Ejector device for scraping strip cut-off equipment

A technology of cutting equipment and ejecting device, which is applied in metal processing and other directions, can solve the problems of unfavorable scraper collection and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

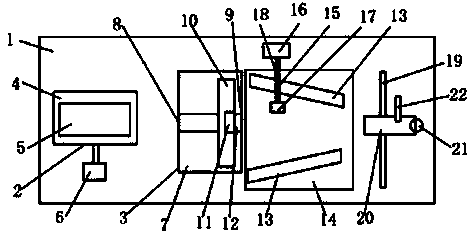

[0011] Combine below figure 1 and figure 2 Specific description embodiment:

[0012] Such as figure 1 and figure 2 As shown, a scraping strip conveying and cutting equipment includes a frame 1, and the frame 1 is provided with a conveying device 2 and a cutting device 3, and the conveying device 2 includes a driving roller 4 and a driven roller 5 , the driving roller 4 is connected with the motor 6, the driving roller 4 and the driven roller 5 are arranged in the upper and lower positions, and there is a gap for the passage of the scraping strip between the driving roller 4 and the driven roller 5; Cutting device 3 comprises base plate 7, and base plate 7 is provided with inlet hole 8 and outlet hole 9 for scraping strip to enter and exit, and base plate 7 is provided with cutter frame 10, and the top of cutter frame 10 is provided with cutter cylinder 11, The output end of cutter cylinder 11 is connected with cutter 12, and cutter 12 is positioned at the top place of ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com