Ice surface anti-slip rubber sports shoe soles and manufacturing method thereof

A technology of sports shoes and rubber, which is applied in the field of soles, can solve problems such as poor anti-slip performance, and achieve good anti-slip performance, enhanced anti-slip performance, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

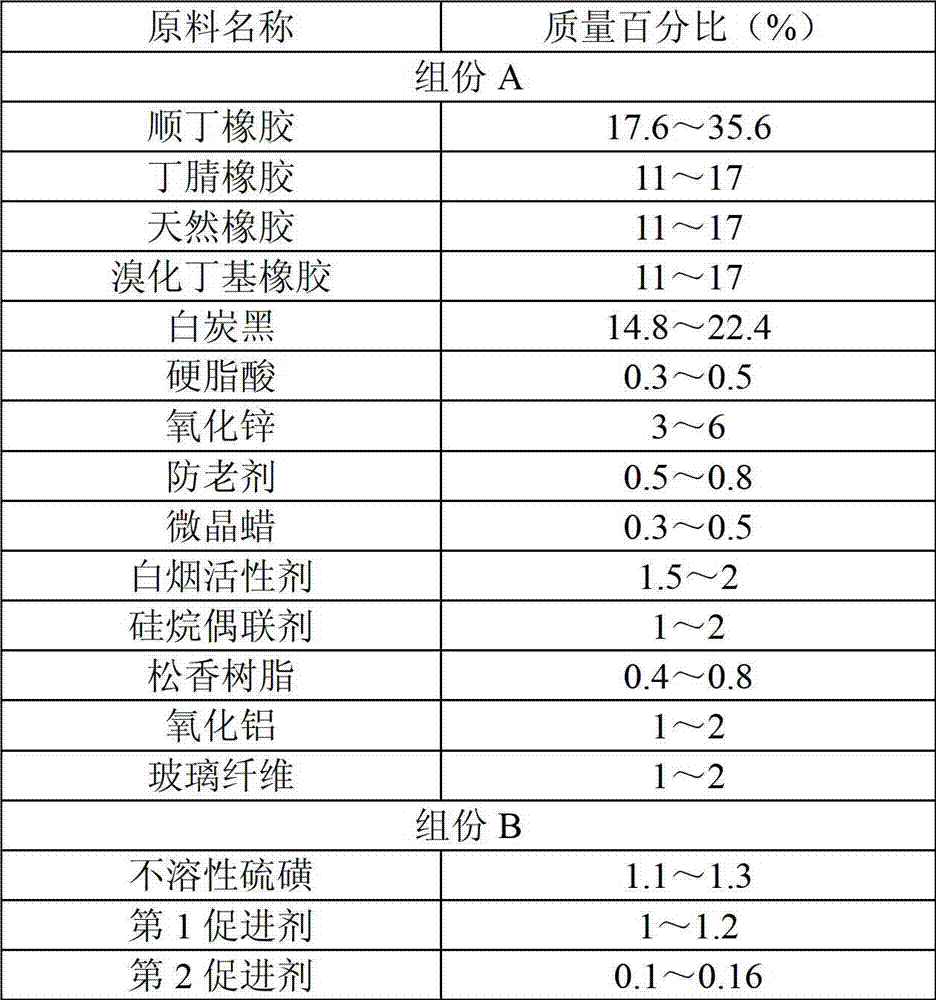

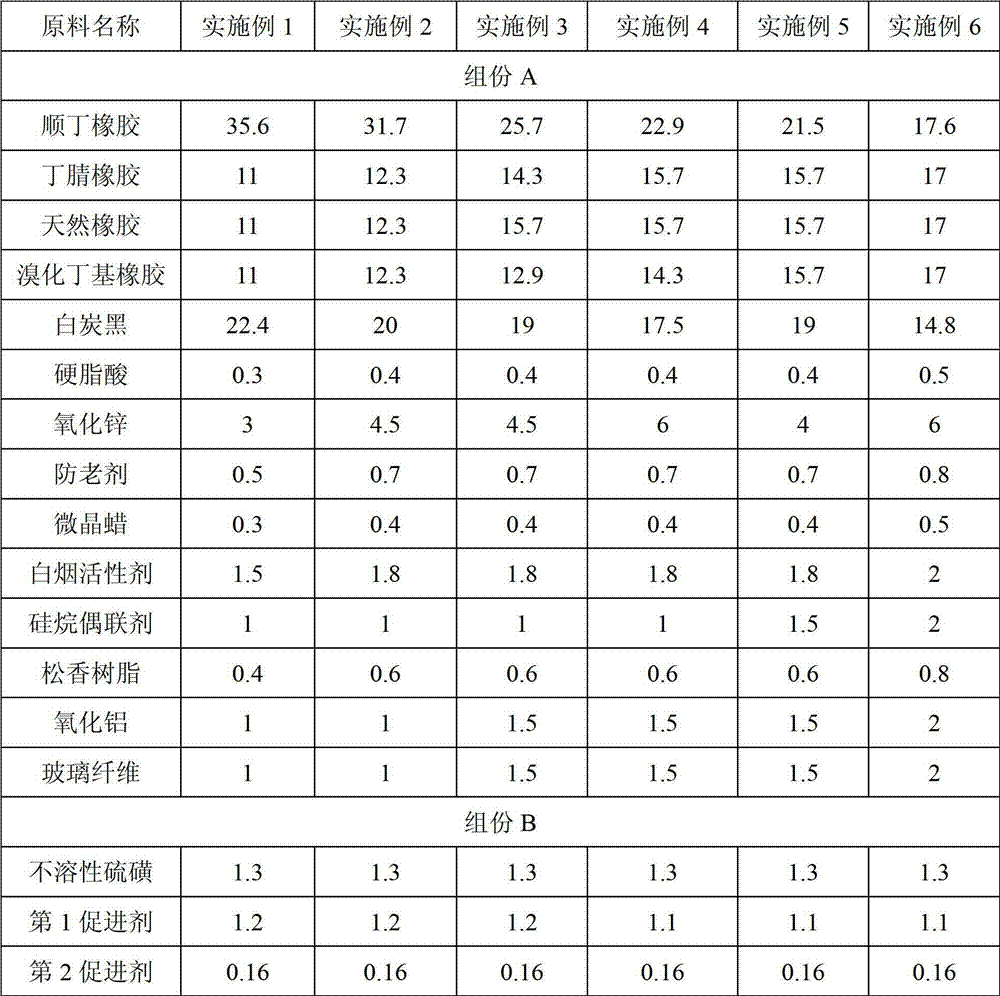

[0021] The product made by the formula and process of the present invention can be tested for physical properties: place the finished rubber sole product in the laboratory (23°C) for 24 hours, then test the physical properties such as DIN wear resistance and hardness, and record the wear resistance and hardness Etc. test values, and anti-slip experiment: SATRA STM 603 standard experimental test machine for rubber anti-slip testing machine. Before the sample test, put the tester in an environment with a constant temperature of 23±2°C, and cut the test sample into standard specifications. , placed on the dry and wet tile interface, sliding test on the ice surface interface, the ratio of the maximum static friction force and sliding area read by the computer is the sliding friction coefficient of the test sample. See Table 1 and Table 2 for the formulation examples of the ice-surface anti-slip rubber outsole of the present invention.

[0022] Table 1 The formulation range of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com