Light high-wear-resistance sports shoe sole material and preparation method thereof

A sole material, high wear-resistant technology, applied in the field of sports shoes, can solve the problems of not conforming to the concept of environmental protection, general rebound rate, not easy to degrade, etc., achieve good hand feeling and heat resistance, high cell density, improve melt The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

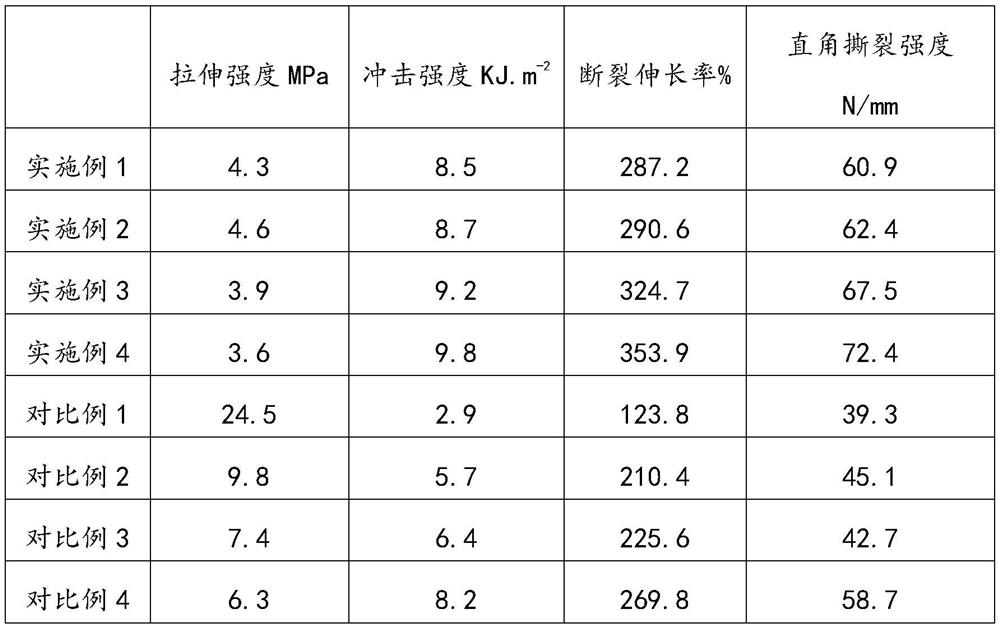

Examples

Embodiment 1

[0031] A light and highly wear-resistant sports shoe sole material, the sole material is composed of the following materials in parts by weight: 50 parts of polylactic acid, 40 parts of polyisobutylene, 20 parts of C5 / C9 copolymer resin, 30 parts of polyether thermoplastic polyurethane Elastomer, 10 parts of waste rubber powder, 8 parts of modified talcum powder, 3 parts of silica fume, 2 parts of silane coupling agent, 4 parts of foaming agent, 1.2 parts of crosslinking agent, 3 parts of active agent, 1 part of vulcanizing agent and 1.5 parts anti-aging agent. According to the preparation method of the sole material of above-mentioned material composition, specifically comprise the following steps:

[0032] (1) Preparation of PLA / PIB blend: Add polylactic acid to a two-roll mill, heat up to 70-90°C, add crosslinking agent and active agent, stir for 0.5-1h, then add polyisobutylene, stir After 2h, the material was discharged to obtain a PLA / PIB blend.

[0033] (2) Add the abov...

Embodiment 2

[0040] A light and highly wear-resistant sports shoe sole material, the sole material is composed of the following materials in parts by weight: 80 parts of polylactic acid, 30 parts of polyisobutylene, 10 parts of C5 / C9 copolymer resin, 20 parts of polyether thermoplastic polyurethane Elastomer, 10 parts of waste rubber powder, 3 parts of modified talcum powder, 5 parts of silica fume, 6 parts of silane coupling agent, 7 parts of foaming agent, 0.8 part of crosslinking agent, 1 part of active agent, 2.5 parts of vulcanizing agent and 0.5 parts anti-aging agent. The preparation method of the shoe sole material according to this material composition is the same as that in Example 1, specifically refer to Example 1.

[0041] The composition of the above polyisobutene is the same as that in Example 1, except that the mass ratio of low molecular weight polyisobutene to high molecular weight polyisobutene is 4:1.

[0042] The above polyether thermoplastic polyurethane elastomer, c...

Embodiment 3

[0046] A light and highly wear-resistant sports shoe sole material, the sole material is composed of the following materials in parts by weight: 60 parts of polylactic acid, 50 parts of polyisobutylene, 15 parts of C5 / C9 copolymer resin, 20 parts of polyether thermoplastic polyurethane Elastomer, 5 parts of waste rubber powder, 5 parts of modified talcum powder, 4 parts of silica fume, 3 parts of silane coupling agent, 5 parts of foaming agent, 1.9 parts of crosslinking agent, 2 parts of active agent, 1.5 parts of vulcanizing agent and 1 part anti-aging agent. The preparation method of the shoe sole material according to this material composition is the same as that in Example 1, specifically refer to Example 1.

[0047] The composition of the above-mentioned polyisobutene is the same as that in Example 1, except that the mass ratio of low-molecular-weight polyisobutene to high-molecular-weight polyisobutene is 3:1.

[0048] The above polyether thermoplastic polyurethane elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com