Graphene natural rubber polymer anti-slip mixed foaming material on ice and preparation method of mixed foaming material

A technology of natural rubber and foaming materials, applied in applications, soles, clothing, etc., can solve the problem of poor anti-slip effect, poor mechanical properties such as tensile strength and elongation at break, comprehensive use of wear resistance and appearance properties Poor performance and other problems, achieve good anti-slip effect, good anti-slip effect, save manpower and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

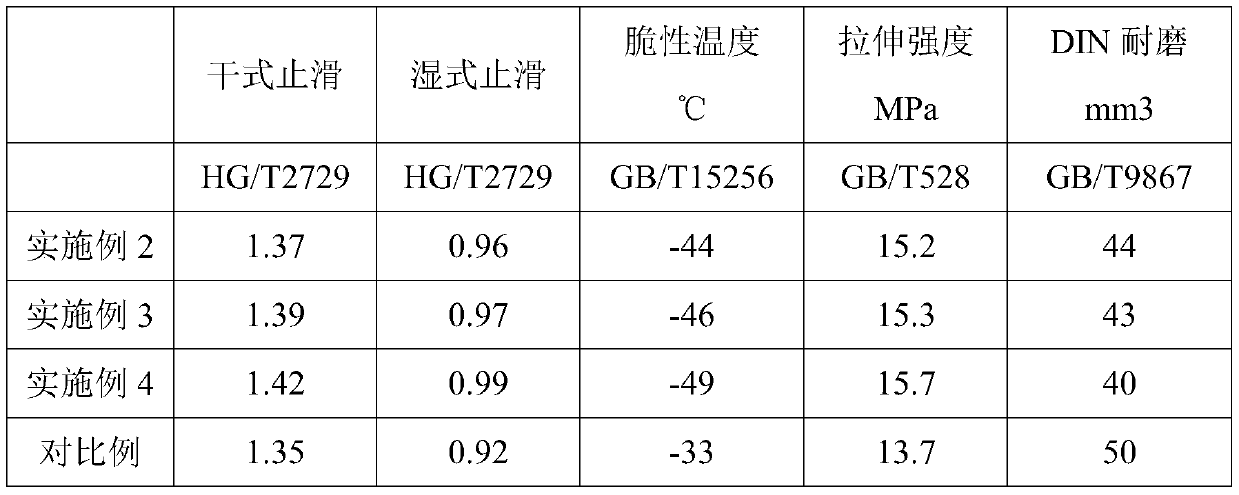

Examples

Embodiment 1

[0041] A kind of graphene natural rubber macromolecule anti-slip mixed foaming material on ice, made of raw materials comprising the following parts by weight:

[0042] 50-60 parts of natural rubber, 32-37 parts of butyl rubber, 8-12 parts of butadiene rubber, 4-6 parts of white carbon black, 2.4-2.8 parts of basalt fiber, 2-3 parts of nano-silica, 2.2 parts of graphene ~2.6 parts, silicone oil 1.4~1.7 parts, zinc oxide 1.2~1.5 parts, zinc stearate 1.5~2.0 parts, stearic acid 1.8~2.4 parts, crosslinking agent 1.6~1.9 parts, flow aid 4.5~5.5 parts part, foaming agent 1.5~2.0 parts; the graphene is a multilayer graphene microsheet; the crosslinking agent is a mixture of sulfur, dicumyl peroxide and zinc dimethacrylate.

[0043] Preferably, the graphene natural rubber polymer ice anti-slip mixed foaming material is made of raw materials comprising the following parts by weight: 55 parts of natural rubber, 35 parts of butyl rubber, 10 parts of butadiene rubber, 5 parts of white ca...

Embodiment 2

[0058] A kind of graphene natural rubber macromolecule anti-slip mixed foaming material on ice, made of raw materials comprising the following parts by weight:

[0059] 50 parts of natural rubber, 32 parts of butyl rubber, 8 parts of butadiene rubber, 4 parts of white carbon black, 2.4 parts of basalt fiber, 2 parts of nano-silica, 2.2 parts of graphene, 1.4 parts of silicone oil, 1.2 parts of zinc oxide , 1.5 parts of zinc stearate, 1.8 parts of stearic acid, 1.6 parts of crosslinking agent, 4.5 parts of flow aid, 1.5 parts of blowing agent; Described graphene is multilayer graphene microchip; Described crosslinking agent is A mixture of sulfur, dicumyl peroxide and zinc dimethacrylate.

[0060] In this embodiment, the number of layers of the multilayer graphene microsheets is 5-8 layers.

[0061] In the present embodiment, the mass ratio of sulfur, dicumyl peroxide and zinc dimethacrylate in the mixture of sulfur, dicumyl peroxide and zinc dimethacrylate is 10: 5:2.

[00...

Embodiment 3

[0074] A kind of graphene natural rubber macromolecule anti-slip mixed foaming material on ice, made of raw materials comprising the following parts by weight:

[0075] 60 parts of natural rubber, 37 parts of butyl rubber, 12 parts of butadiene rubber, 6 parts of white carbon black, 2.8 parts of basalt fiber, 3 parts of nano-silica, 2.6 parts of graphene, 1.7 parts of silicone oil, 1.5 parts of zinc oxide , 2.0 parts of zinc stearate, 2.4 parts of stearic acid, 1.9 parts of crosslinking agent, 5.5 parts of flow aid, 2.0 parts of blowing agent; Described graphene is multilayer graphene microchip; Described crosslinking agent is A mixture of sulfur, dicumyl peroxide and zinc dimethacrylate.

[0076] In this embodiment, the number of layers of the multilayer graphene microsheets is 8-10 layers.

[0077] In the present embodiment, the mass ratio of sulfur, dicumyl peroxide and zinc dimethacrylate in the mixture of sulfur, dicumyl peroxide and zinc dimethacrylate is 10: 7:3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com