Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Good fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-proof antiskid rubber sole and preparation method thereof

ActiveCN104277274AImprove wear resistanceImprove wet skid resistanceSolesPolymer scienceVulcanization

The invention relates to a sole, and discloses an oil-proof antiskid rubber sole and a preparation method thereof. The oil-proof antiskid rubber sole comprises: butadiene-acrylonitrile rubber, epoxidized rubber, brominated butyl rubber, nanosilicon dioxide, a plasticizer, an antiaging agent, a white smoke activator, a silane coupling agent, polyethylene wax, zinc oxide, sulfur and a vulcanization accelerant. Compared with the prior art, by adopting the epoxidized rubber as base rubber and combining the butadiene-acrylonitrile rubber with high acrylonitrile content, the sole is excellent in oil-proof property, has good antiskid performance on the oil-polluted interfaces, can keep excellent wear-resistant property while having high oil-proof and antiskid properties, and is wide in application range including places such as ships, petrochemical plants, motor car repair shops, oil plants where oil is accumulated or splashes, the oil-proof antiskid rubber sole can protect people who walk and work on oil dirt areas from difficultly falling down, and the oil-proof antiskid rubber sole is simple in production procedures, easy in industrial production and has good market prospects.

Owner:MAOTAI FUJIAN SOLES CO LTD

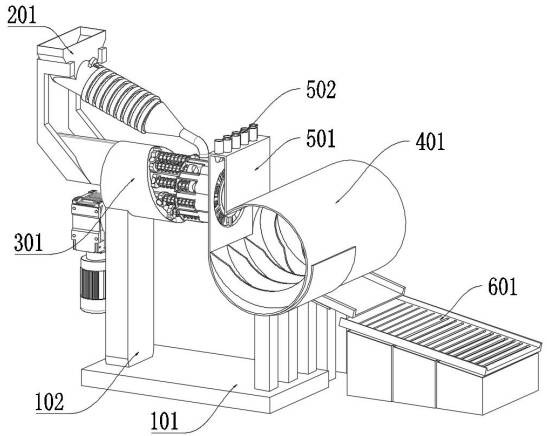

Device for recycling construction waste for brick making

InactiveCN109603987AAvoid damageTo achieve the separation effectMagnetic separationGrain treatmentsBrickIron removal

The invention relates to the technical field of brick making devices and discloses a device for recycling construction waste for brick making. The device comprises a base; a fixed block is fixedly connected to the edge of the top of the base; an iron removal box with one end being open is fixedly connected to the top of the fixed block; a first discharge outlet is formed in the bottom of the ironremoval box; electromagnets are fixedly connected to four vertical inner side walls of the iron removal tank; a conveying mechanism is arranged on the top of the base; a smashing tank with one end being open is fixedly connected to the side wall of the base; a cover plate matched with the opening of the smashing tank is fixedly connected to the top of the smashing tank through a plurality of bolts; a feed inlet is formed in the top of the cover plate; a supporting plate is fixedly connected to the top of the cover plate; a motor is fixedly connected to the side wall of the supporting plate; and an output shaft of the motor is fixedly connected with a link rod groove through a coupler. The device for recycling construction waste for brick making is capable of separating broken stone with metal, thereby protecting a smasher; and components inside the smasher can be conveniently cleaned.

Owner:轩重建筑节能科技(上海)有限公司

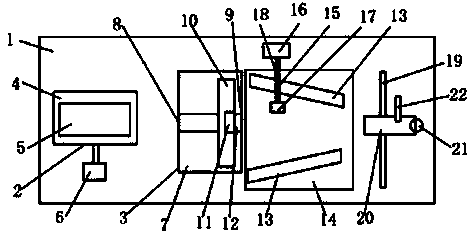

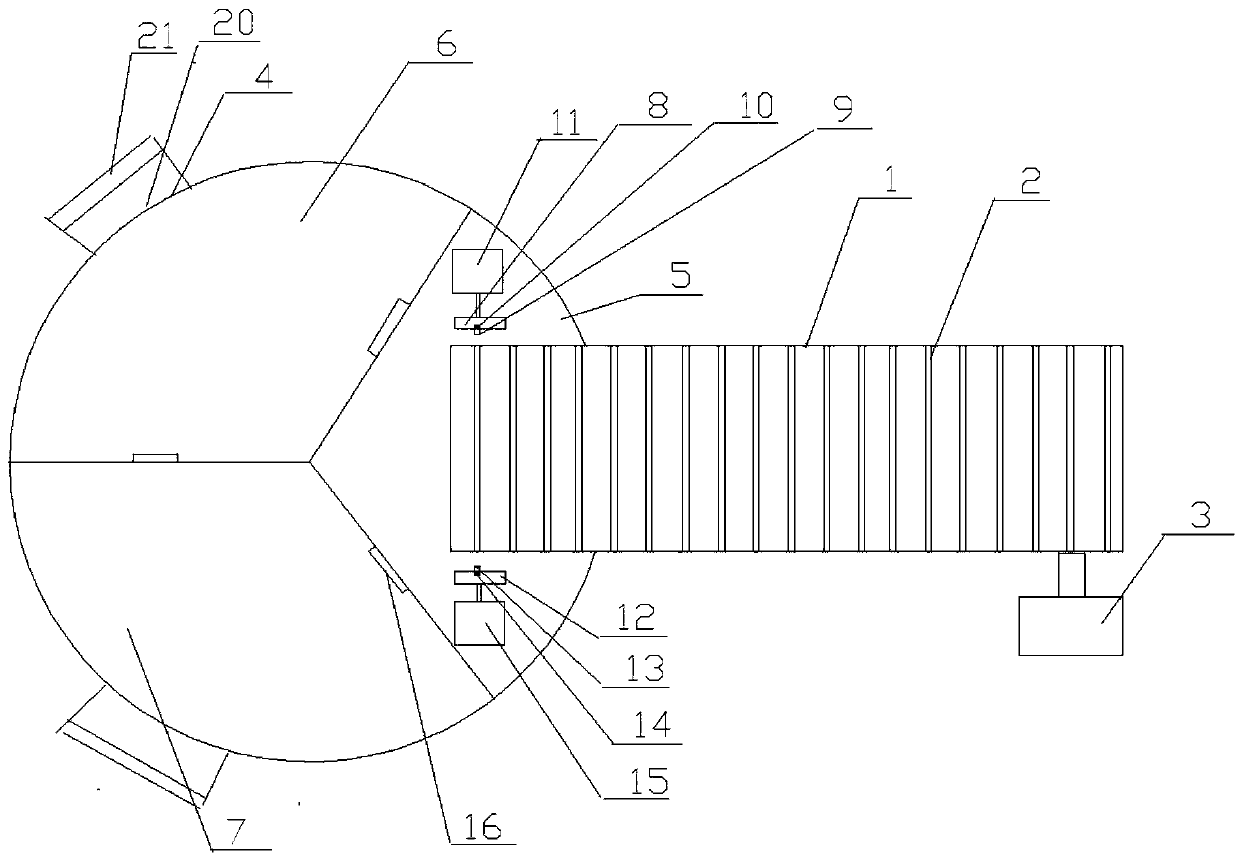

Powder cleaning device of laser sintering equipment

InactiveCN111037921AEasy to recycleEasy to reuseAdditive manufacturing apparatusManufacturing recyclingElectric machineryEngineering

The invention discloses a powder cleaning device of laser sintering equipment. The powder cleaning device comprises a powder cleaning box assembly, a beating assembly, a blowing assembly and a vibrating screen assembly, wherein the powder cleaning box assembly comprises a supporting frame, a box body, a grid plate, a door plate, an observation window and an electric push rod; the beating assemblycomprises a connecting block, a guide rod, a compression spring, a sliding block, a connecting frame, an electromagnet and a beating hammer; the blowing assembly comprises a fan, a corrugated hose, anair guide pipe and a nozzle; and the vibrating screen assembly comprises a vibrating motor, a vibrating screen, a slag guide plate and a supporting block. According to the powder cleaning device, a powder cleaning space is formed through the powder cleaning box assembly, the surface side of a product to be subjected to powder cleaning is beaten through the beating assembly, and the preliminary powder cleaning process is achieved; blowing is conducted through the blowing assembly in the beating process, and fine powder particles are removed from the surface side of the product; and large-particle sundries and small-particle sundries generated by powder cleaning are screened through the vibrating screen assembly, and subsequent recycling is facilitated.

Owner:安徽卓锐三维科技有限公司

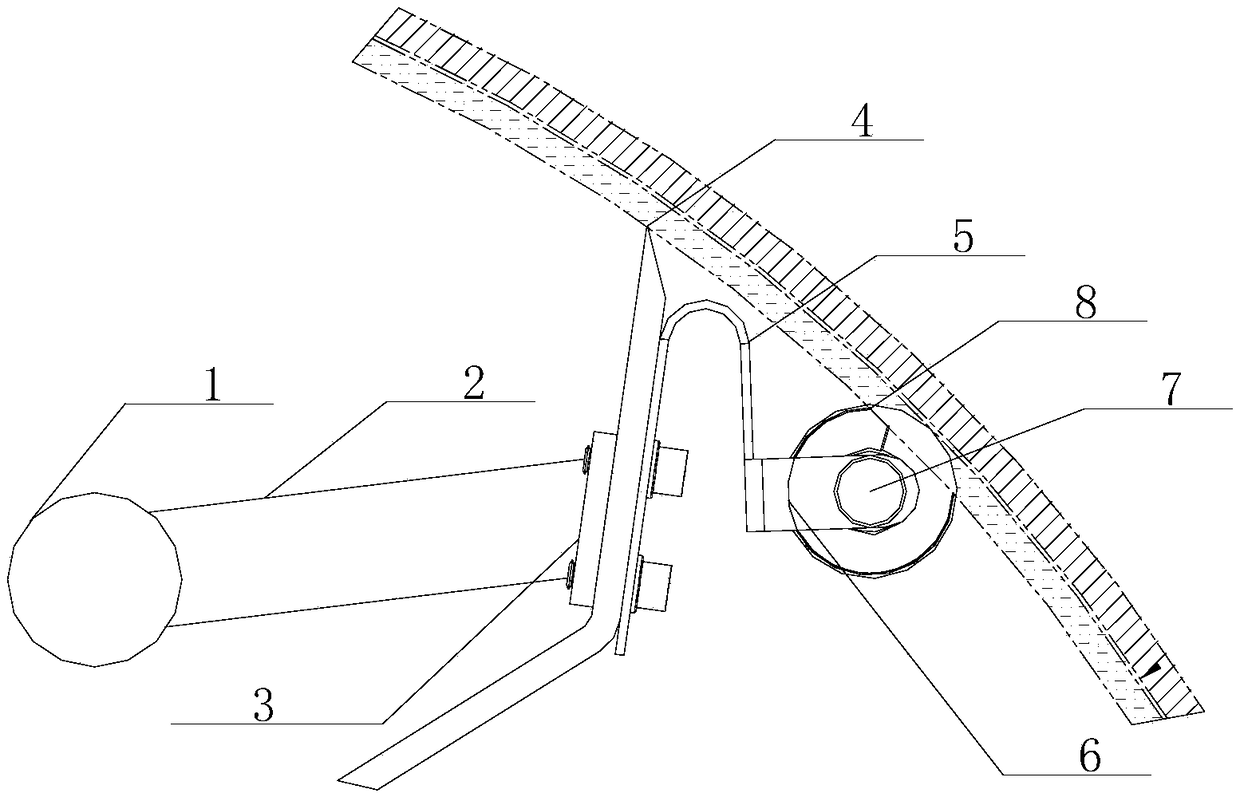

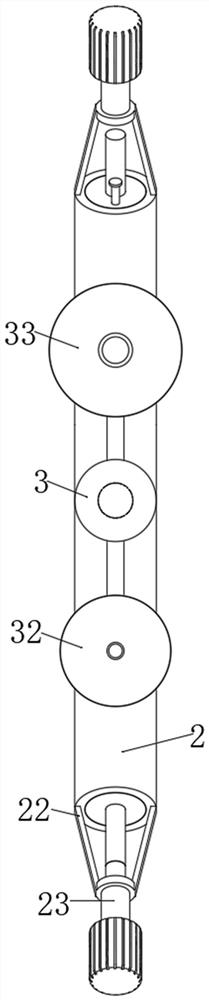

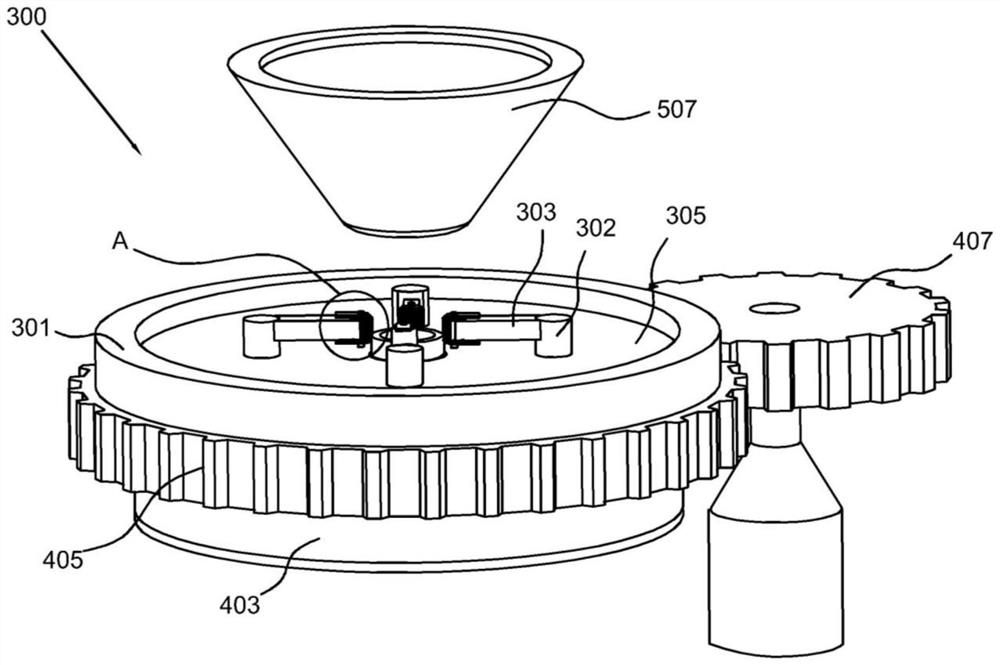

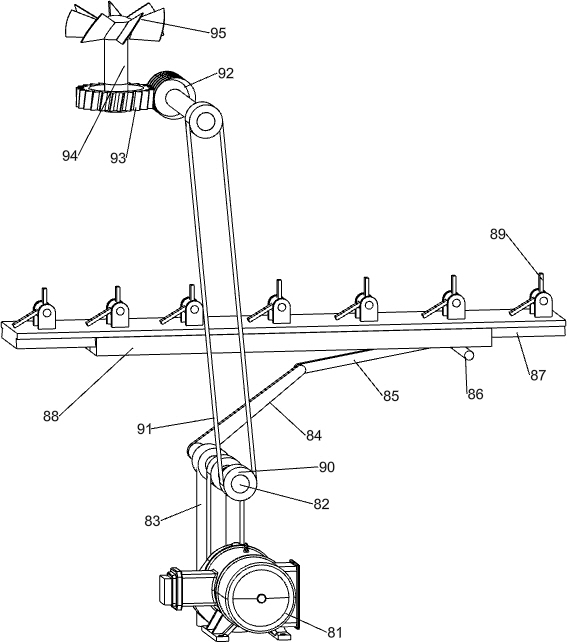

Multi-head type sampling device for detecting soil

InactiveCN108680383AAdd practical functionsImprove sexual functionWithdrawing sample devicesCircular discEngineering

The invention relates to a multi-head type sampling device for detecting soil. The multi-head type sampling device comprises a storage box, a supporting plate, a hoisting column and a containing groove, wherein a drawing box is arranged on the outer surface of the storage box; a handle is fixed on the outer surface of the drawing box; inlets are formed in the upper end of the storage box; a bracket is mounted at the upper ends of the left and right side of the inlets; first fixed columns are fixed at the upper end of the bracket; sliding blocks are fixed at the bottom end of the storage box; sliding grooves are arranged below the sliding blocks; the supporting plate is fixed to the bottom ends of the sliding grooves; a hydraulic air cylinder is fixed at the middle position of the lower side of the supporting plate; the bottom end of the hydraulic air cylinder is connected with a connecting rod; the lower side of the connecting rod is connected with a circular disc; first fixed columnsare mounted at the bottom end of the circular disc. The multi-head type sampling device for detecting the soil, provided by the invention, has the beneficial effects that the multi-head type samplingdevice is provided with 6 sampling heads so that a plurality of times of sampling can be carried out in one step and the problem that a sampling process is relatively complicated is avoided.

Owner:丽水市知科科技有限公司

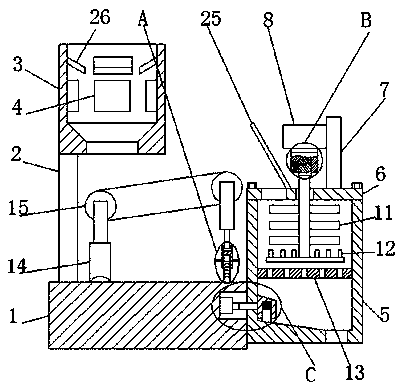

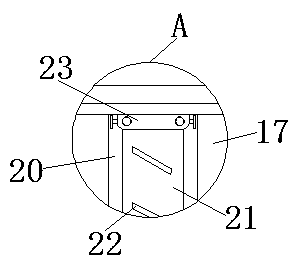

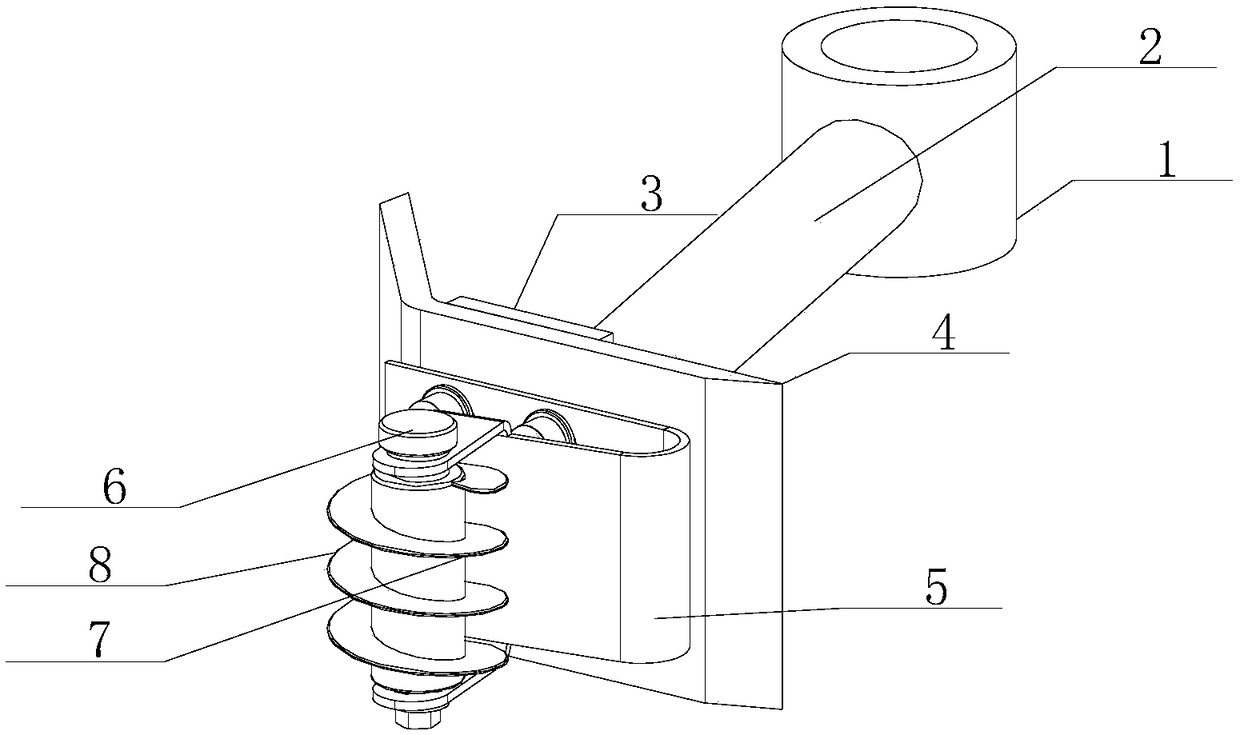

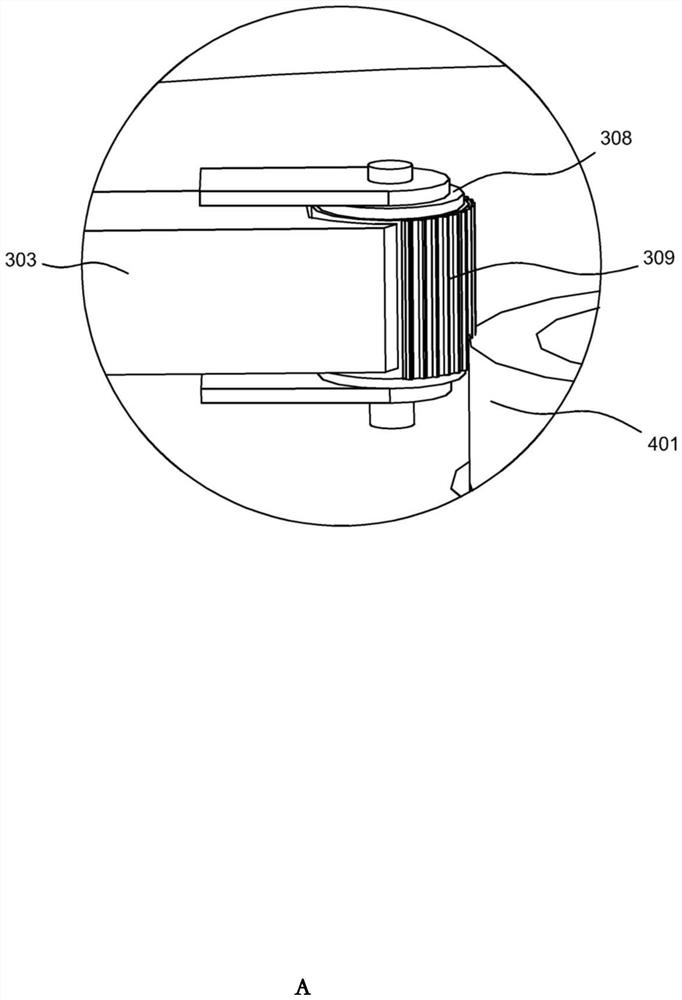

Centrifuge scraper mechanism

PendingCN108927298ASmall vertical force componentGood fallCentrifugesEngineeringMechanical engineering

The invention discloses a centrifuge scraper mechanism with a good scraping effect. The centrifuge scraper mechanism comprises a cylindrical mounting base connected with a scraper driving mechanism; the mounting base is provided with a cutting arm; the end of the cutting arm is provided with a mounting seat; the mounting seat is provided with a scraper; the scraper comprises a main blade forming a100-110-degree angle with the main axis of the cutting arm; the main blade is provided with a material guide plate forming a 20-35-degree angle with the main axis of the cutting arm; the scraper is provided with a roller seat which is elastic in the direction of the cutting arm; the roller seat is provided with a mounting frame; a cutting roller shaft is arranged on the mounting frame and arranged in the vertical direction; and a spiral cutting piece is arranged on the outer circumference of the cutting roller shaft.

Owner:JIANGSU JIEDA CENTRIFUGE MFR

Pediatric medical medicine crushing device capable of conveniently preventing medicine powder from being thrown out

InactiveCN109046698AEasy to prevent throwing outGood fallSievingScreeningEngineeringPediatric Medicine

The invention discloses a pediatric medical medicine crushing device capable of conveniently preventing medicine powder from being thrown out. The device comprises a base, a stand column, a reset spring and a hinge, wherein a groove is formed in one side of the base, the stand column is vertically installed at one end of the base, one side, close to the groove, of the stand column is provided witha pressing buckle in a vertical penetrating mode, a plastic spring is arranged at one end of the pressing buckle, the plastic spring is arranged at one end, close to the stand column, of a telescopicrod, the reset spring is arranged between the telescopic rod and the stand column, and the hinge is fixedly installed on one side, close to a collection box, of the stand column. According to the pediatric medical medicine crushing device capable of conveniently preventing the medicine powder from being thrown out, a sliding groove and a sliding block are arranged, a grinding device is rotated tobe taken down from the collection box, then the grinding device is turned upside down and shaken so as to make a sieve plate slide out through sliding between the sliding block and the sliding groove, then the sieve plate is taken down, in such arrangement, after the medicine crushing, the remaining medicine powder on the sieve plate can be washed off conveniently, so that the safety and sanitation of the device are improved.

Owner:ZIBO KUAKE MEDICINE TECH

Electronic packaging solder paste processing device adopting pressurization and gas supply

InactiveCN113941279AAvoid enteringAvoid wastingTransportation and packagingMixer accessoriesThermodynamicsProcess engineering

The invention relates to the technical field of solder paste processing, in particular to an electronic packaging solder paste processing device adopting pressurization and gas supply. A material grinding assembly comprises a material grinding box body, a discharging pipeline, a settling box, a gas storage tank, a gas outlet pipeline, a gas inlet pipeline, a vibrator, a branch pipeline, a disconnecting plate, a distance increasing partition plate and a collecting frame, the discharging pipeline is fixed to the middle side of the upper end of the material grinding box body through screws, the settling box is fixed to the lower end of the material grinding box body through screws, the gas storage tank is located on one side of the grinding material box body, the gas outlet pipeline is fixed to the middle side of the upper end of the gas storage tank through screws, and the gas inlet pipeline is fixed to the middle side of the lower end of the gas storage tank through screws, so that powdery solder paste can be prevented from directly entering the gas storage tank together with inert gas, waste of the solder paste is avoided, and meanwhile, the powdery solder paste can better fall into the collecting frame through the vibrator.

Owner:深圳市鑫富锦新材料有限公司

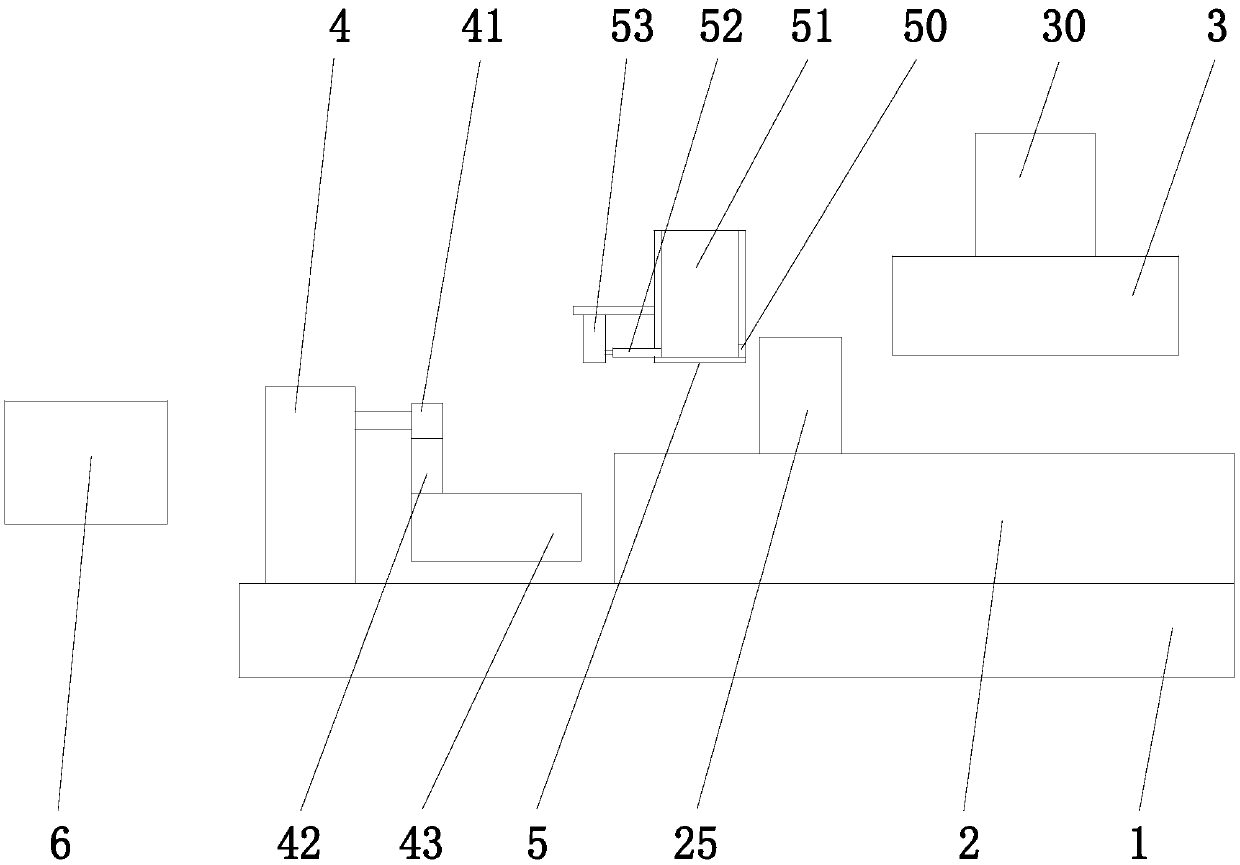

Garbage sorting and winnowing system

The invention discloses a garbage sorting and winnowing system. The garbage sorting and winnowing system comprises a garbage bin, a fine light material collector, a dust collector and an induced draftfan; a first inclined bottom plate, a second inclined bottom plate and a third inclined bottom plate are arranged in the garbage bin, and are distributed in a stepped manner; a feeding opening, an air inlet, a light material outlet, a heavy material outlet and a light and floating material outlet are formed in the garbage bin; a blower is arranged on one side of the air inlet, and is arranged obliquely; an outer shell is arranged on the garbage bin; an air chamber is formed between the outer shell and the garbage bin; a high-pressure pump is arranged on one side of the outer shell; an air outlet of the high-pressure pump communicates with the air chamber; a first spray nozzle, a second spray nozzle and a third spray nozzle are arranged on the garbage bin, and are all arranged obliquely; and the garbage sorting and winnowing system is high in sorting efficiency.

Owner:鲍文胜

A kind of die-cutting waste stripping equipment for printing factory

InactiveCN111571702BQuick clearReduce labor intensityBox making operationsPaper-makingMechanical engineeringIndustrial engineering

The invention relates to a waste cleaning device, in particular to a die-cutting waste cleaning device for a printing factory. The technical problem to be solved by the present invention is how to provide a die-cutting waste stripping equipment for a printing factory that can quickly strip waste and reduce the labor intensity of workers. In order to solve the above technical problems, the present invention provides such a die-cutting waste stripping equipment for printing plants, which includes: a base, the bottom of which is rotatably connected with rollers, and the top of the base is connected with a handle frame; a sliding column, the base of which is close to the handle frame The top is connected with a sliding column, the handle frame is slidably connected with a sliding frame, a lifting frame is connected between one side of the sliding frame, the lifting frame is sleeved on the sliding column, and a pull rod is connected between the inner sides of the sliding frame; the rejecting mechanism, A rejecting mechanism is installed on the lifting frame; a pressing mechanism is installed on one end of the sliding column. The plurality of rejecting wheels of the present invention rotate and move downwards, and can cut waste pieces in various directions on the die-cut paper shell.

Owner:赣州惠彩印刷有限公司

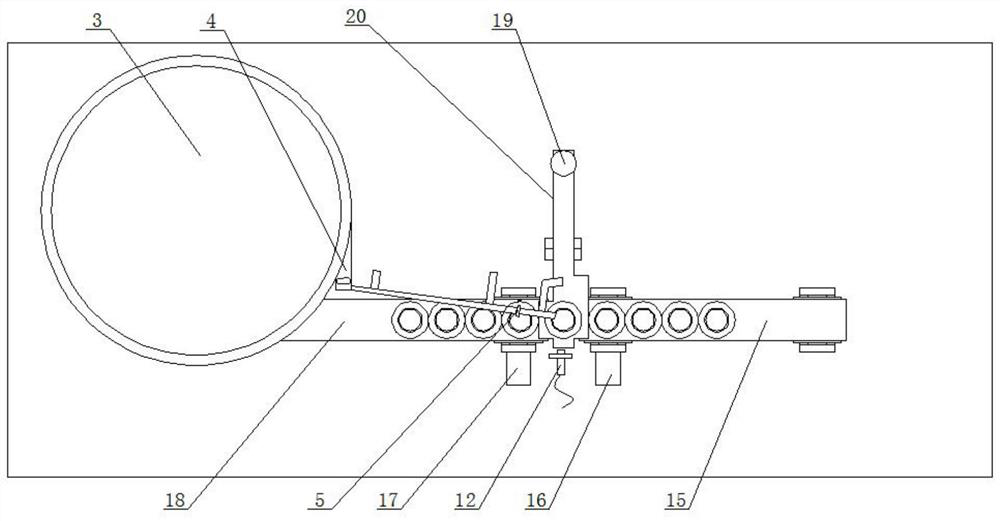

Bottle collecting and conveying device of penicillin bottle straightening machine

PendingCN108082921AReasonable structurePrevent tippingConveyorsConveyor partsBottleChemical engineering

The invention discloses a bottle collecting and conveying device of a penicillin bottle straightening machine. The bottle collecting and conveying device of the penicillin bottle straightening machinecomprises a rack which is provided with a bottle discharging trough; the bottle discharging trough is located below a bottle erecting platform of the bottle straightening machine; the bottle erectingplatform is provided with a row of left bottle falling openings and a row of right bottle falling openings; the bottom of the bottle discharging trough is provided with a row of left bottle collecting openings a row of right bottle collecting openings; the left bottle collecting openings correspond to the left bottle falling openings one by one in the vertical direction, and the right bottle collecting openings correspond to the right bottle falling openings one by one in the vertical direction; a left bottle collecting base and a right bottle collecting base are vertically installed below the left bottle collecting openings and the right bottle collecting openings in a sliding mode and located on the rack; the left bottle collecting base and the right bottle collecting base are driven toascend and descend by a bottle collecting power device; and the rack is provided with a bottle discharging plate horizontally in a sliding mode, and the bottle discharging plate is driven by a bottledischarging power device to horizontally push penicillin bottles in the bottle discharging trough out. The bottle collecting and conveying device can collect the penicillin bottles at two different positions of the bottle erecting platform and convey the penicillin bottles out, so that the bottle collecting and feeding actions are more smooth.

Owner:HIT SMART FACTORY CO LTD

An electromechanical machining and cutting device

The invention relates to the technical field of electromechanical processing, and in particular to a cutting device for electromechanical processing. The cutting device for the electromechanical processing comprises a workbench, the left and right sides of the top end of the workbench are provided with supporting columns, the supporting column at the right side is fixedly connected with the workbench, the supporting column at the left side is slidingly connected with the workbench, a fixing plate is arranged between the supporting columns at one side, two connecting balls are arranged at the bottom of the fixing plate, the relative sides of the connecting plates are provided with clamping plates, third telescopic rods are arranged between the clamping plates and the connecting plates, thethird telescopic rods are rotationally connected with the clamping plates, an opening is arranged on the right side of the top end of the workbench, a cutting mechanism is arranged on the lower side of the opening, and a dust removing mechanism is arranged on the left side of the cutting mechanism, through using the stretching of a first telescopic rod, the cutting device can drive the supportingcolumn at the left side rod to lift, so the plate fixed by the clamping plates rotates, and the cutting blade can cut the plate at different angles.

Owner:江苏新界机械配件有限公司

Cutting device for electromechanical processing

The invention relates to the technical field of electromechanical processing, and in particular to a cutting device for electromechanical processing. The cutting device for the electromechanical processing comprises a workbench, the left and right sides of the top end of the workbench are provided with supporting columns, the supporting column at the right side is fixedly connected with the workbench, the supporting column at the left side is slidingly connected with the workbench, a fixing plate is arranged between the supporting columns at one side, two connecting balls are arranged at the bottom of the fixing plate, the relative sides of the connecting plates are provided with clamping plates, third telescopic rods are arranged between the clamping plates and the connecting plates, thethird telescopic rods are rotationally connected with the clamping plates, an opening is arranged on the right side of the top end of the workbench, a cutting mechanism is arranged on the lower side of the opening, and a dust removing mechanism is arranged on the left side of the cutting mechanism, through using the stretching of a first telescopic rod, the cutting device can drive the supportingcolumn at the left side rod to lift, so the plate fixed by the clamping plates rotates, and the cutting blade can cut the plate at different angles.

Owner:江苏新界机械配件有限公司

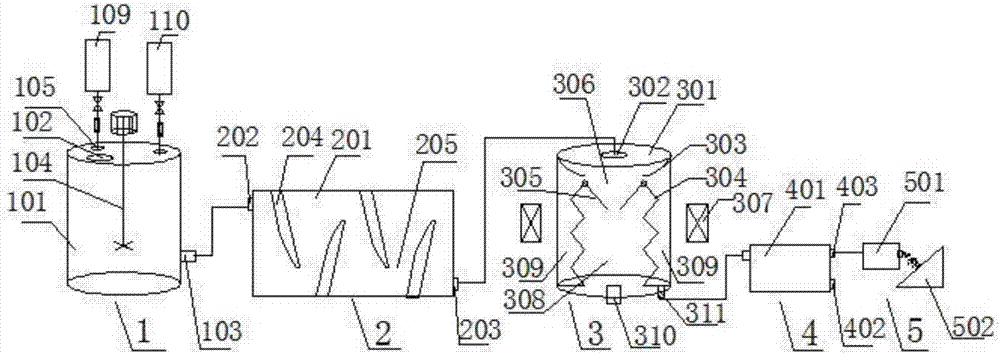

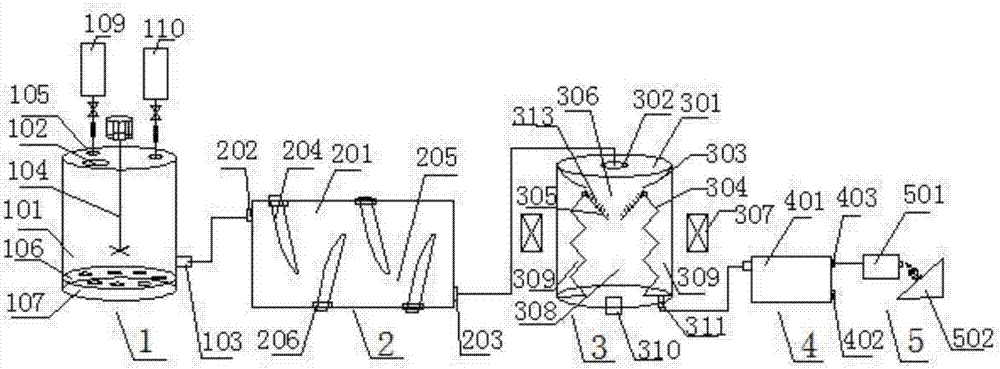

Efficiently loaded flocculation sewage treatment device

PendingCN107879448AIncrease contact timeIncrease distanceSludge treatment by de-watering/drying/thickeningWater/sewage treatment by magnetic/electric fieldsFlocculationWater flow

The invention relates to an efficiently loaded flocculation sewage treatment device which comprises an adjusting device, a reaction tank, an electromagnetic flocculation device, an extrusion device and a separation magnetic seed / pollutant device, wherein the reaction tank is arranged inside or outside the adjusting device; the reaction tank comprises a tank body; water flow regulation and controlbaffle pieces are arranged at intervals inside the tank body to form flow holes; a certain angle is formed between the water flow regulation and control baffle pieces and the tank body; the electromagnetic flocculation device comprises a second bucket body; a third water inlet is formed in the upper end of the second bucket body; an arc-shaped baffle plate is arranged inside the second bucket body; the arc-shaped baffle plate is arranged around the third water inlet; a waved partition plate is arranged on the inner side of the second bucket body and forms a joint hole with the arc-shaped baffle; a moveable baffle plate is fixedly connected with the upper end of the waved partition plate rotationally; an oscillation circuit and an electromagnetic sensing coil are arranged on the outer sideof the second bucket body. The efficiently loaded flocculation sewage treatment device provided by the invention is high in reaction efficiency, long in service life, easy to maintain and high in popularization and application value.

Owner:北京奥友兴业科技发展有限公司

Automatic plate block press

InactiveCN109604454APrecise positioningEasy to useShaping toolsMetal-working feeding devicesEngineeringAutomation

The invention discloses an automatic plate block press. The automatic plate block press comprises a machine table, an upper die, a lower die, a first pushing and pulling device, an automatic feeding machine, a lower pressure device, and a control device, the detachable lower die is mounted on a base and is in a long strip shape, a model groove is formed in the lower die, the lower die is transversely arranged, and openings are formed in the left and right ends of the lower die; and the upper die matched with the lower die is arranged above the lower die, the top of the upper die is connected with the lower pressure device, the first pushing and pulling device is mounted on the machine table, located on the left side of the lower die and connected with a mounting plate, a plurality of pushing plate used for pushing plates are mounted at the bottom of the mounting plate, and a pushing block adapted to the model groove is fixed at the bottom of the pushing plate. According to the automatic plate block press, through the combination of the first pushing and pulling device and the automatic feeding machine, the feeding of the plate and the discharging of the pressed finished product canbe completed automatically, the use is convenient, and the degree of automation is high.

Owner:嘉兴通林智能装备股份有限公司

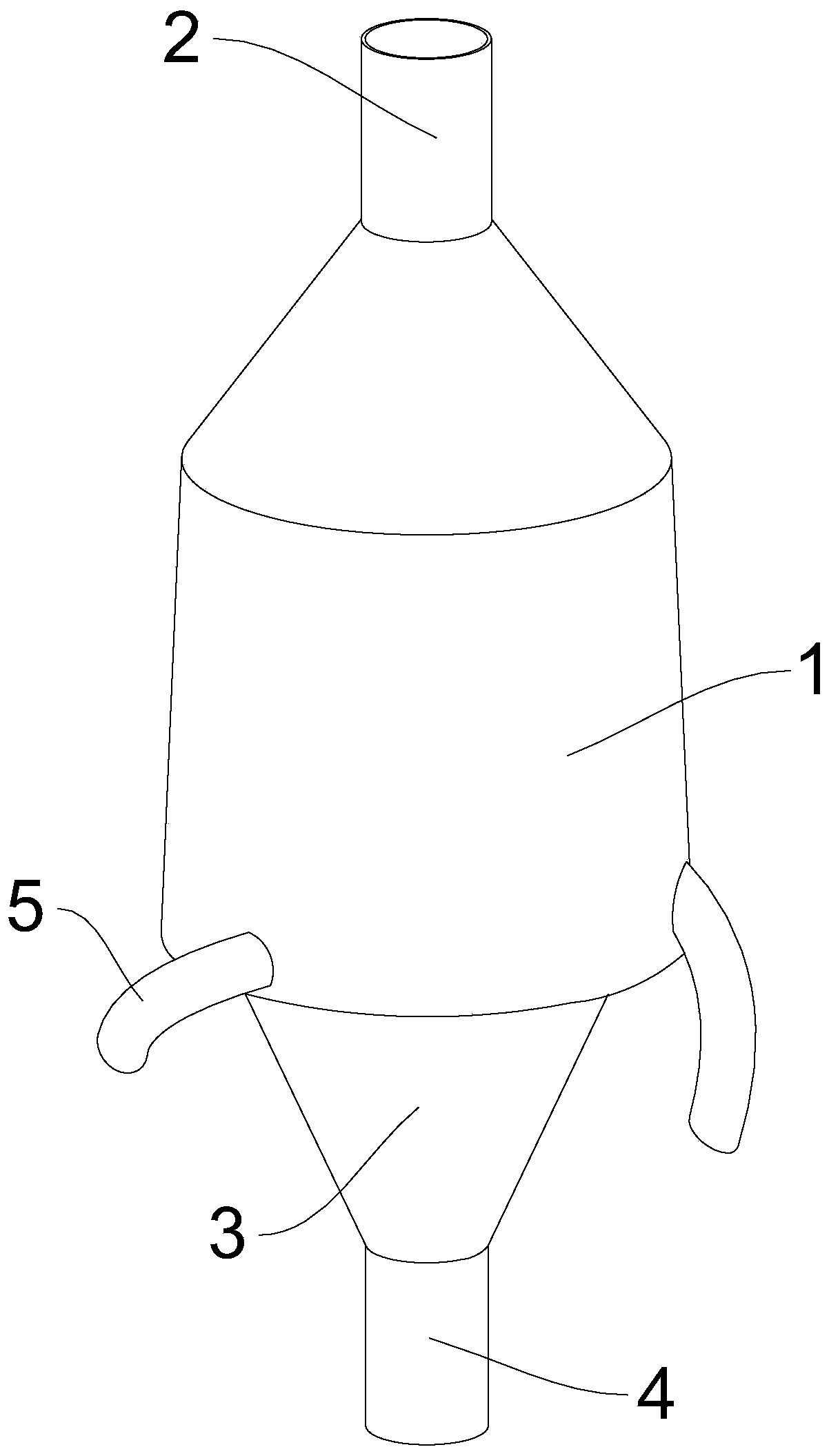

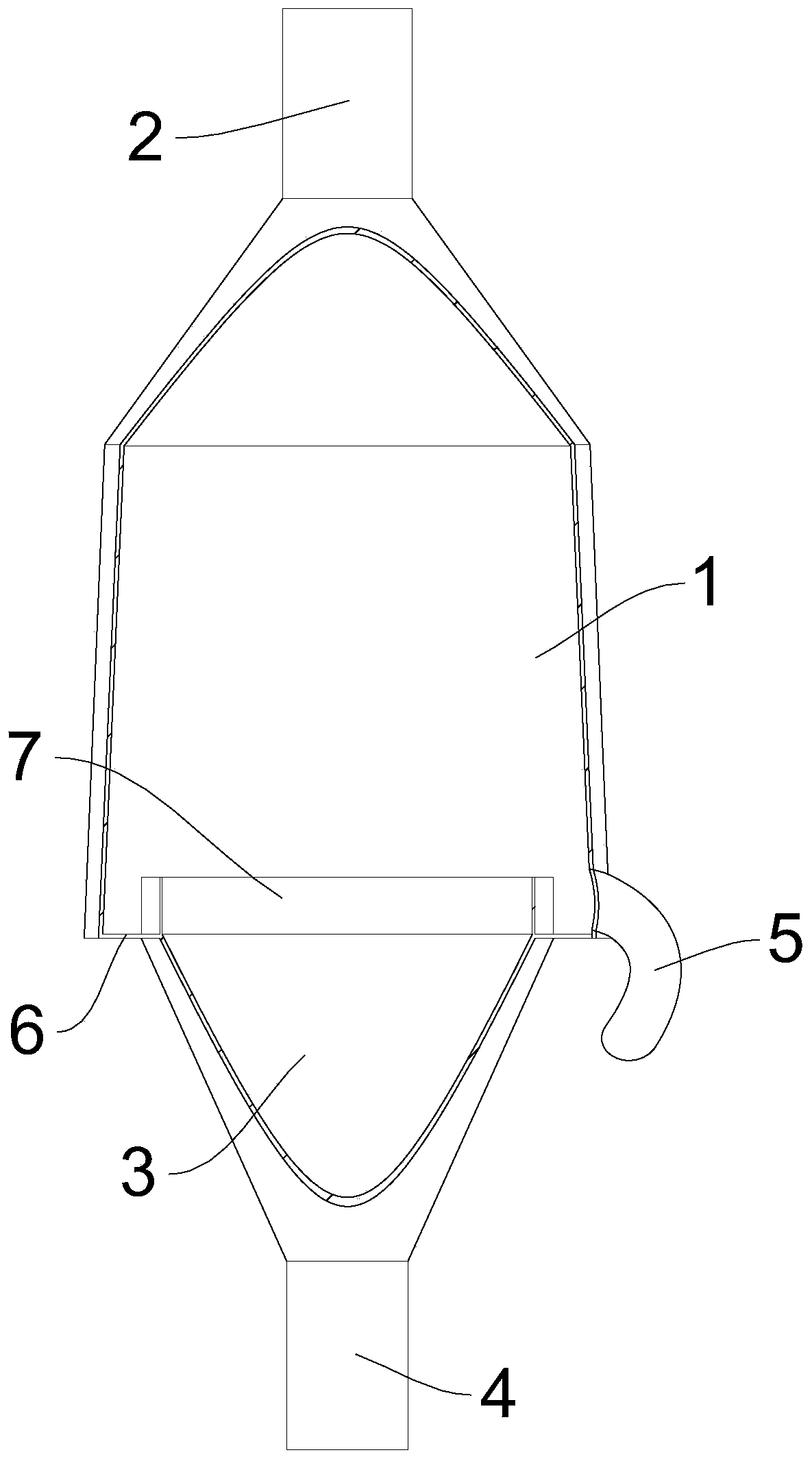

Liquefaction device for producing starch sugar and liquefaction method

InactiveCN110106078AAvoid influenceGood fallBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringImpurity

The invention relates to the technical field of starch sugar production, and discloses a liquefaction device for producing starch sugar and a liquefaction method. The liquefaction device comprises a cylinder with a circular cross section, a liquid outlet pipe communicated with the top of the cylinder, a collecting bucket located at the outer side of the bottom of the cylinder and a discharging pipe communicated with the bottom of the collecting bucket; the collecting bucket is conical, and the end, with the larger conical cross section, of the collecting bucket is connected with the cylinder;the liquefaction device further comprises feeding pipes communicated with the bottom of the cylinder, the feeding pipes are inclined, the tops of the feeding pipes are connected with the cylinder, a tangent line of the end, connected with the cylinder, of each feeding pipe is tangent to the cylinder, and the feeding pipes can make liquid fit the inner wall of the cylinder to flow. By means of theliquefaction device for producing the starch sugar and the liquefaction method, the impurity removal effect is better.

Owner:纳来创硕湖北生物科技有限公司

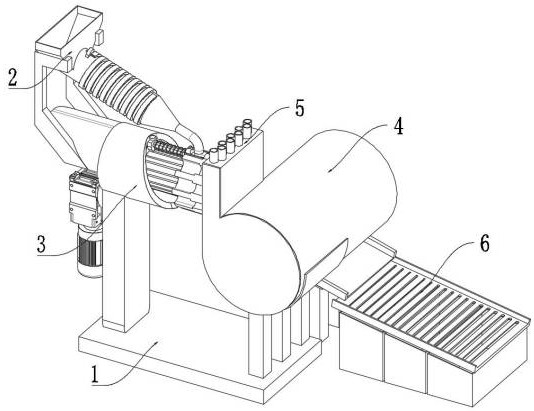

Preparation method of micro-capsule coated fat powder and hot spray drying device

The invention provides a preparation method of micro-capsule coated fat powder and a hot spray drying device. The hot spray drying device comprises a supporting structure, afeeding structure, a pushing structure, and a preparation structure, wherein the feeding structure is arranged to be in an inclined downward shape, and the feeding structure is installed at the upper left end of the supporting structure in a clamped mode; the pushing structure is arranged to be of a horizontal structure, and the pushing structure is installed at the lower end position of the feeding structure; and the preparation structure is arranged to be in the shape of a hollow rectangular plate, and the rectangular plate is fixed to the right side end of the pushing structure. Materials are poured in through a funnel structure at the top of the feeding cylinder; the materials can directly fall into the bearing cylinder, and because the bearing cylinder is installed on the rotating shaft in a rotating state, the outer end of the pressing rod connected in the bearing cylinder in a sleeving mode can pressurize the materials to extrude the materials towards the right side of the bearing cylinder under the action of the inclined face of the right side of the fixed cylinder, and the materials are extruded out of the miniature through hole of the bearing cylinder; and extruded materials can be poked by five groups of blocking rods on the discharging plate, and the materials are cut into particles.

Owner:SHANDONG HUIERJIA BIOLOGICAL CO LTD

Novel efficient crushing equipment for quartz sand production

The invention discloses novel efficient crushing equipment for quartz sand production. The equipment comprises: a bearing assembly, wherein the bearing assembly comprises a bearing main body, a crushing space formed in the bearing main body, and a conveying pipeline arranged at the upper end of the bearing main body; a crushing assembly, wherein the crushing assembly comprises two crushing wheels rotationally connected into the crushing space, crushing teeth arranged on the outer surfaces of the crushing wheels and a primary screening plate arranged below the crushing wheels, and the two crushing wheels are arranged in an attached mode; and an auxiliary crushing assembly, wherein the auxiliary crushing assembly is arranged at the upper end of the crushing assembly.

Owner:新沂市永恒熔融石英有限公司

Automatic precise bottling device and bottling method

The invention discloses an automatic precise bottling device and a bottling method. The automatic precise bottling device comprises a rack, the rack comprises a blanking mechanism, and the blanking mechanism communicates with a small funnel. The rack is connected with a bottle outlet conveying belt and a bottle inlet conveying belt and is further connected with seesaws, and the seesaws are arranged between the bottle outlet conveying belt and the bottle inlet conveying belt. The seesaws comprise the upper seesaw and the lower seesaw, a balancing weight is placed on the upper seesaw, the lower seesaw is connected with a material falling guide pipe, the material falling guide pipe is in contact with the small funnel to form a channel for allowing capsules to penetrate through, and the upper end of the material falling guide pipe is further fixedly connected with a material blocking plate. An inductive switch is arranged below the lower seesaw. A medicine containing bottle is further placed on the lower seesaw. The rack is fixedly connected with a guide sleeve, a first baffle is slidably connected into the guide sleeve, the upper end of the first baffle is connected with a pull rope, and the pull rope is connected with the lower seesaw through a transition wheel. By means of the device and method, accurate counting of contained capsules can be achieved, and the phenomenon of feeding blockage to affect displaying is prevented.

Owner:烟台久和开源健康营养中心

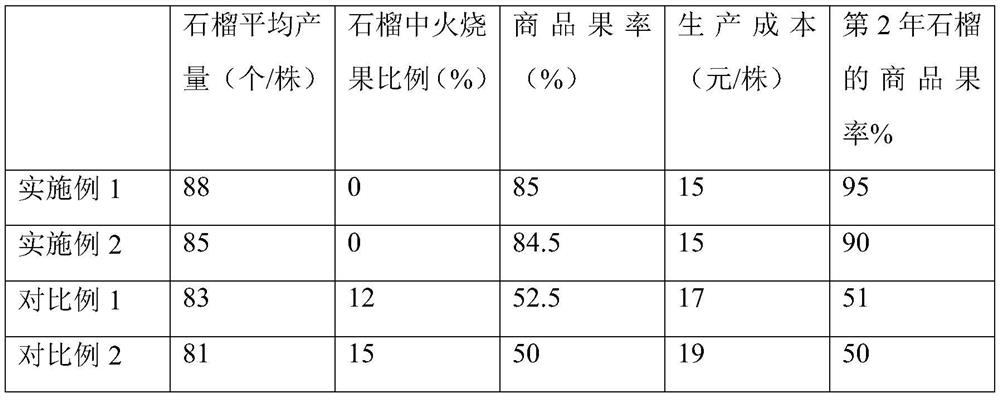

Pomegranate tree spring twig management method

ActiveCN108849023AGood ventilation and light transmissionReduce workloadHorticulture methodsEngineeringTwig

The invention belongs to the technical field of pomegranate planting management, and particularly relates to a pomegranate tree spring twig management method. The pomegranate tree spring twig management method is provided aiming at the problems that the erasing cost of pomegranate tree spring twigs is high, and pomegranate trees grow badly after the spring twigs are erased. The method includes thefollowing steps that a, when the lengths of 30-40% of pomegranate tree spring twigs reach 40 cm, the spring twigs with the lengths smaller than 40 cm are erased, aiming at the spring twigs with the lengths larger than or equal to 40 cm, branches are clockwise rotated and twisted at first growing thorn positions till a rattle is heard; b, after pomegranate tree fruits are borne stably, and pomegranate branches are trimmed; the spring twigs on trunks are trimmed to the lengths of 25-40 cm, branches on the upper portions of pomegranate trees are trimmed to the lengths of 20-30 cm, branches in the middles of the pomegranate trees are trimmed to the lengths of 20-30 cm, and branches on the lower portions of the pomegranate trees are trimmed to the lengths of 30-40 cm. The firing fruit rate canbe reduced, the commercial fruit rate is increased by 30% or above, and the novel method is provided for improving the quality of pomegranates.

Owner:会理市成润农业开发科技有限公司

Ternary copper catalyst alloy full fusion preparation process

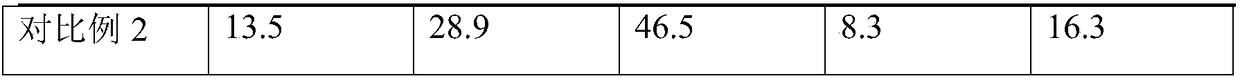

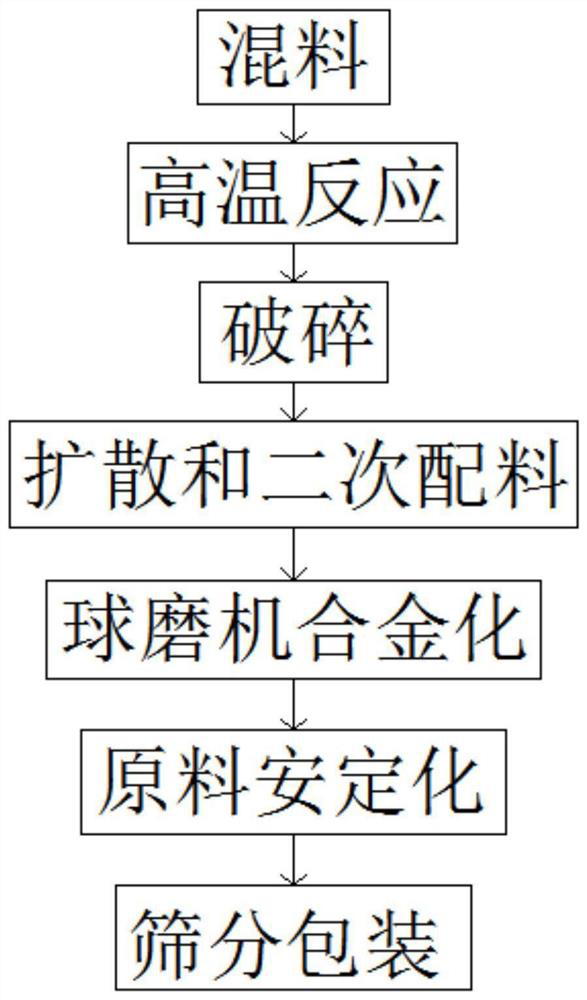

PendingCN113941709AReduce processing finenessHigh proportion of contentTransportation and packagingMetal-working apparatusPtru catalystAlloy

The invention discloses a ternary copper catalyst alloy full fusion preparation process. The ternary copper catalyst alloy full fusion preparation process comprises the following steps of mixing materials, specifically, mixing and stirring 40%-60% of fine copper powder and 40%-60% of oxygen-containing copper according to a certain proportion for about half an hour; high-temperature reaction, specifically, putting the mixed raw materials into a high-temperature diffusion furnace, enabling aerobic copper and copper powder to react at high temperature, under the anaerobic condition, filling nitrogen for whole-process protection, carrying out high-temperature reaction for four hours, controlling the center temperature to be about 7000 DEG C, and discharging to be blocky; and crushing, specifically, primarily crushing the blocky raw materials, and then crushing again. According to the ternary copper catalyst alloy full fusion preparation process, nitrogen is added for protection in the processes of secondary batching, ball mill alloying, raw material stabilization, screening and packaging, the processing fineness of the copper powder can be effectively reduced, meanwhile, the content proportion of cuprous oxide is increased, and the problem that the use effect is poor due to the fact that the processing fineness of the copper powder is large and the content proportion of the cuprous oxide is small is solved.

Owner:安徽德诠新材料科技有限公司

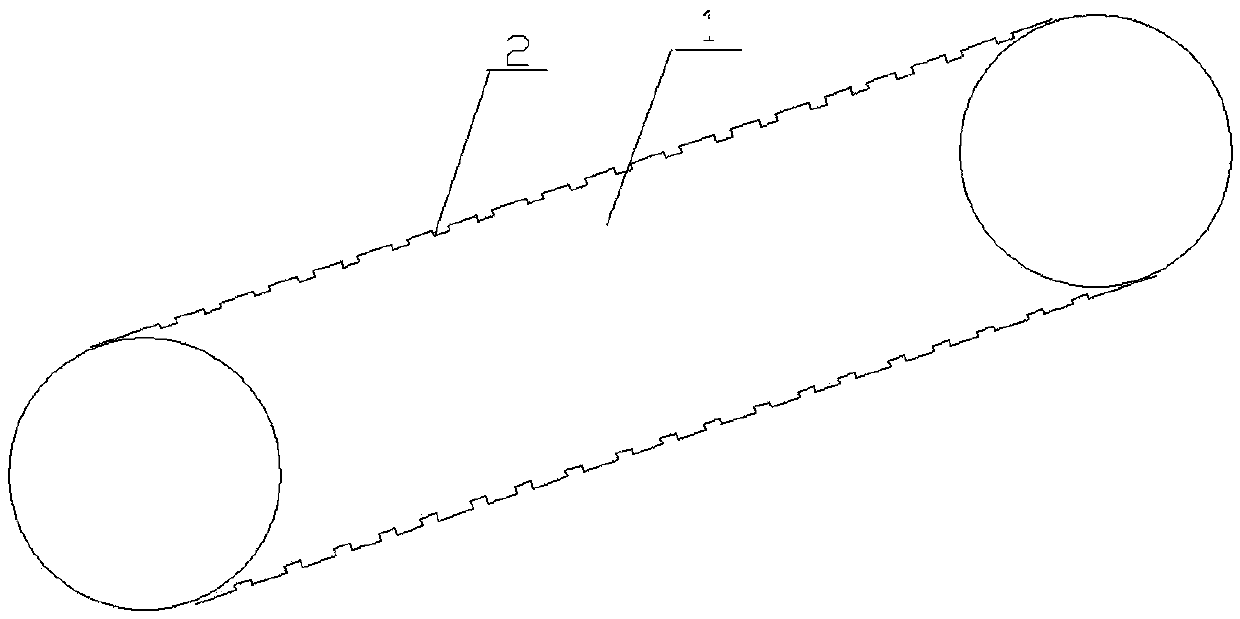

Ejector device for scraping strip cut-off equipment

InactiveCN104260144AIncrease kinetic energyEasy to collectMetal working apparatusPulp and paper industry

The invention belongs to the technical field of scraping strip production tools, and particularly relates to an ejector device for scraping strip cut-off equipment. The ejector device for the scraping strip cut-off equipment comprises a frame, a bottom plate is arranged on the frame, an outlet hole and an inlet hole are formed in the bottom plate, two baffle plates are arranged on one side of the frame positioned at the outlet hole, collection boxes are arranged below the two baffle plates, a scraping strip passes the inlet hole and the outlet hole and then enters the space between the two baffle plates, a hole is formed in one baffle plate, an ejector cylinder is arranged on the frame, an output end of the ejector cylinder penetrates the hole in the baffle plate and then is connected with an ejector plate, the ejector plate is positioned between the two baffle plates, and a spring is arranged between the ejector cylinder and the baffle plate with the hole. The ejector device has the advantage that cut-off scraping strips dispersedly drop into the collection boxes and are conveniently collected.

Owner:德清县申华塑料厂

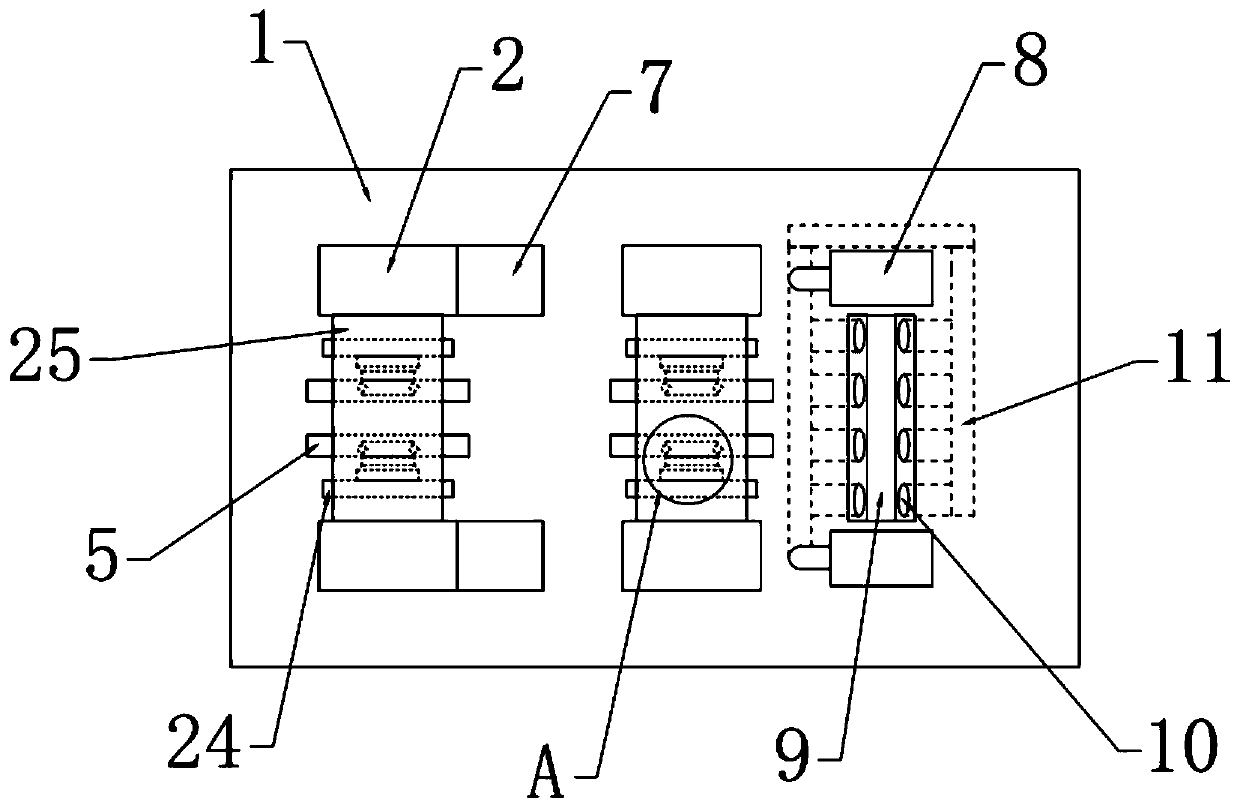

Knitting needle defective product detecting and sorting device

PendingCN110605250AThe detection process is simpleSave manpower and material resourcesSortingMaterial resourcesBiomedical engineering

The invention discloses a knitting needle defective product detecting and sorting device. The knitting needle defective product detecting and sorting device comprises a conveying belt, a material receiving barrel and length detecting mechanisms. The material receiving barrel is arranged at the discharging end of the conveying belt. The length detecting mechanisms are arranged on the two sides of the conveying belt. The conveying belt is connected with a stepping motor. The surface of the conveying belt is provided with a needle placing groove. The needle placing groove is perpendicular to thelength direction of the conveying belt. The width of the conveying belt is smaller than the width of a knitting needle. According to the knitting needle defective product detecting and sorting device,the lengths of a plurality of knitting needles can be detected at one time by detecting whether the lengths of the knitting needles meet standards or not through the length detecting mechanisms; thedetection process is simple, rapid and convenient; the lengths of the knitting needles can be sorted while the knitting needles are conveyed; and the detection and sorting efficiency is greatly improved, and manpower and material resources are saved.

Owner:SHANGHAI FENGWEI KNITTING NEEDLE MFG

Smoke purification device of steam boiler for spinning

PendingCN114700176AImprove filtering effectGuarantee efficient completionLighting and heating apparatusElectrostatic separationProcess engineeringFlue gas

The invention discloses a textile steam boiler flue gas purification device which comprises a supporting pipe, one end of the supporting pipe is fixedly connected with a working pipe, the working pipe and the supporting pipe communicate with each other, the end, away from the supporting pipe, of the working pipe is fixedly connected with a connecting pipe, and the connecting pipe and the working pipe communicate with each other. A disc-shaped pipe is fixedly connected to the side wall, away from the working pipe, of the connecting pipe, the disc-shaped pipe and the connecting pipe communicate with each other, an air inlet pipe is fixedly connected to the outer wall of the end, away from the working pipe, of the supporting pipe, the air inlet pipe and the supporting pipe communicate with each other, and a rotating motor is fixedly connected to the outer wall of one side of the working pipe. And a rotating shaft is arranged on the rotating motor, one end of the rotating shaft penetrates through the working pipe, and a rotating frame is fixedly connected to the rotating shaft. According to the device, a user can effectively and continuously clean the annular filter screen, and then the device can efficiently complete boiler flue gas purification work.

Owner:南通安昇纺织品有限公司

Pomegranate tree spring shoot management method

ActiveCN108849023BGood ventilation and light transmissionReduce workloadHorticulture methodsShootTwig

Owner:会理市成润农业开发科技有限公司

Die cutting waste removal equipment for printshop

InactiveCN111571702AQuick clearReduce labor intensityBox making operationsPaper-makingEnvironmental protectionDie cutting

The invention relates to waste removal equipment, in particular to die cutting waste removal equipment for a printshop. The technical problem to be solved is how to provide die cutting waste removal equipment for a printshop and capable of rapidly removing waste and reducing the labor intensity of workers. In order to solve the above technical problem, the die cutting waste removal equipment for the printshop is provided and comprises a base, sliding columns, removal mechanisms and a pressing mechanism. Rolling wheels are rotationally connected to the bottom of the base, and a handle holder isconnected to the top of the base. The position, close to the handle holder, of the top of the base is connected with the sliding columns, sliding frames are in sliding connection to the handle holder, a lifting frame is connected between one side faces of the sliding frames and is arranged on the sliding columns in a sleeving manner, and a pull rod is connected between the inner side faces of thesliding frames. The removal mechanisms are mounted on the lifting frame. The pressing mechanism is mounted at one ends of the sliding columns. Multiple removal wheels of the die cutting waste removalequipment rotate and move downwards, and waste sheets in various directions on paper shells obtained after die cutting can be cut.

Owner:赣州惠彩印刷有限公司

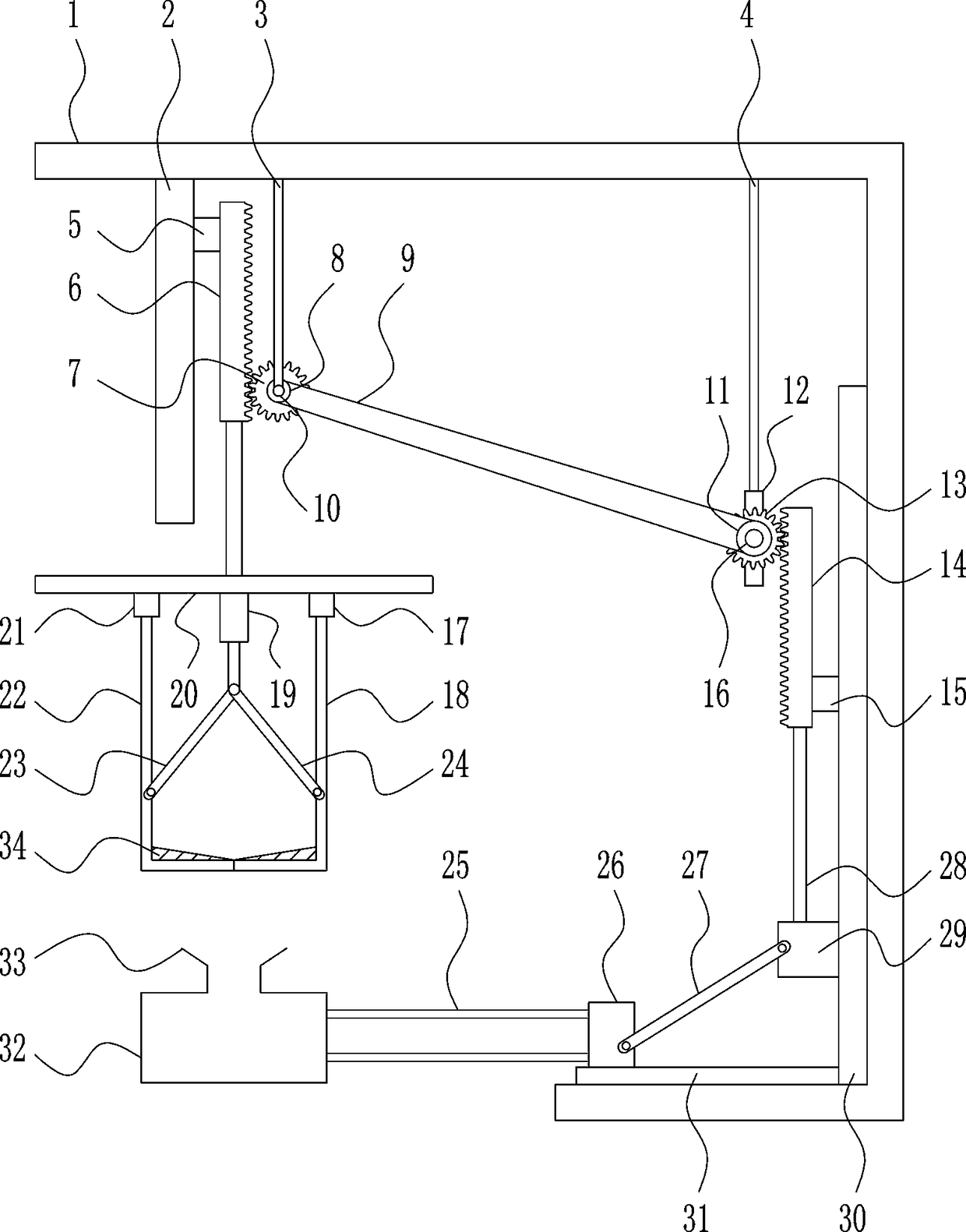

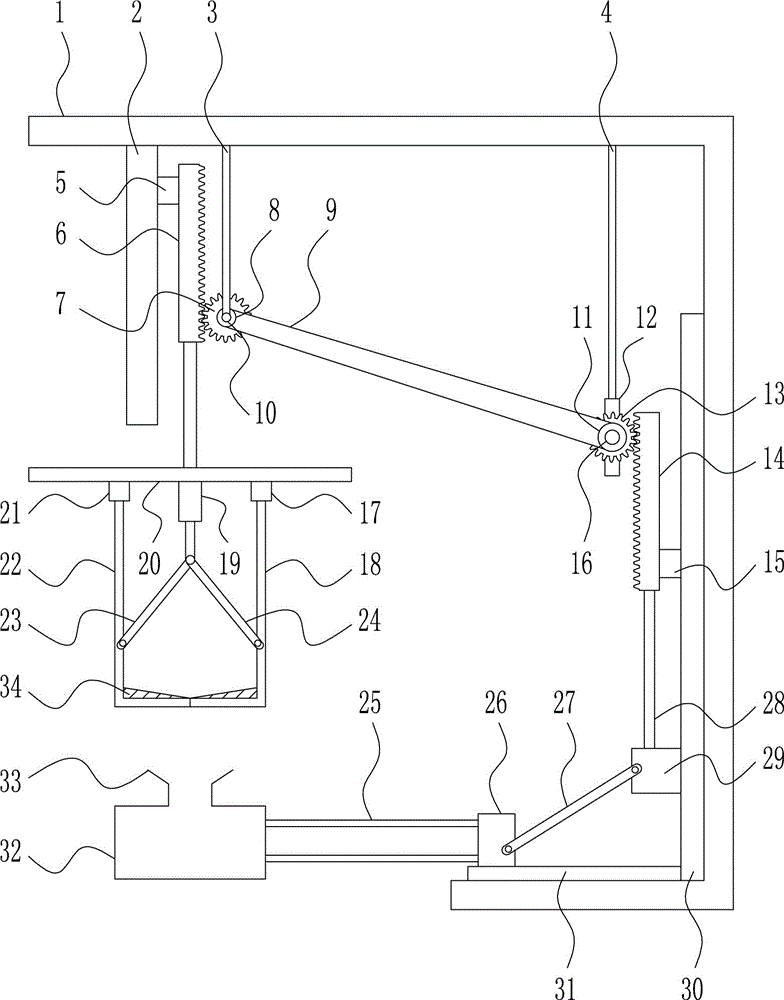

Batch pouring equipment for concrete cement blocks

ActiveCN111409170BReduce the difficulty of operationReduce labor costsFeeding arrangmentsAuxillary shaping apparatusIndustrial engineeringSupport plane

The invention relates to pouring equipment, in particular to a batch pouring equipment for concrete cement blocks. The technical problem to be solved by the present invention is how to provide a batch pouring equipment for concrete cement blocks that reduces the difficulty of manual operation and reduces the labor cost of the factory. In order to solve the above-mentioned technical problems, the present invention provides such a batch pouring equipment for concrete cement blocks, including: a bottom plate, the top of which is connected with a lower mold box of a slide rail frame, and a lower mold box is installed on one side of the top of the slide rail frame, and the lower mold box The bottom of the box is provided with a lower mold opening; the supporting frame is connected to both sides of the middle of the bottom plate, and the supporting frames on both sides are symmetrically arranged; the lowering barrel is connected to the top of the supporting frames on both sides; A material tube is connected to the side of the feeding barrel, and a valve is installed on the material tube. The present invention cooperates with the driving mechanism and the feeding mechanism, and does not need to manually place the pouring mold, which reduces the difficulty of manual operation.

Owner:苏州造丽新型建材有限公司

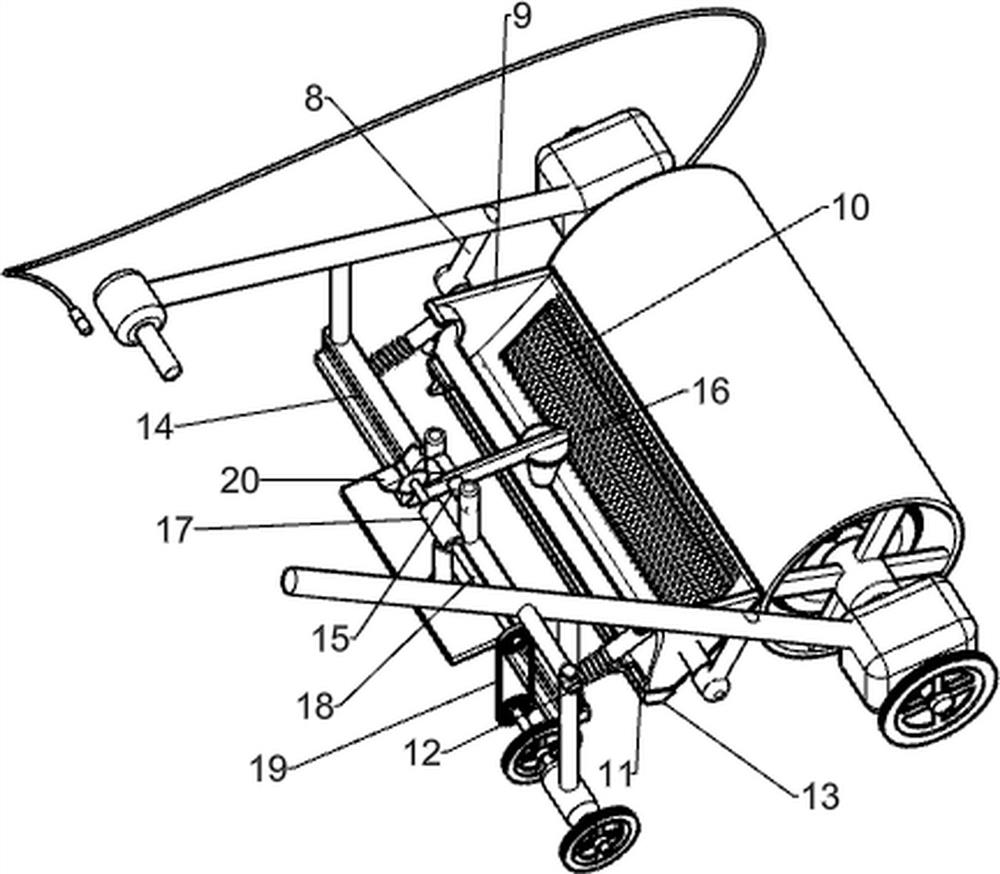

A high-efficiency mining device for rare earth raw materials

The invention relates to a mining device, in particular to an efficient rare earth raw material mining device, and aims at achieving the technical purpose of providing an efficient rare earth raw material mining device which is high in rare earth raw material mining speed. For achieving the technical purpose, the efficient rare earth raw material mining device comprises a support, a first sliding rail, a first support rod, a second support rod, a first sliding block, a first rack, a first gear, a small belt pulley, a flat belt, a motor, a small belt pulley, a bearing pedestal, a second gear, a second rack, a second sliding block, a rotating shaft, a fourth sliding block, a second collecting bucket and the like; the first sliding rail, the first support rod and the second support rod are sequentially arranged on the top inside the support from left to right, the first sliding block is arranged on the first sliding rail, and the first rack is arranged at the right end of the first sliding block. The mining device achieves the advantages of being high in rare earth raw material mining speed and easy to operate.

Owner:浙江虞申防火材料有限公司

Buffering vibration type baiting grate mesh structure

PendingCN110076087AGood and even vibrationNot easy to get confusedSievingScreeningDrive shaftEngineering

The invention discloses a buffering vibration type baiting grate mesh structure. The buffering vibration type baiting grate mesh structure comprises a grate mesh component, a vibration mechanism and abuffering mechanism, wherein the grate mesh component comprises an outer frame, a plurality of mutually-parallel first steel bars are arranged in the outer frame, the end angle of the outer frame isprovided with a first supporting seat, and the side end of the outer frame is connected with a vibration transmission plate; the buffering mechanism comprises the plurality of buffer spring assemblies, and the lower end of each first support seat is connected with a buffer spring assembly; the lower end of the outer frame is provided with a first hopper, and the buffer spring assembly is connectedto the first hopper; the vibration mechanism comprises a first motor, the first motor is connected to the first hopper through a first support, a transmission shaft of the first motor is connected with a vibration exciter, and the vibration exciter is connected with the vibration transmission plate. The grate mesh structure is convenient to mount and dismount, better in baiting effect, simple incomponent replacement, simpler and novel in structure, and high in practicability.

Owner:SHANDONG XINGHUA CONSTR GRP

Iron nail attracting equipment for building construction protection

ActiveCN112127311AAchieve freedom of movementEasy to collectRoad cleaningBuilding material handlingArchitectural engineeringMechanical engineering

The invention relates to iron nail attracting equipment, in particular to iron nail attracting equipment for building construction protection. According to the iron nail attracting equipment for building construction protection, iron nails can be collected conveniently, the iron nails do not need to be taken down manually, and moving is convenient. The iron nail attracting equipment for building construction protection comprises a rack, a mounting frame, first elastic parts, an iron attracting mechanism, a handle and a fixing mechanism, wherein a first sliding block is arranged on the rack ina sliding mode; the mounting frame is arranged on the first sliding block; the first elastic parts are symmetrically connected between the first sliding block and the rack; the iron attracting mechanism is arranged on the mounting frame; the handle is arranged on the mounting frame; and the fixing mechanism is arranged on the side, away from the first sliding block, of the rack. The equipment is worn on the body of a user through the fixing mechanism to be driven to move freely, then a servo motor and a storage battery are started to enable a sleeve to rotate and enable an electrified coil togenerate magnetic force, then iron nails and other small iron parts are attracted to the sleeve, and therefore convenience is provided for people.

Owner:徐小兵

Efficient rare earth raw material mining device

The invention relates to a mining device, in particular to an efficient rare earth raw material mining device, and aims at achieving the technical purpose of providing an efficient rare earth raw material mining device which is high in rare earth raw material mining speed. For achieving the technical purpose, the efficient rare earth raw material mining device comprises a support, a first sliding rail, a first support rod, a second support rod, a first sliding block, a first rack, a first gear, a small belt pulley, a flat belt, a motor, a small belt pulley, a bearing pedestal, a second gear, a second rack, a second sliding block, a rotating shaft, a fourth sliding block, a second collecting bucket and the like; the first sliding rail, the first support rod and the second support rod are sequentially arranged on the top inside the support from left to right, the first sliding block is arranged on the first sliding rail, and the first rack is arranged at the right end of the first sliding block. The mining device achieves the advantages of being high in rare earth raw material mining speed and easy to operate.

Owner:浙江虞申防火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com