Efficiently loaded flocculation sewage treatment device

A sewage treatment device and flocculation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the difficulty of solid-liquid separation of mud and water, hinder smooth circulation, and reaction time Long and other problems, to increase the distance and residence time, reduce the volume of equipment, prolong the effect of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

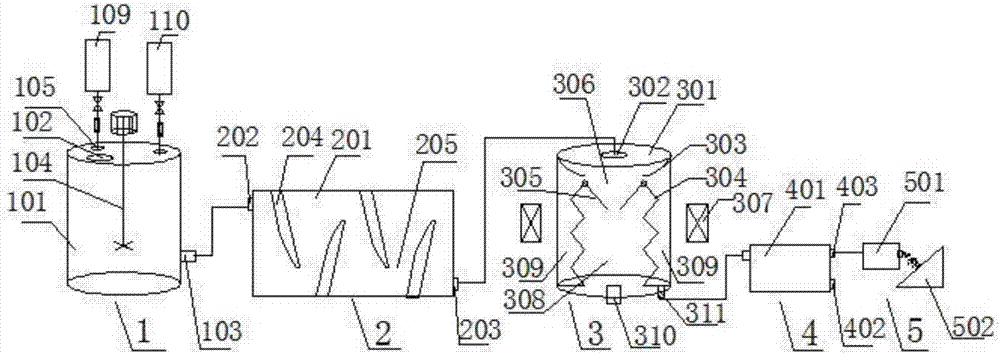

[0044] Such as figure 1 As shown, the present invention provides a high-efficiency loading flocculation sewage treatment device, comprising: a regulating device 1, a reaction box 2, an electromagnetic flocculation device 3, an extrusion device 4 and a separation magnetic seed / dirt device 5; the reaction box 2 is provided with Inside or outside the regulating device 1; in this embodiment, the reaction box 2 is arranged outside the regulating device 1 and communicated with the regulating device 1;

[0045] The regulating device 1 includes a first barrel body 101, a first water inlet 102 and a first water outlet 103 are respectively arranged on the first barrel body 101, a stirring device 104 is arranged in the first barrel body 101, the first barrel body The upper part of the body 101 is provided with a dosing port 105, and the upper part of the first barrel body 101 communicates with the magnetic seed adding device 110;

[0046] The reaction box 2 includes a box body 201, and ...

Embodiment 2

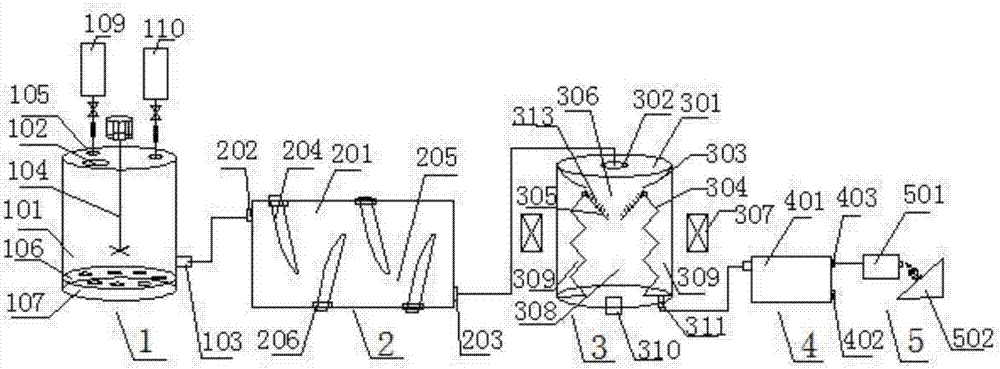

[0056] Such as figure 2 As shown, the present invention provides a high-efficiency loading flocculation sewage treatment device, comprising: a regulating device 1, a reaction box 2, an electromagnetic flocculation device 3, an extrusion device 4 and a separation magnetic seed / dirt device 5; the reaction box 2 is provided with Inside or outside the regulating device 1; in this embodiment, the reaction box 2 is arranged outside the regulating device 1 and communicated with the regulating device 1;

[0057] The regulating device 1 includes a first barrel body 101, a first water inlet 102 and a first water outlet 103 are respectively arranged on the first barrel body 101, a stirring device 104 is arranged in the first barrel body 101, the first barrel body The upper part of the body 101 is provided with a dosing port 105, and the upper part of the first barrel body 101 communicates with the magnetic seed adding device 110;

[0058] The reaction box 2 includes a box body 201, and...

Embodiment 3

[0070] Such as image 3 As shown, the present invention provides a high-efficiency loading flocculation sewage treatment device, comprising: a regulating device 1, a reaction box 2, an electromagnetic flocculation device 3, an extrusion device 4 and a separation magnetic seed / dirt device 5; the reaction box 2 is provided with Inside or outside the regulating device 1; in this embodiment, the reaction box 2 is arranged outside the regulating device 1 and communicated with the regulating device 1;

[0071] The regulating device 1 includes a first barrel body 101, a first water inlet 102 and a first water outlet 103 are respectively arranged on the first barrel body 101, a stirring device 104 is arranged in the first barrel body 101, the first barrel body The upper part of the body 101 is provided with a dosing port 105, and the upper part of the first barrel body 101 communicates with the magnetic seed adding device 110;

[0072] The reaction box 2 includes a box body 201, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com