANGAN UNIV

Ice surface anti-slip rubber sports shoe soles and manufacturing method thereof

ActiveCN102964645BStrong slip resistanceImprove slip resistanceSolesMicrocrystalline waxVulcanization

The invention and relates to a pair of soles and discloses a pair of ice surface anti-slip rubber sports shoe soles which has a good anti-slip effect on road surface interfaces of thin ice, snowfield and tundra and long service life and a manufacturing method thereof. The raw materials of the ice surface anti-slip rubber sports shoe soles include components A and components B, wherein the component A consists of butadiene rubber, nitrile rubber, natural rubber, brominated butyl rubber, white carbon black, stearic acid, zinc oxide, anti-aging agent, microcrystalline wax, white smoke active agent, silane coupling agent, rosin resin, alumina and glass fiber; and the component B consists of insoluble sulfur, a first accelerant, a second accelerant. The manufacturing method comprises the following steps of: weighing the materials, banburying, open milling, dosing, measuring a vulcanization curve and oil-pressure forming.

Owner:ANQING TAIYA SHOES CO LTD

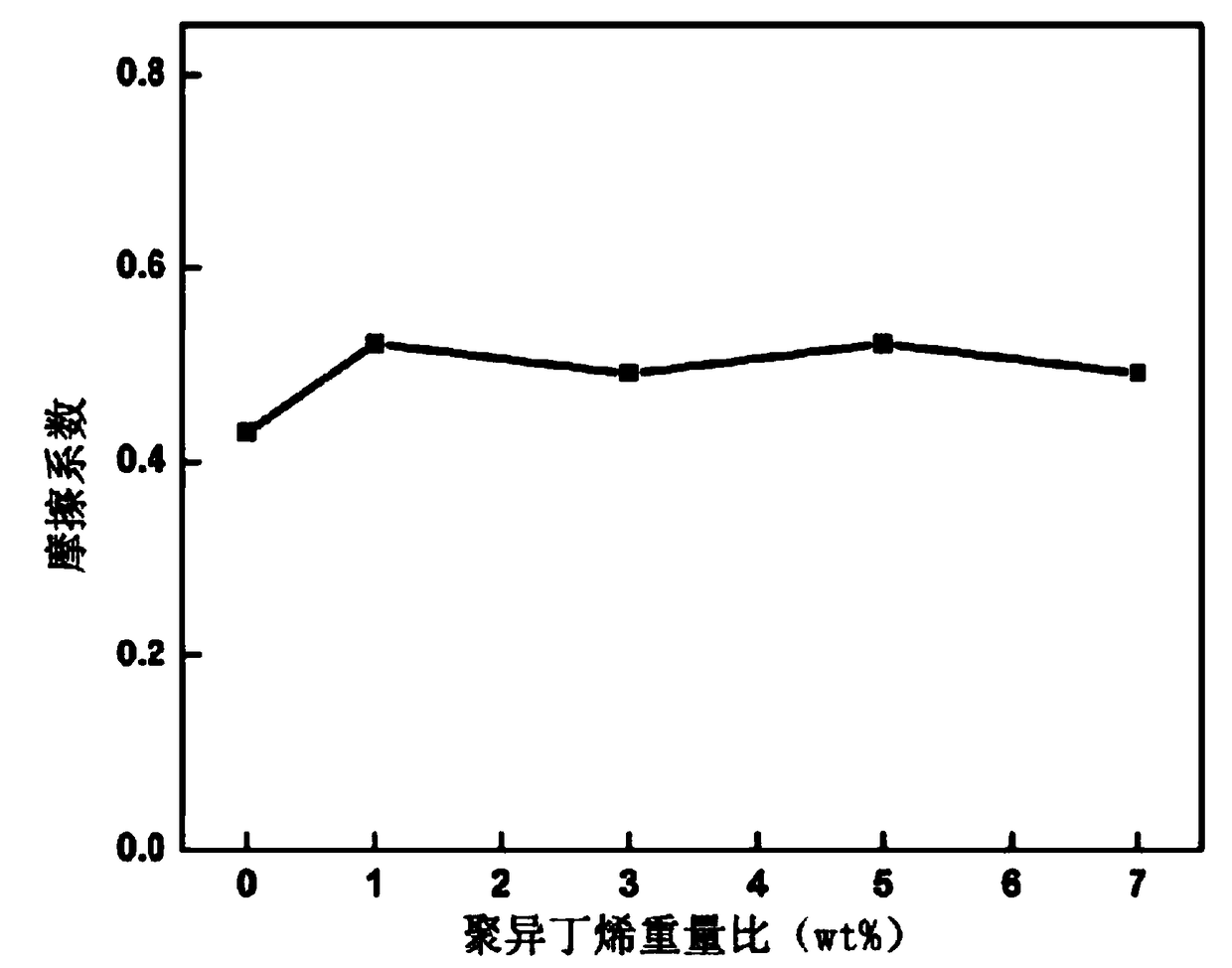

Anti-slip agent particle for shoe material and preparation method thereof

The invention discloses an anti-slip agent particle for a shoe material in the technical field of sole materials. The anti-slip agent particle for shoe materials comprises the following components inpercentage by weight: 5-25% of C5 petroleum resin, 10-30% of silicon dioxide, 5-25% of rubber oil, 10-40% of polyisobutene, 5-25% of SEBS and 10-50% of EVA resin. The invention also discloses a preparation method of the anti-slip agent particle for the shoe material, which comprises the following steps: weighing the materials; adding C5 petroleum resin, silicon dioxide, rubber oil, SEBS and EVA resin into an internal mixer, primarily mixing, adding polyisobutene by several times, and mixing again; discharging and cooling to obtain a master batch semi-finished product; processing the master batch semi-finished product by a double-screw extruder to form a material strip; granulating the material strips to obtain granules, and screening the granules to obtain anti-slip agent particle; according to the invention, the polyisobutene is prepared into the anti-slip agent particles taking EVA as a carrier, so that the anti-slip agent particles are easy to store and use, the volume and time of materials needing to be treated by directly adding the polyisobutene into the shoe material are reduced, and the anti-slip agent particles are well dispersed in the EVA shoe material and have effectiveanti-slip performance.

Owner:厦门翔矽新材料有限公司

Light high-wear-resistance sports shoe sole material and preparation method thereof

ActiveCN112592568AGood biocompatibilityFeel goodSolesTextile/flexible product manufacturePolymer scienceActive agent

The invention discloses a light high-wear-resistance sports shoe sole material and a preparation method thereof, and relates to the technical field of sports shoes. The invention discloses a light high-wear-resistance sports shoe sole material, which is prepared by the following steps: carrying out graft crosslinking on polylactic acid and polyisobutene under the action of a crosslinking agent andan active agent to generate a PLS / PIB blend, and carrying out mold pressing foaming on the PLS / PIB blend, C5 / C9 copolymer resin, a polyether thermoplastic polyurethane elastomer, waste rubber powderand other raw materials. According to the sports shoe sole material, the raw materials are environmentally friendly, the preparation process is simple and easy to operate, the density is low, the elasticity is high, the sports shoe sole material has excellent impact resistance, abrasion resistance, weather resistance, corrosion resistance and wet skid resistance, meanwhile, the degradation performance of the material is improved, and pollution to the environment is reduced.

Owner:莆田市城厢区恒鑫鞋材有限公司

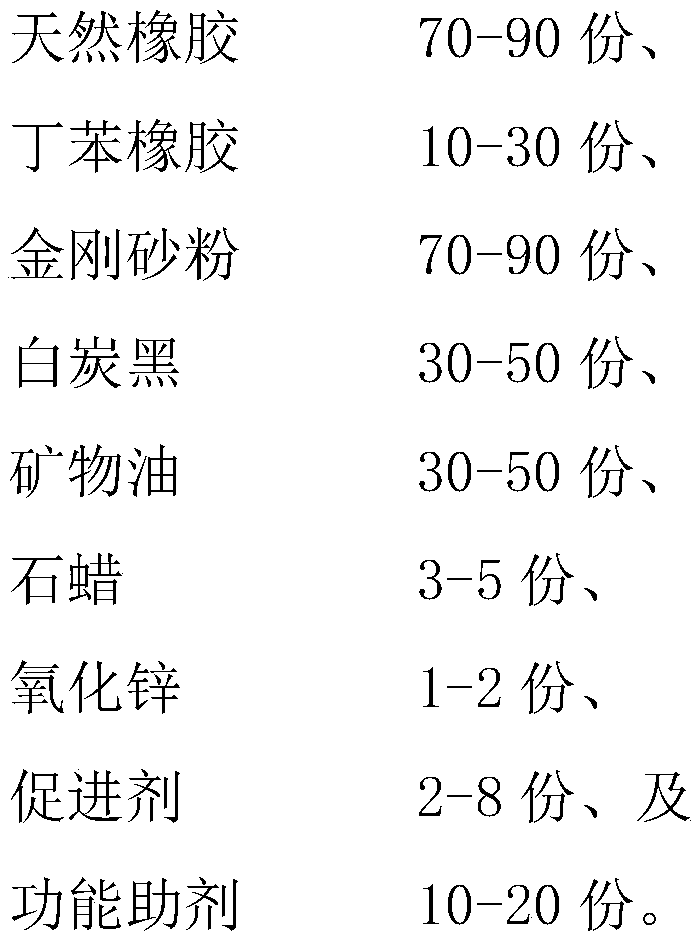

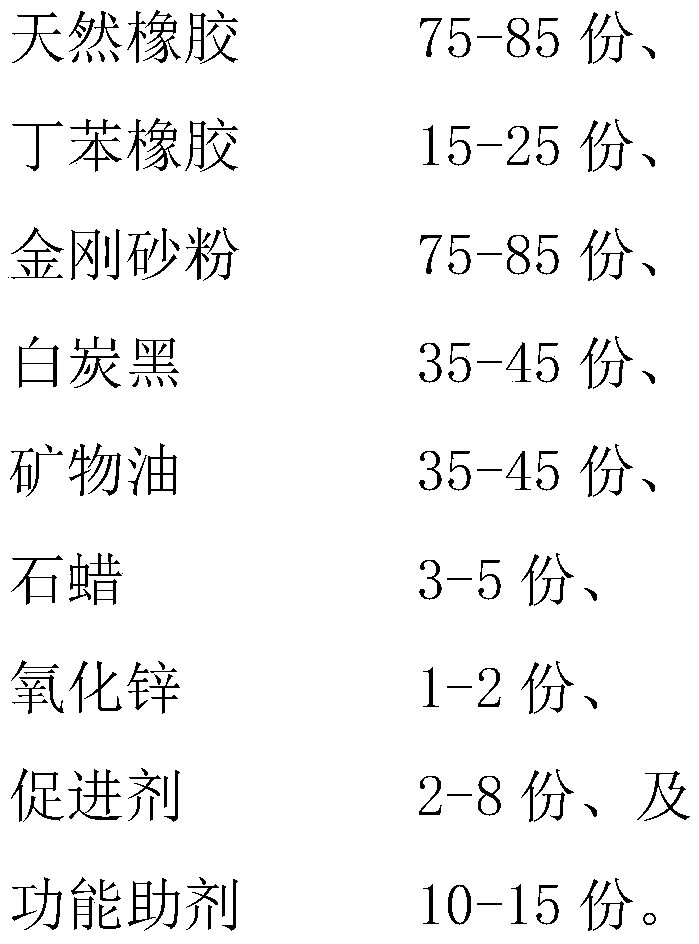

Prefabricated sports field surface material and preparation method thereof

InactiveCN110408090AImprove wear resistanceGood physical propertiesGround pavingsEnvironmental resistanceButadiene-styrene rubber

The invention relates to a prefabricated sports field surface material and a preparation method thereof. The prefabricated sports field surface material is prepared from, by weight, 70-90 parts of natural rubber, 10-30 parts of styrene-butadiene rubber, 70-90 parts of silicon carbide powder, 30- 50 parts of white carbon, 30-50 parts of mineral oil, 3-5 parts of paraffin, 1-2 parts of zinc oxide, 2-8 parts of an accelerator, and 10-20 parts of a functional additive. The prefabricated sports field surface material prepared by the preparation method has good wear resistance, sulfur vulcanizationis not needed, and the preparation process is environmentally friendly.

Owner:广州同欣体育股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com